Heat-conducting adhesive tape and manufacturing method thereof

A production method and tape technology, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problem of easy bending of thermally conductive tapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

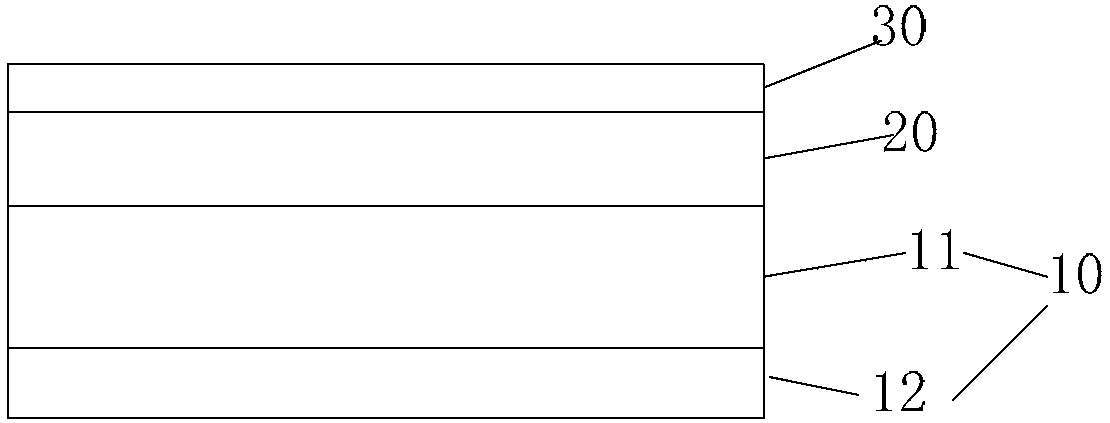

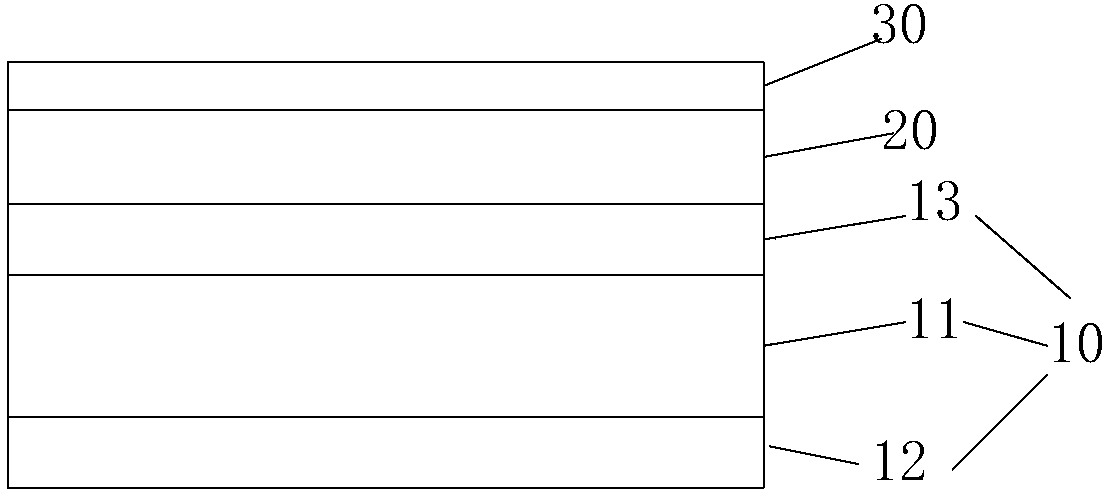

[0046] This embodiment provides a thermally conductive tape whose structure is as figure 1 As shown, it includes the first metal coating layer, the graphite layer, the pressure-sensitive adhesive layer and the release film from bottom to top. Concrete preparation process is as follows:

[0047] A graphite sheet is provided, and the upper surface of the graphite sheet is provided with a first protective film, and the lower surface opposite to the upper surface is provided with a second protective film; both the first protective film and the second protective film are made of PET with a thickness of 50 μm; The thickness of the graphite sheet is 17μm, and the thermal conductivity is 1500w / (m.k).

[0048] Tear off the first protective film, vapor-deposit metal copper on the exposed side of the graphite sheet, the vapor-deposition speed is 300m / min, and the thickness of the coating is

[0049] Coat the pressure-sensitive adhesive on the light release film with a coating thickne...

Embodiment 2

[0053] This embodiment provides a thermally conductive tape whose structure is as figure 1 As shown, it includes the first metal coating layer, the graphite layer, the pressure-sensitive adhesive layer and the release film from bottom to top. Concrete preparation process is as follows:

[0054] A graphite sheet is provided, and the upper surface of the graphite sheet is provided with a first protective film, and the lower surface opposite to the upper surface is provided with a second protective film; both the first protective film and the second protective film are made of PET with a thickness of 50 μm; The thickness of the graphite sheet is 25μm, and the thermal conductivity is 1500w / (m.k).

[0055] Tear off the first protective film, vapor-deposit metal copper on the exposed side of the graphite sheet, the vapor-deposition speed is 300m / min, and the thickness of the coating is

[0056] Coat the pressure-sensitive adhesive on the light release film with a coating thickne...

Embodiment 3

[0060] This embodiment provides a thermally conductive tape whose structure is as figure 1 As shown, it includes the first metal coating layer, the graphite layer, the pressure-sensitive adhesive layer and the release film from bottom to top. Concrete preparation process is as follows:

[0061] A graphite sheet is provided, and the upper surface of the graphite sheet is provided with a first protective film, and the lower surface opposite to the upper surface is provided with a second protective film; both the first protective film and the second protective film are made of PET with a thickness of 50 μm; The thickness of the graphite sheet is 17μm, and the thermal conductivity is 1500w / (m.k).

[0062] Tear off the first protective film, vapor-deposit metal copper on the exposed side of the graphite sheet, the vapor-deposition speed is 300m / min, and the thickness of the coating is

[0063] Coat the pressure-sensitive adhesive on the light release film with a coating thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com