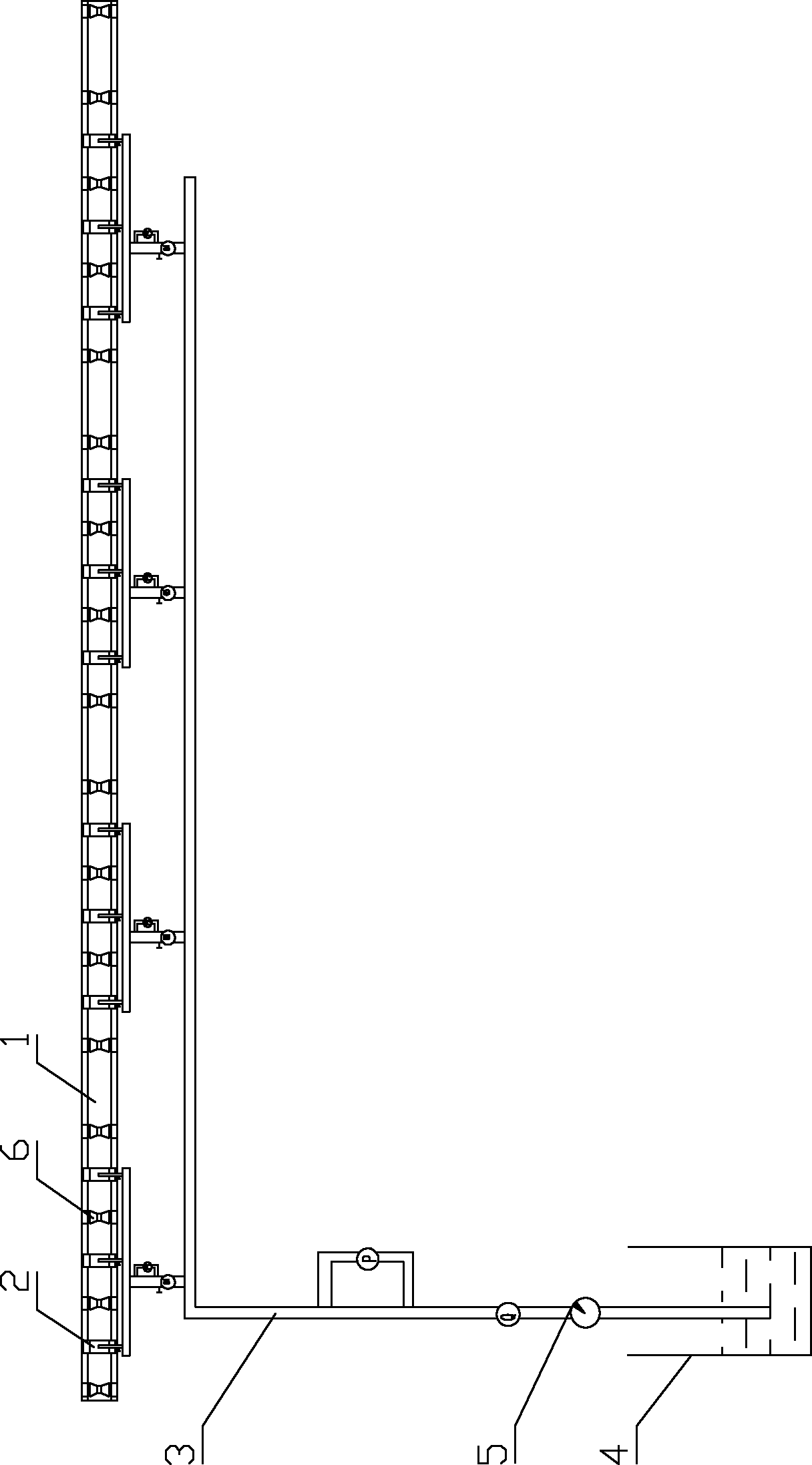

Device and technology for controlling cooling after hot rolling perforation of GCr15 bearing steel pipe billets

A bearing steel pipe, hot-rolled piercing technology, applied in the direction of rolling mill control devices, metal rolling, manufacturing tools, etc., can solve the problems of increasing production costs, prolonging the time of spheroidizing annealing, and reducing the output of rolling mills, so as to improve production efficiency and improve The effect of spheroidizing annealing structure level and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

