Patents

Literature

44results about How to "Uniform flatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

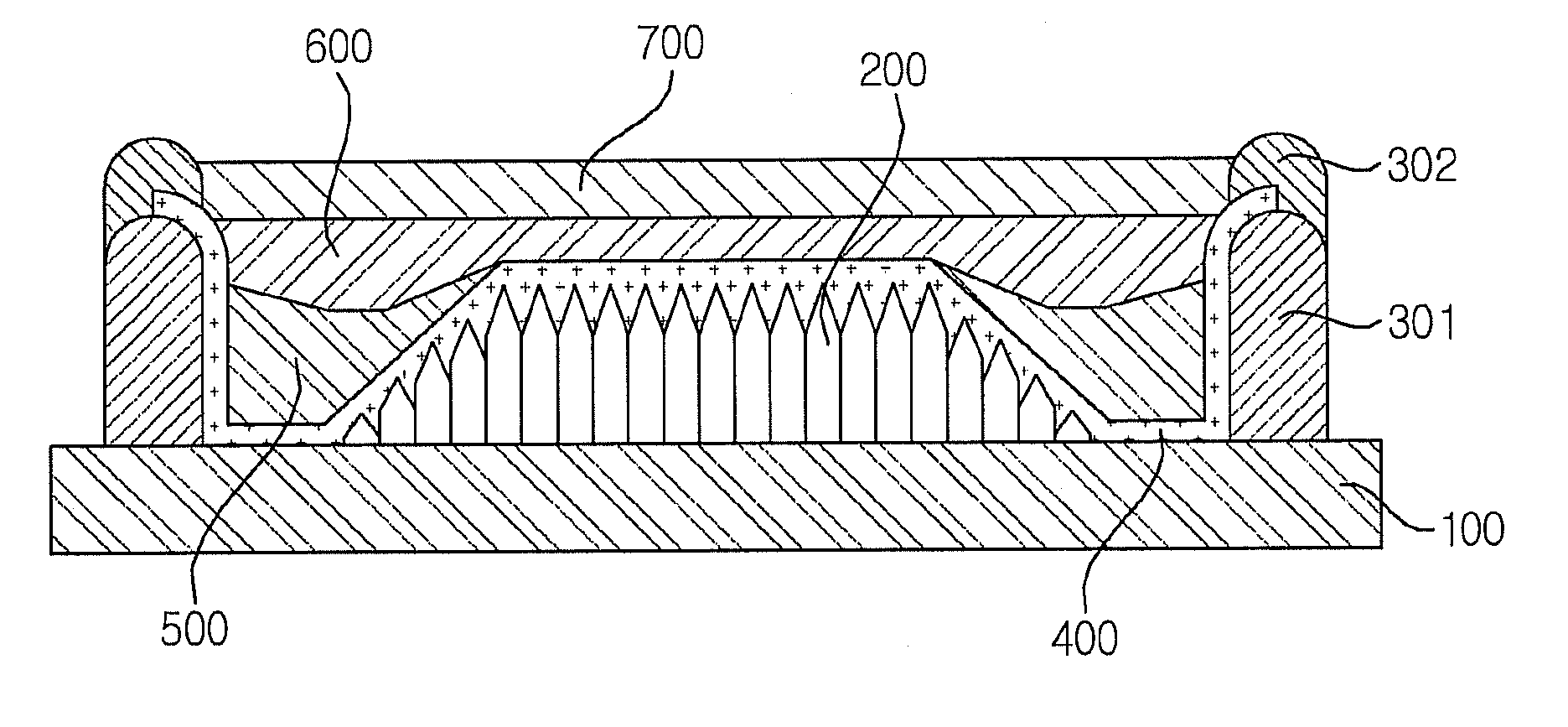

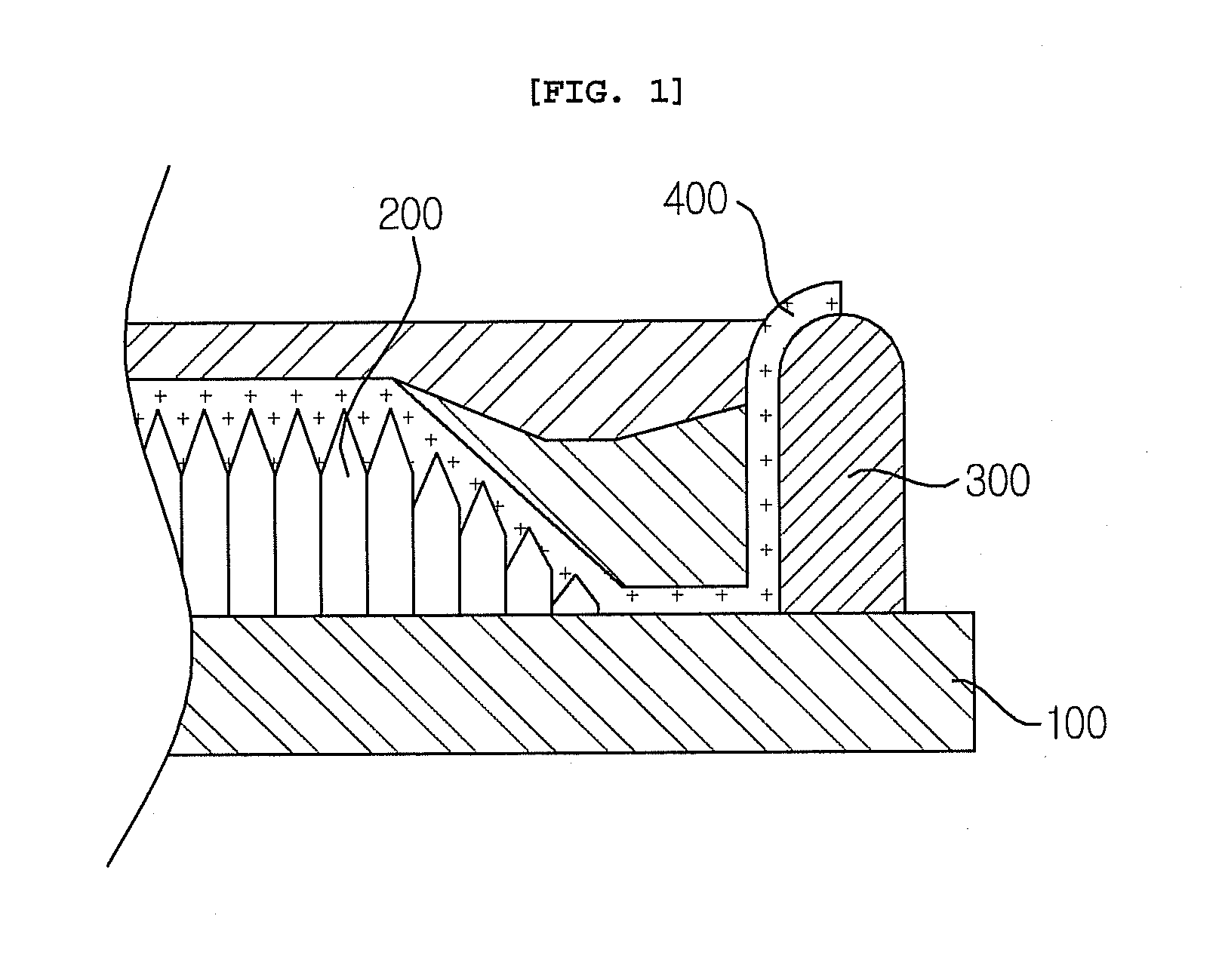

Scintillator panel and method of manufacturing the scintillator panel

InactiveUS20120288688A1Prevent moisture infiltrationUniform flatnessLayered productsThin material handlingLength waveScintillator

Disclosed is a scintillator panel, including a substrate, a scintillator layer formed on the substrate and including a plurality of columnar crystals so that radiation is converted into light at a predetermined wavelength, a dam structure formed on the substrate to be spaced apart by a predetermined interval from a peripheral edge of the scintillator layer, a protective layer formed on a surface of the scintillator layer, a surface of the substrate defined between the scintillator layer and the dam structure and a portion of a surface of the dam structure, a first coating layer formed on the protective layer to be disposed in a space between a peripheral surface of the scintillator layer and the dam structure, and a second coating layer formed on the first coating layer and the protective layer.

