Novel manufacturing method for linen-cotton blended yarn

A production process and blended yarn technology, which is applied in yarn, textiles, papermaking, fiber processing, etc., can solve the problems of poor quality of finished yarn, defective rate of finished fabrics, and low production efficiency, so as to reduce friction coefficient and eliminate Static electricity, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

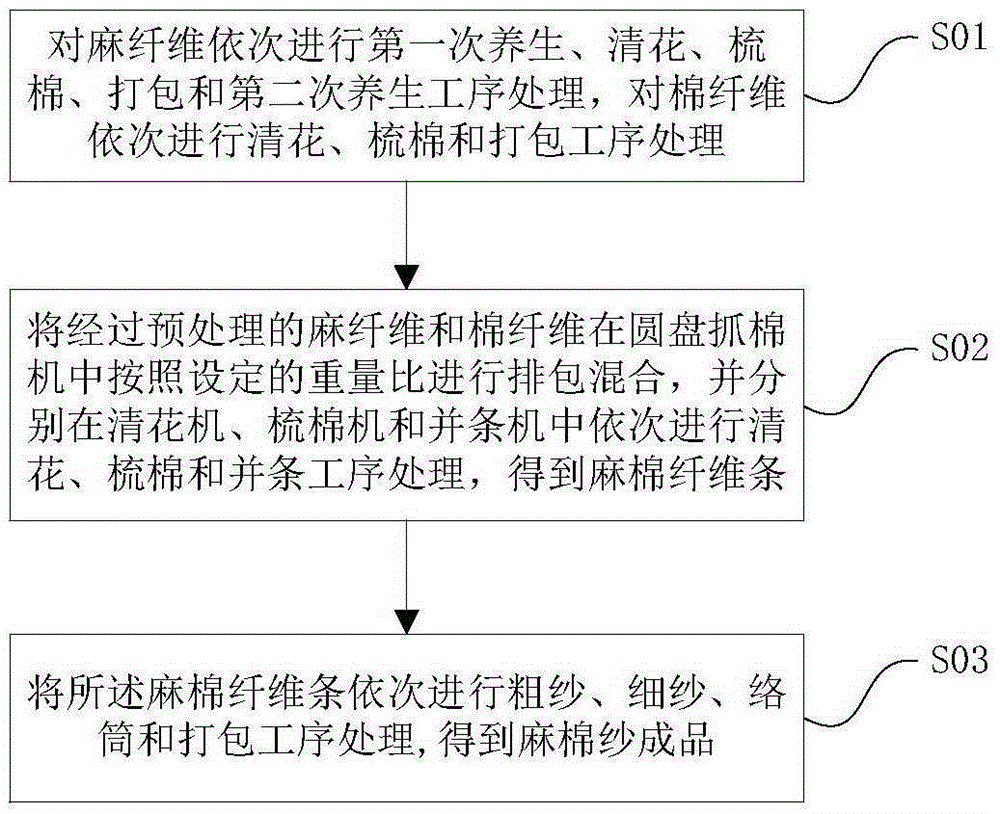

[0026] Such as figure 1 As shown, a production process flow chart of a novel hemp-cotton blended yarn includes the following procedures:

[0027] Step S01, raw material pretreatment: sequentially perform the first health care, cleaning, carding, packing and second health care process on the hemp fiber, and perform cleaning, carding and packing process on the cotton fiber in sequence;

[0028] Step S02, pre-spinning treatment: arrange and mix the pretreated hemp fiber and cotton fiber in the disc bale machine according to the set weight ratio, and separate them in the cleaning machine, carding machine and draw frame Blowing, carding and drawing are carried out sequentially in the process to obtain hemp cotton fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com