Hydraulic valve

A hydraulic valve and valve body technology, applied in the field of hydraulic valves, can solve the problems of affecting work efficiency, increasing the sliding resistance of the valve core, and reducing the transmission medium, achieving good flexibility and anti-corrosion performance, improving sealing effect, manufacturing low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

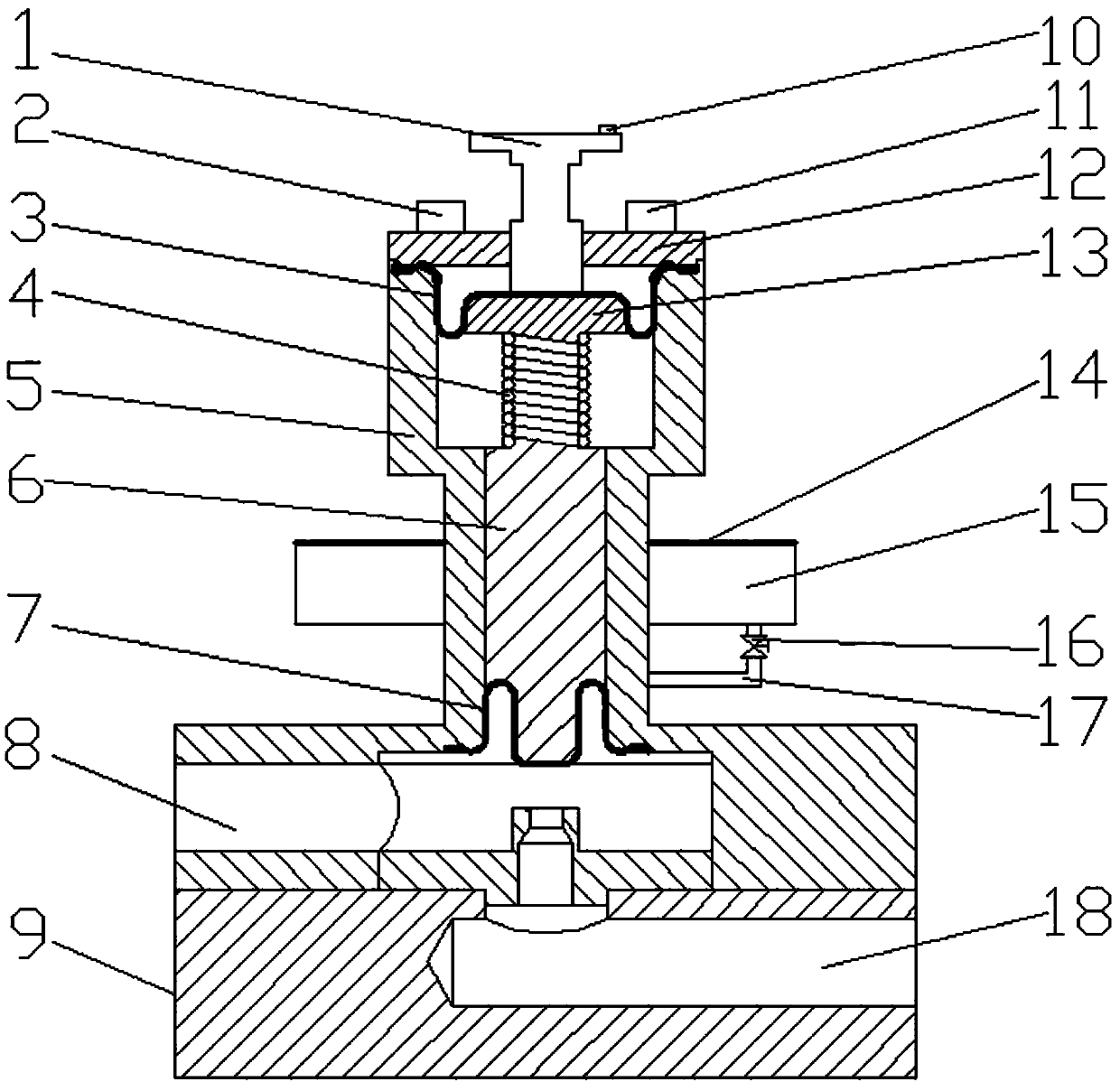

[0012] figure 1 A specific embodiment of the present invention is shown: a hydraulic valve, including a valve body 5, a valve core 6, a valve seat 9, a valve cover 12, a timer 2, a PLC controller 11, an operating handle 1, a spring valve seat 13, a power switch 10. Return spring 4, annular oil bearing groove 15, sealing cover 14, pipe 17, valve 16, upper diaphragm 3, lower diaphragm 7, upper oil port 8, lower oil port 18, valve body 5 is filled with sealing oil, valve seat 9 A valve core 6 is provided between the part extending into the valve body 5 and the hydraulic valve cover 12; The lower end of the valve body 5; the timer 2 is fixed on the left end of the valve cover 12; the PLC programmable controller 11 is fixed on the right end of the valve cover 12, and one end of the PLC programmable controller 11 is connected to the timer 2; the operating handle 1 is connected to the spring below Valve seat 13; power switch 10 is located at the right end of the upper surface of ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com