Self-cleaning light-transmitting window for urban high-rise building

A high-rise building, self-cleaning technology, used in construction, cleaning equipment, building components, etc., can solve problems such as poor effect, water stains, large labor force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

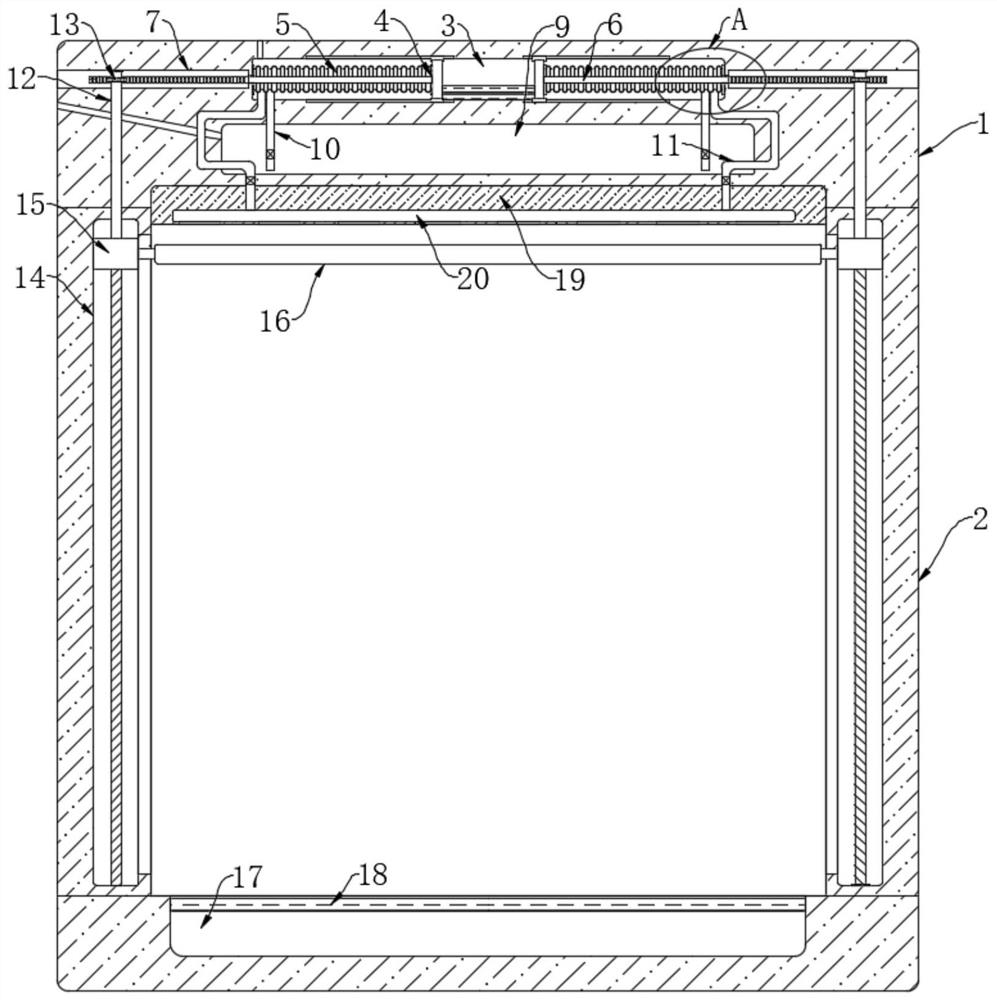

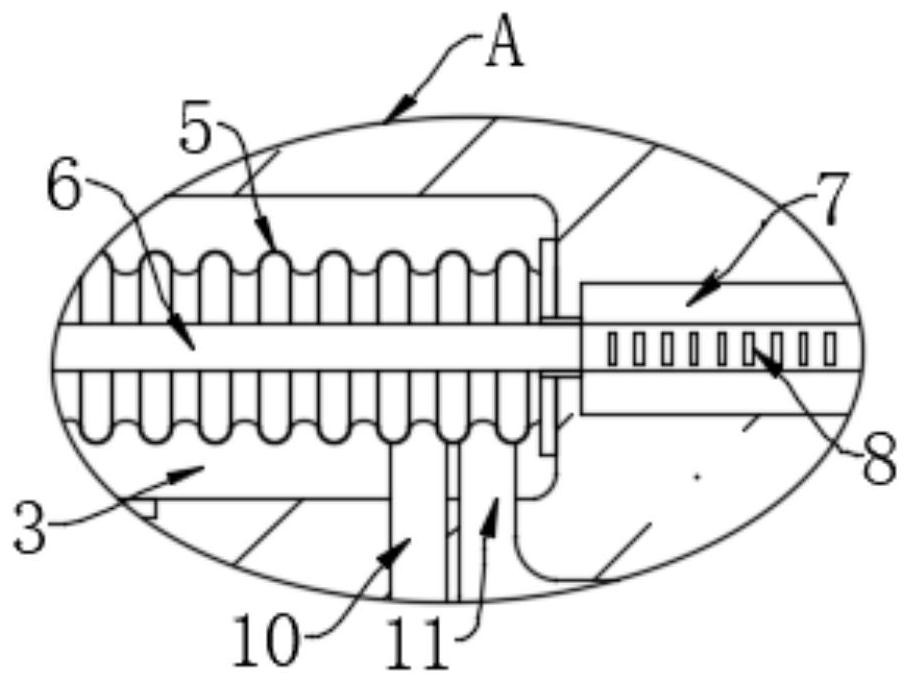

[0027] refer to Figure 1-2 , a self-cleaning light-transmitting window for urban high-rise buildings, including a window frame, the window frame is composed of two installation blocks 1 and two vertical plates 2, the size of the two installation blocks 1 can be designed according to the actual situation, and can be two There are two installation blocks 1 with different sizes, the two vertical plates 2 are located between the two installation blocks 1, glass is installed in the window frame, and a trigger cavity 3 is opened in the upper installation block 1, and inside the trigger cavity 3 A low-boiling point solution is provided. The low-boiling point solution can be organic matter such as aldehydes and ethers. The boiling point is generally between 20 and 35 degrees. The upper end of the mounting block 1 below is provided with a collection tank 17, which is convenient for collecting dust. , the notch place of collection tank 17 is equipped with dust-proof net 18, and dust-pr...

