Carburizing bearing steel and preparation method thereof

A technology of carburizing bearings and bearing steel, which is applied in the field of carburizing bearing steel and its preparation, and can solve the problems that electroslag bearing steel and double vacuum bearing steel cannot meet production requirements and cost increases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention provides a method for preparing carburized bearing steel described in the above scheme, comprising the following steps:

[0034] Smelting the raw materials for preparing carburized bearing steel to obtain a steel ingot; the chemical composition of the steel ingot corresponds to the chemical composition of the carburized bearing steel described in the above scheme;

[0035] After the steel ingot is homogenized, it is processed into a bar;

[0036] Carburizing, quenching and annealing are sequentially performed on the bar to obtain carburized bearing steel.

[0037] The invention smelts the raw materials for carburizing bearing steel to obtain steel ingots. In the present invention, the smelting method is preferably electroslag smelting, double vacuum smelting, out-of-furnace refining or vacuum induction furnace smelting. In order to reduce production costs, the present invention further preferably adopts out-of-furnace refining or vacuum induction...

Embodiment 1

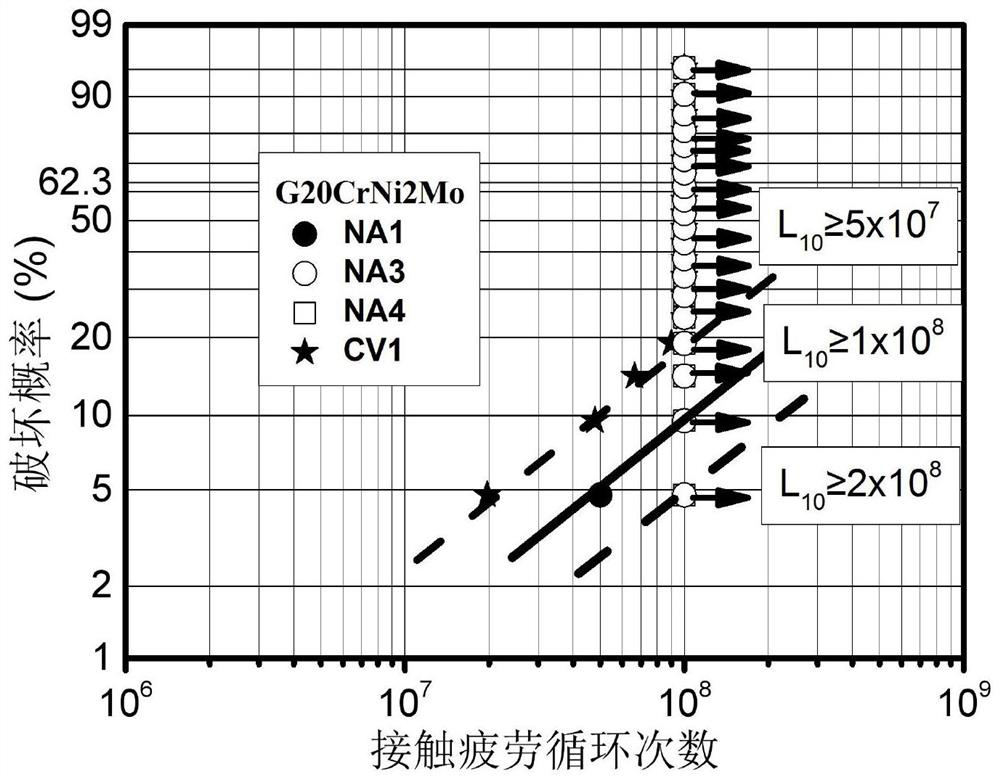

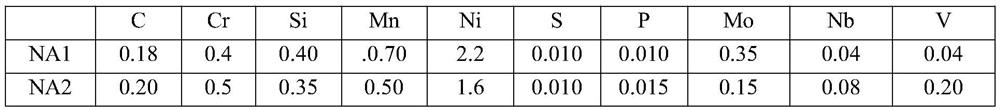

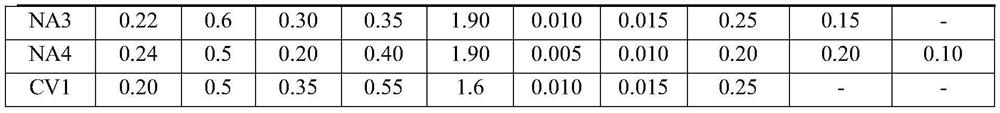

[0048] The steel of the present invention is smelted by a laboratory vacuum induction furnace, and the casting ingot shape is a 50kg round ingot. A total of 5 furnaces of steel are smelted for forging rod-shaped samples. The chemical composition is shown in Table 1. NA1-NA4 steels are carburized bearing steels of the present invention and CV1 bearing steels for comparison. The steel ingots smelted by vacuum induction smelting in the laboratory are subjected to 1200°C and 6-hour high-temperature homogenization treatment, and then forged and opened. The initial forging temperature is 1150°C, and the final forging temperature is 900°C. A round bar with a cross-sectional size of 60 mm is water-cooled to room temperature after forging. A round bar with a diameter of 60mm is carburized at 930°C for 12 hours, oil-cooled to room temperature; then quenched at 820°C for 0.5 hours, oil-quenched to room temperature; finally annealed at 170°C for 2 hours, and air-cooled to room temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com