Carburizing bearing steel

A technology of carburizing bearings and chemical elements, which is applied in the field of ferrous metal material manufacturing and processing, and can solve problems such as matching strength and toughness, and easy coarse grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

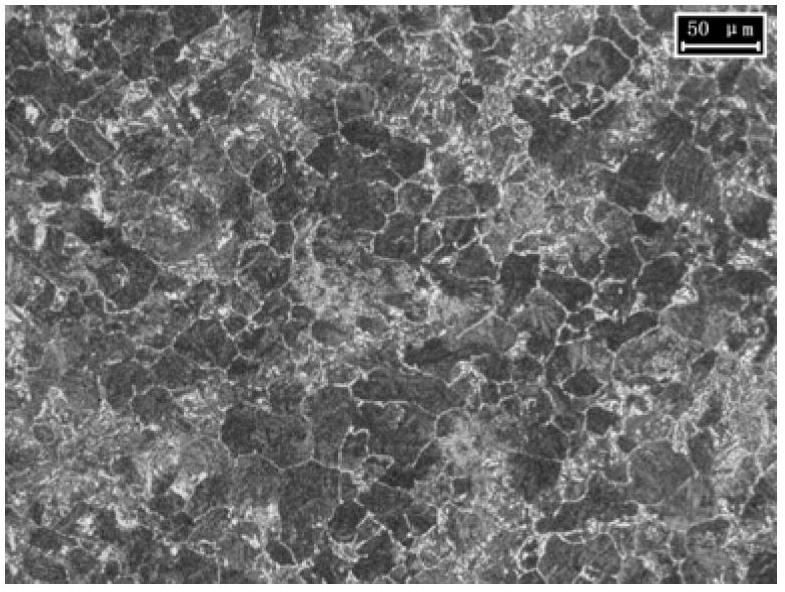

Image

Examples

Embodiment Construction

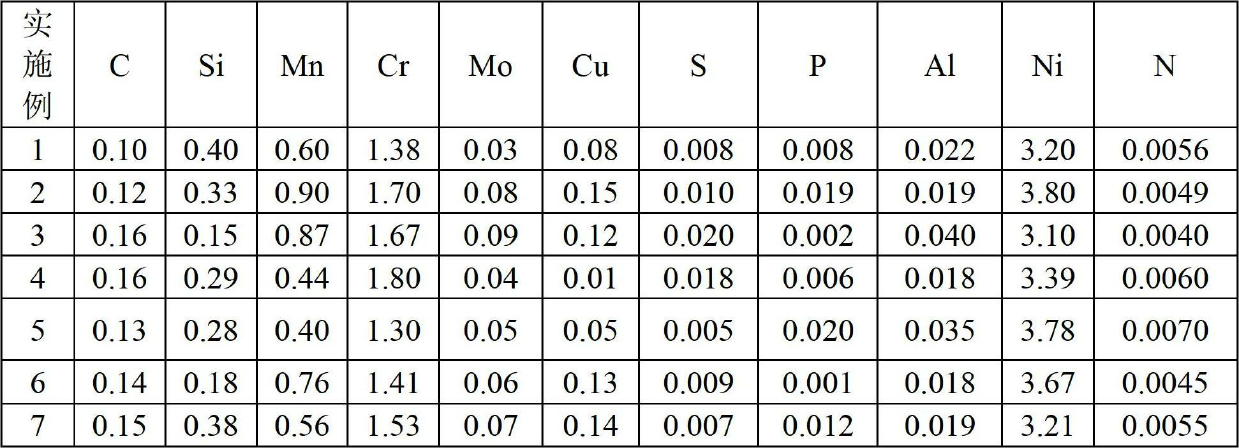

[0056] Table 1 is the chemical composition and material properties of the steel grades of the present invention. Embodiments of the present invention adopt the following preparation methods:

[0057] The first step: electric furnace smelting → ladle furnace refining → vacuum furnace degassing → pouring molten steel into ingots; the second step: billet opening → rolling into round steel; the third step: annealing.

[0058] Step 1: Smelting

[0059] In the 40-ton AC electric furnace, the low-phosphorization and low-titanization of the primary molten steel are carried out to reduce the residual phosphorus content and titanium content in the steel to below 0.003% and 0.0005% respectively. On the AC ladle refining furnace matching the capacity of the electric furnace, the low oxygen and low titanium of the molten steel are carried out, so that the oxygen content of the molten steel is reduced to below 0.0010%, and the titanium content and sulfur content in the steel are reduced. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com