Quick-change locking mechanism for power battery

A locking mechanism and power battery technology, which is applied in the direction of power devices, electric power devices, battery/battery traction, etc., can solve the problems of complex structure and complex operation of the locking mechanism, so as to improve NVH performance and reduce impact load , the effect of axial height reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]In order to have a clearer understanding of the technical features, objectives and effects of the present invention, the specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

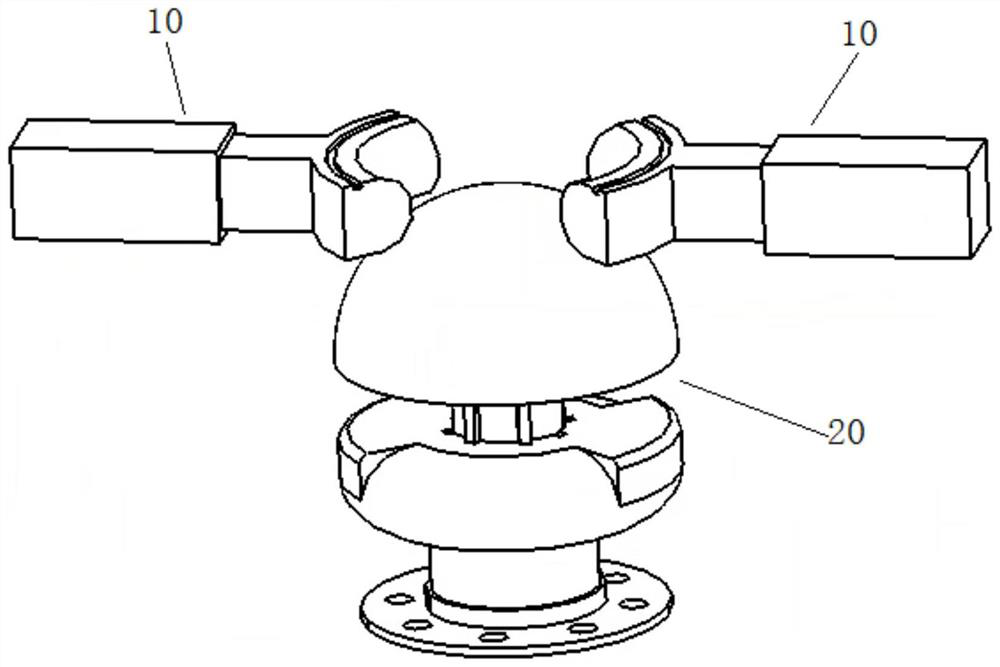

[0036]Such asfigure 1 As shown, a power battery quick-change locking mechanism provided by an embodiment of the present invention includes a fixing assembly 10 and a locking assembly 20.

