Carburized bearing steel

A carburizing bearing and bearing steel technology, applied in the manufacturing and processing field of bearing steel in the metallurgical industry, can solve the problems of complex process, high carburizing process, coarse grains, etc., achieve high relative purity, optimize comprehensive performance, grain size high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

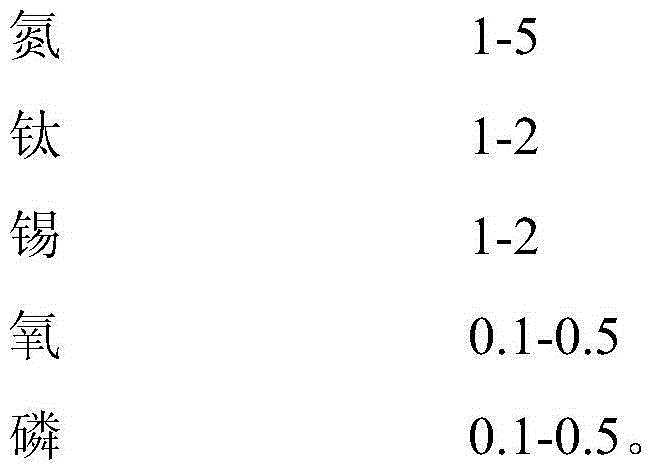

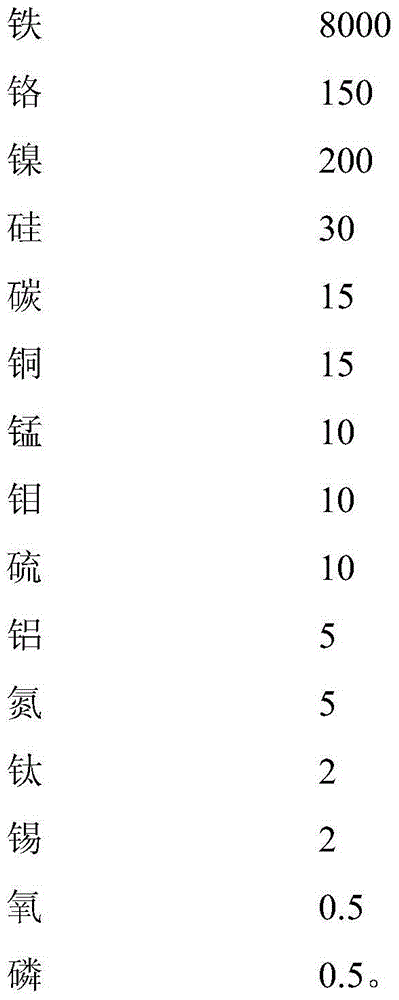

[0021] Proportion the bearing steel according to the composition of the following weight ratio:

[0022]

[0023] It is smelted in an electric furnace, degassed in a vacuum furnace, poured into a steel ingot, and then rolled into a round steel, and then annealed. Heat treatment by carburizing method (heat treatment process: heat preservation at 800°C for 10 hours, furnace cooling to 200°C and air cooling). The obtained bearing steel is subjected to quenching at 900°C and secondary tempering heat treatment at 170°C. Finally, the obtained carburized bearing steel is tested for mechanical properties and other comprehensive properties. Obtained after detection and analysis: The bearing steel obtained in the embodiment of the present invention has the mechanical properties and other comprehensive properties after testing. Carbon bearing steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com