Owner:ABYZ R

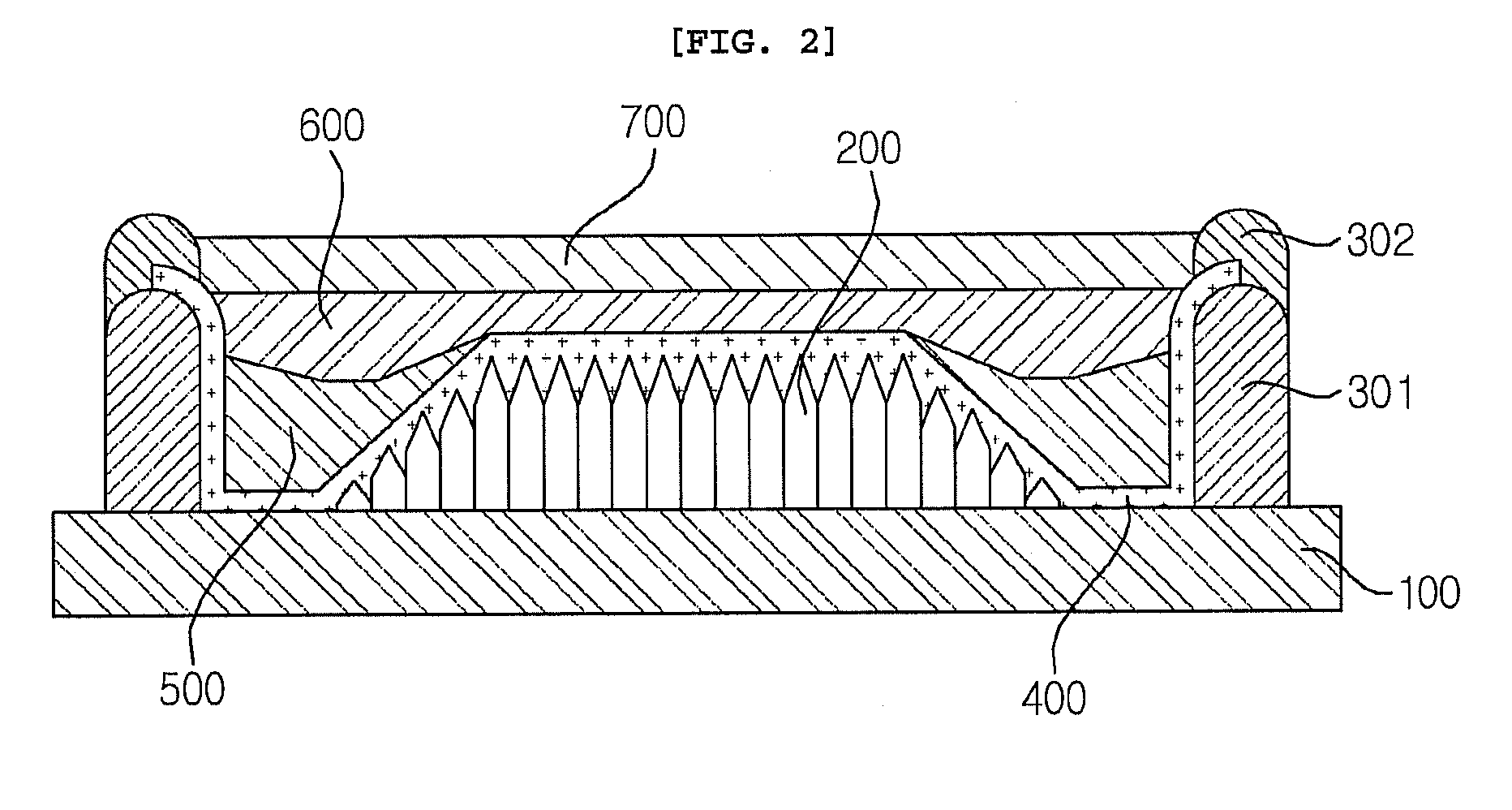

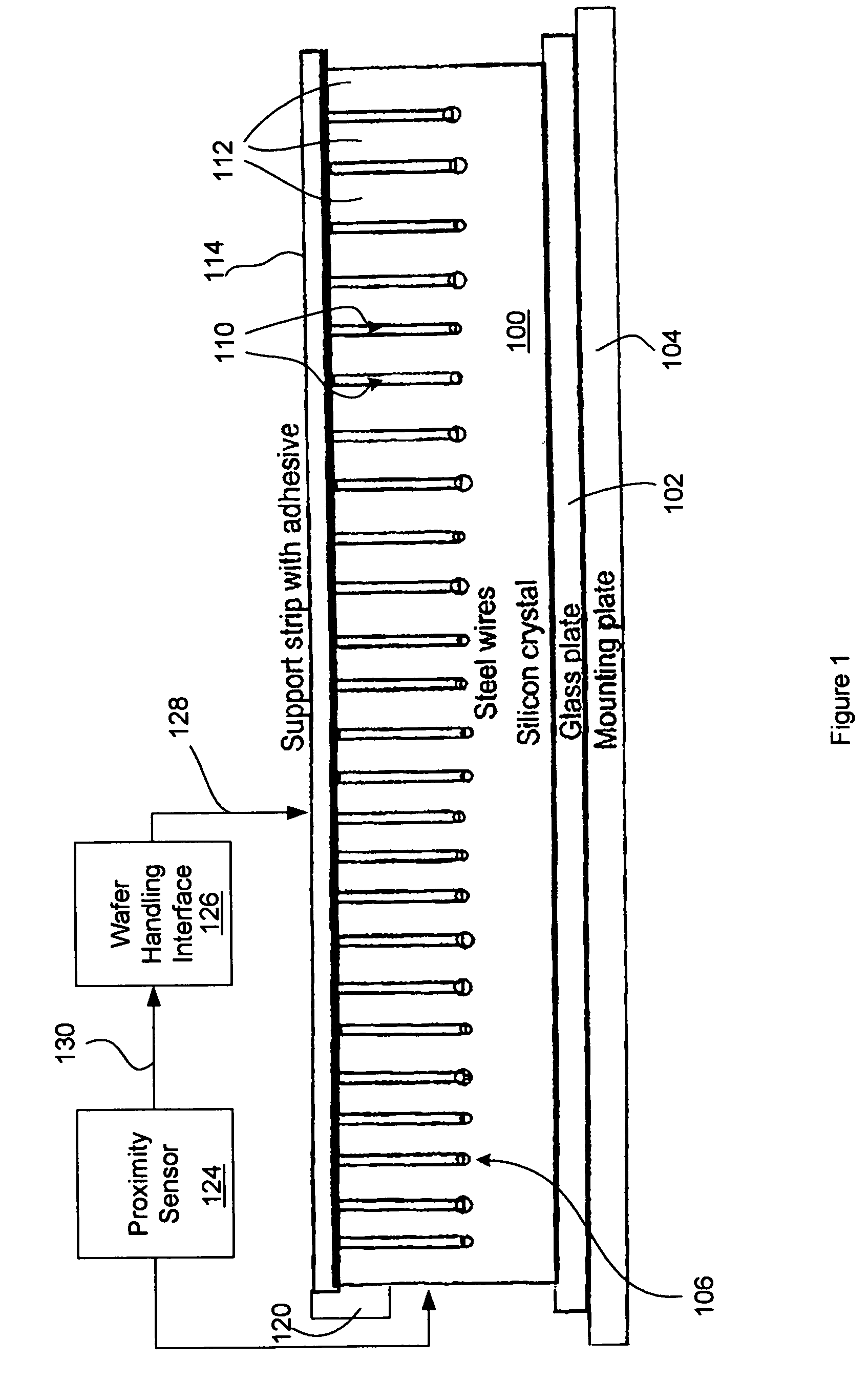

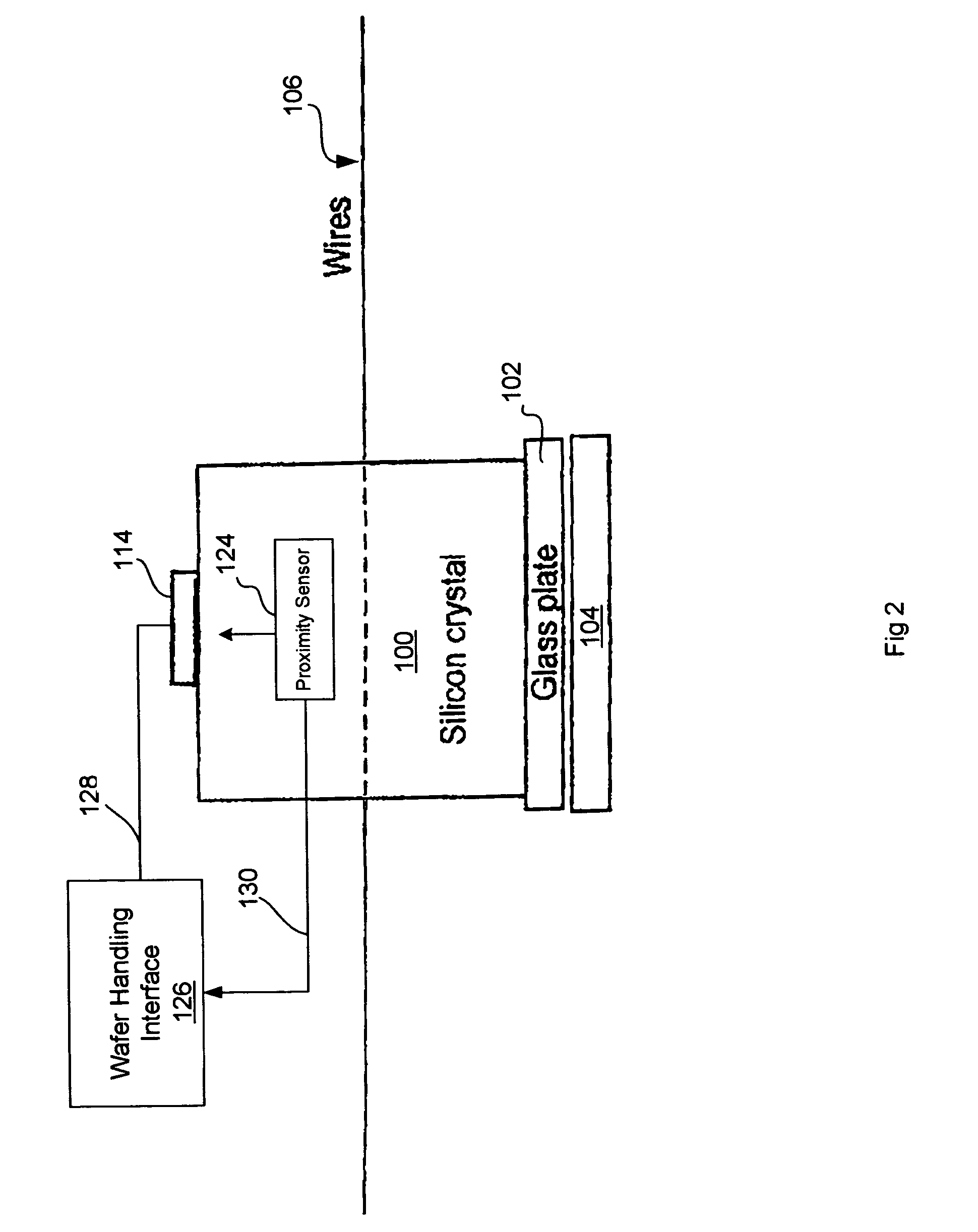

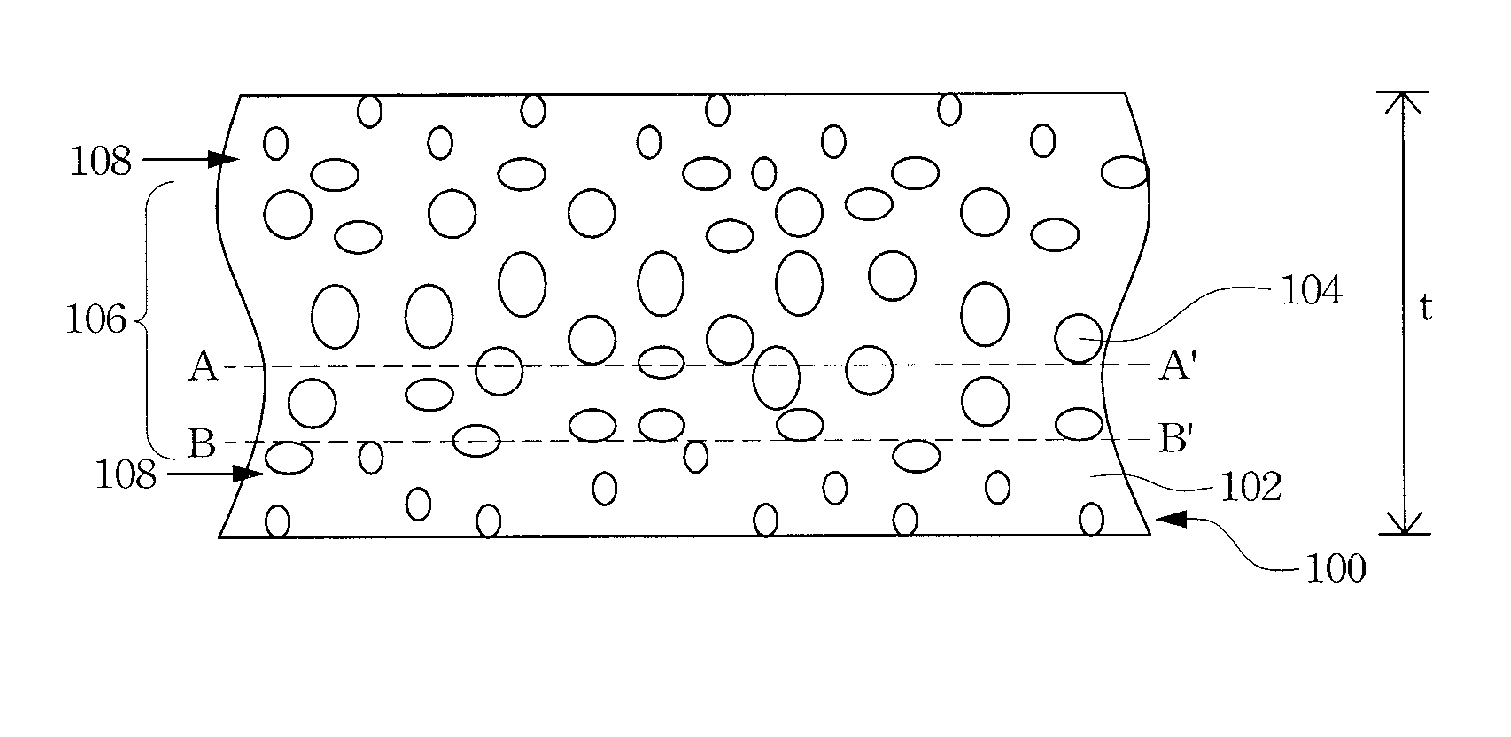

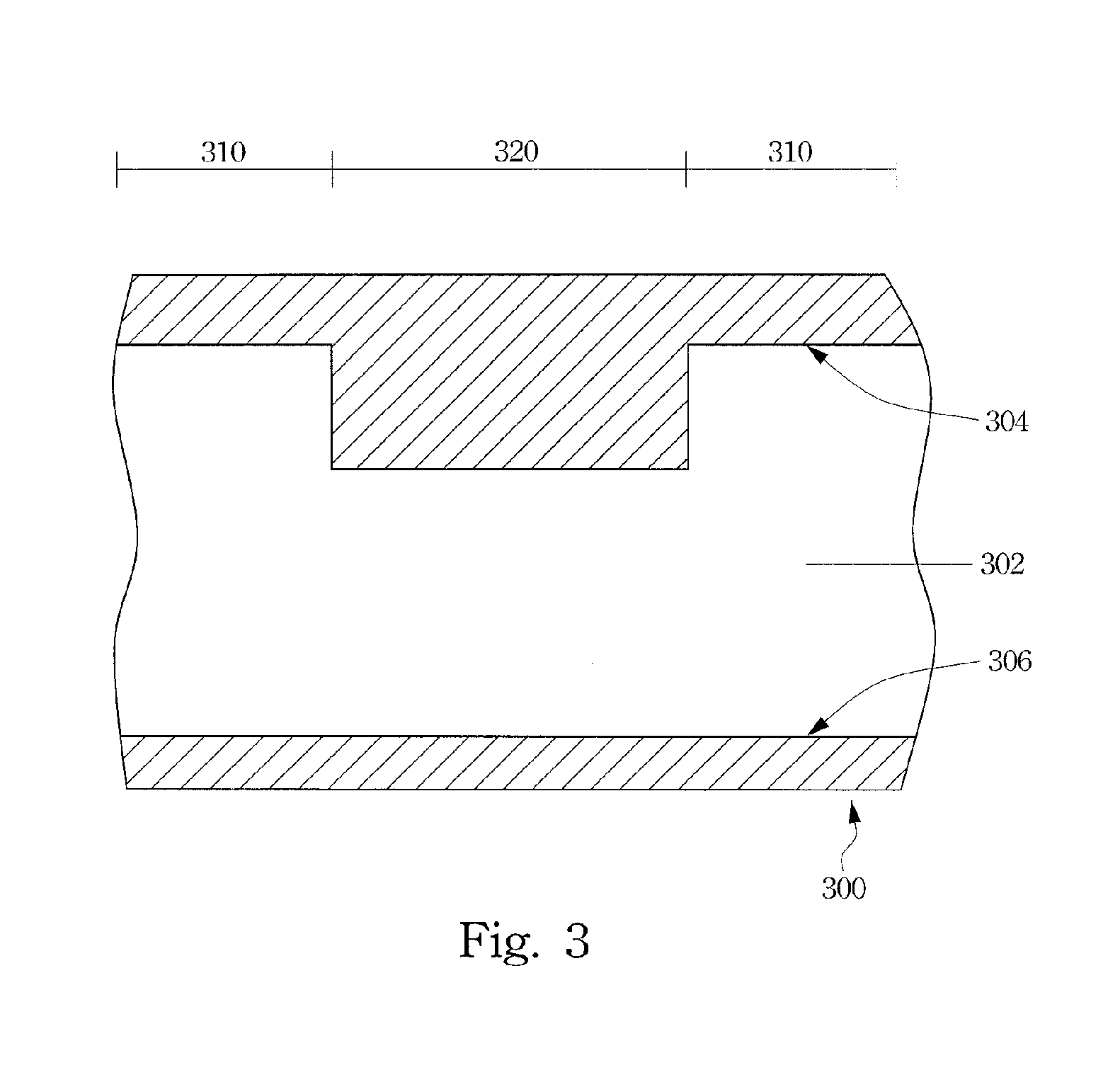

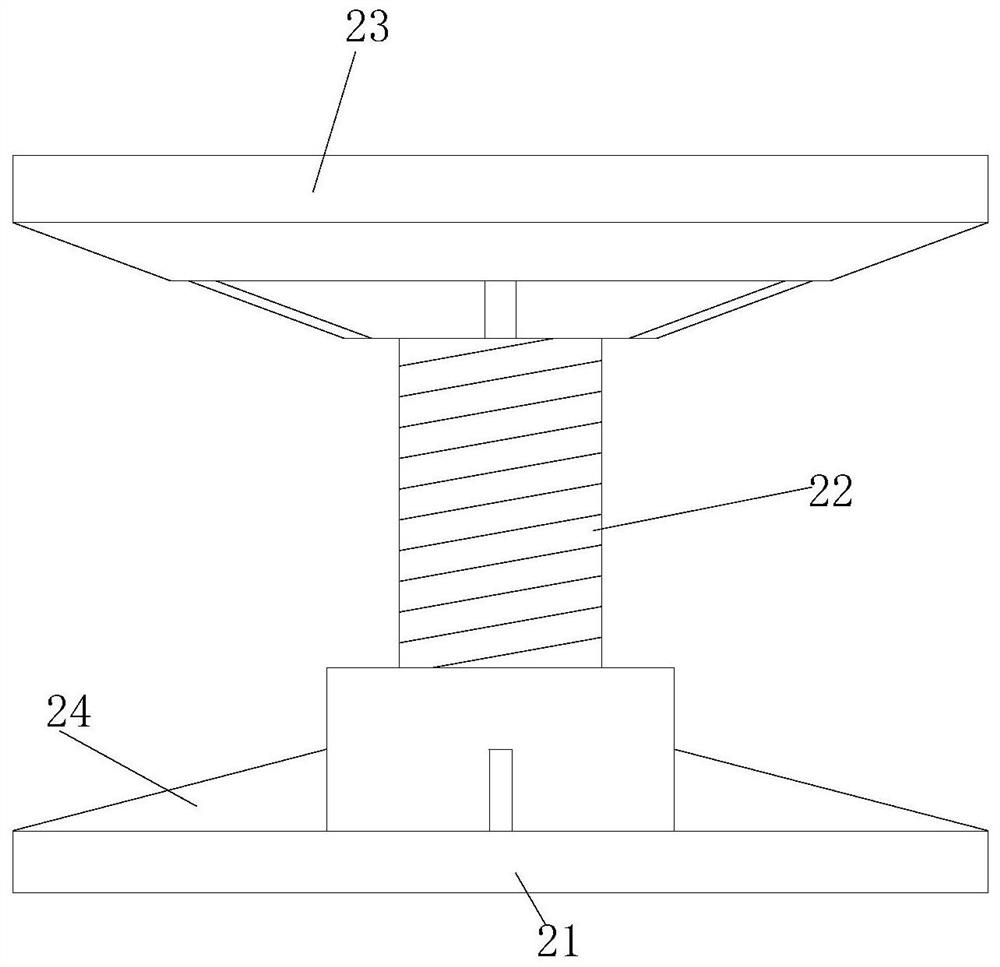

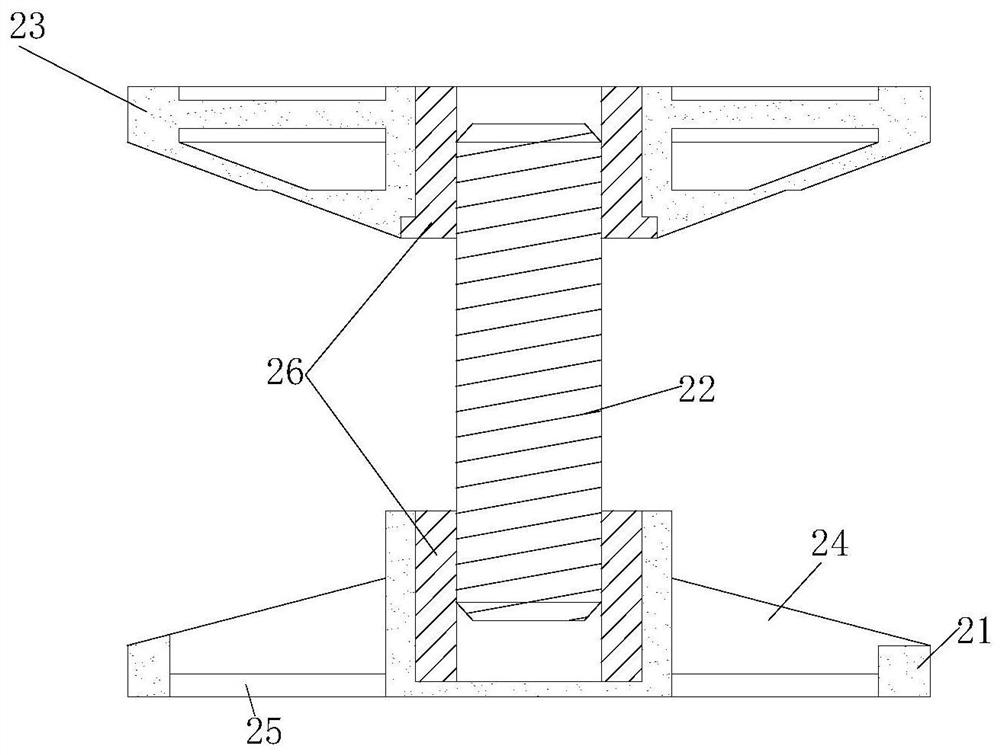

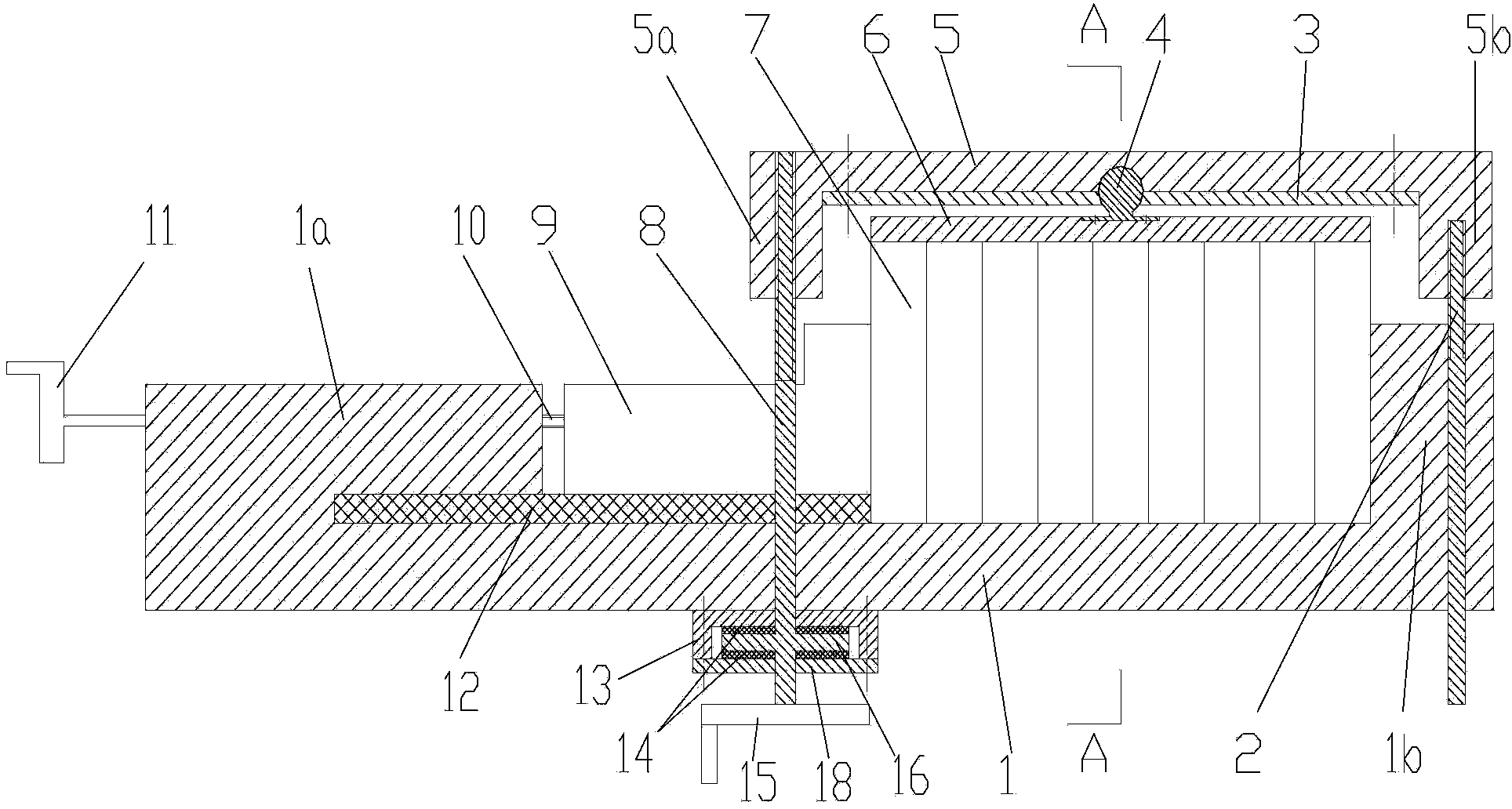

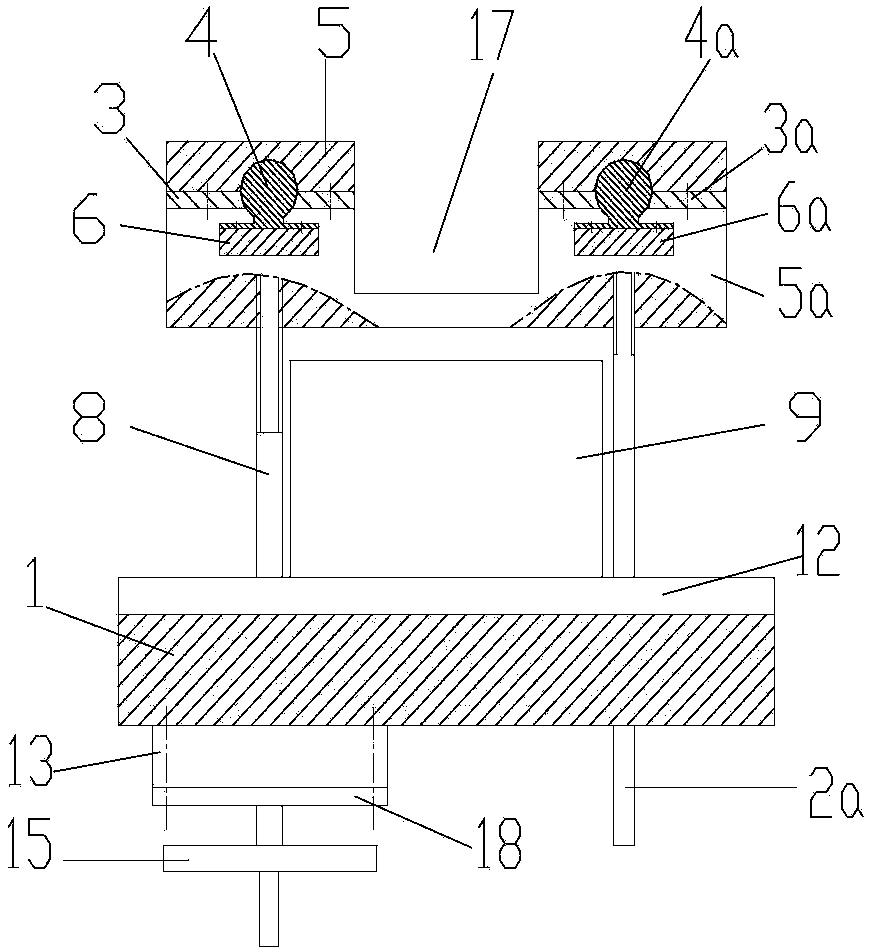

Method and apparatus for cutting ultra thin silicon wafers

InactiveUS7025665B2Uniform flatnessEasy to controlMetal sawing devicesBelt grinding machinesWaferingIngot

A wire saw and wafer stabilizing system are provided for holding wafer sections invariantly against vibration and unwanted movement during the sawing process. A stabilizing means is applied to the ends of partially defined wafer sections at an early stage when the wafer sections are partially cut through a silicon ingot or block of silicon material. The stabilizing means serves to stabilize the wafer sections immovably against vibration, oscillation, or unwanted contact during the subsequent sawing process. The stabilizing system also accelerates handling of the wafers after slicing is completed, facilitates the cleaning process, and allows for more rapid or automated placement of the wafers in cassettes. Wafers produced by the stabilizing system are characterized by a minimized total thickness variation, substantially uniform planarity, and substantially without bow or warp.

