Pile foundation

A technology of pile foundation and abutment is applied to pile foundation. It can solve the problems of long construction period, easy hollowing of pile foundation and fracture of joints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

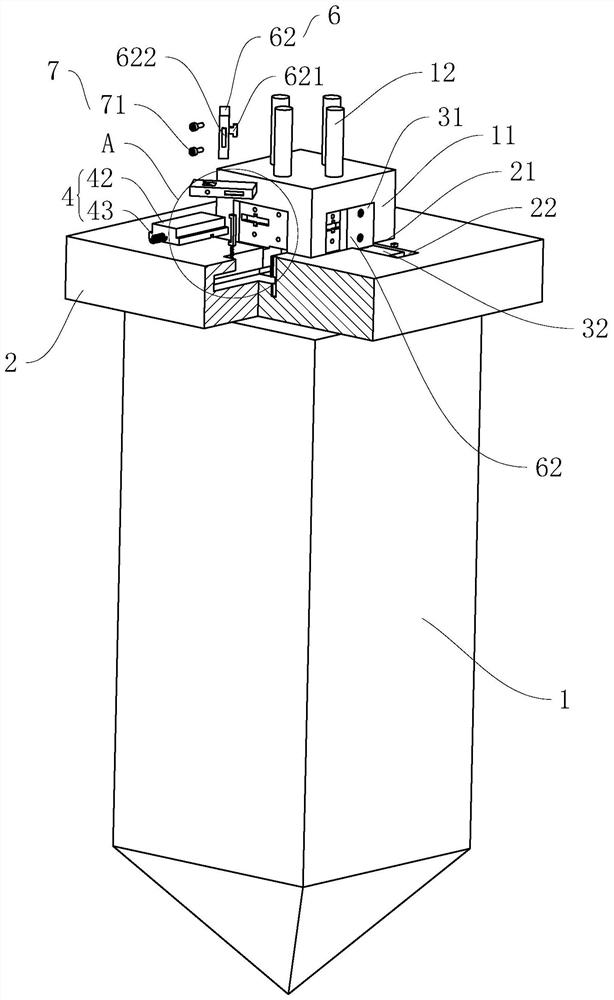

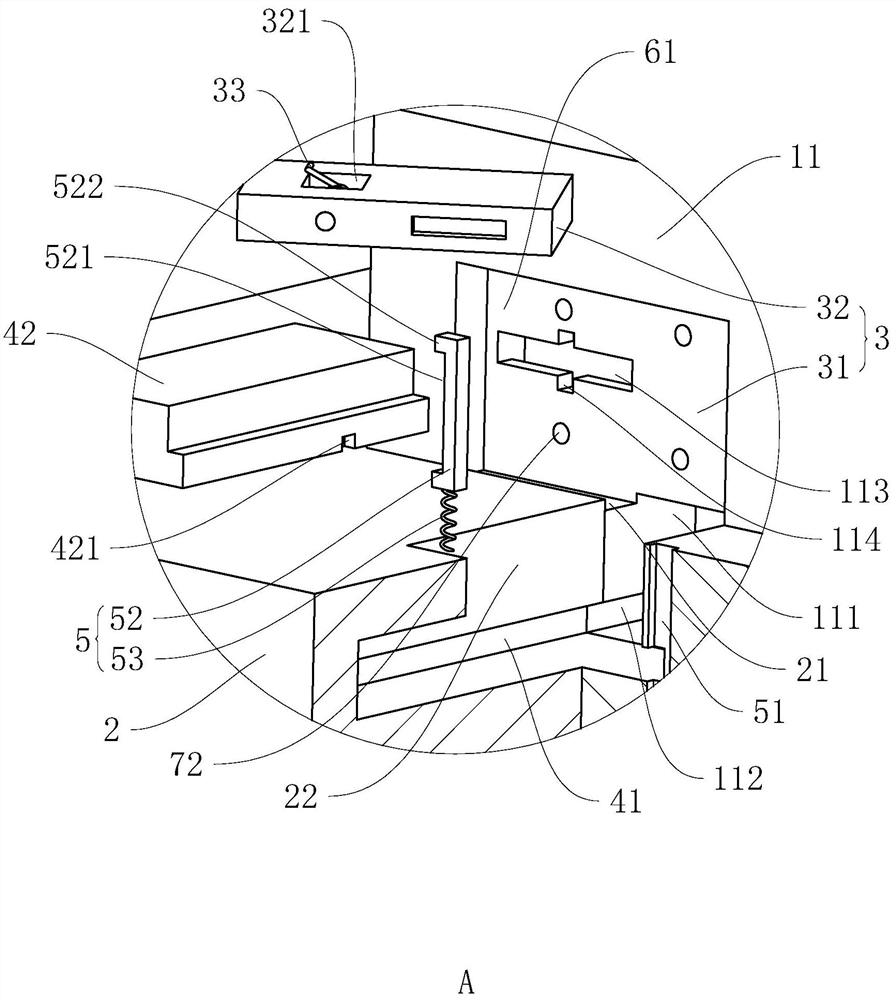

[0034] The following is attached Figure 1-2 The application is described in further detail.

[0035] The embodiment of the present application discloses a pile foundation, referring to figure 1, including a pile 1, an abutment 2 and a connecting mechanism 3, the end surface of one end of the pile 1 is integrally formed with a connecting column 11 whose cross-sectional size is smaller than that of the pile 1, and at this time a ladder-like gap is formed between the connecting column 11 and the pile 1 Connecting platform 13, in order to strengthen the connection strength between the pile foundation and the load-bearing column of building, the pre-embedded steel bar 12 in the connecting column 11 extends outwards, so that there is a reinforcing bar 12 that can be connected with the load-bearing column above the connecting column 11. The planar size of the abutment 2 is larger than that of the pile 1, and an assembly hole 21 is opened in the center of the abutment 2. During inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com