Acrylic emulsion with self-crosslinked core-shell structure, and preparation method of acrylic emulsion

A technology of self-crosslinking acrylic acid and core-shell structure, which is applied in coatings, anti-corrosion coatings, fire-proof coatings, etc. It can solve the problems of poor comprehensive performance of acrylic emulsion, poor dispersion of small molecule corrosion inhibitors, unstable corrosion resistance, etc. problems, to achieve the effect of changing strength and toughness, improving protection performance, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

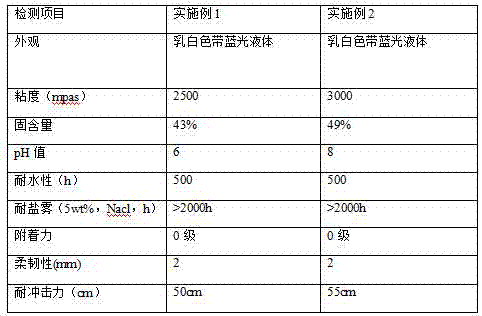

Embodiment 1

[0039]The raw materials are as follows: based on 100 parts of the total weight of the core raw materials, the amount of acrylic hard monomer (styrene and methyl methacrylate weight ratio 1:1) is 30 parts, and the amount of self-crosslinking monomer I (diacetone acrylamide) The amount of vinylidene chloride is 5 parts, the amount of vinylidene chloride is 10 parts, the amount of organic corrosion inhibitor (benzotriazole) is 1 part, the amount of emulsifier I (sodium dodecylbenzenesulfonate) is 2 parts, and the amount of initiator I ( Potassium persulfate) is 1 part, and the balance is deionized water; based on 100 parts of the total weight of raw materials for the shell part, acrylic soft monomer (butyl acrylate and 2-ethylhexyl acrylate weight ratio 1:1) The dosage is 20 parts, the dosage of self-crosslinking monomer II (dihydrazine adipate) is 5 parts, the organic fluorine active monomer (dodecafluoroheptyl methacrylate) is 10 parts, the phosphoric ester monomer (PAM-100 ) i...

Embodiment 2

[0049] The raw materials are as follows: based on 100 parts of the total weight of the core raw materials, the amount of acrylic hard monomer (styrene and methyl methacrylate weight ratio 1:3) is 40 parts, self-crosslinking monomer I (acetoacetate methyl methacrylate) Glycol ester) dosage is 10 parts, vinylidene chloride dosage is 15 parts, organic corrosion inhibitor (mercaptobenzothiazole) dosage is 4 parts, emulsifier I (alkylphenol polyoxyethylene ether and fatty alcohol polyoxyethylene ether Weight ratio 1:1) dosage is 4 parts, initiator I (sodium persulfate) dosage is 3 parts, and the balance is deionized water; Hydroxyethyl ester (weight ratio 1:2) is 35 parts, self-crosslinking monomer II (succinic acid dihydrazide) is 10 parts, organic fluorine active monomer (hexafluorobutyl acrylate) is 15 parts, phosphate The amount of monomer (PAM-200) is 5 parts, the amount of emulsifier II (alkylphenol polyoxyethylene ether phosphate) is 10 parts, the amount of initiator II (sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com