Method for heat treatment of ultrahigh-carbon bearing steel

A heat treatment method and bearing steel technology, applied in the field of high carbon steel and bearing steel, can solve the problems of low impact toughness of ultra-high carbon steel, and achieve the effect of improving impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

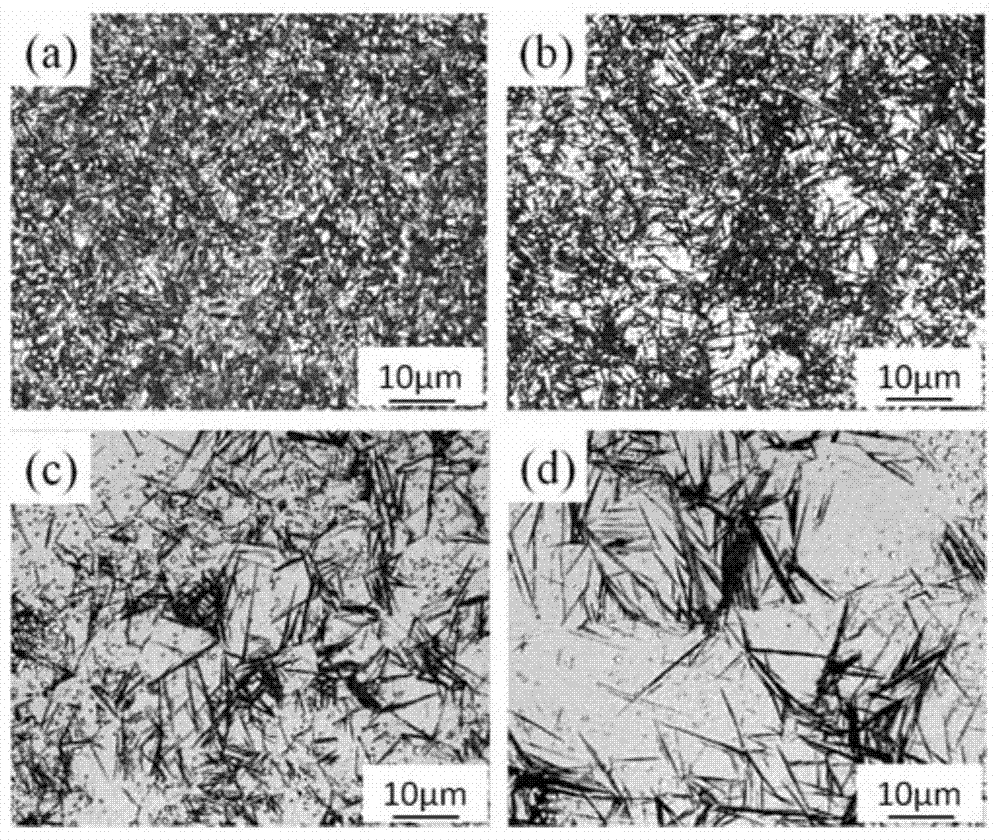

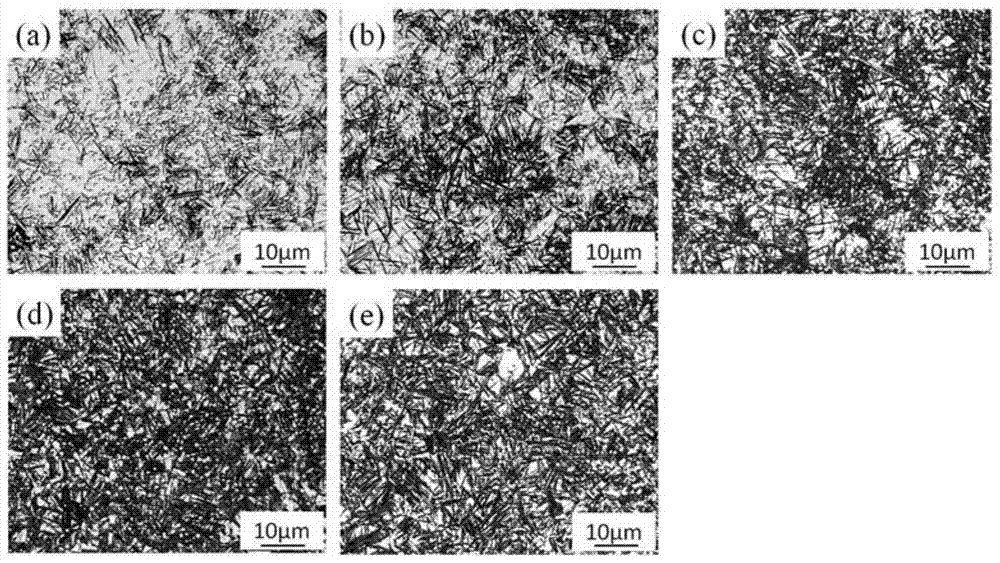

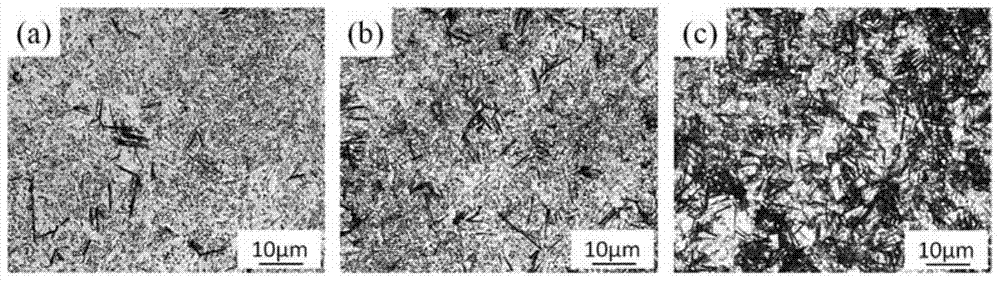

[0023] Example: An ultra-high carbon bearing steel, according to the weight percentage (wt.%), its chemical composition is C: 1.10-1.50, Cr: 1.00-2.00, Mn: 0.25-1.00, Si: 0.20-1.50, Al : 1.0-2.0%, the rest is Fe; firstly, this ultra-high carbon bearing steel is forged and spheroidized according to the standard of high-carbon chromium bearing steel, so as to make organizational preparations for further heat treatment.

[0024] After spheroidizing, the ultra-high carbon bearing steel is partially austenitized and retains a certain amount of residual carbides; then, a certain amount of super bainite is formed isothermally in the lower bainite zone (Bs-Ms), and isothermally After oil quenching or water cooling to obtain part of the martensite. The austenitizing temperature is 860-950°C. The heating time for the austenitization is determined according to the effective thickness of the workpiece and the heating coefficient is 1.0-2.0 min / mm. The isothermal temperature is 150-350°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact toughness | aaaaa | aaaaa |

| Shock | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com