Oil groove sealing structure of fuel injection pump body

A technology of sealing structure and fuel injection pump, which is applied in the direction of pump components, variable displacement pump components, liquid fuel engines, etc. It can solve the problems of thick riser, low pouring pass rate, and many raw materials consumed, so as to prevent oil tank Good oil leakage and sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

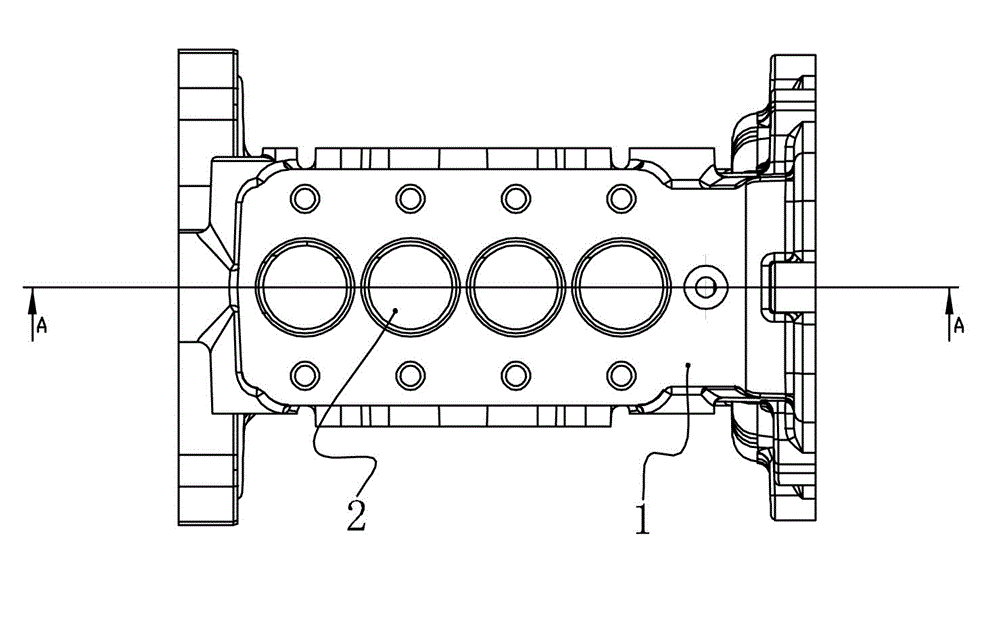

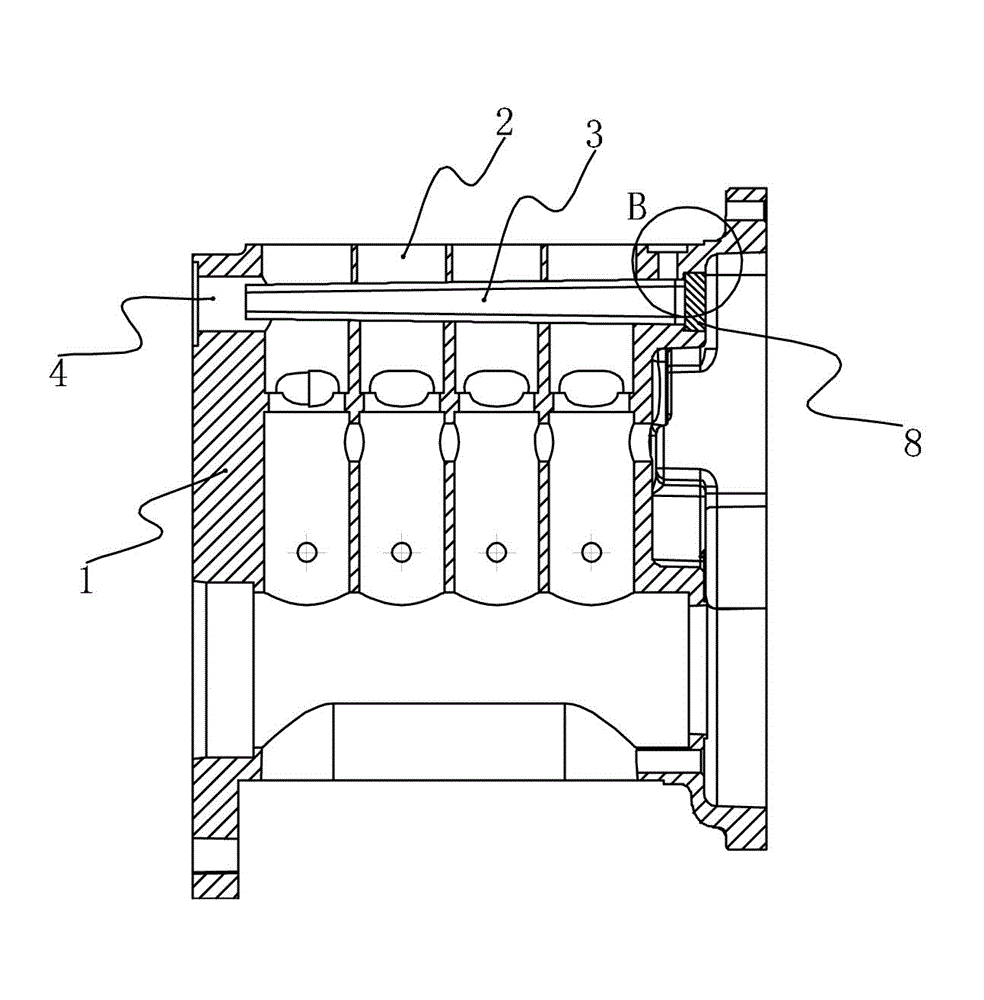

[0014] Embodiment 1: as figure 1 , figure 2 , image 3 and Figure 4 Shown: a fuel injection pump body oil groove sealing structure, including a fuel injection pump body 1 formed by die-casting aluminum alloy raw materials. After the oil tank 3 is core-pulled and demoulded, a core-pulling hole 5 will be formed on the tank wall opposite to the oil inlet hole 4 of the oil tank 3 .