Owner:SOLAICX

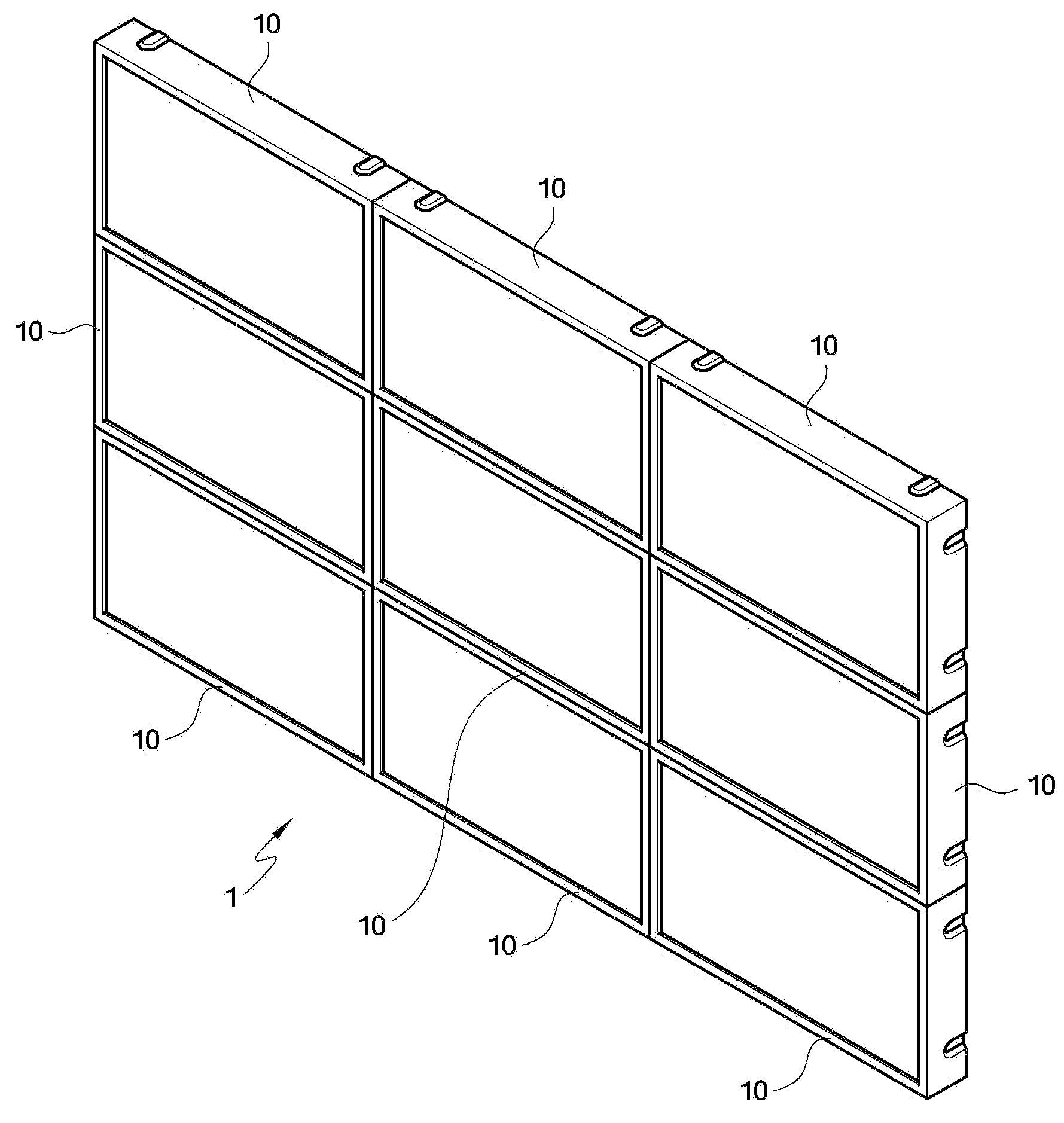

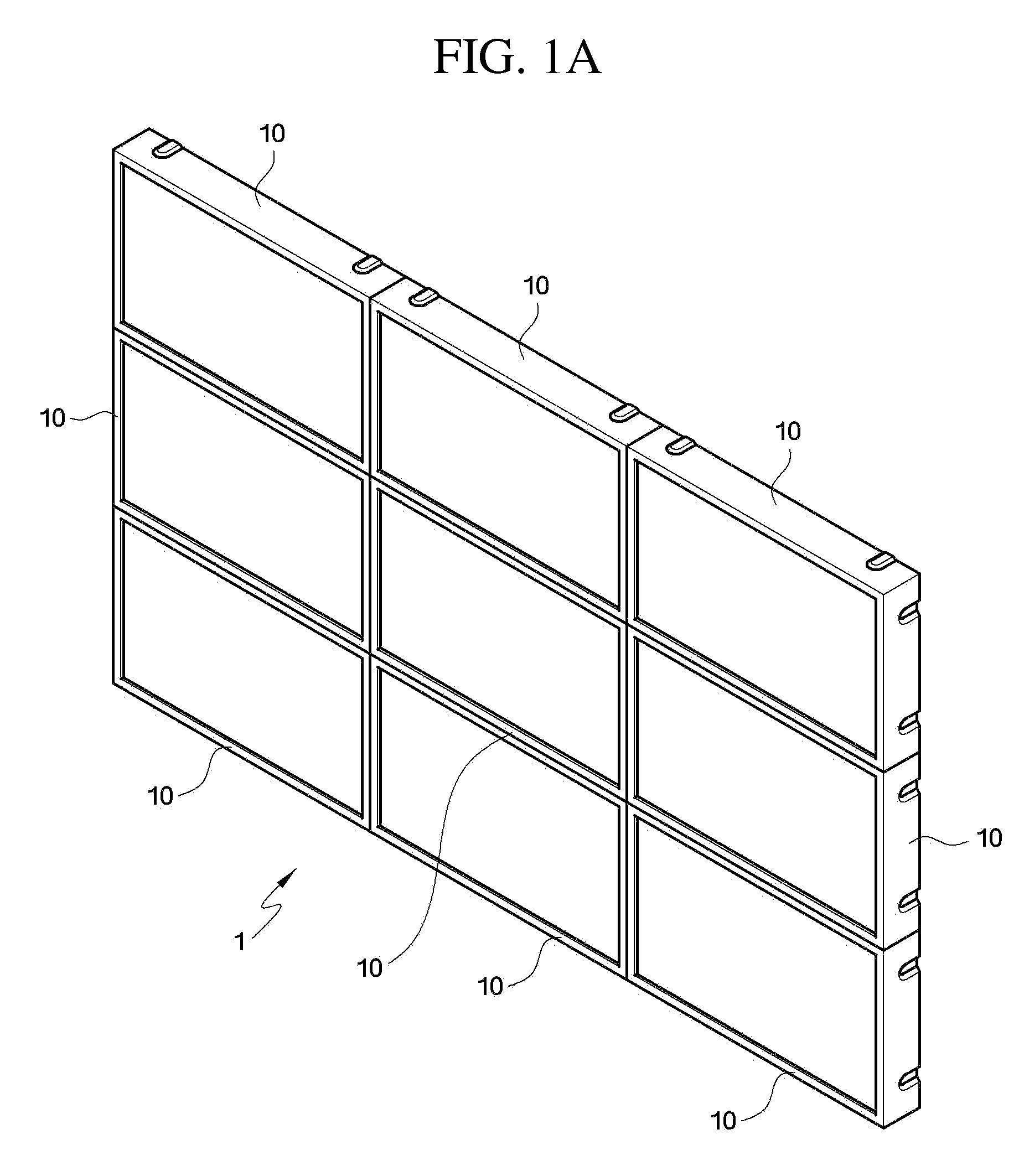

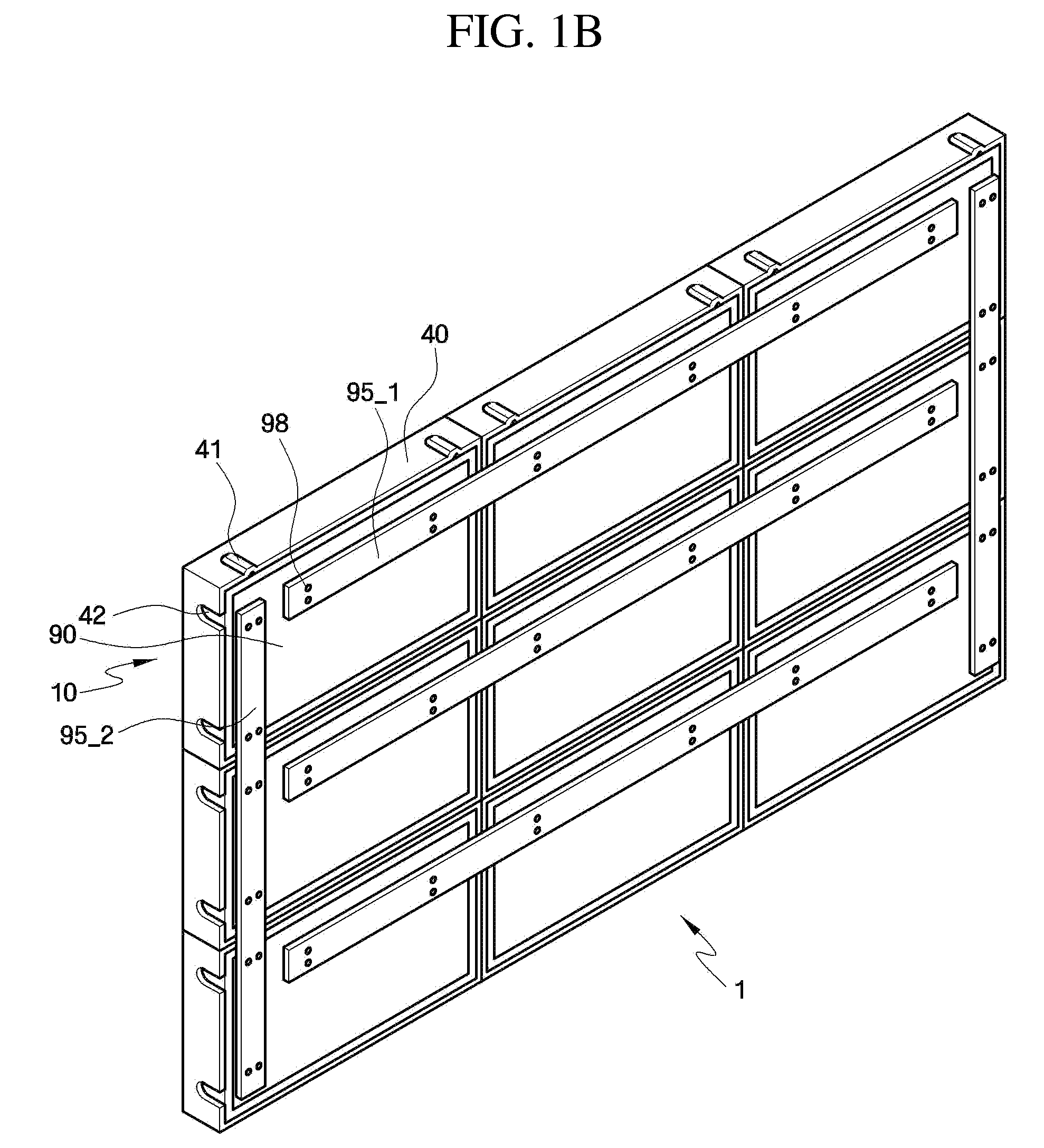

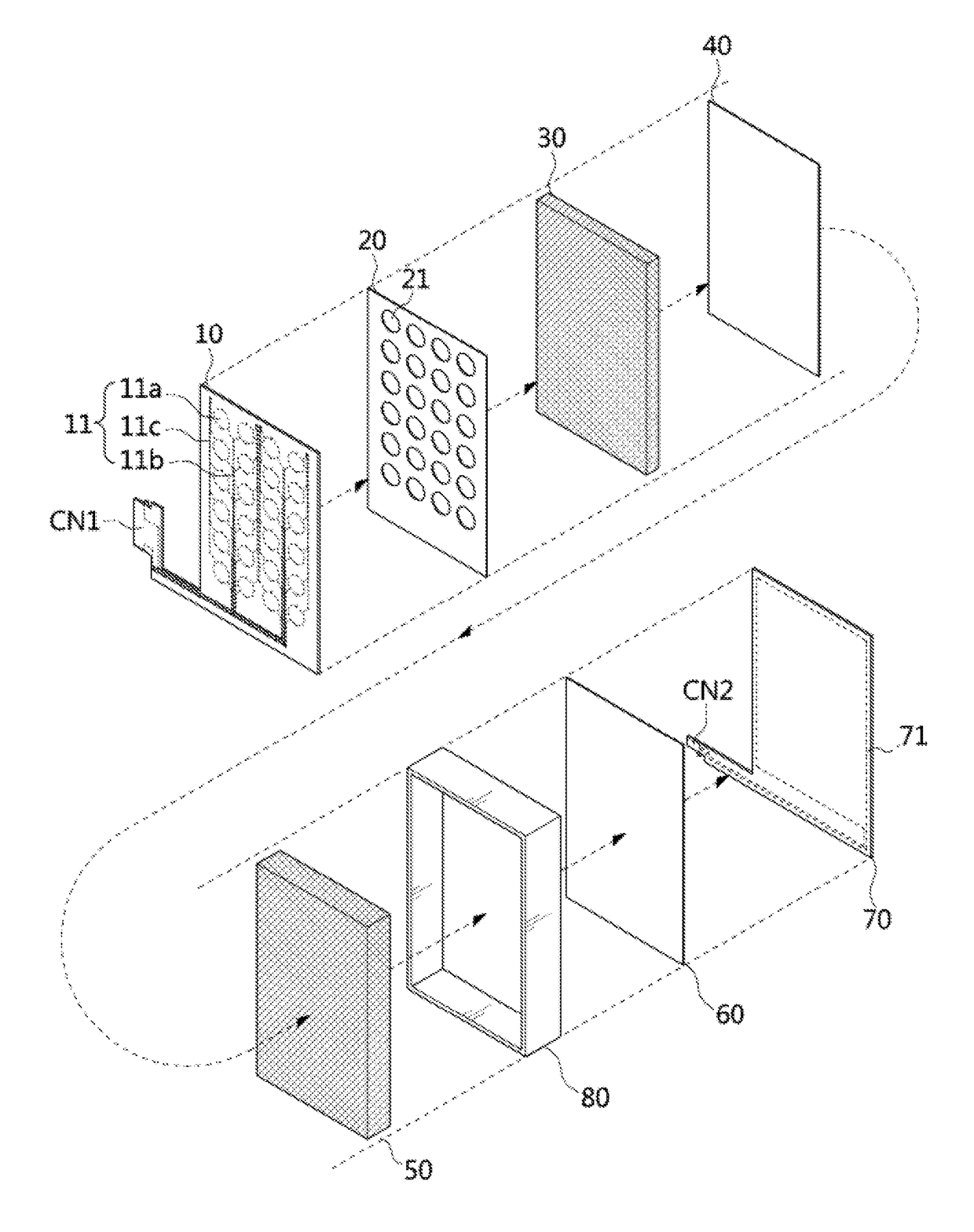

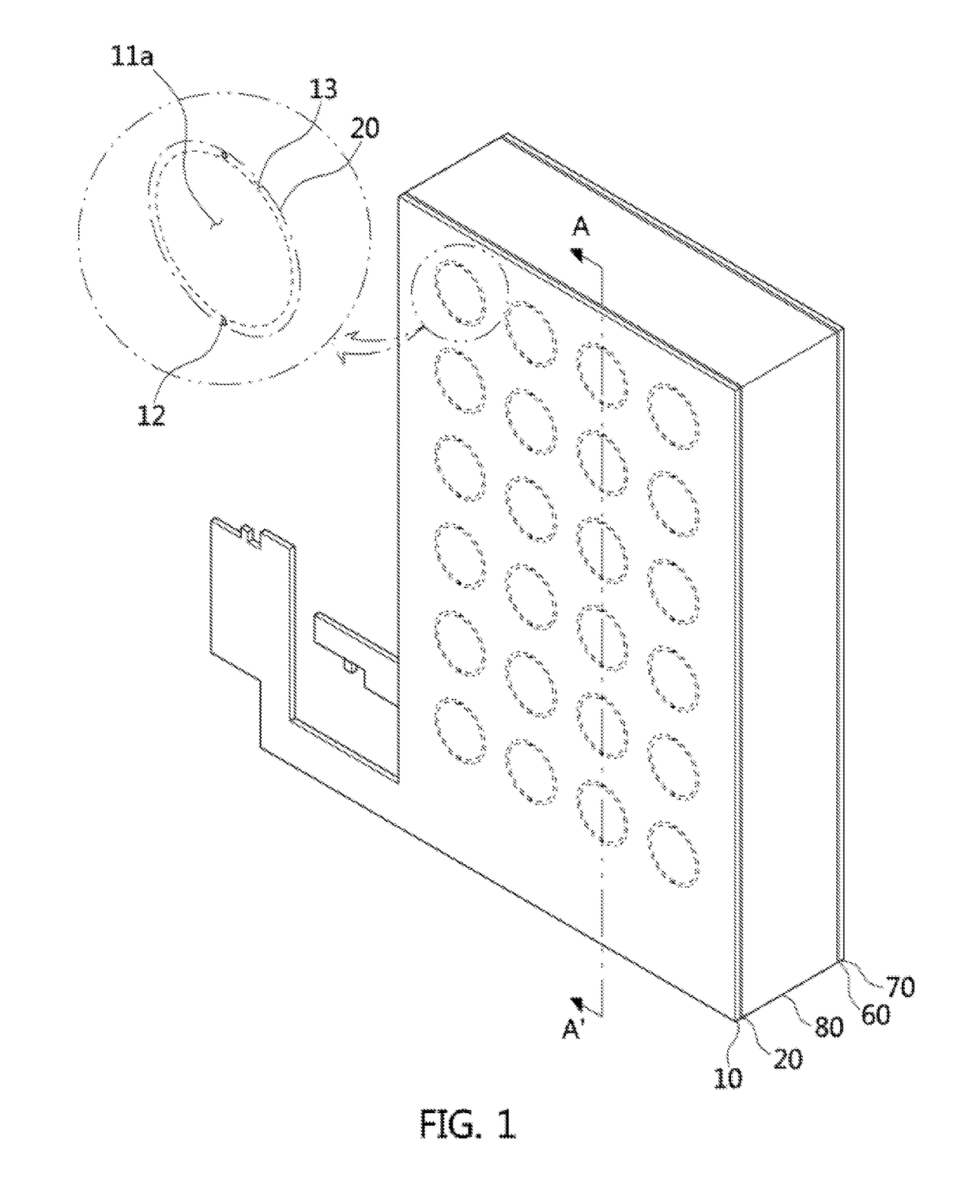

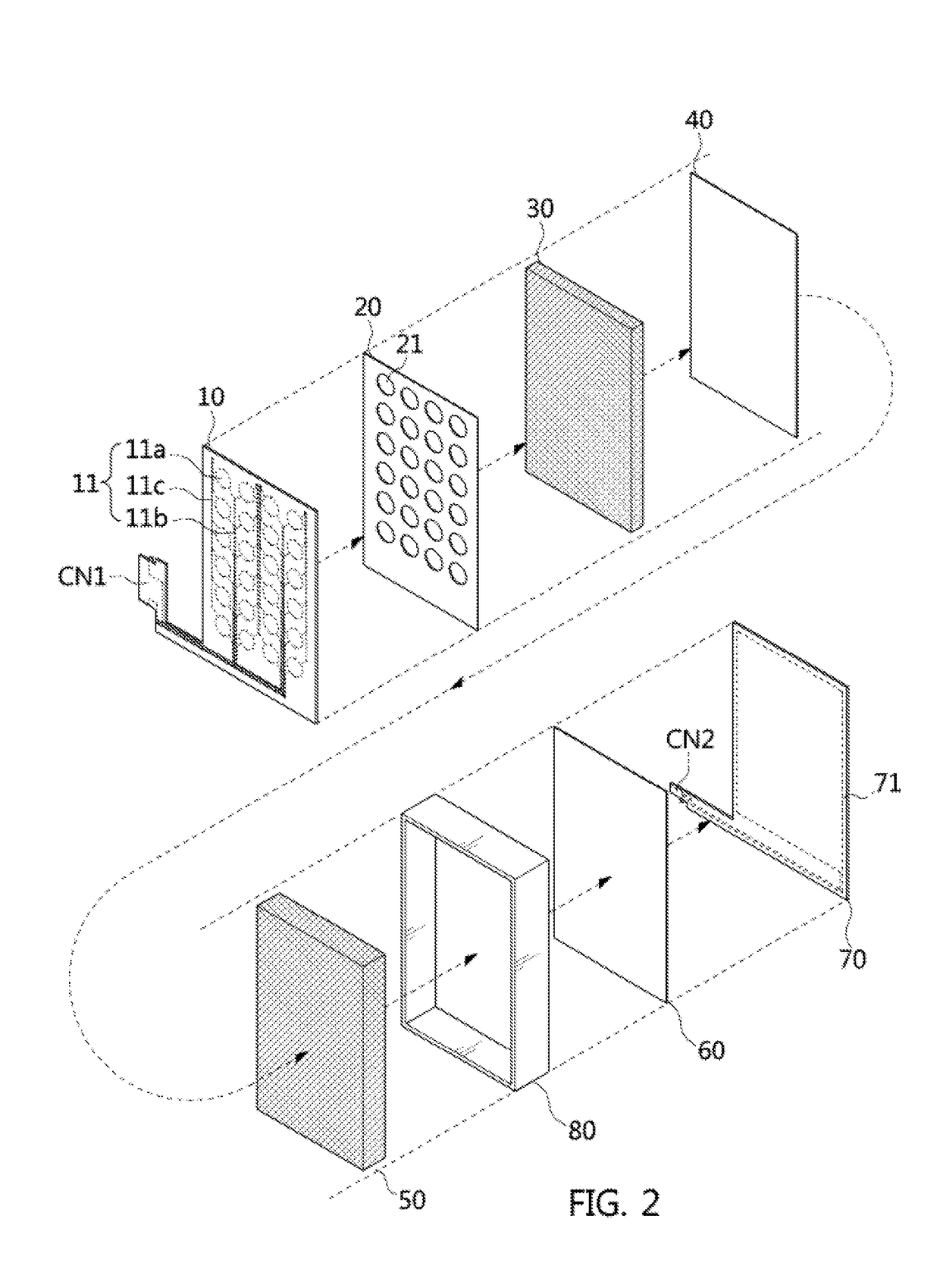

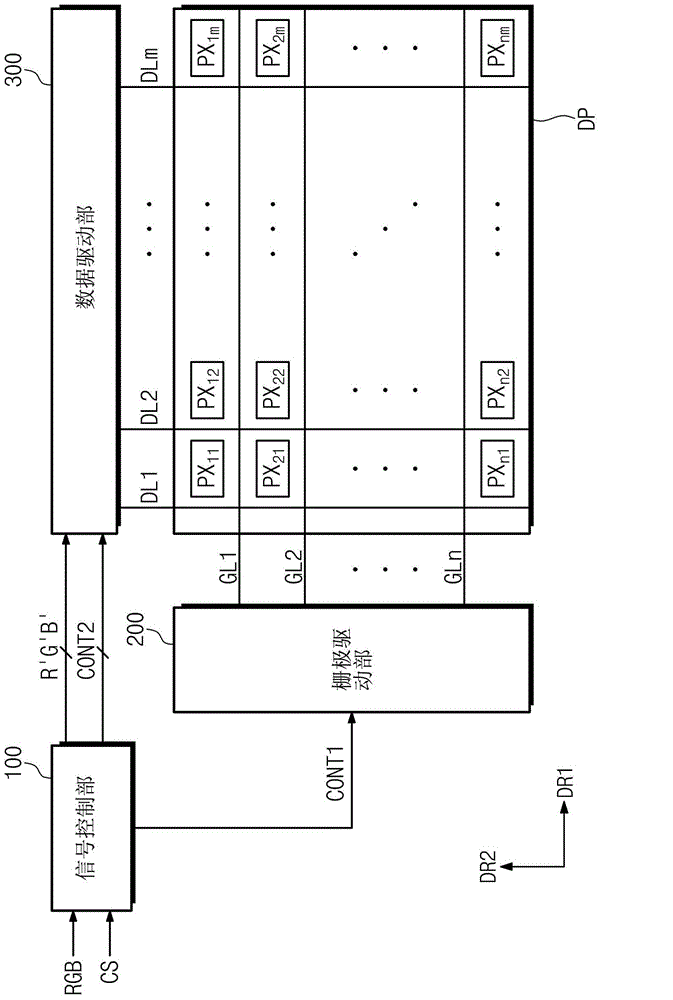

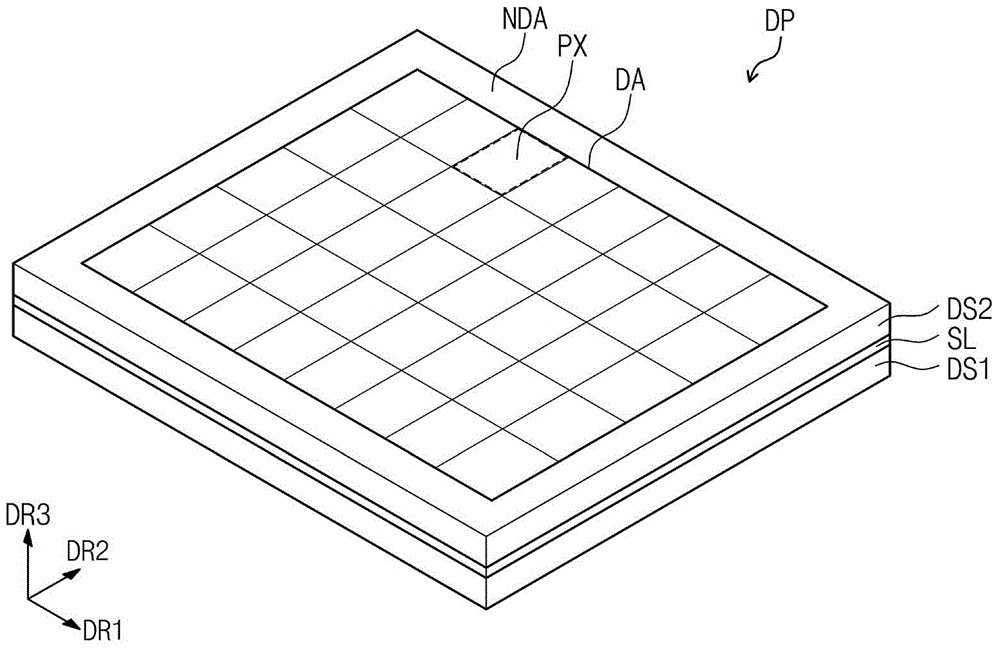

