Forging forming method for inner ring and outer ring of motor train unit bearing with reasonable streamline distribution

A technology of inner and outer rings and EMUs, applied in heat treatment furnaces, manufacturing tools, heat treatment equipment, etc., can solve the problems of affecting the mechanical properties of forgings, the disorder of metal streamlines, and the lack of effective technology to ensure the distribution of forging streamlines, etc., to improve mechanical properties performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

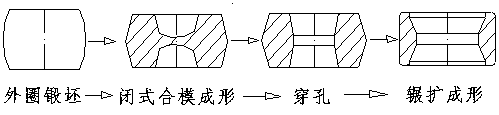

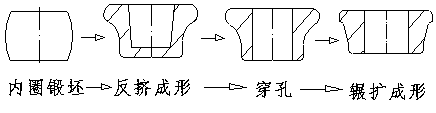

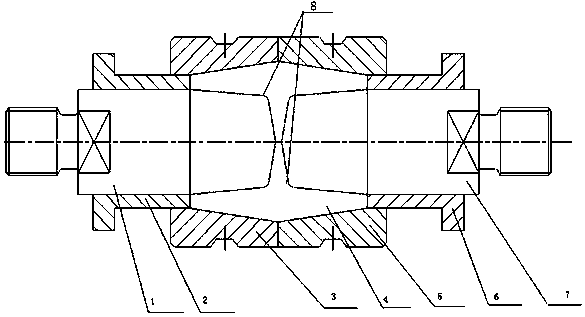

[0019] The following combination Figure 1 ~ Figure 3 And specific embodiments, the present invention is described further. It should be understood that the following examples are only used to illustrate the present invention but not to limit the scope of the present invention.

[0020] The concrete steps that the present invention implements are as follows:

[0021] 1) Deform simulation using process simulation system: simulate the entire processing process on the computer, analyze various forming processes and heat treatment processes in metal forming and related industries, and then simulate and optimize punches and adjust the fit gap between molds;

[0022] 2) Simulation and display of streamline distribution: Use carburized steel with low purity to replace the newly developed DZC1 carburized bearing steel with high purity to manufacture forgings with the same structure and size. Carry out wire cutting processing in the height direction of the ferrule, and after grinding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com