Embodiment 2

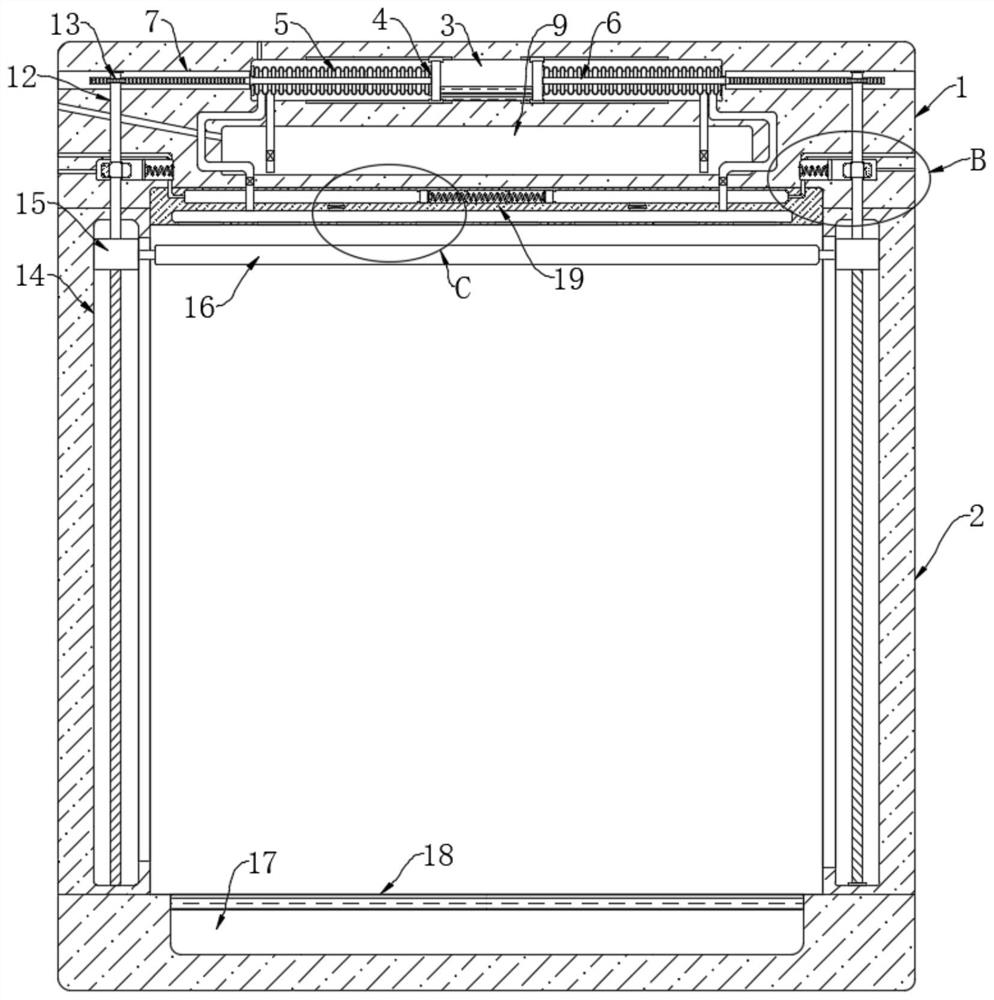

[0038] refer to Figure 3-6 The difference between this embodiment and Embodiment 1 is that it also includes two blowing mechanisms, the two blowing mechanisms are respectively arranged on the left and right sides of the liquid storage chamber 9, and the blowing mechanisms include openings in the installation block 1 located above The rotating chamber 21 of the rotating rod 12 runs through the rotating chamber 21, and the part of the rotating rod 12 located in the rotating chamber 21 is provided with a one-way bearing 23. The one-way bearing 23 is a prior art, and can rotate freely in one direction. A bearing that is locked in the other direction. Two fan blades 22 are fixedly connected to the one-way bearing 23, one of the fan blades 22 is magnetic, and the magnetic fan blade 22 repels the adjacent surface of the magnetic piston 24, and the rotating chamber 21 There is a magnetic piston 24 for moving left and right. The side of the magnetic piston 24 away from the fan blade 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com