Fuel pump, fuel supply equipment using fuel pump and method for manufacturing fuel pump

A fuel supply and fuel pump technology, applied in liquid fuel feeders, mechanical equipment, manufacturing of motor generators, etc., can solve the problems of increased sliding resistance, increased sliding friction, and no introduction, etc., to reduce sliding resistance and fuel emissions. The effect of reducing the number and reducing the drive current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

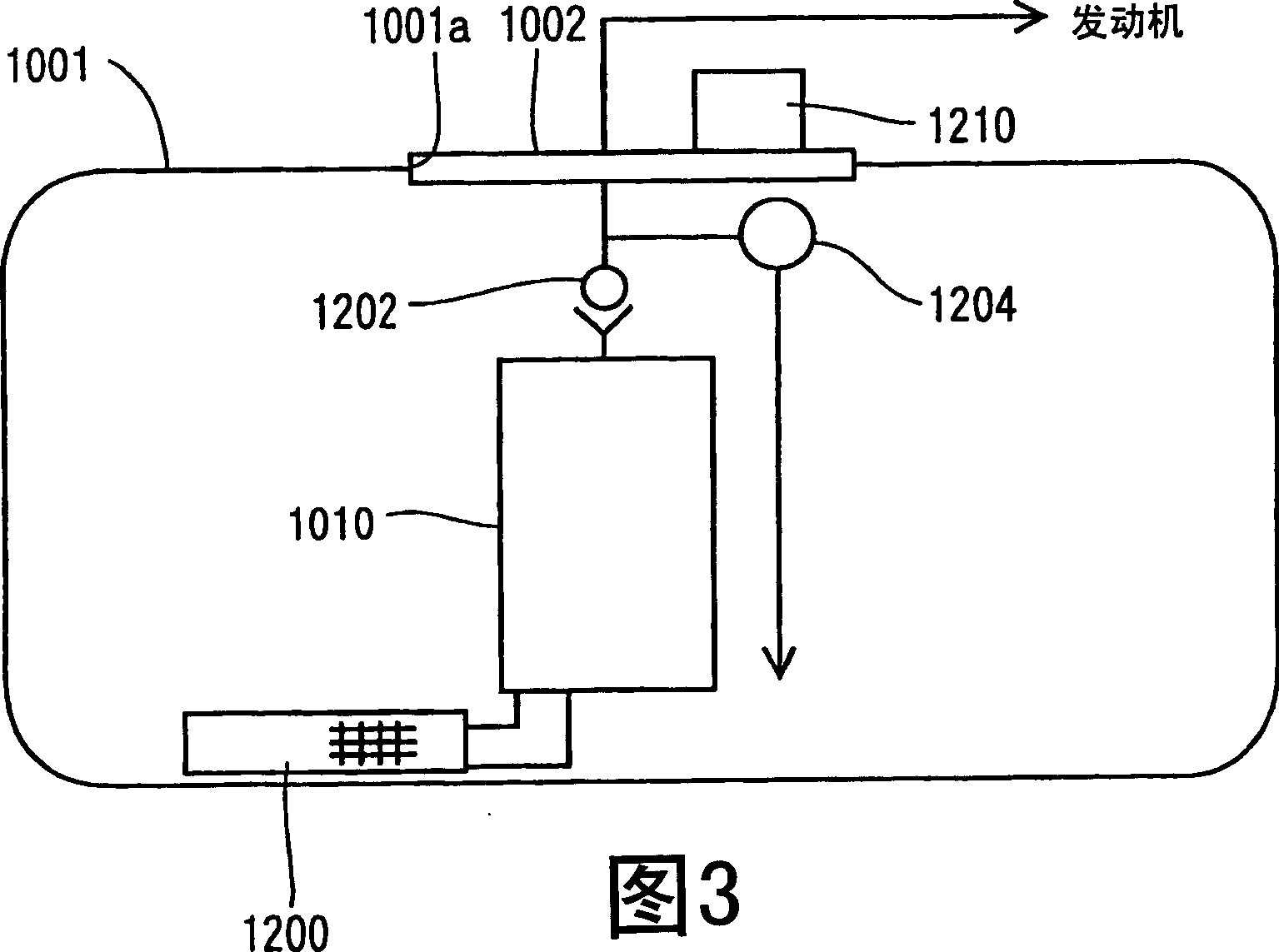

[0109] Figure 7 shows a second preferred embodiment. This preferred embodiment is basically the same in structure as the first preferred embodiment, except that the pump 1060 is different from the pump 1013 in the first preferred embodiment. Components that are substantially the same as those of the first preferred embodiment are designated with the same reference numerals.

[0110] In the second preferred embodiment, the pump 1060 constitutes a trochoidal pump, the outer rotor 1064 is provided in the inner peripheral side of the casing 1062 , and the inner rotor 1066 is provided in the inner periphery of the outer rotor 1064 . Internal teeth 1065 formed on the inner periphery of the outer rotor 1064 mesh with outer teeth 1067 formed on the outer periphery of the inner rotor 1066 . The center of the outer rotor 1064 is eccentric with respect to the center of the inner rotor 1066 . The number of internal teeth 1065 is one more than the number of external teeth 1067 . When th...

no. 3 example

[0112] Figure 8 A third preferred embodiment of the present invention is shown. Basically the same constituent elements as those of the first preferred embodiment are denoted by the same reference numerals.

[0113] In the third preferred embodiment, the control device 1220 includes a three-phase circuit 1230 , a current detector 1240 and a PWM (Pulse Width Modulation) control element 1250 . The three-phase circuit 1230 in the third preferred embodiment is basically the same as Figure 5 The control device 1210 shown is the same. The three-phase circuit 1230, the current detector 1240, and the PWM control element 1250 are constituted as one terminal IC element as one circuit assembly.

[0114] The current detector 1240 compares the sum of the currents flowing through the six coils 1024 of the fuel pump 1010 with a preset value, and sends the comparison result to the PWM control element 1250 .

[0115] On the PWM control element 1250 serving as a limiting circuit, a corres...

no. 7 example

[0188] Figure 19 and 20 show a seventh preferred embodiment of the present invention. The same elements as those in the fifth preferred embodiment are represented by the same symbols.

[0189] Figure 19 The illustrated stator core 2090 includes an outer peripheral core 2092 and six coil cores 2094 protruding from the outer peripheral core 2092 toward the rotor 2050 separated from the outer peripheral core 2092 . The outer peripheral core 2092 and the coil core 2094 are formed as a stack of magnetic steel sheets having an insulating film covered thereon. Coil 2042 and coil core 2094 are insulated by insulating resin 2048 .

[0190] Figure 20A and 20B One method of manufacturing stator core 2090 and coils 2042 is shown.

[0191] 6 coil cores 2094 are fixed on tools such as fixtures and installed on Figure 20A at the position shown. In this state, the coil 2042 and the insulating resin 2048 are not formed. The six coil cores 2094 are poured and fixed by the insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com