Intelligent waste weft yarn processing device of water-jet loom

A water-jet loom, intelligent processing technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of increasing oil pollution, affecting the filtering effect of filter cotton, affecting the normal use of water pumps, etc. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

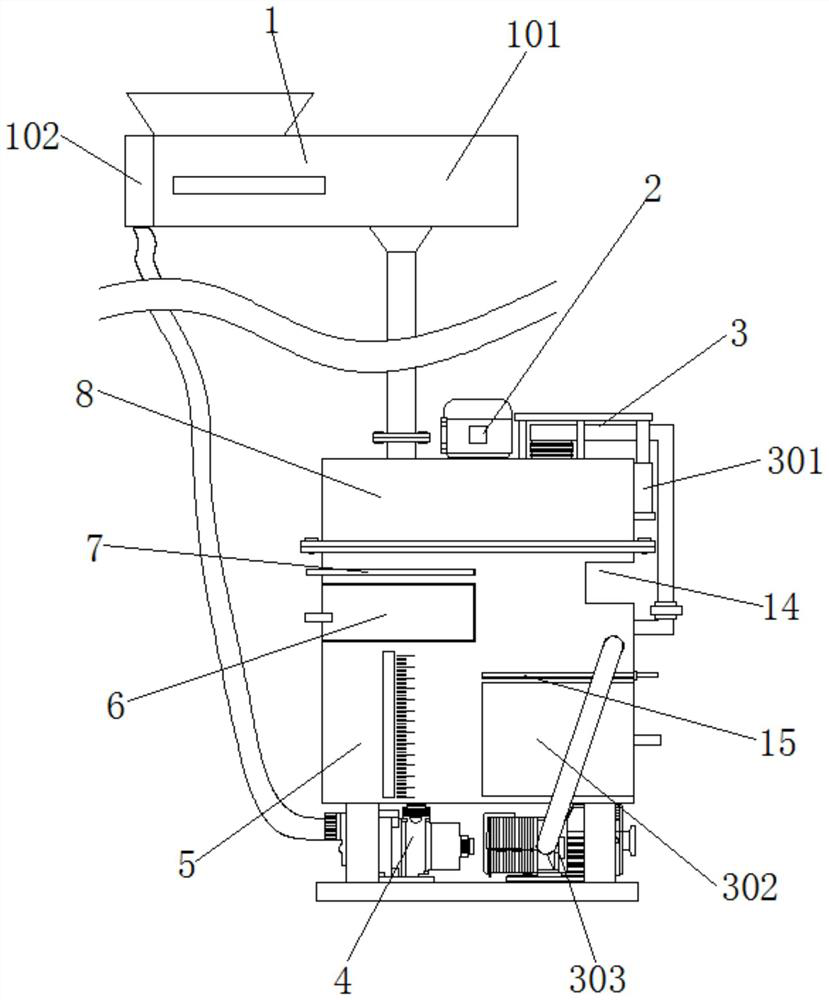

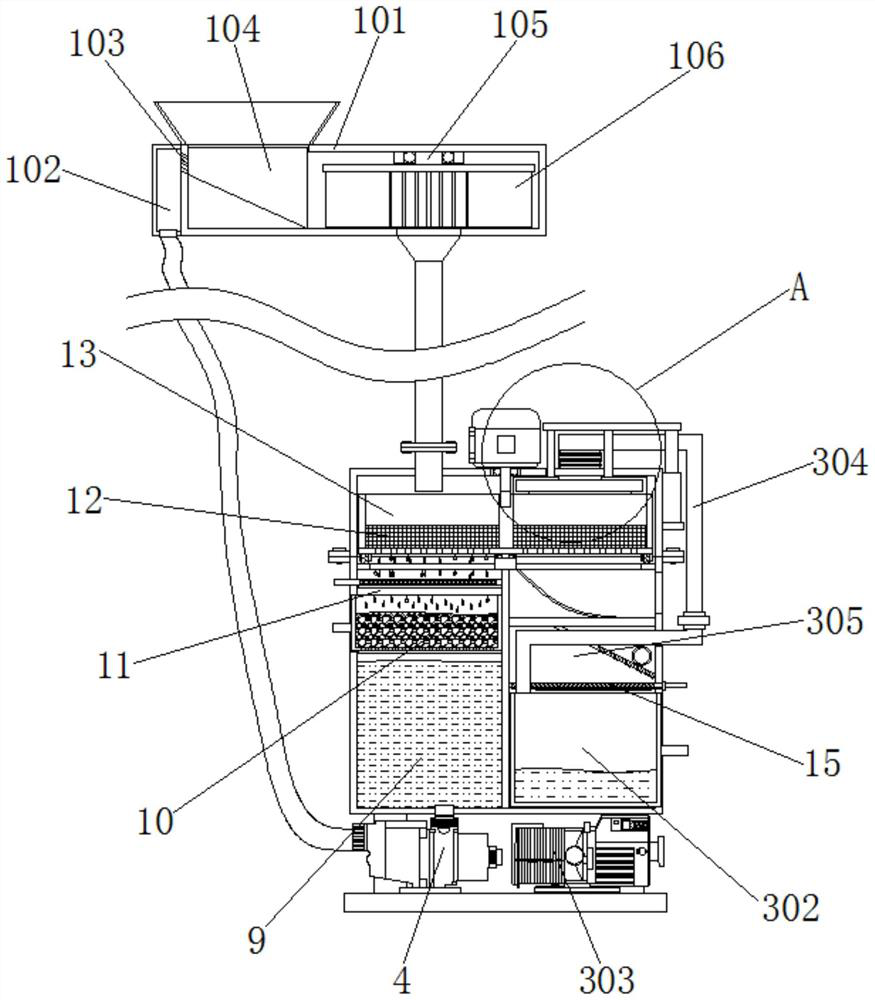

[0040] Example 1, such as figure 1 , 2 , 7 and 8, when the waste weft yarn falls into the inside of the guide groove 104, the water pump 4 is controlled by an external control panel to transport the clear water inside the water storage bin 9 to the inside of the water spray bin 102, and then the water flows from the water spray hole 103 Jetting, the waste weft yarns are rushed to the position of the turbofan 106 together, and the water flow drives the turbofan 106 to rotate, so that the water flow carries the waste weft yarns into the inside of the top cover 8 in the form of a spiral, so as to avoid part of the waste weft yarns sticking to the water flow channel for a long time On the inner wall, after the water flow with waste weft yarns enters the top cover 8, it will not always impact the same position on the top of the filter cotton 12, which ensures the filter blocking effect of the filter cotton 12 on the waste weft yarns.

