Telescopic lens cone

A lens barrel, elastic expansion technology, applied in telescopes, instruments, optics, etc., can solve the problems of reduced volume, heavy weight, and long lens barrel, and achieve the effects of weight reduction, simple extension and shortening, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

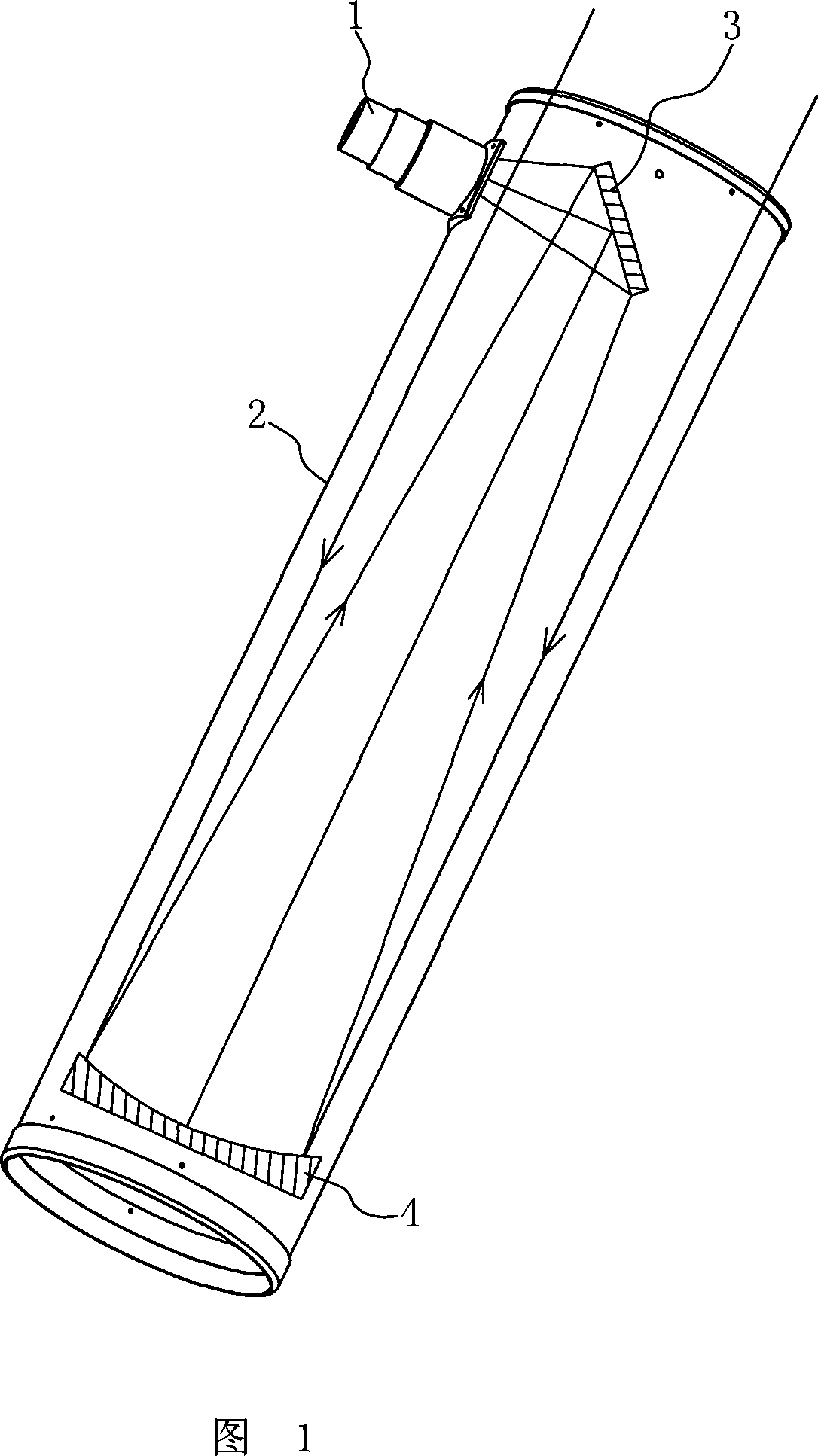

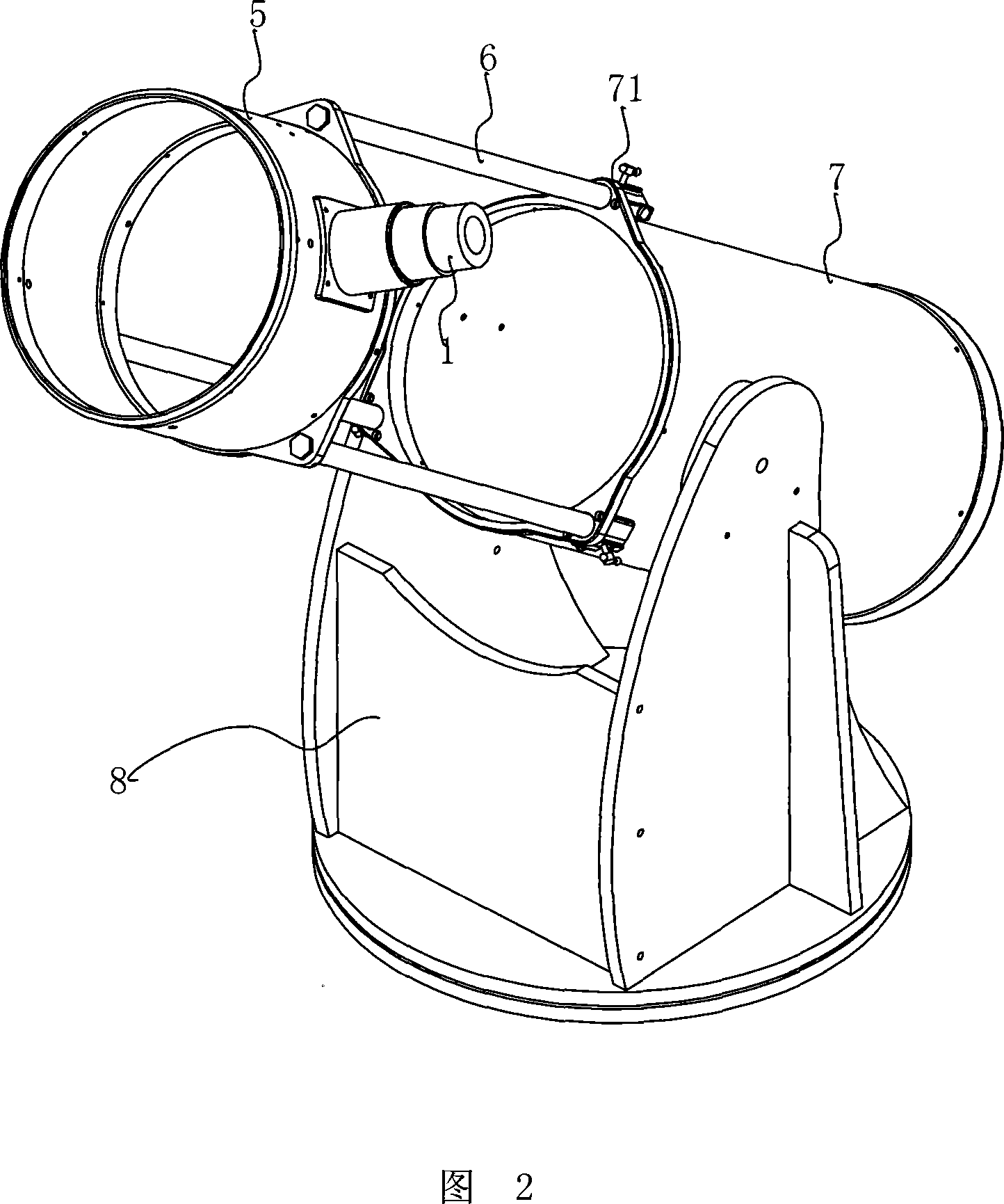

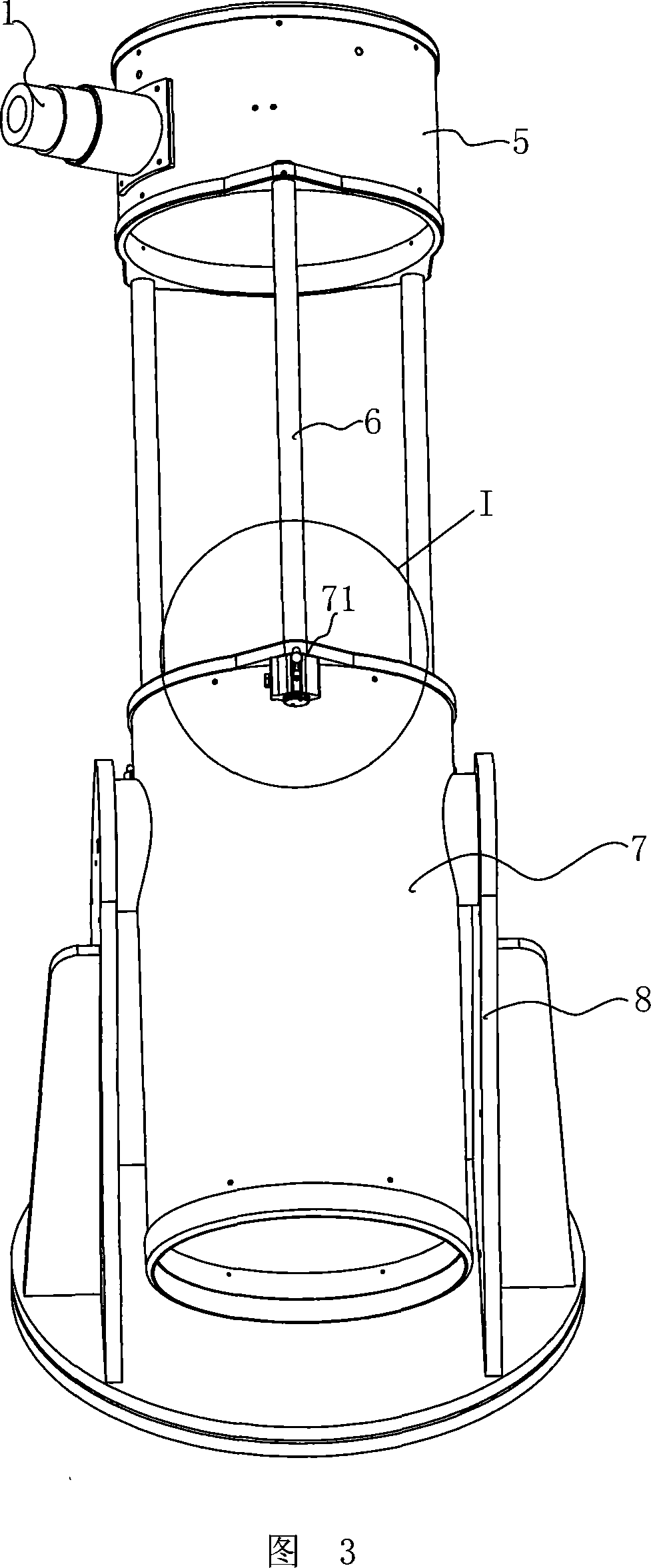

[0028] As shown in Fig. 1 to Fig. 4, the retractable lens barrel is mainly composed of an upper lens barrel 5, a connecting rod 6, a lower lens barrel 7 and a bracket 8, the upper lens barrel 5 is fixedly provided with an eyepiece 1, and the inside of the upper lens barrel is used for installation Plane reflector, the lower segment lens barrel 7 is erected on a support 8 and can rotate along the support shaft, and the bottom in the lower segment lens barrel is used for fixing the objective lens. The upper lens barrel 5 and the lower lens barrel 7 are coaxially arranged, the length of the upper lens barrel is 1 / 3 of the length of the lower lens barrel, the length of the pull rod 6 is slightly less than the length of the lower lens barrel, and the lower outer wall of the upper lens barrel The upper ends of the three connecting rods are evenly fixed, and the connecting rods are arranged parallel to the axis of the lens barrel. Three sliding sleeves 71 for the pull rods to pass are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com