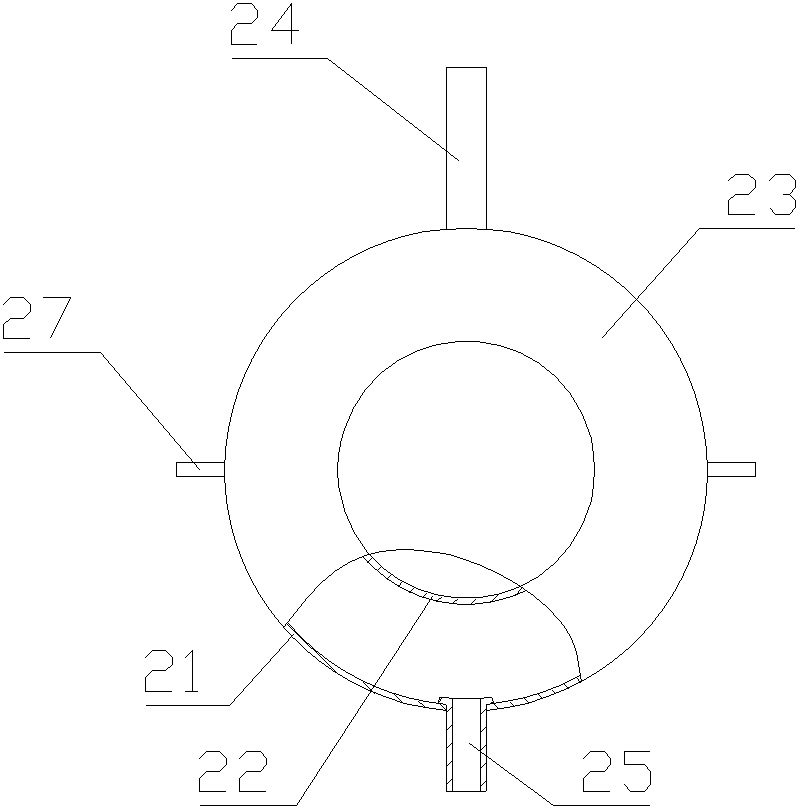

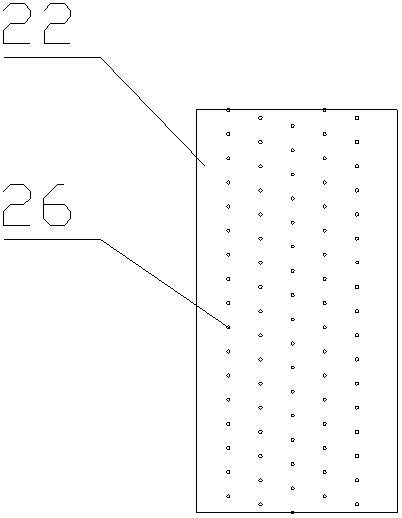

Method used

Image

Examples

Embodiment 1

[0036] The temperature of the hot-rolled and pierced bearing steel pipe is controlled at 1000°C, the linear speed of the V-shaped roller table is 2m / s, the ratio of water cooling time to air cooling time is 1:8, and the bearing steel pipe is sent out of the cooling device after 15 seconds; After the steel pipe is sent out of the cooling device, the surface temperature is controlled at 600°C, the surface reddening temperature is controlled at 650°C, and the reddening time is 1 second.

Embodiment 2

[0038] The temperature of the hot-rolled and pierced bearing steel pipe is controlled at 980°C, the linear speed of the V-shaped roller table is 1.6m / s, the ratio of water cooling time to air cooling time is 1:7, and the bearing steel pipe is sent out of the cooling device after 10 seconds; The surface temperature of the bearing steel pipe after it is sent out of the cooling control device is controlled at 620°C, the surface reddening temperature is controlled at 680°C, and the reddening time is 1.5 seconds.

Embodiment 3

[0040] The temperature of the hot-rolled and pierced bearing steel pipe is controlled at 950°C, the linear speed of the V-shaped roller table is 1.2m / s, the ratio of water cooling time to air cooling time is 1:7, and the bearing steel pipe is sent out of the cooling control device after 12 seconds; The surface temperature of the bearing steel pipe after it is sent out of the cooling control device is controlled at 570°C, the surface reddening temperature is controlled at 620°C, and the reddening time is 2 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com