Bainite isothermal quenching thermal treatment process method for medium-carbon bearing steel

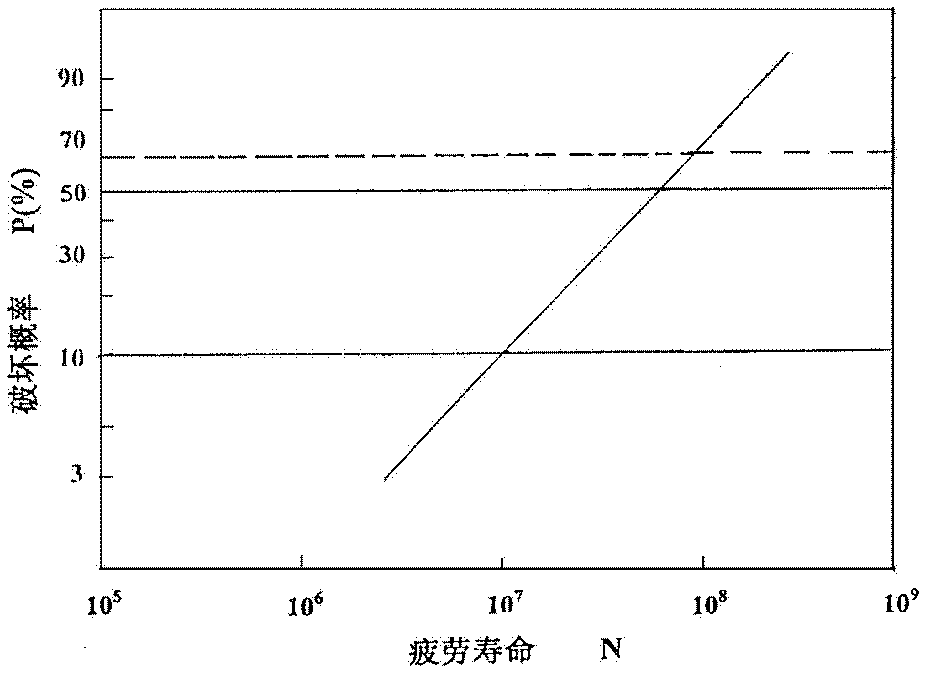

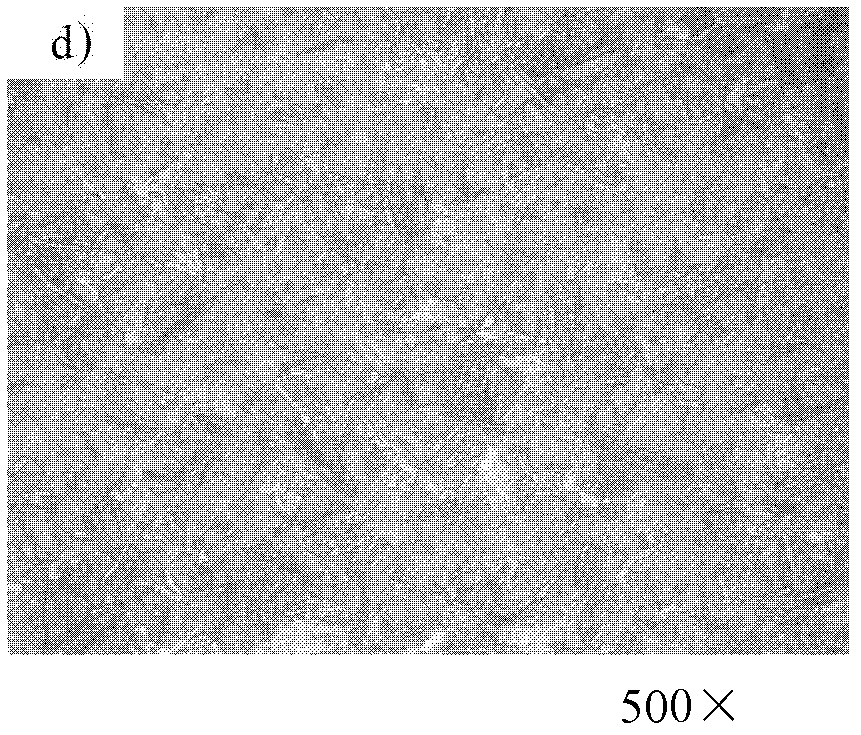

A technology of austempering and medium carbon bearings, which is applied in heat treatment equipment, quenching agents, manufacturing tools, etc., can solve the problems of long production cycle, peeling of seepage layer, long time, etc., and achieve bearing manufacturing cost reduction, high contact fatigue life, Good wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