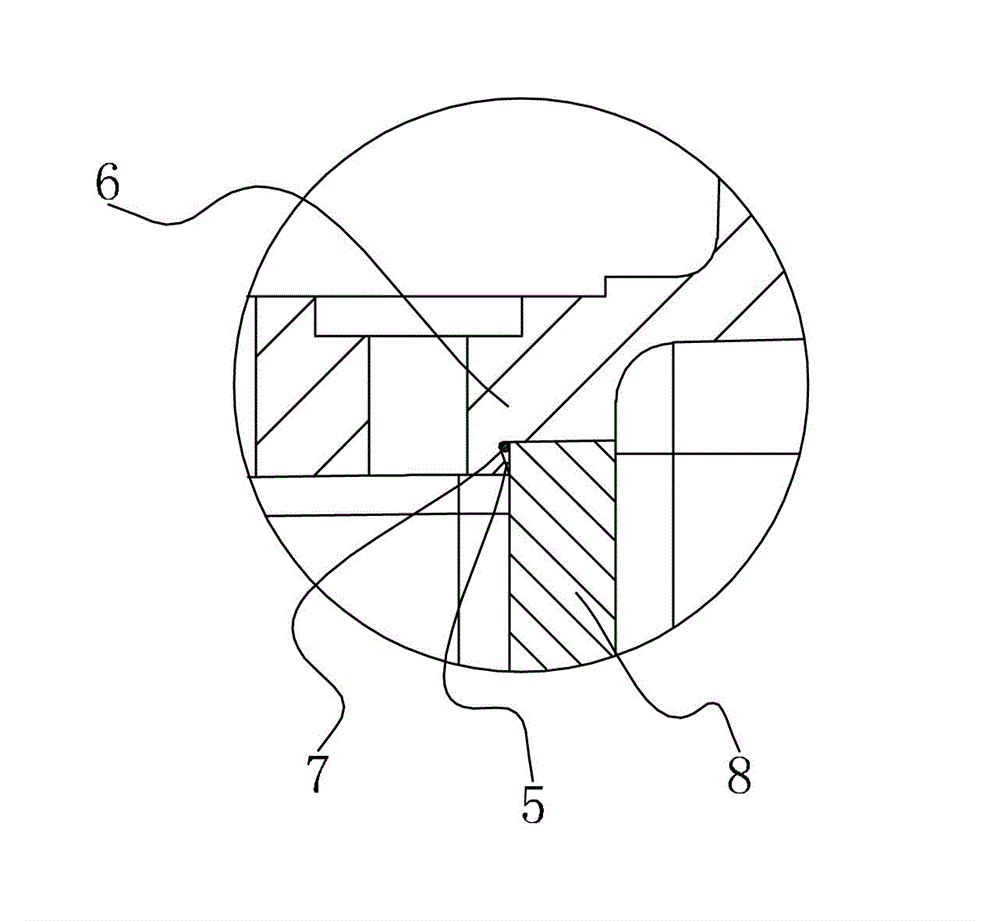

[0015] The opening of the core-pulling hole 5 is square, and a step 6 is formed in the core-pulling hole 5. The angle between the step 6 and the wall of the core-pulling hole 5 is less than 90°, and the fluorine rubber sealing ring 7 is inserted into the angle; The core-pulling hole 5 is equipped with a plug 8 matching the step 6 , the plug 8 is a square aluminum alloy block, and the plug 8 is interference-fitted with the core-pulling hole 5 .

[0016] The step 6 of the core-pulling hole 5 can be a single-layer step, a double-layer step or a multi-layer step, and the plug 8 can be a flat squar...

Embodiment 2

[0017] Embodiment 2: The difference from Embodiment 1 is that the angle between the step 6 and the wall of the core-pulling hole 5 is filled with sealant, and other features are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com