Embodiment 2

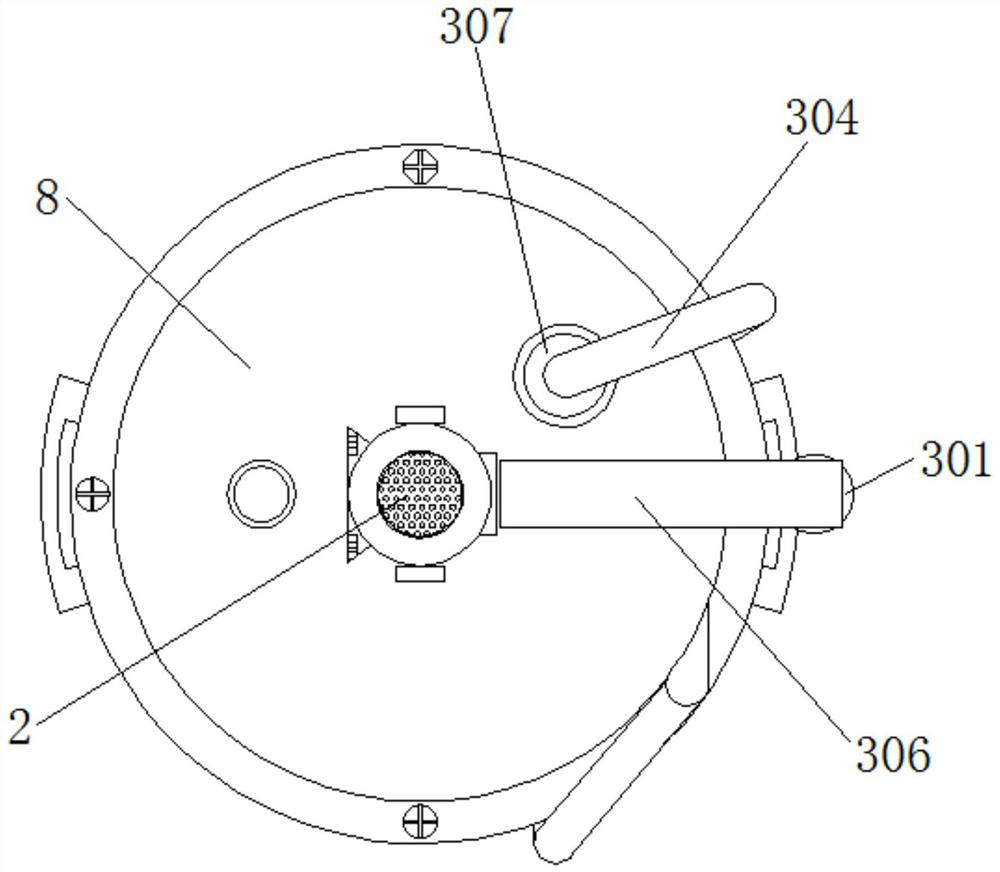

[0041] Example 2, such as figure 1 , 2 , 3, 4, 5, 6 and 9, when the first group of filter cotton 12 tops filter and block more waste weft yarns, the control servo motor 2 drives the entire rotating bin 13 to rotate clockwise 180°, so that the inside of the rotating bin 13 The second group of filter cotton 12 moves to the bottom of the top water outlet in the top cover 8, and uses the second group of filter cotton 12 to continue to filter and intercept the waste weft yarn in the water flow, while the first group of filter cotton 12 moves to the semicircular warehouse 308, then control the electric lifting rod 301 to shorten, so that the semicircular bin 308 moves to the inside of the rotating bin 13 and touches the top of the corresponding first group of filter cotton 12, and then controls the suction pump 303 to make the first The waste weft yarn at the top of the group of filter cotton 12 enters the interior of the collection bin 302 after passing through the semicircular bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com