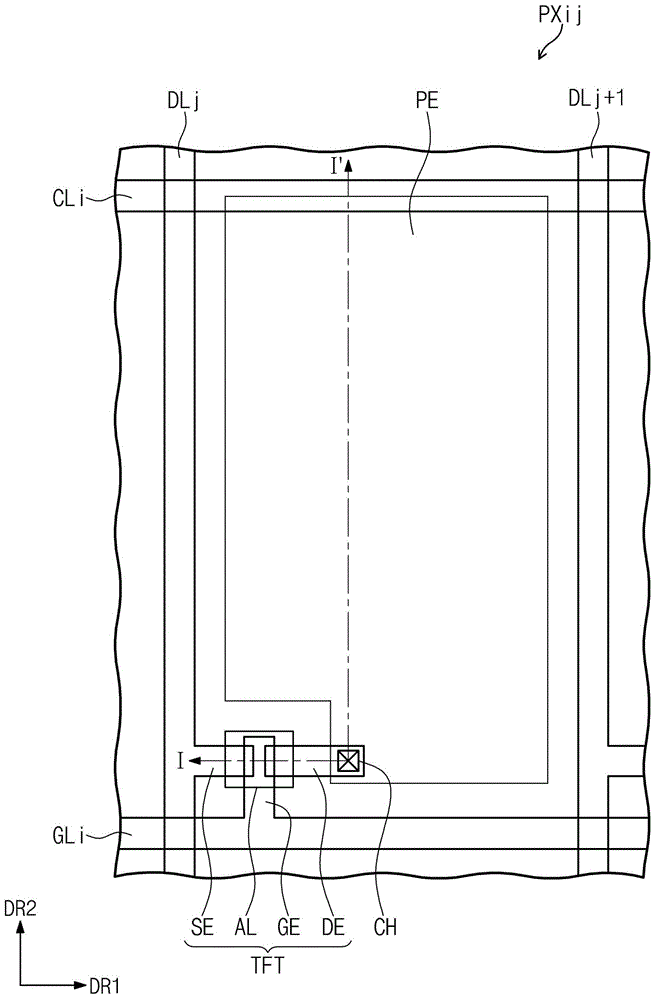

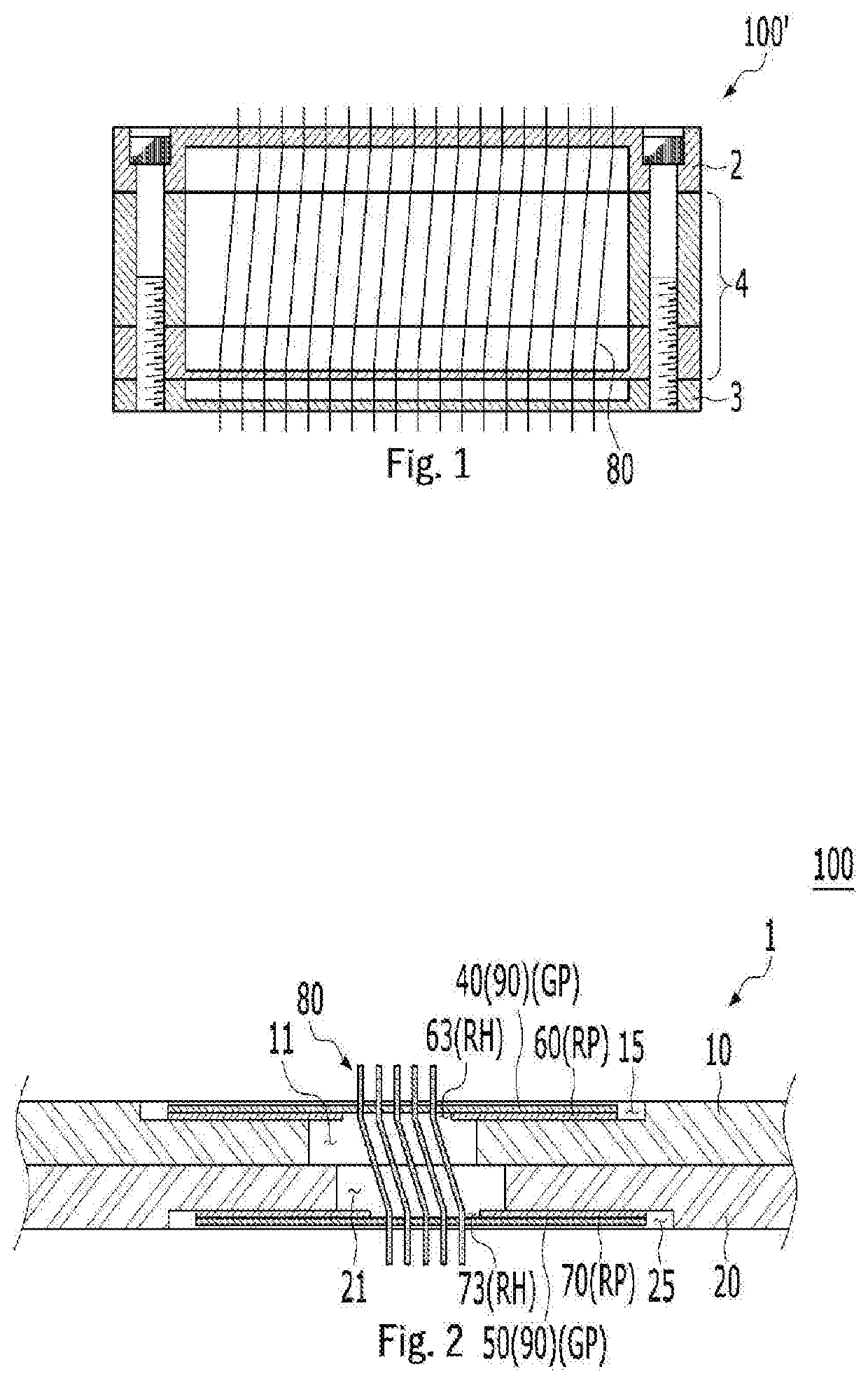

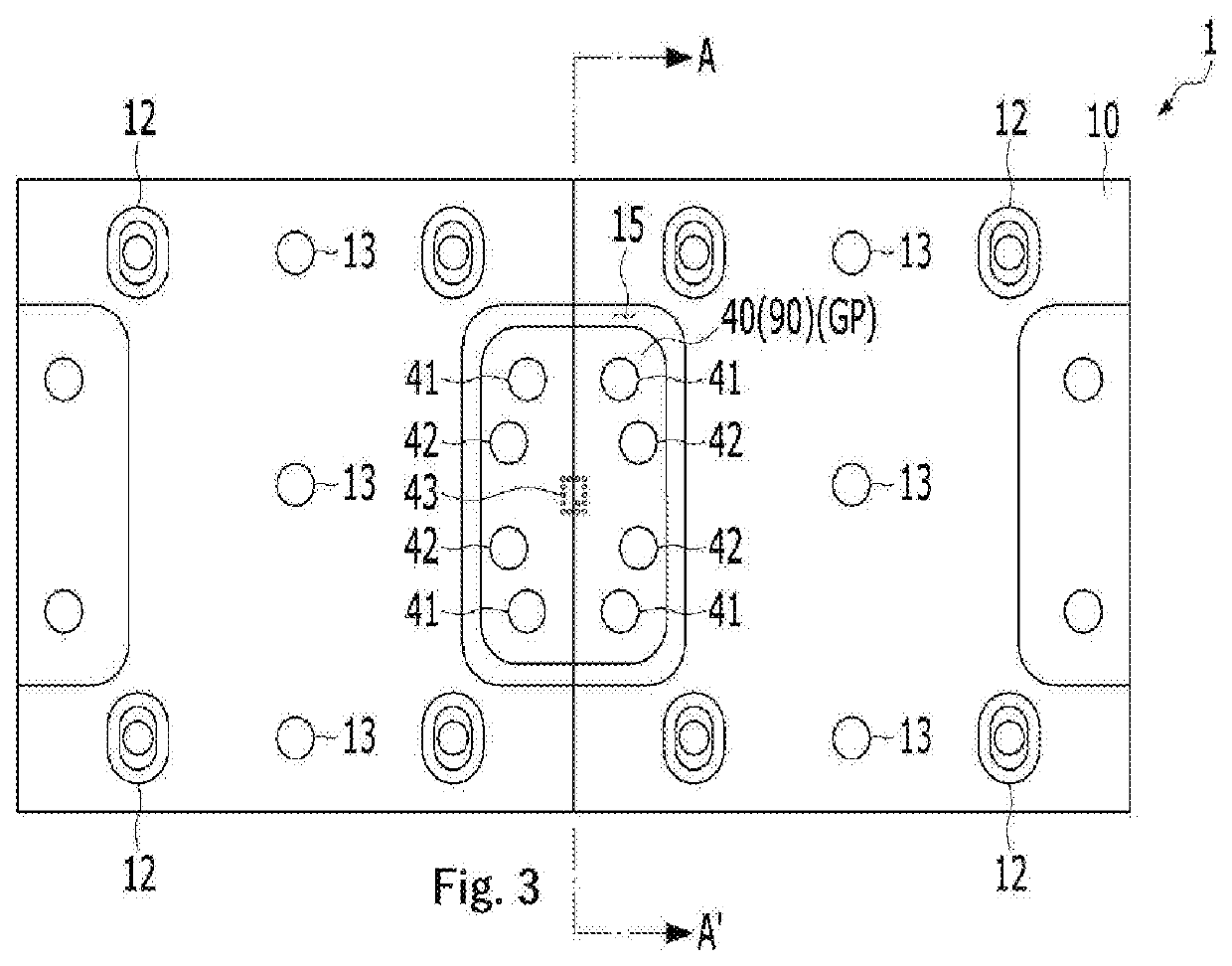

Display unit and multi-display device having the same

ActiveUS20090225506A1Easily joinUniform flatnessTelevision system detailsSide-by-side/stacked arrangementsEngineeringSurface plate