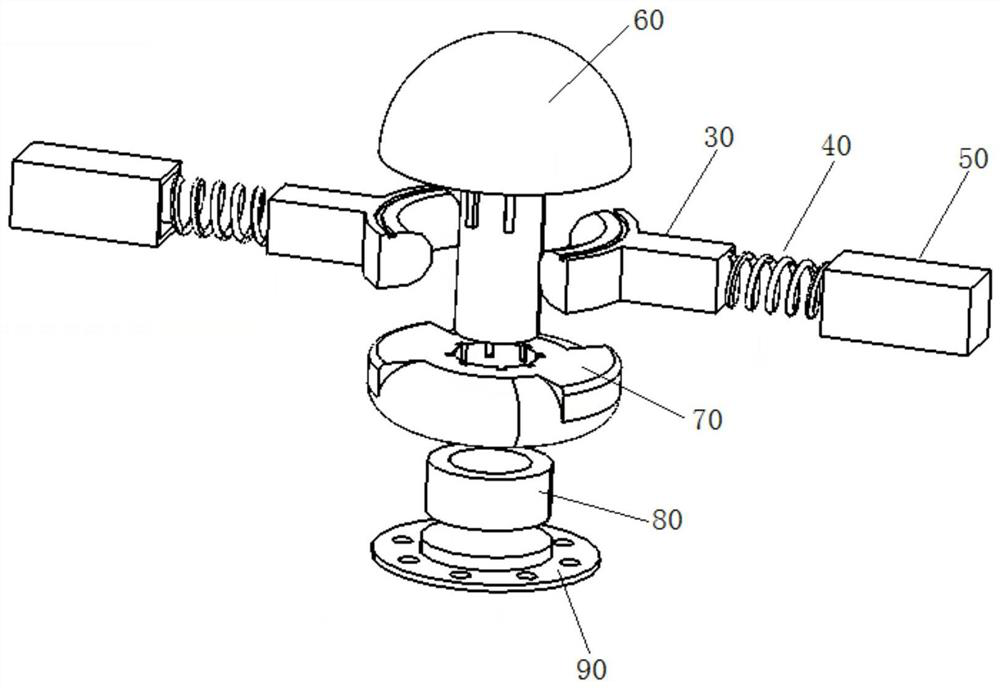

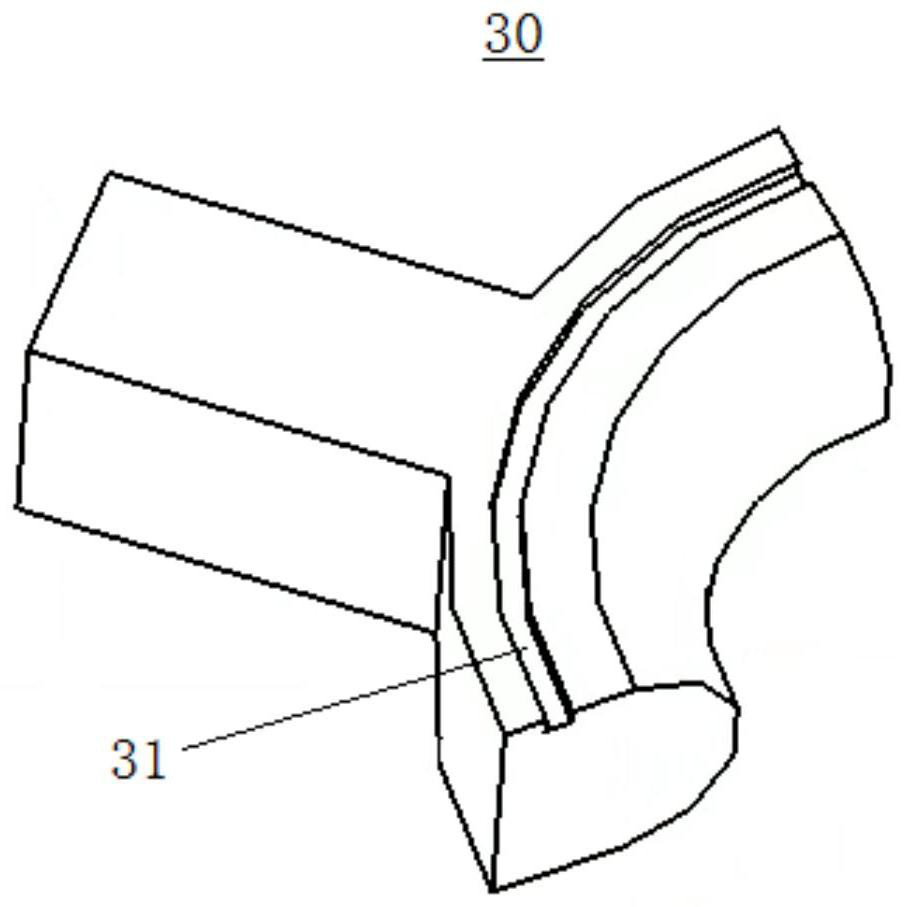

[0037]Such asfigure 2 As shown, the fixing assembly 10 includes a push rod 30, a first elastic member 40 and a fixing block 50. The fixed block 50 is a hollow structure with one end open, and is fixedly connected to the vehicle body longitudinal beam; one end of the push rod 30 is inserted into the fixed block 50, the first elastic member 40 is located between the push rod 30 and the fixed block 50, and the first elastic member 40 The two ends are respectively connected with the push rod 30 and the fixed block 50. Such asimage 3 As shown, the push rod 30 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com