Method for improving contact fatigue life of spray coating layer

A contact fatigue and spray coating technology, applied in the coating, metal material coating process, melt spraying and other directions, can solve the problems affecting the contact fatigue life of the coating, the limited service performance of the spray coating, and the low bonding strength, etc., to eliminate the problems. Adverse effects, increased hardness, good deposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 Application method of the present invention prepares iron-based self-fluxing alloy coating

[0027] Concrete preparation steps:

[0028] 1. Optimization of the spraying parameters of the working coating: use orthogonal experiments to calculate the spraying parameters of the working coating.

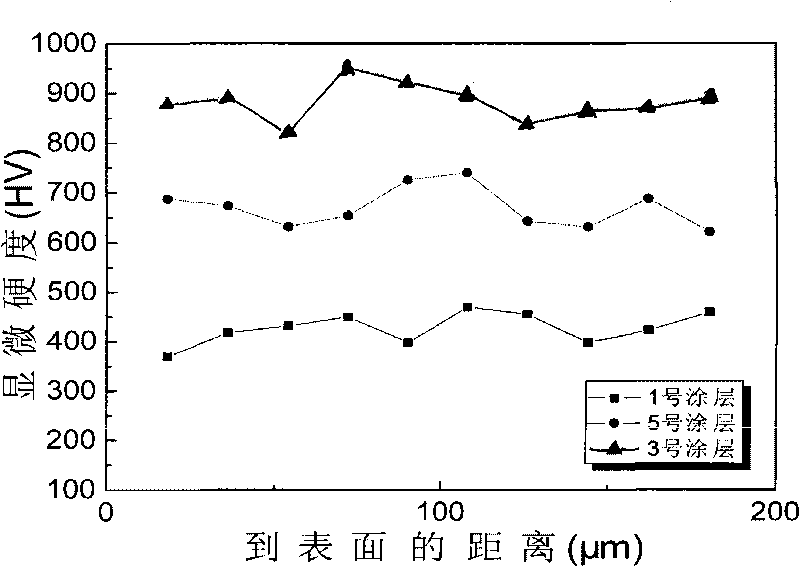

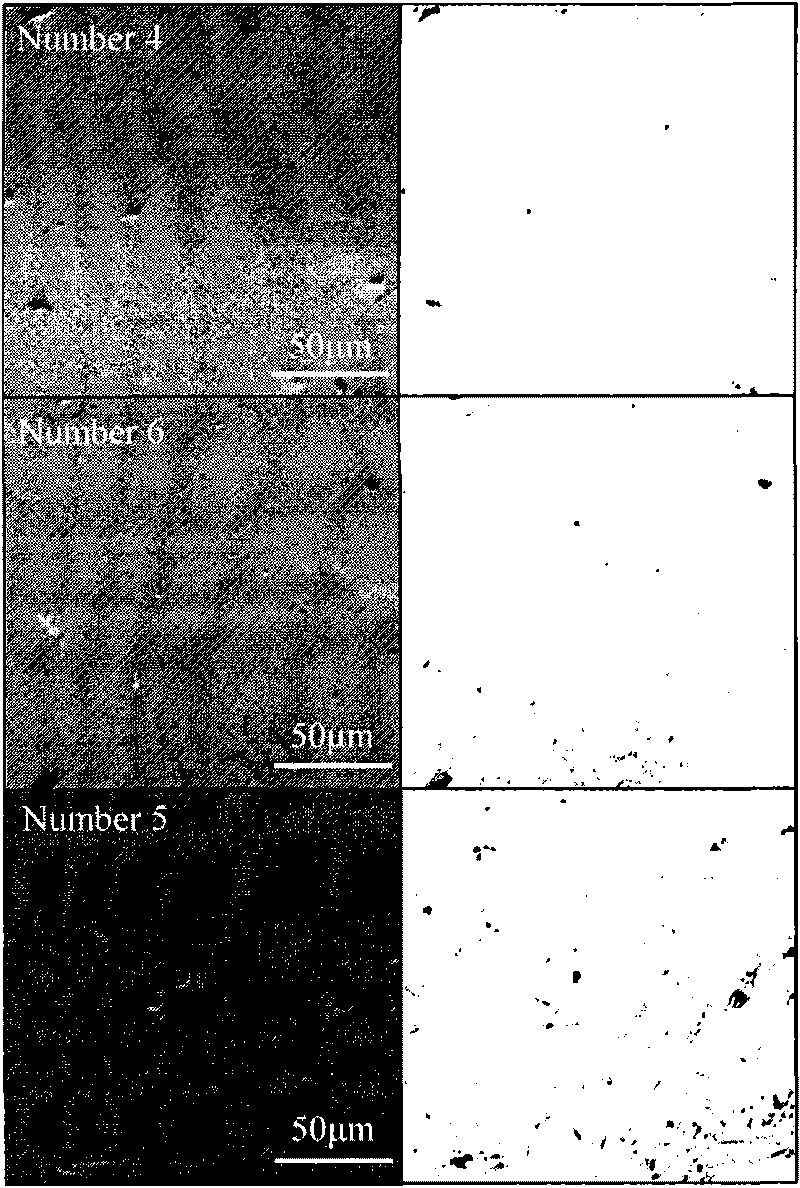

[0029] In the embodiment, the three parameters that have the greatest impact on coating performance in plasma spraying, i.e. spraying distance, spraying voltage, and spraying current are extracted, and are determined according to the power and average thermal efficiency of the HEPjet supersonic plasma spraying equipment and the melting point of the sprayed material The parameter levels of , as shown in Table 1 of the orthogonal experiment, fixed the main air flow rate, powder feeding rate and coating thickness factors. In plasma spraying, these three parameters can be determined, but for other spraying technologies, the three parameters that have a greater impact on t...

Embodiment 2

[0063] Embodiment 2 Evaluation of the contact fatigue performance of the coating prepared in Example 1 of the present invention and the coating prepared in the prior art

