Automatic winding and roll changing system for wet-process lithium battery diaphragm

A technology for lithium battery diaphragm, rewinding and changing rolls, which is applied to battery pack parts, circuits, electrical components, etc. It can solve the problems that the rolls cannot be changed automatically, and the membrane surface is prone to wrinkles or slack, so as to save the roll changing time, membrane The effect of good roll tension uniformity and uniform film surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

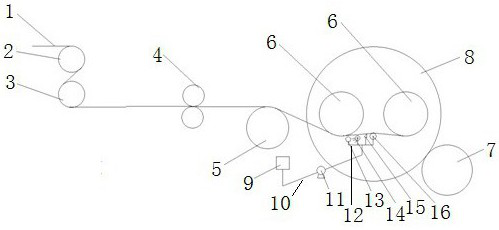

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] The structure of an embodiment of the present invention is as figure 1 As shown, the wet-process lithium battery diaphragm rewinding and changing system of this embodiment includes guide rollers 2 and tension rollers 3 arranged at intervals up and down. Tension bearings (not shown in the drawings) are installed on the ends of tension rollers 3. First pass above the guide roller 2, then pass between the guide roller 2 and the tension roller 3, and then pass under the tension roller 3, the diaphragm 1 passes the guide roller 2 and the tension roller 3 in an S shape.

[0023] Along the advancing direction of the diaphragm 1, a pair of shearing rollers 4 are provided behind the guide roller 2 and the tension roller 3, and the upper and lower sides of the diaphragm 1 are attached to the two shearing rollers 4 respectively.

[0024] After t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com