Preparation process of hypoeutectic aluminum-silicon alloy inoculated by high-entropy alloy

A high-entropy alloy and aluminum-silicon alloy technology, applied in the field of aluminum-silicon alloy inoculation, can solve the problems of splitting the continuity of the alloy matrix, reducing the mechanical properties of the hypoeutectic aluminum-silicon alloy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

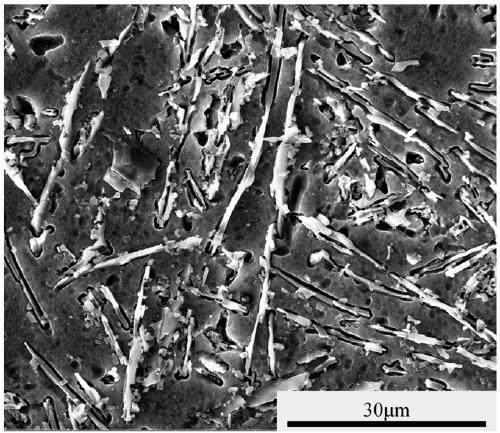

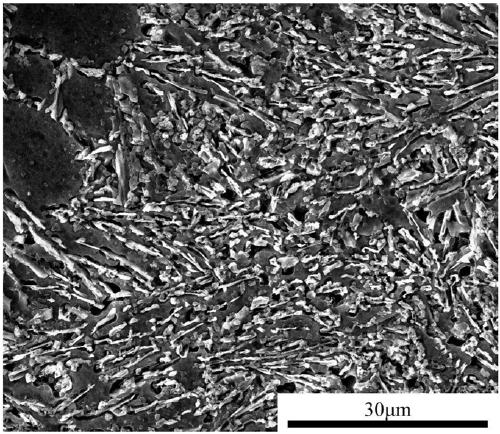

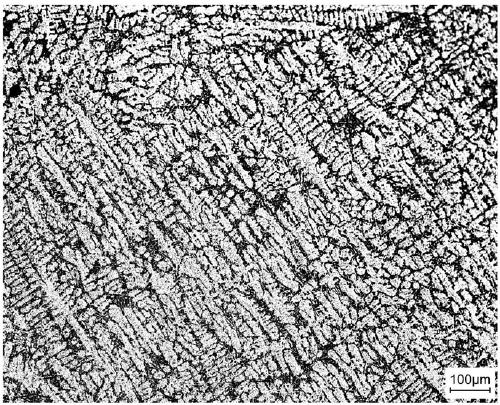

Image

Examples

Embodiment

[0019] (1) First prepare AlCoCrFeNiTix (x=0.5~1.5) high-entropy alloy inoculant, and prepare six metal elements of Al, Co, Cr, Fe, Ni and Ti with a purity greater than 99.9% according to the molar ratio, put them into a vacuum In the electric arc furnace, under the protection of high-purity argon gas, smelting at a current of 200A for 2.0min-5.0min until it is completely melted, and repeatedly smelting 5-6 times to ensure its uniform composition, and then obtain 40g of high-entropy alloy samples.

[0020] (2) Mix industrial pure aluminum and Al-20Si alloy in proportion, heat them in a Si-C rod crucible furnace at a temperature of 800 °C until they are completely melted, and keep at a temperature of 750 °C for 15 minutes to obtain Al-(6-9) Si alloy melt;

[0021] (3) 0.8wt% C2Cl6 is covered with aluminum foil and pressed into the melt of step (1), high-purity argon gas is introduced, stirring and refining, slag removal and degassing, and then poured into a metal mold at 720 ° C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com