Owner:SAMSUNG DISPLAY CO LTD

Synthetic leather prepared from non-woven fabric and slurry and its production method

A synthetic leather is prepared from non-woven fabric and slurry. Said non-woven fabric is prepared from the fibres of small-area leather and chemical fibres. Said slurry is prepared from polyurethane resin, solvent, assistant, pigment and wooden powder. Its preparing process includes such steps as immersing non-woven fabric in slurry, rolling, scrapping, coagulating, washing, squeezing, baking, grinding, wet coating, solidifying, water washing, baking, and coating film or polishing. Its advantages are high quality and low cost.

Owner:徐银松

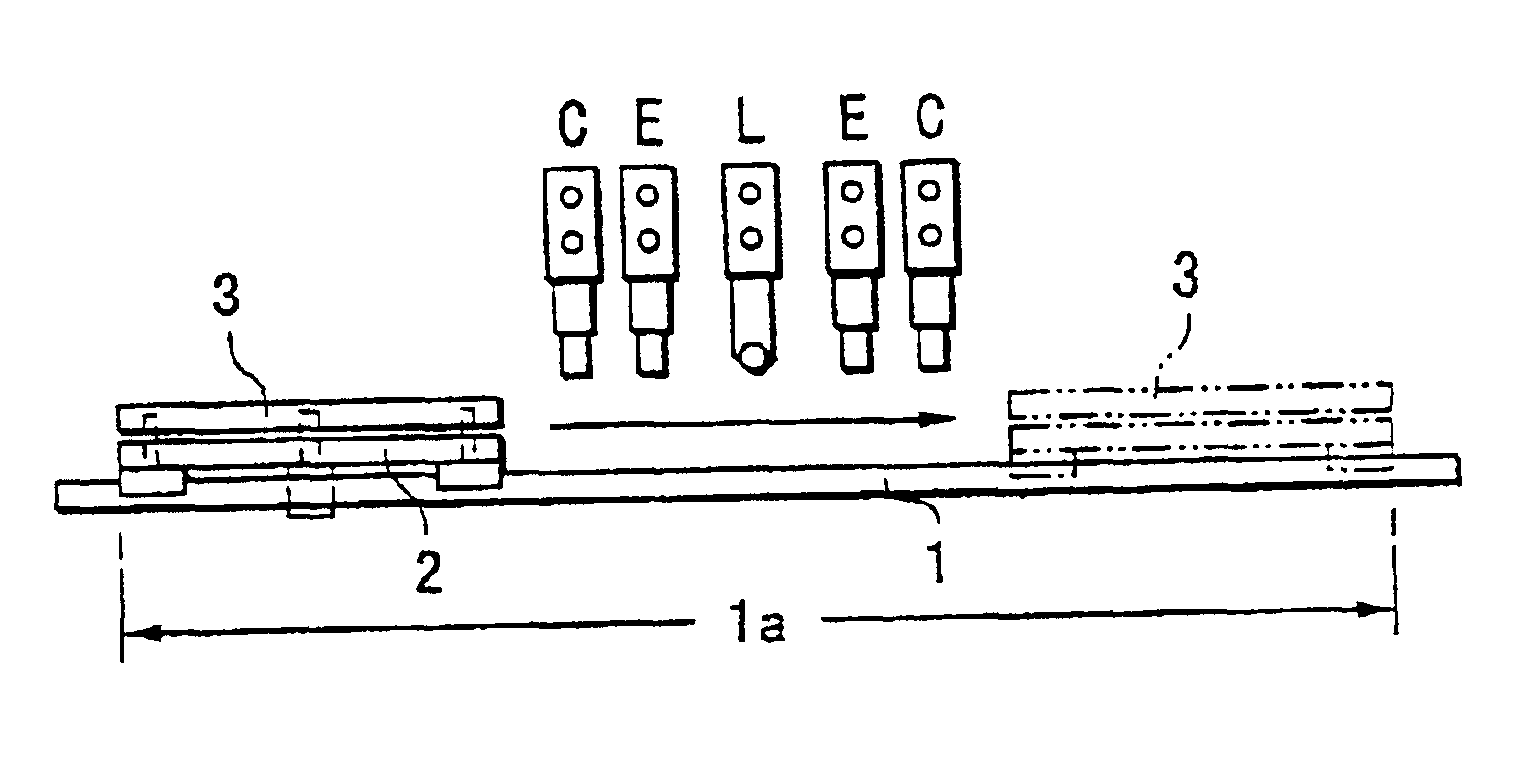

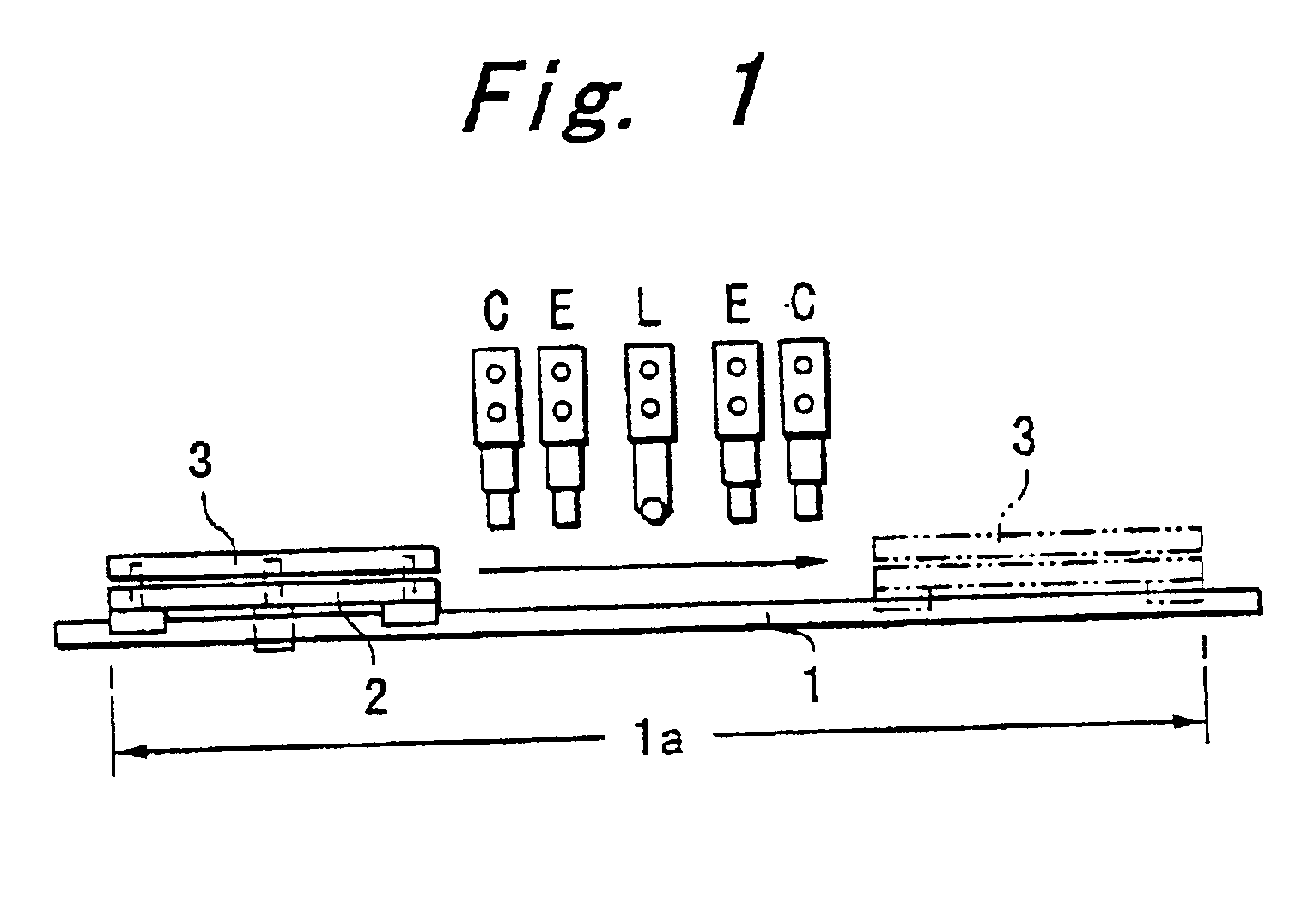

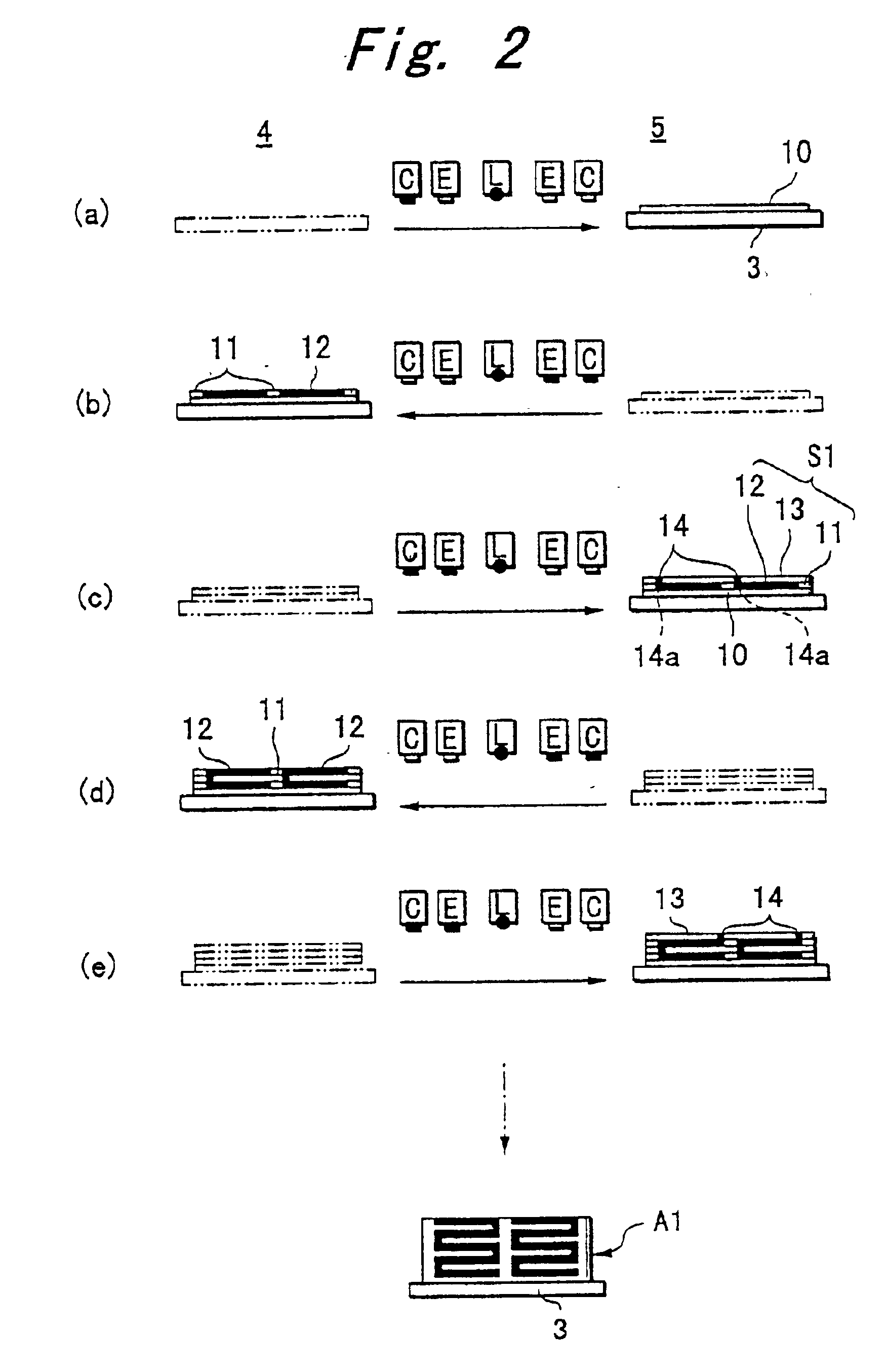

Apparatus for manufacturing laminated member

InactiveUS6868885B2Improve accuracyUniform flatnessLiquid surface applicatorsManual label dispensersConductive pasteReciprocating motion

A manufacturing speed for a laminated member for every layer is increased to improve productivity and at the same time a small-sized manufacturing apparatus capable of being practically realized is provided. A base plate is mounted at a linear predetermined segment path in such a way that it can be reciprocated and moved up and down, each of one to a plurality of an insulating layer forming means for discharging ceramics slurry or insulating resin paste, conductive layer forming means for injecting conductive paste by an ink jet system and drying means for drying said slurry, paste are arranged side by side on the segment path, the thin film layer having a predetermined electrode pattern arranged thereon is formed on the ceramics insulating layer while the base plate reciprocates by once to several times over the segment path, and these operations are repeated to form the laminated member.

