Exhaust gas bypass actuating mechanism and turbocharger with mechanism

A technology for turbochargers and actuators, which is applied in the direction of machines/engines, mechanical equipment, combustion engines, etc., and can solve the problems of easy wear and deformation of the pin hole of the actuator tie rod, decreased working stability of the actuator, and radial fit clearance of the hole shaft Larger and other problems, to improve the percussion problem, simple structure, small changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further illustrate the technical means and effects of the present invention to achieve the intended purpose of the invention, the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

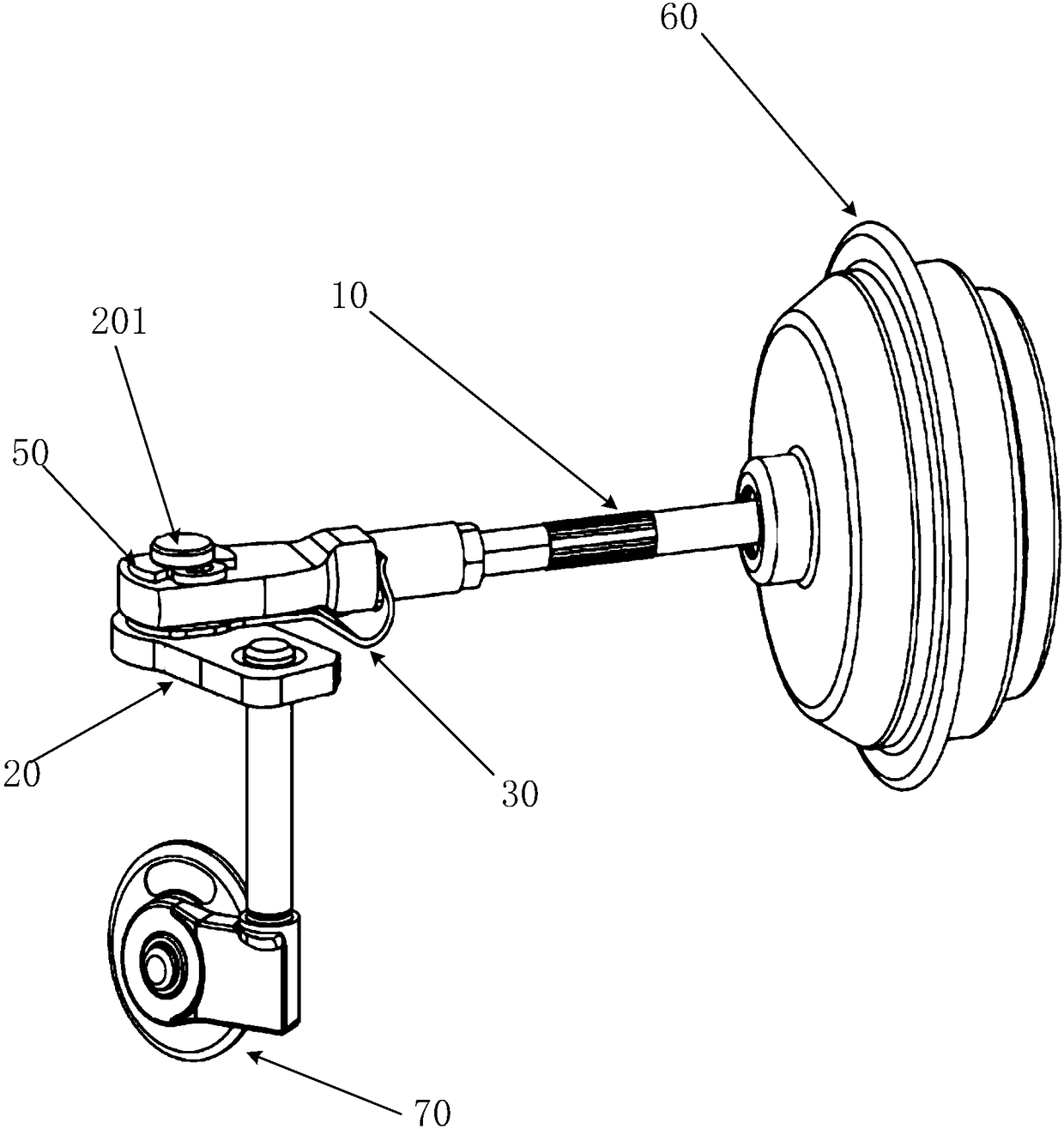

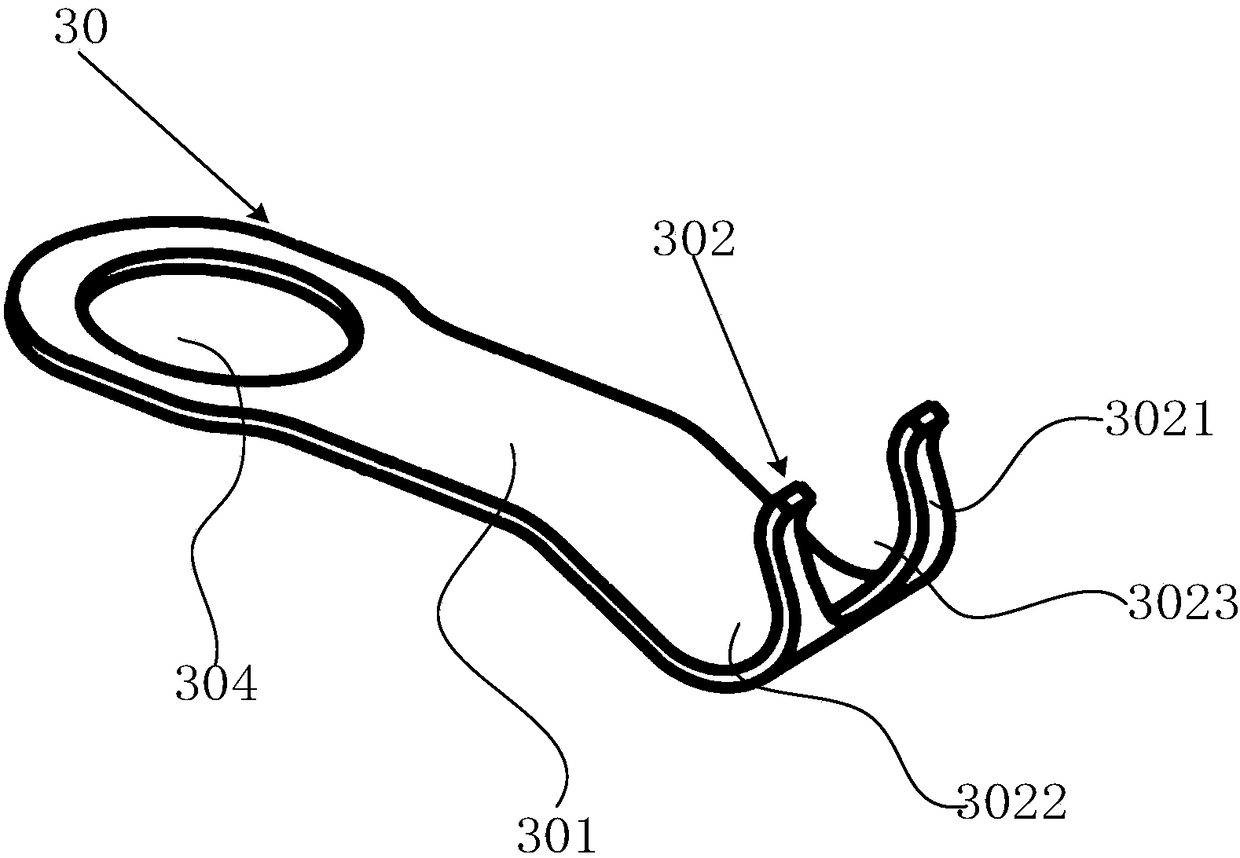