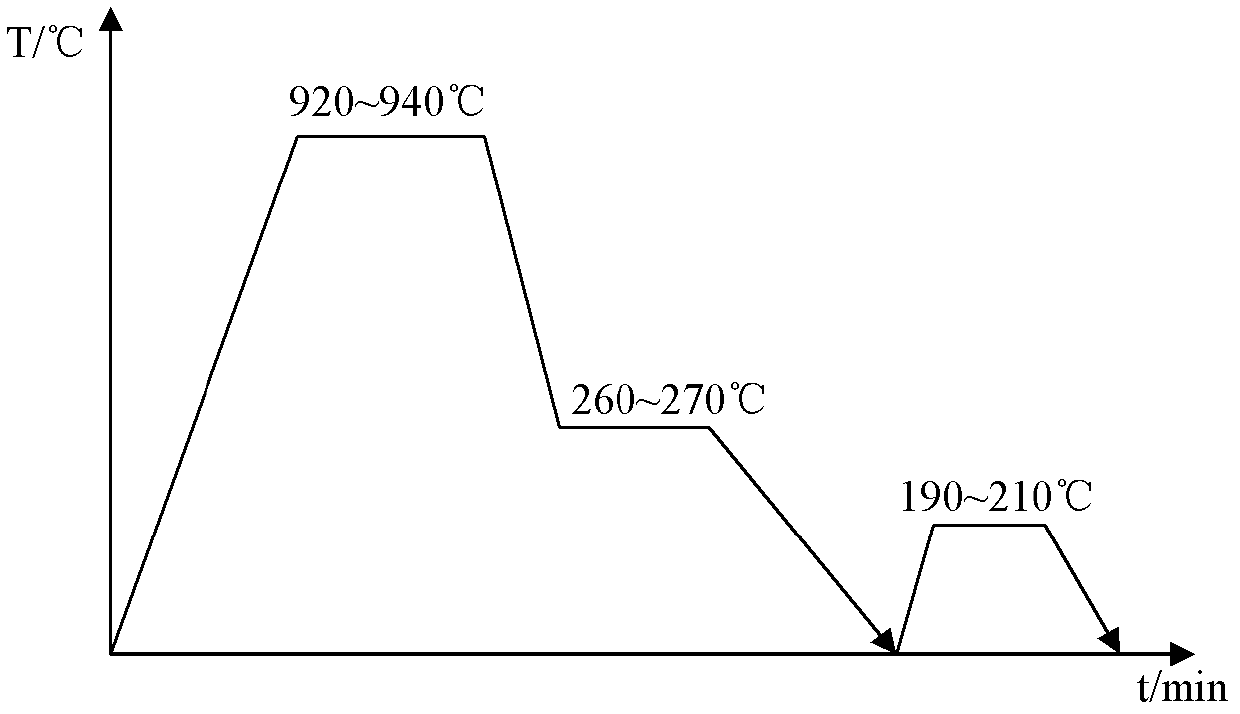

[0027] The bearing wall thickness is 40mm. The bainite austempering process includes the following steps:

[0028] The bearing steel after blanking is firstly forged and heated in a gas furnace at the bottom of the car. The heating temperature is 1140-1160°C, the holding time is 0.3-0.8min / mm, the initial forging temperature is 1090-1110°C, and the final forging temperature is controlled at 890~910℃. After forging, carry out normalizing + spheroidizing annealing; normalizing temperature is 860-890°C, keep warm for 20-40 minutes, leave the furnace and air-cool to form flaky pearlite structure; carry out spheroidizing annealing after normalizing, and the spheroidizing annealing temperature is 750-780°C , keep it warm for 4-6 hours, cool it to 600°C with the furnace, and then air-cool it to form a fine and uniform spheroidized structure. The steel parts after spheroidizing annealing are subjected to bainite isothermal quenching and low-temperature tempering treatment; the baini...

Embodiment 2

[0030] The bearing wall thickness is 30mm. The bainite austempering process includes the following steps:

[0031]The bearing steel after blanking is firstly forged and heated in a gas furnace at the bottom of the car. The heating temperature is 1140-1160°C, the holding time is 0.3-0.7min / mm, the initial forging temperature is 1090-1110°C, and the final forging temperature is controlled at 890~910℃. After forging, carry out normalizing + spheroidizing annealing; normalizing temperature is 860-890°C, keep warm for 20-40 minutes, leave the furnace and air-cool to form flaky pearlite structure; carry out spheroidizing annealing after normalizing, and the spheroidizing annealing temperature is 750-780°C , keep it warm for 4-6 hours, cool it to 600°C with the furnace, and then air-cool it to form a fine and uniform spheroidized structure. The steel parts after spheroidizing annealing are subjected to bainite isothermal quenching and low-temperature tempering treatment; the bainit...

Embodiment 3

[0033] The bearing wall thickness is 20mm. The bainite austempering process includes the following steps:

[0034] The bearing steel after blanking is firstly forged and heated in a bottom-mounted gas furnace at a heating temperature of 1140-1160°C, a holding time of 0.3-0.6min / mm, an initial forging temperature of 1090-1110°C, and a final forging temperature of 890~910℃. After forging, carry out normalizing + spheroidizing annealing; normalizing temperature is 860-890°C, keep warm for 20-40 minutes, leave the furnace and air-cool to form flaky pearlite structure; carry out spheroidizing annealing after normalizing, and the spheroidizing annealing temperature is 750-780°C , keep it warm for 4-6 hours, cool it to 600°C with the furnace, and then air-cool it to form a fine and uniform spheroidized structure. The steel parts after spheroidizing annealing are subjected to bainite isothermal quenching and low-temperature tempering treatment; the bainite isothermal quenching proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com