Bearing for high-voltage equipment switch

A high-voltage equipment and bearing technology, applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as affecting the normal operation of the bearing, falling off, and blocking the axial clearance of the bearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

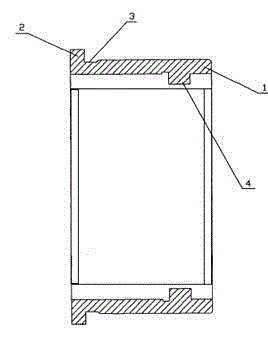

[0013] In order to facilitate the understanding of those skilled in the art, the structural principle of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings:

[0014] Such as figure 1 As shown, the present invention is a bearing used for high-voltage equipment switches, which is characterized in that it includes an outer ring, an inner ring, a needle roller, a support frame and a washer.

[0015] To further illustrate, the washer is fixedly installed at one end of the bearing, and a convex step is provided on the outer diameter of the outer ring.

[0016] To further illustrate, the inner surface of the outer ring facing the washer is provided with a boss that can limit the axial displacement of the needle roller.

[0017] To further illustrate, the root of the convex step on the outer diameter of the outer ring is provided with a tool undercut, and the width of the undercut is 0.5-1.2mm....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com