A kind of copper-iron master alloy with uniform composition and preparation method thereof

A master alloy, copper-iron technology, applied in the field of copper-iron master alloy and its preparation, can solve the problems of difficult industrial application of copper-iron alloy, difficult alloying of copper-iron alloy, difficult industrial application, etc. Humidity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

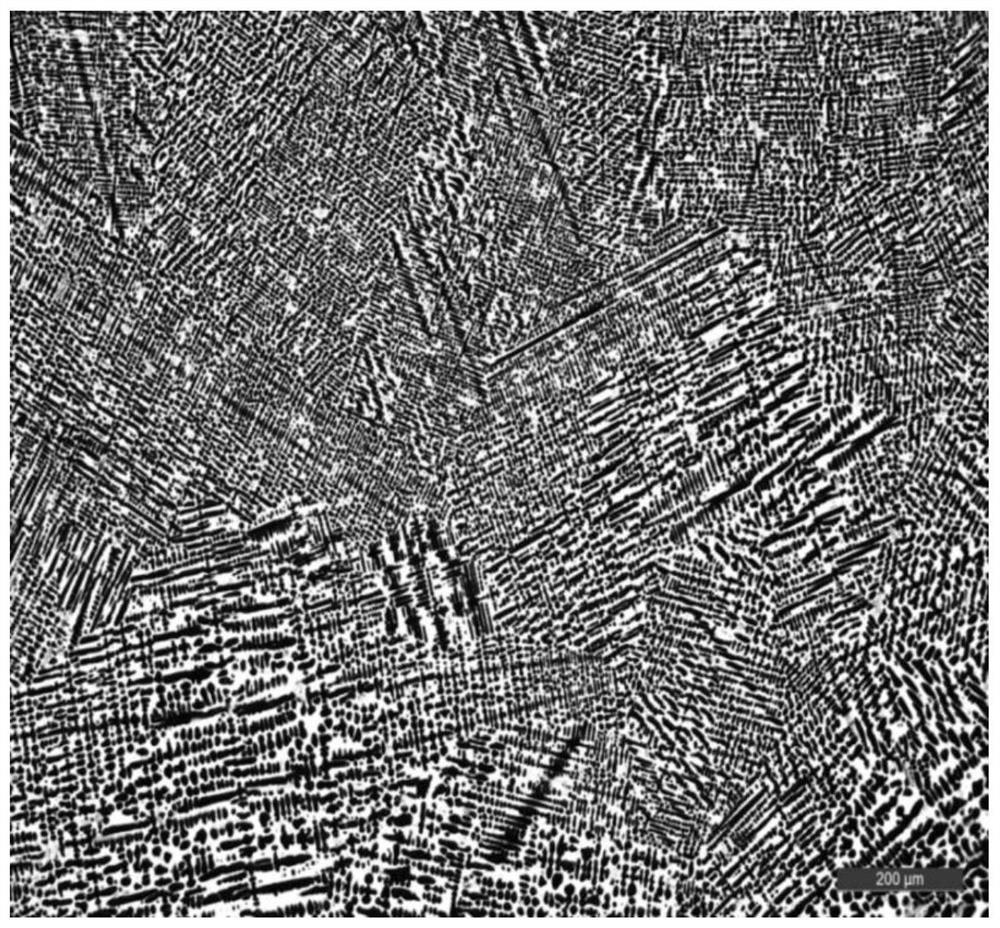

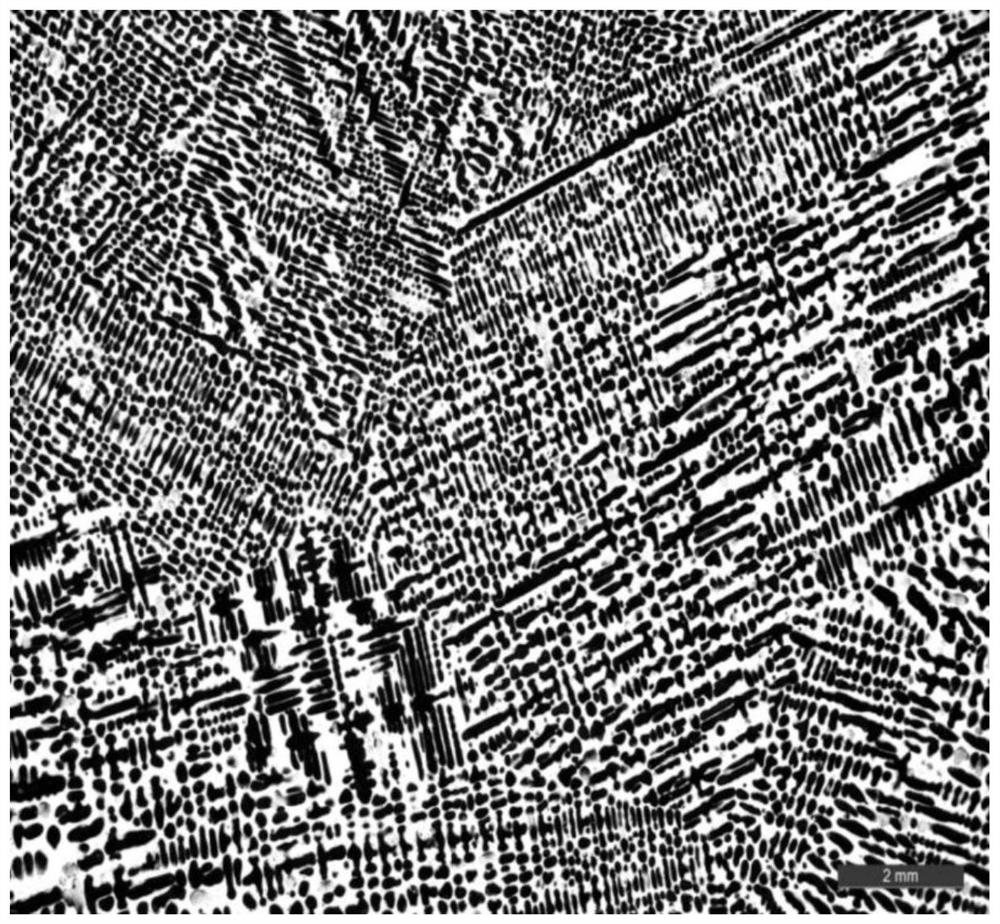

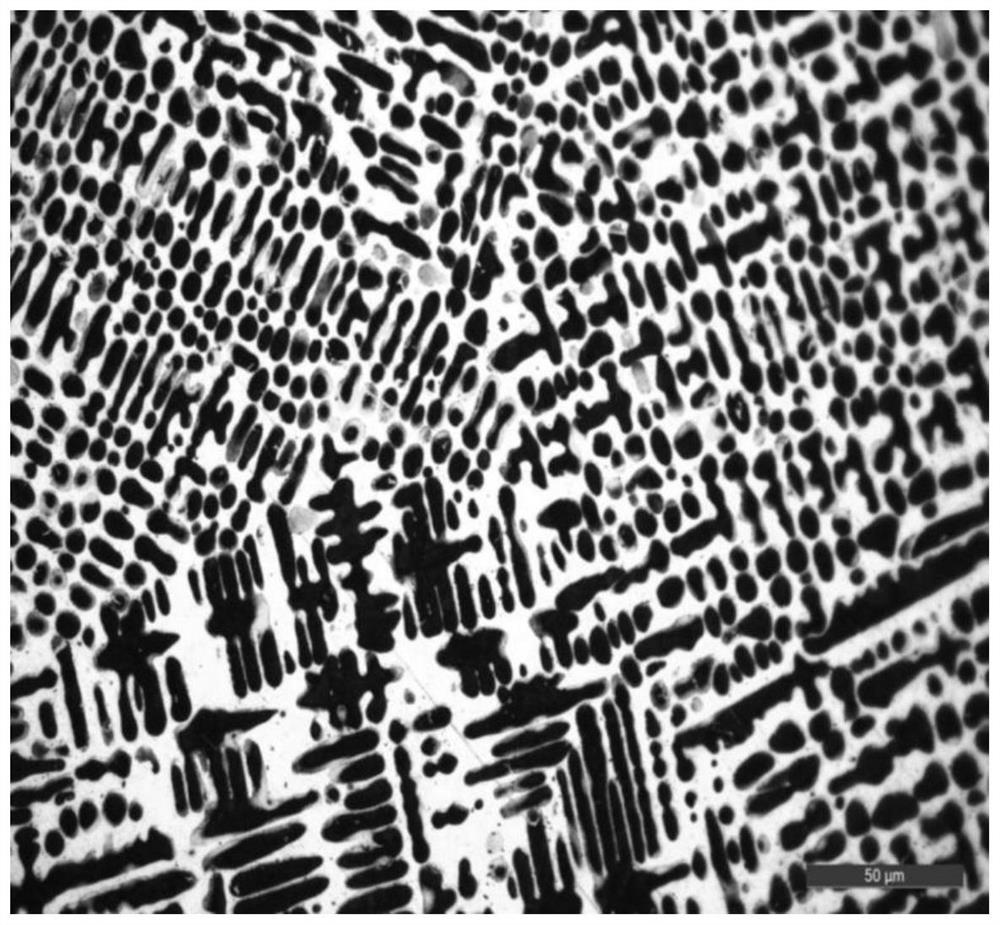

Image

Examples

Embodiment 1-4

[0042] S1. Ingredients: According to Table 1, ingredients are carried out by mass percentage. Among them, Fe is added in the form of pure iron, copper is added in the form of electrolytic copper, Ti is added in the form of copper-titanium master alloy, and Mg is added in the form of copper-magnesium master alloy.

[0043] S2, smelting: smelting in an intermediate frequency furnace, adding pure iron according to the prepared materials, adding the prepared electrolytic copper after the iron is melted, and adding the prepared copper-titanium master alloy and copper-magnesium master alloy after all melting. The smelting temperature was controlled at 1500°C and kept for 1h. The smelting process is covered with the following covering agent, the composition of which is calculated by mass percentage: SiO 2 10wt%, CaF 2 5wt%, TiO 2 5wt%, MgO 10wt%, CaO balance.

[0044] S3, melt oxygen blowing: blow oxygen into the melt at 20L / min, carry out melt sampling every 2 minutes for com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com