A method for shortening the spheroidizing annealing time of gcr15 bearing steel by controlled rolling and controlled cooling process

A technology of controlled rolling, controlled cooling, and annealing time, applied in heat treatment process control, manufacturing tools, heat treatment equipment, etc., can solve the problems of long austenitization time and extremely uneven cementite particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

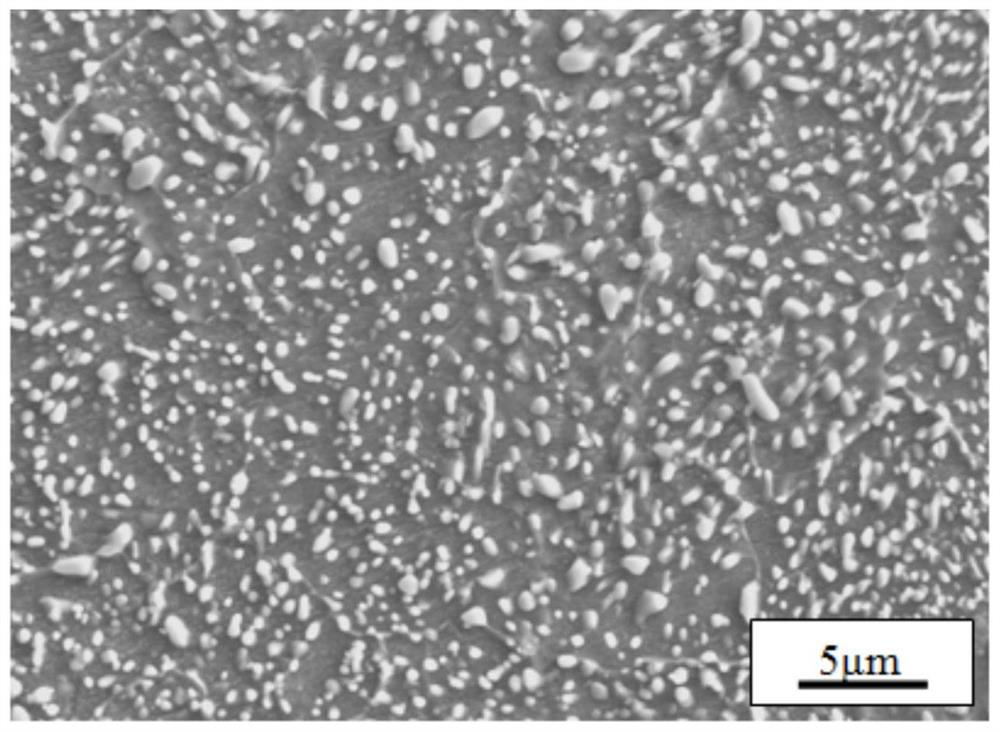

Embodiment 1

[0029] A method for shortening the spheroidizing annealing time of GCr15 bearing steel by controlled rolling and controlled cooling process, comprising the following process steps:

[0030] 1. Heat the GCr15 bearing steel sample to 1150°C and treat it isothermally for 30 minutes.

[0031] 2. The initial thickness of the sample is 30mm. After isothermal treatment, a single-pass rolling is carried out at 950°C with a reduction of 9mm and a thickness of 21mm after rolling. The purpose is to reduce the austenite grains.

[0032]3. After the first pass of rolling, air-cool until the temperature drops to 900°C, then carry out the second pass of rolling, the reduction is 4mm, and the thickness after rolling is 17mm. The purpose is to refine the austenite grains, and at the same time, the deformation leads to the fracture of a small amount of proeutectoid cementite formed at the grain boundary, so as not to form reticular cementite.

[0033] 4. After the second pass of rolling, cool ...

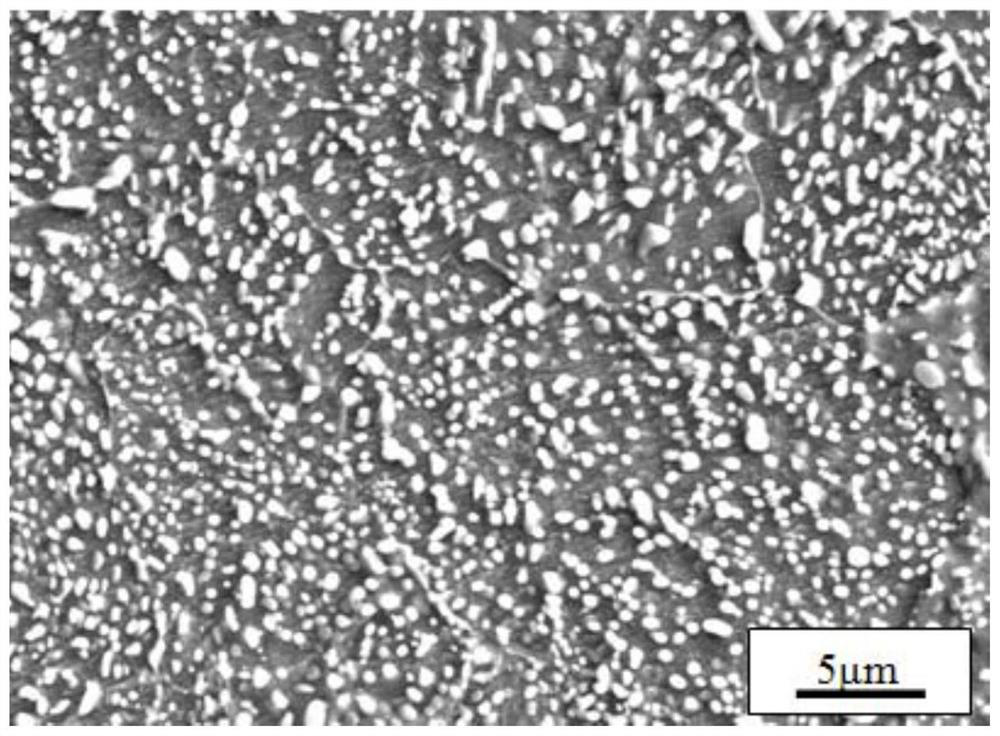

Embodiment 2

[0040] A method for shortening the spheroidizing annealing time of GCr15 bearing steel by controlled rolling and controlled cooling process, comprising the following process steps:

[0041] 1. Heat the GCr15 bearing steel sample to 1150°C and treat it isothermally for 30 minutes.

[0042] 2. The initial thickness of the sample is 30mm. After isothermal treatment, a single-pass rolling is carried out at 950°C with a reduction of 9mm and a thickness of 21mm after rolling. The purpose is to reduce the austenite grains.

[0043] 3. After the first pass of rolling, air-cool until the temperature drops to 900°C, then carry out the second pass of rolling, the reduction is 4mm, and the thickness after rolling is 17mm. The purpose is to refine the austenite grains, and at the same time, the deformation leads to the fracture of a small amount of proeutectoid cementite formed at the grain boundary, so as not to form reticular cementite.

[0044] 4. After the second pass of rolling, air-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com