High-efficiency graded screening and cleaning device for construction sand and gravel

A technology for grading screening and cleaning devices, which is applied in the fields of filter sieve, solid separation, cleaning methods and utensils, etc. It can solve the problems of difficulty in meeting production and life, low efficiency of sand and gravel screening, etc., and achieves improved service life, convenient movement, and convenience Adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

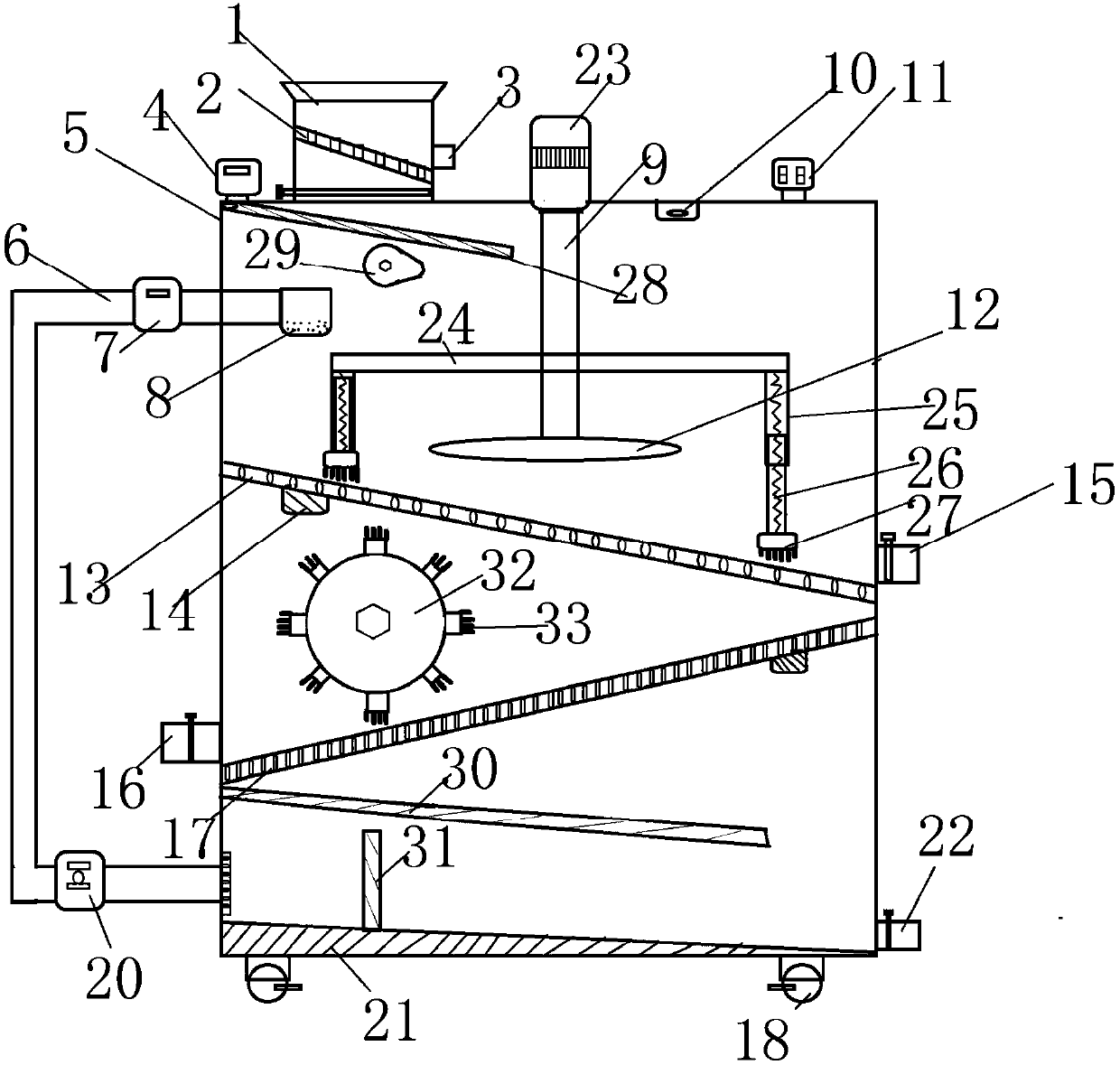

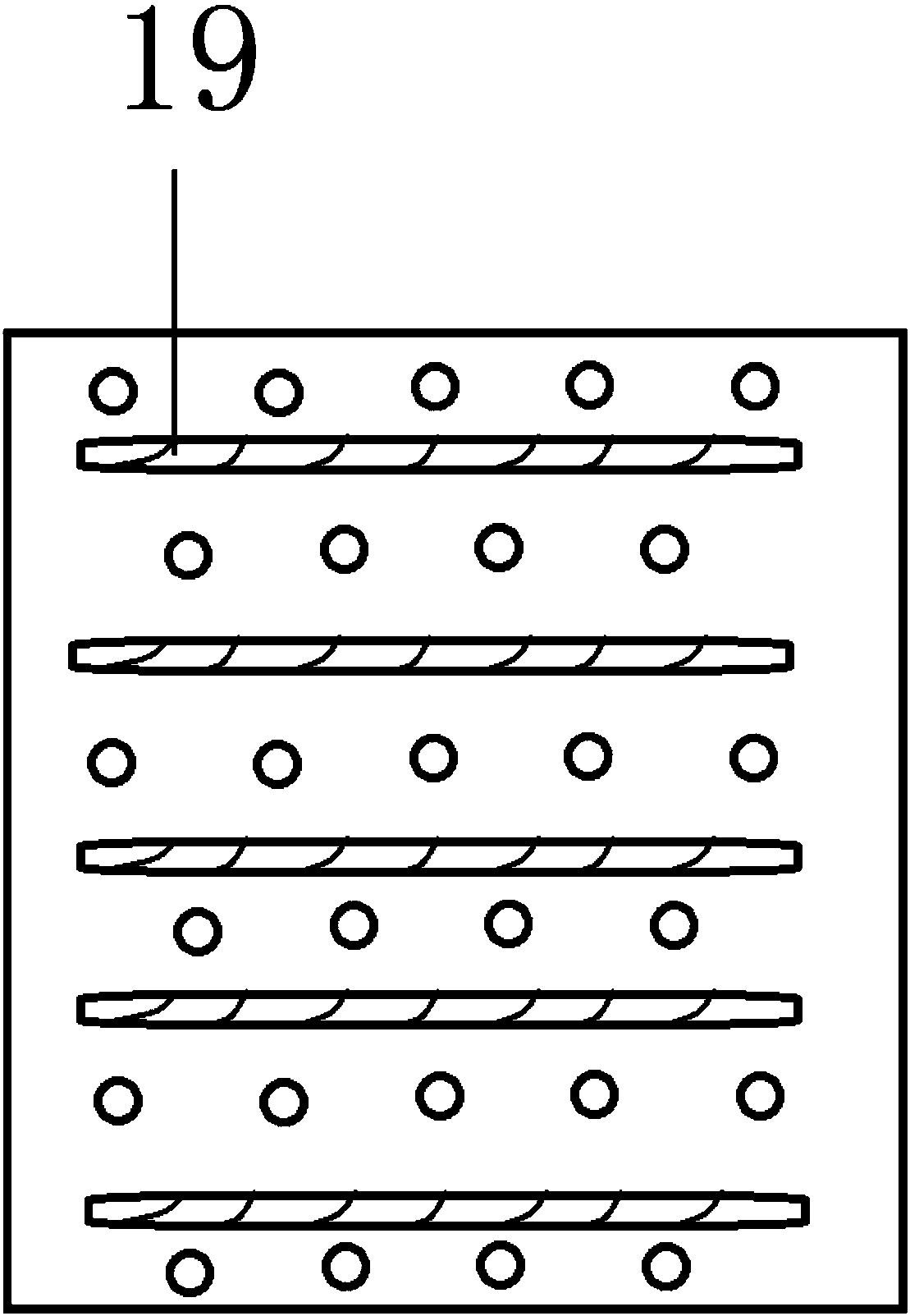

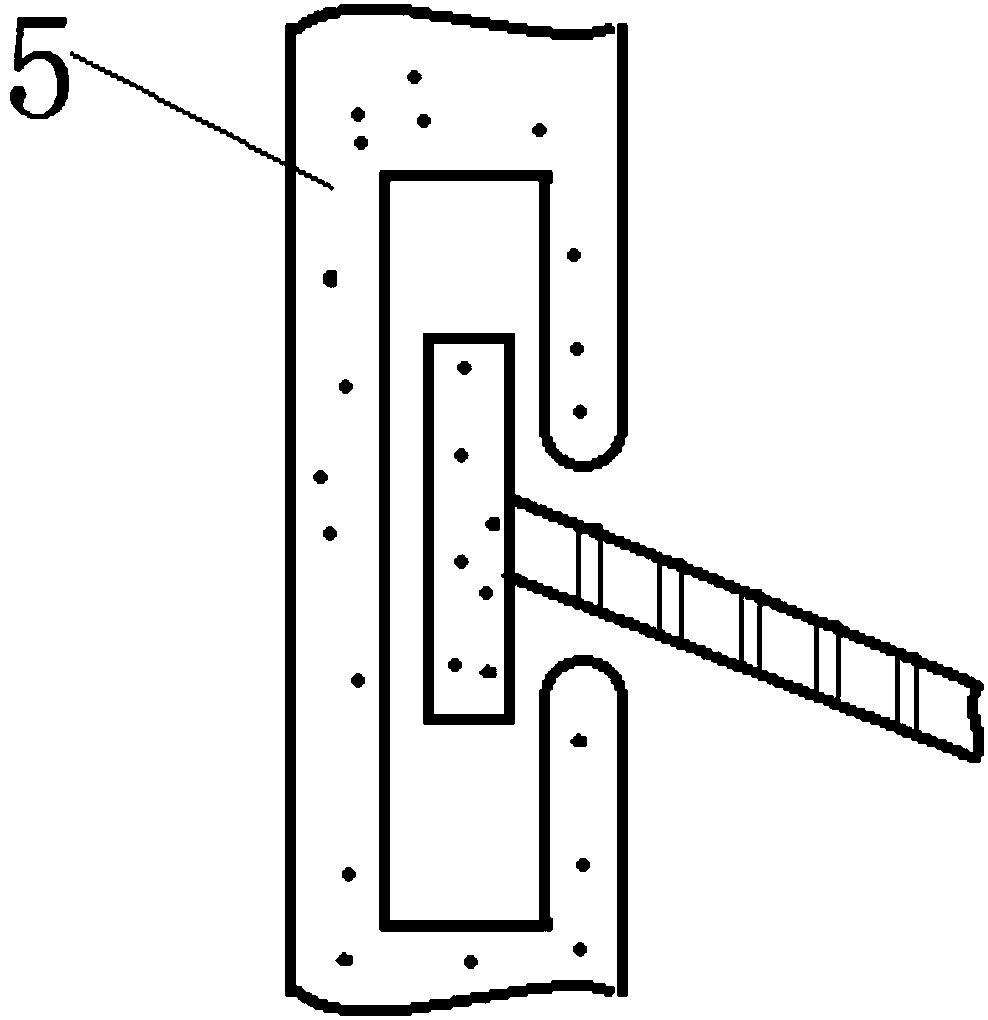

[0020] see Figure 1-4 , a high-efficiency grading and screening cleaning device for construction sand, comprising feed tube 1 , grid 2, liquid level gauge 4, box body 5, water inlet pipe 6, flow meter 7, nozzle 8, rotating shaft 9, camera 10, timer 11, impeller 12, sieve plate and vibrator 14, coarse sand discharge pipe 15 and a fine sand discharge pipe 16, the top of the box body 5 is provided with a feed pipe 1, and the inside of the feed pipe 1 is obliquely provided with a grid 2, and the lowest end of the grid 2 is provided with an impurity discharge pipe 3, and the raw material sand and gravel from The feed pipe 1 enters, and the impurities such as branches and fallen leaves are removed through the grid 2, and are discharged from the impurity discharge pipe 3. The inner top of the box body 5 is provided with a shaker plate 28, and the shake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com