Owner:UHT CORP

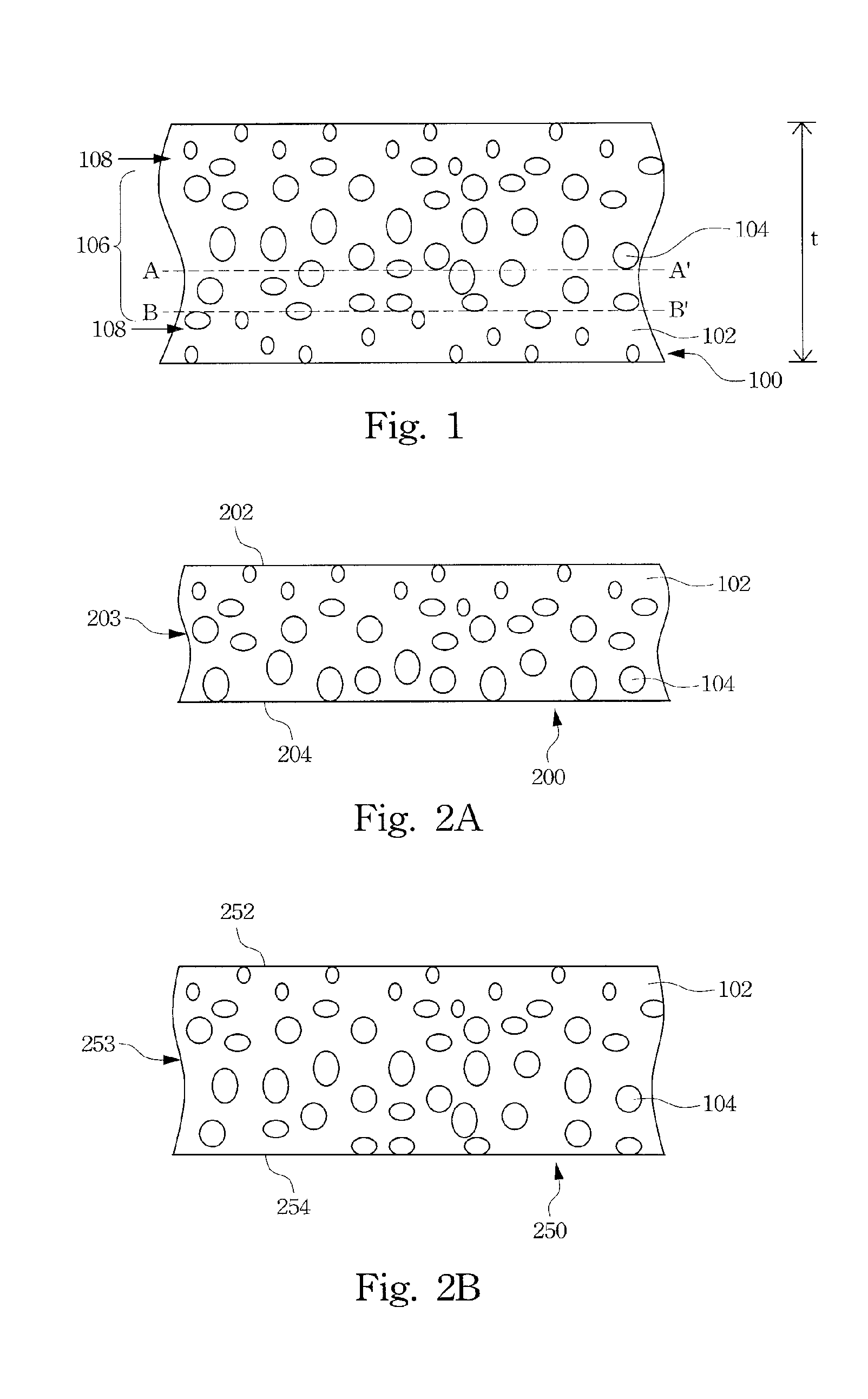

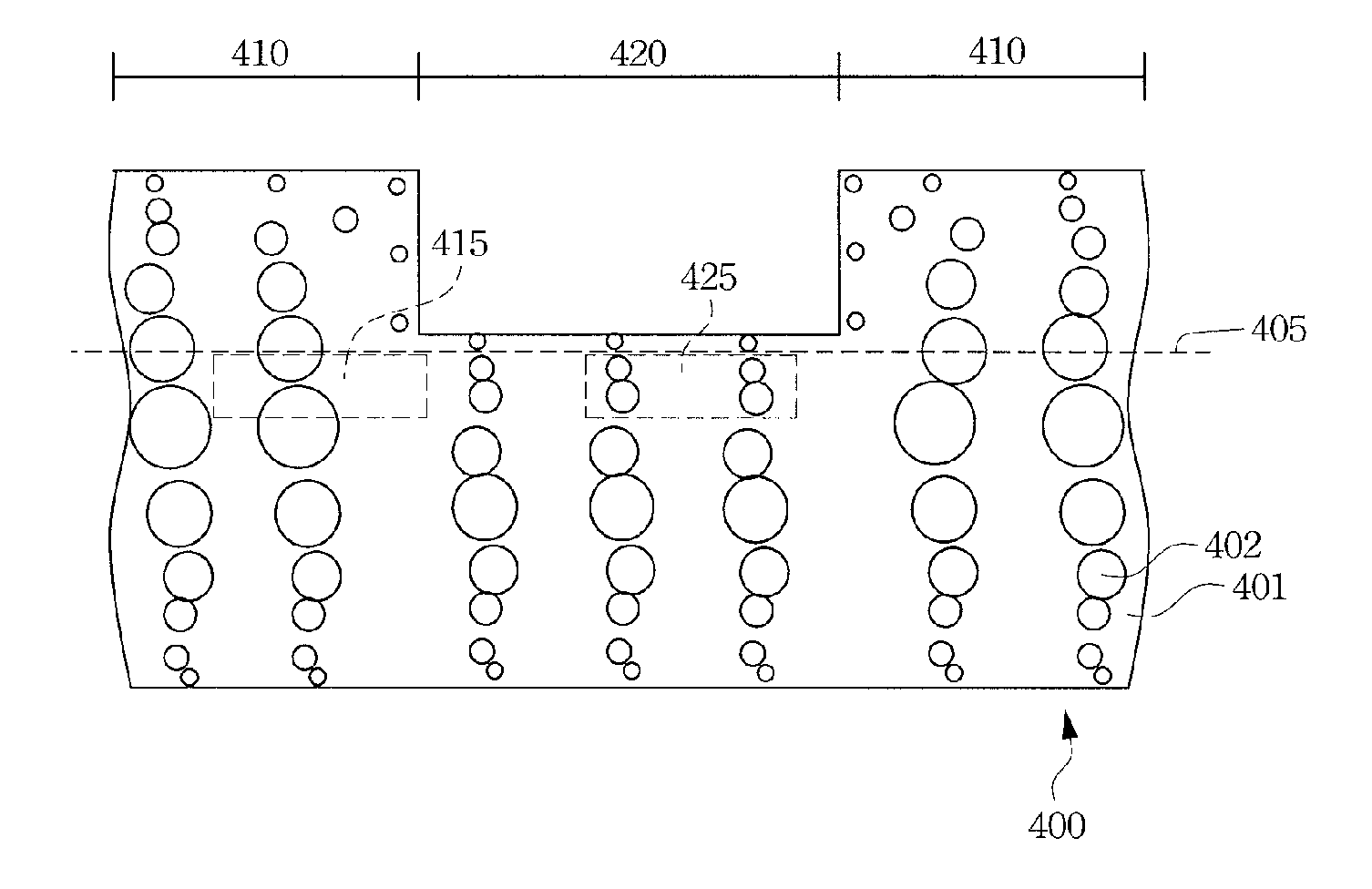

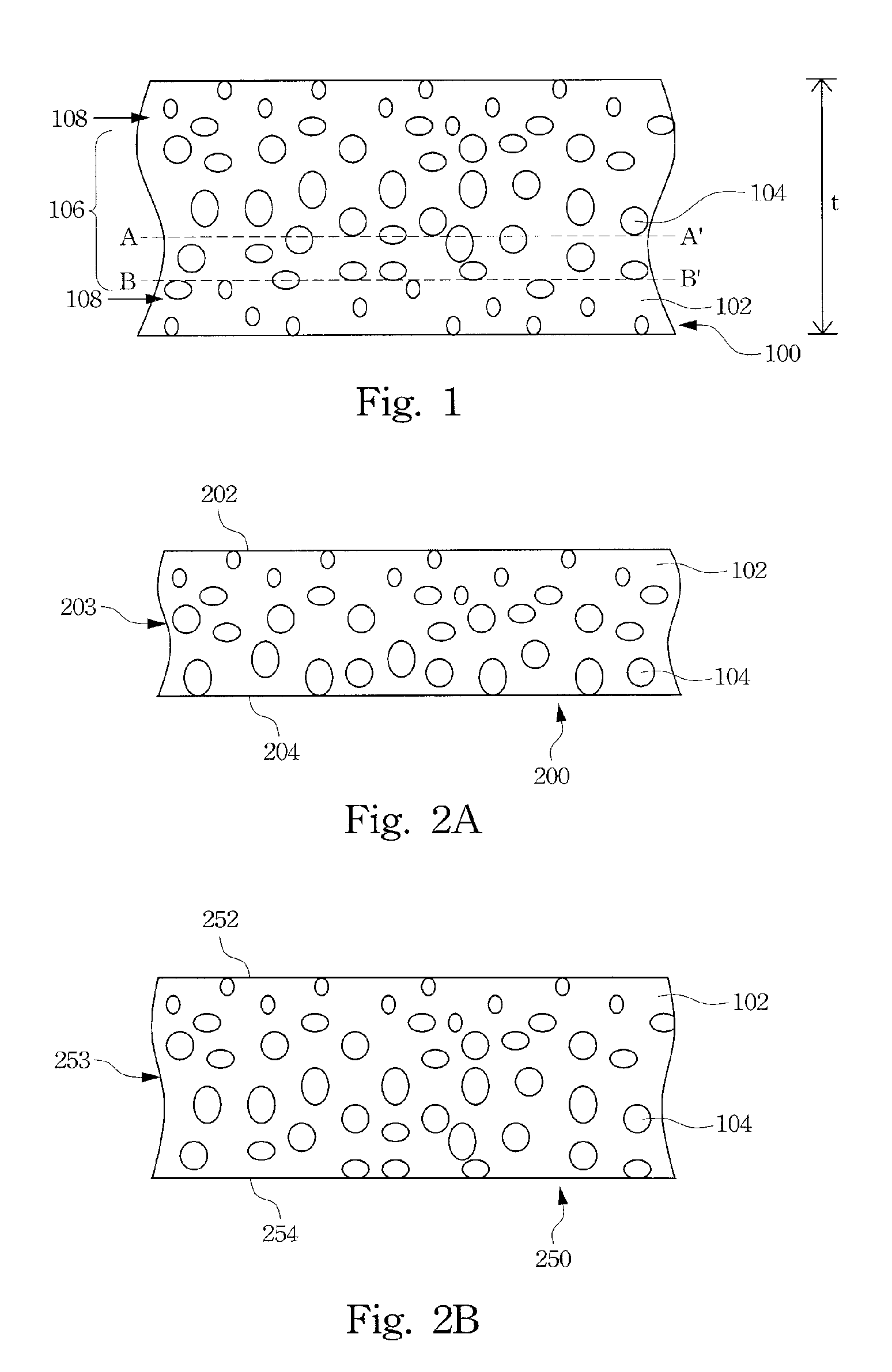

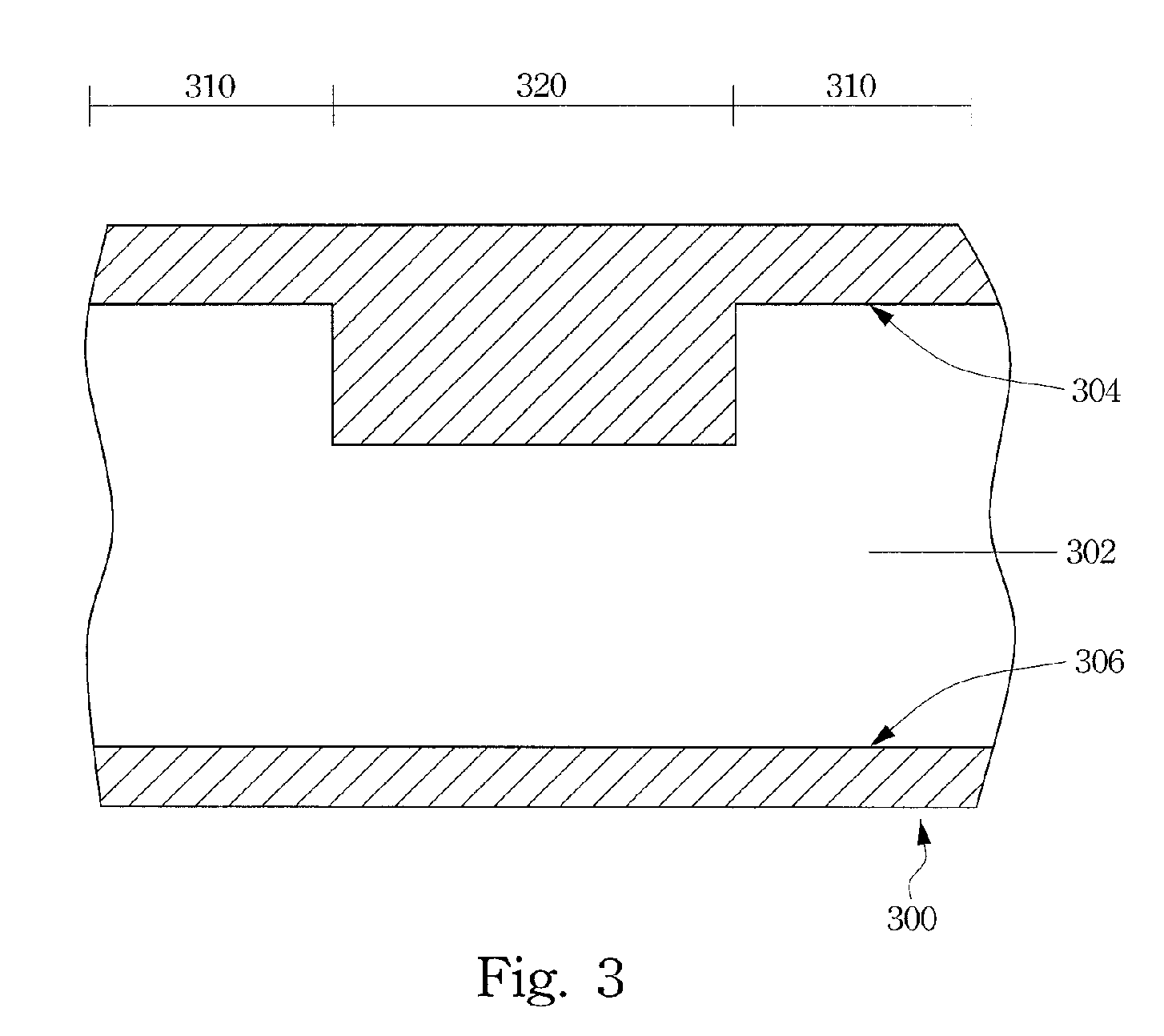

Single-layer polishing pad and method of producing the same

ActiveUS20050250431A1High CMP process throughputLow costLaminationLapping machinesEngineeringMechanical engineering

A foamed plastic is cut to form a single-layer polishing pad having a desired rigidity and compressibility. A polishing surface of the polishing pad has a higher density than a mounting surface of the polishing pad. The polishing surface and the mounting surface may have different areas having different densities for achieving desired rigidity and compressibility property. Furthermore, methods of making such single-layer polishing pads are also disclosed.