[0064] In order to investigate the contact fatigue performance of the coating (prepared in Example 1) prepared by the new process method proposed here, the coating prepared by the new process method and the coating directly prepared (without preparing the bonding bottom layer and using orthogonal calculation optimization, the spraying parameters are shown in Table 5)

[0065] table 5

[0066]

[0067] Under the same experimental conditions (stress level and friction conditions), 10 groups of contact fatigue experiments were carried out. The experimental method: spray the coating on the prefabricated substrate, and use the contact fatigue testing machine to conduct the contact fatigue experiment. The experimental equipment is: YS-1 ball-on-disk contact fatigue testing machine independently developed by Ya...

Embodiment 3

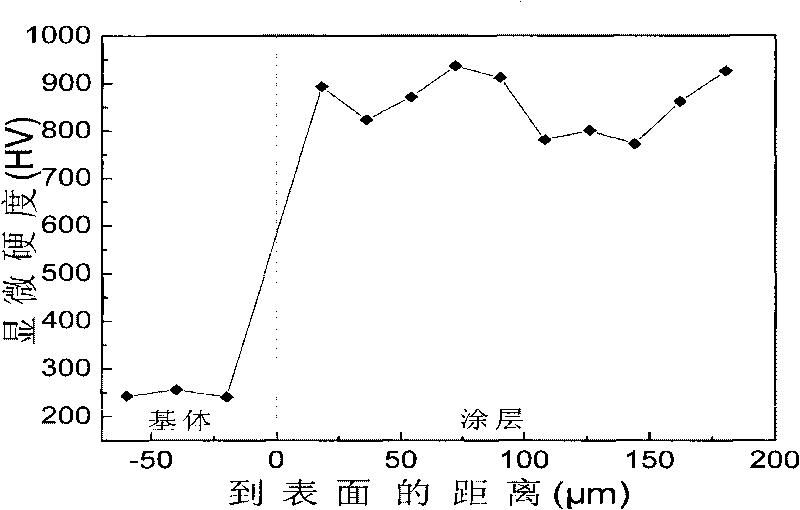

[0069] Embodiment 3 Evaluation of contact fatigue performance of the coating prepared in Example 1 of the present invention and the coating prepared in the prior art

[0070] The coating prepared by Example 1 of the present invention and the coating directly prepared were compared with the coating which only applied spray primer without orthogonal optimization.

[0071] The spraying parameters of the directly prepared coating described in this embodiment are the same as in Example 2 and are shown in Table 5. Spray the coating of the bottom layer, and the spraying parameters of the bottom layer are shown in Table 3. The test method and equipment of coating contact fatigue performance are the same as those in Implementation 2.

[0072] The fatigue life of the three coatings was characterized using a two-parameter Weibull probability of failure plot. It can be seen from the figure that under the same stress level and friction conditions, the failure probability of the primer co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com