[0023] figure 1 It is a schematic structural diagram of a wastegate actuator according to an embodiment of the present invention. Such as figure 1 with Figure 4 As shown, the present invention provides a wastegate actuator, including a pull rod 10, a rocker arm 20, and a locking member 30.

[0024] Wherein, the pull rod 10 is hinged with the rocker arm 20, and one end of the locking member 30 is connected to the rocker arm 20, and the other end is fixed to the pull rod 10, so as to stabilize the relative position between the pull rod 10 and the rocker arm 20, and improve mutual collision and wear. , Reduce noise, and increase service life.

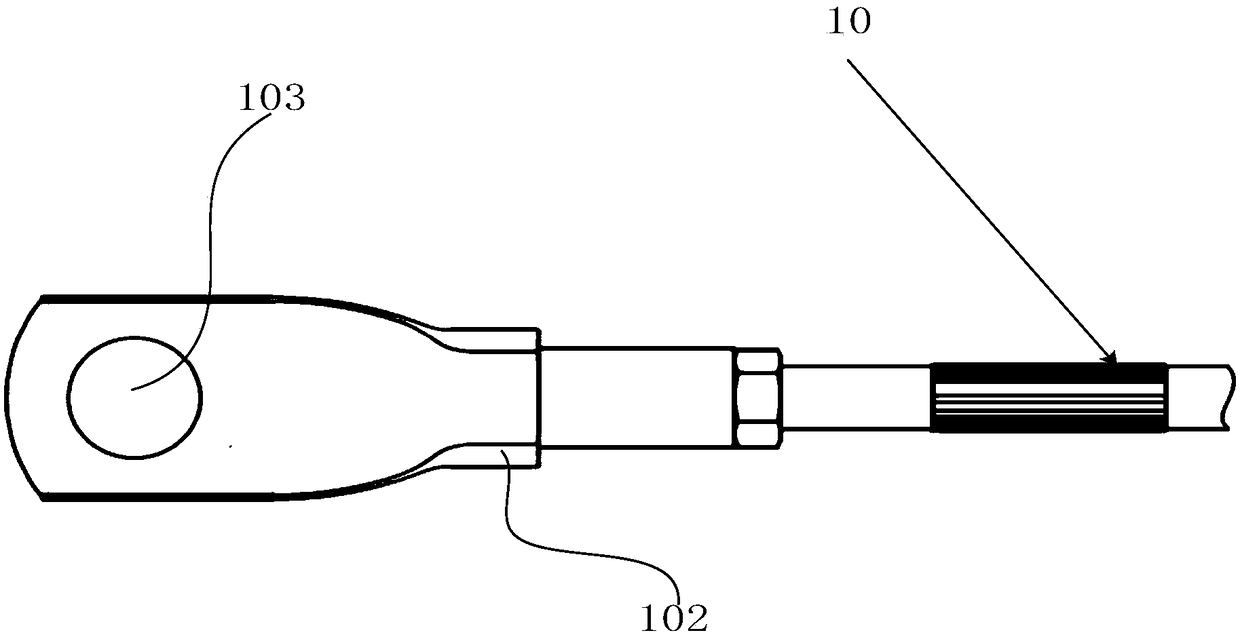

[0025] In this embodiment, as figure 2 As shown, the pull rod 10 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com