Owner:IV TECH CO LTD

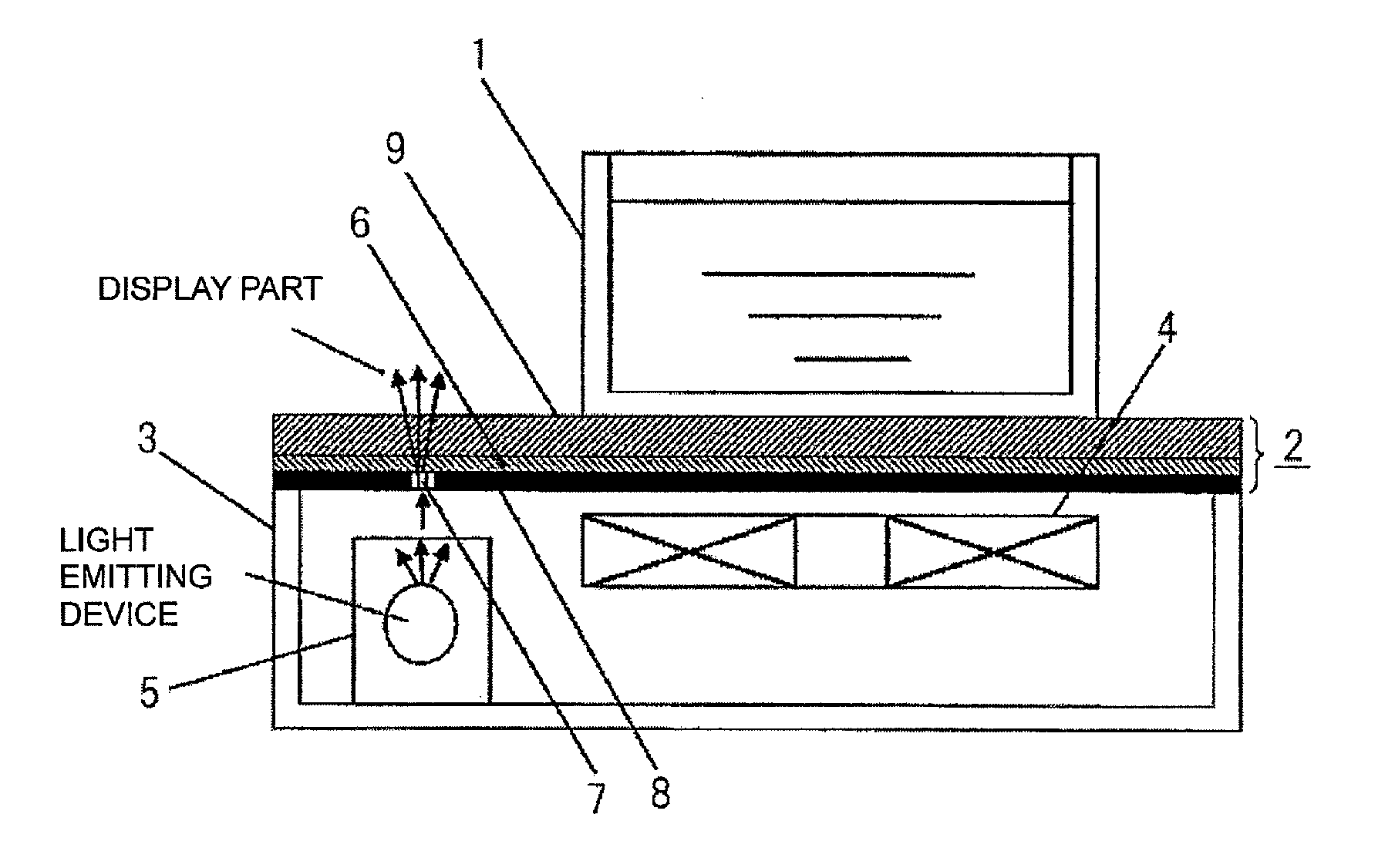

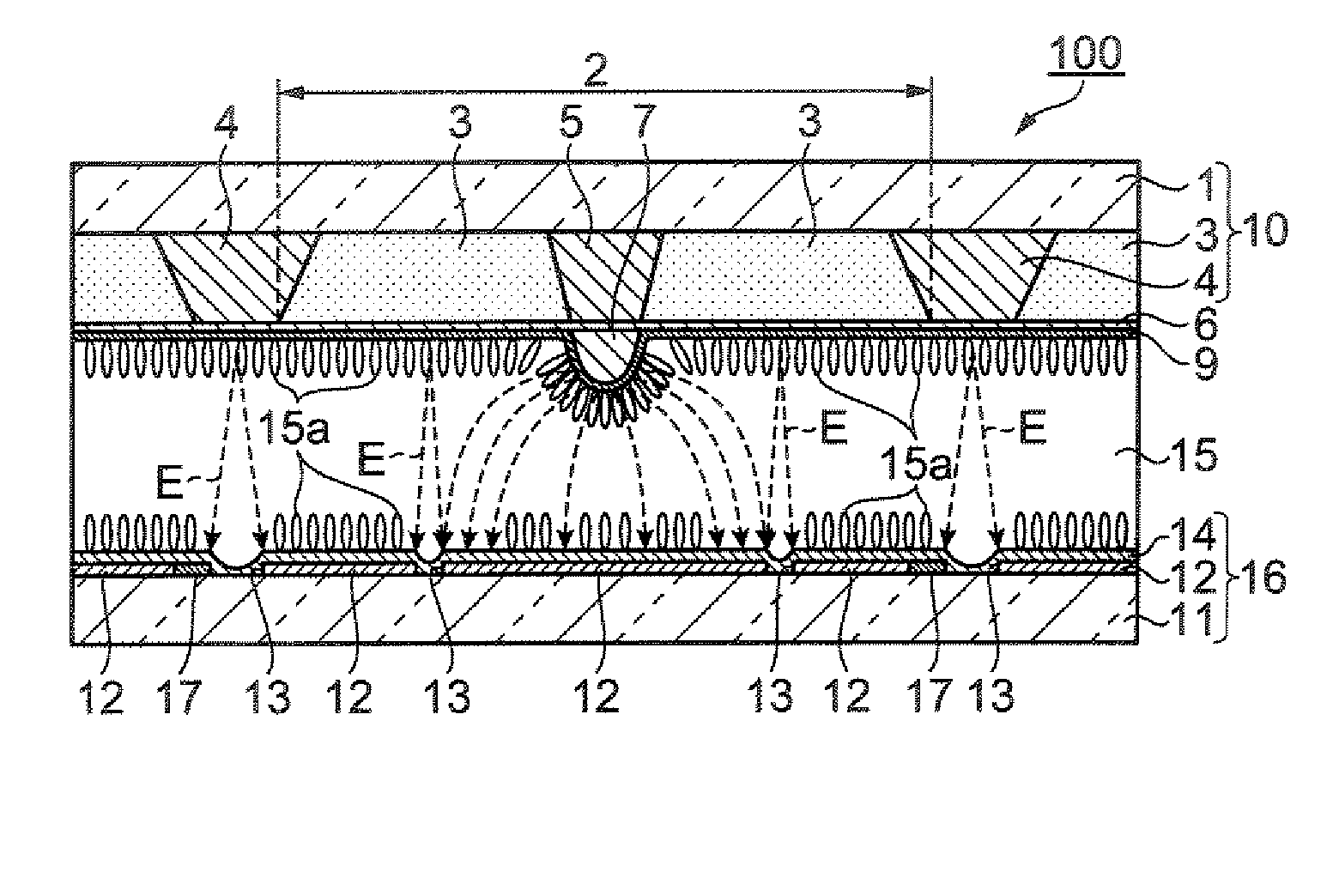

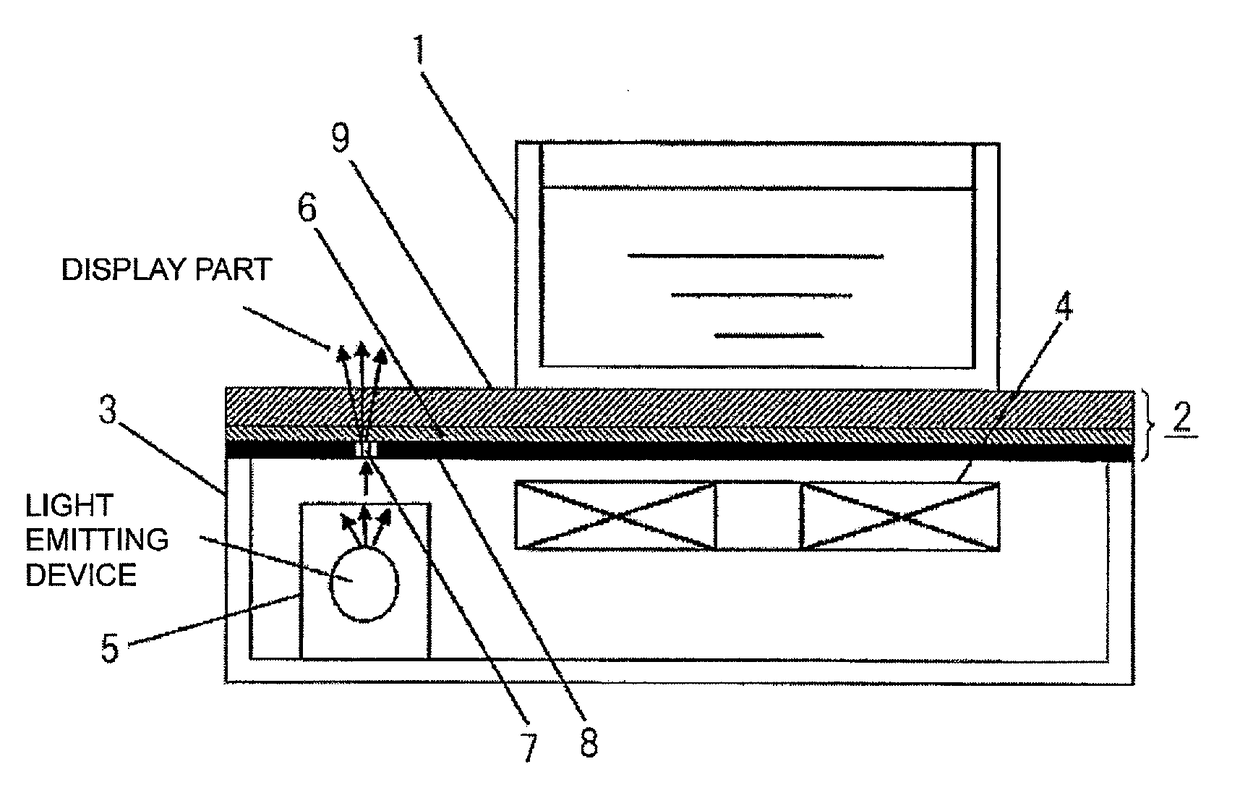

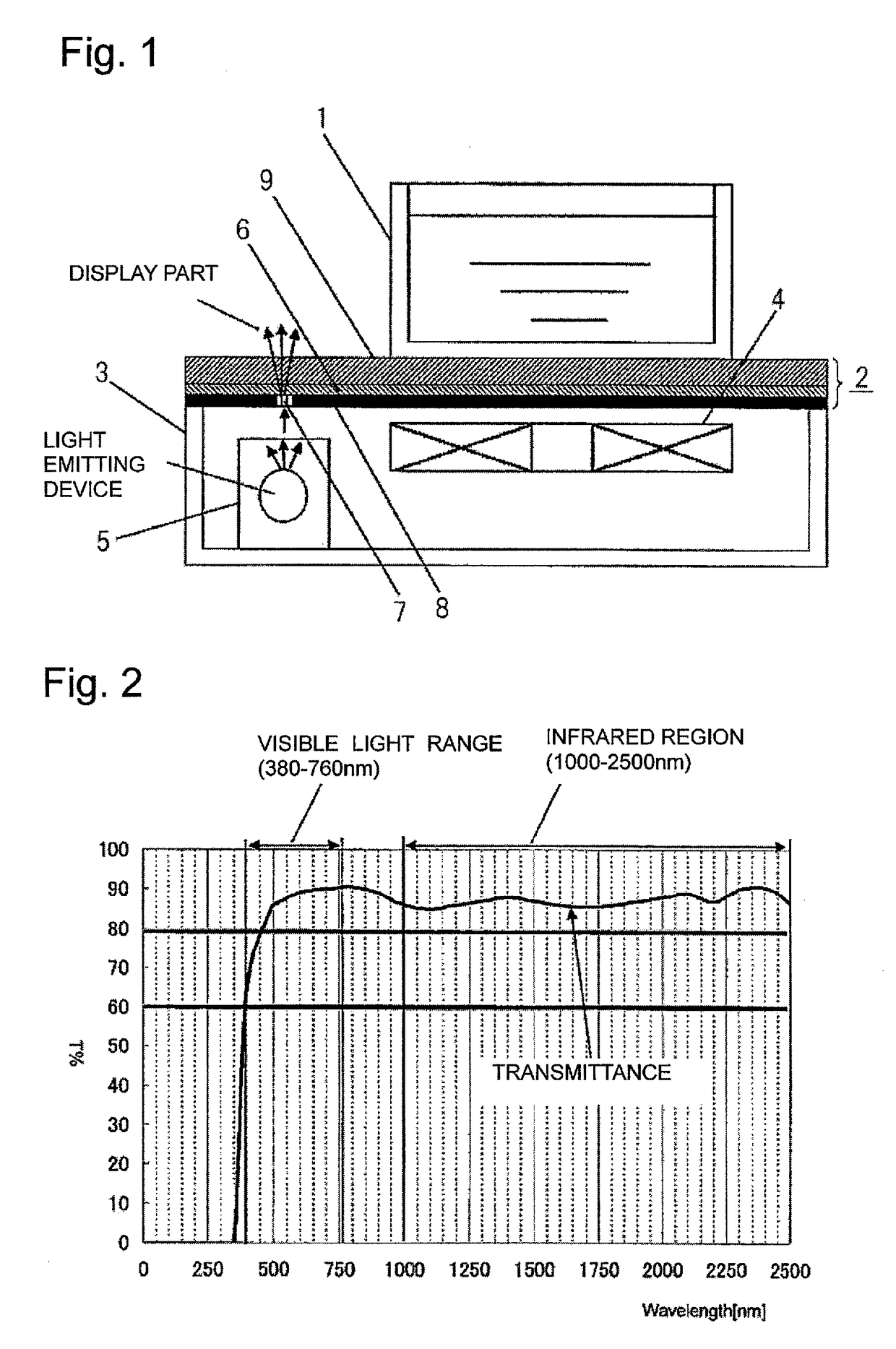

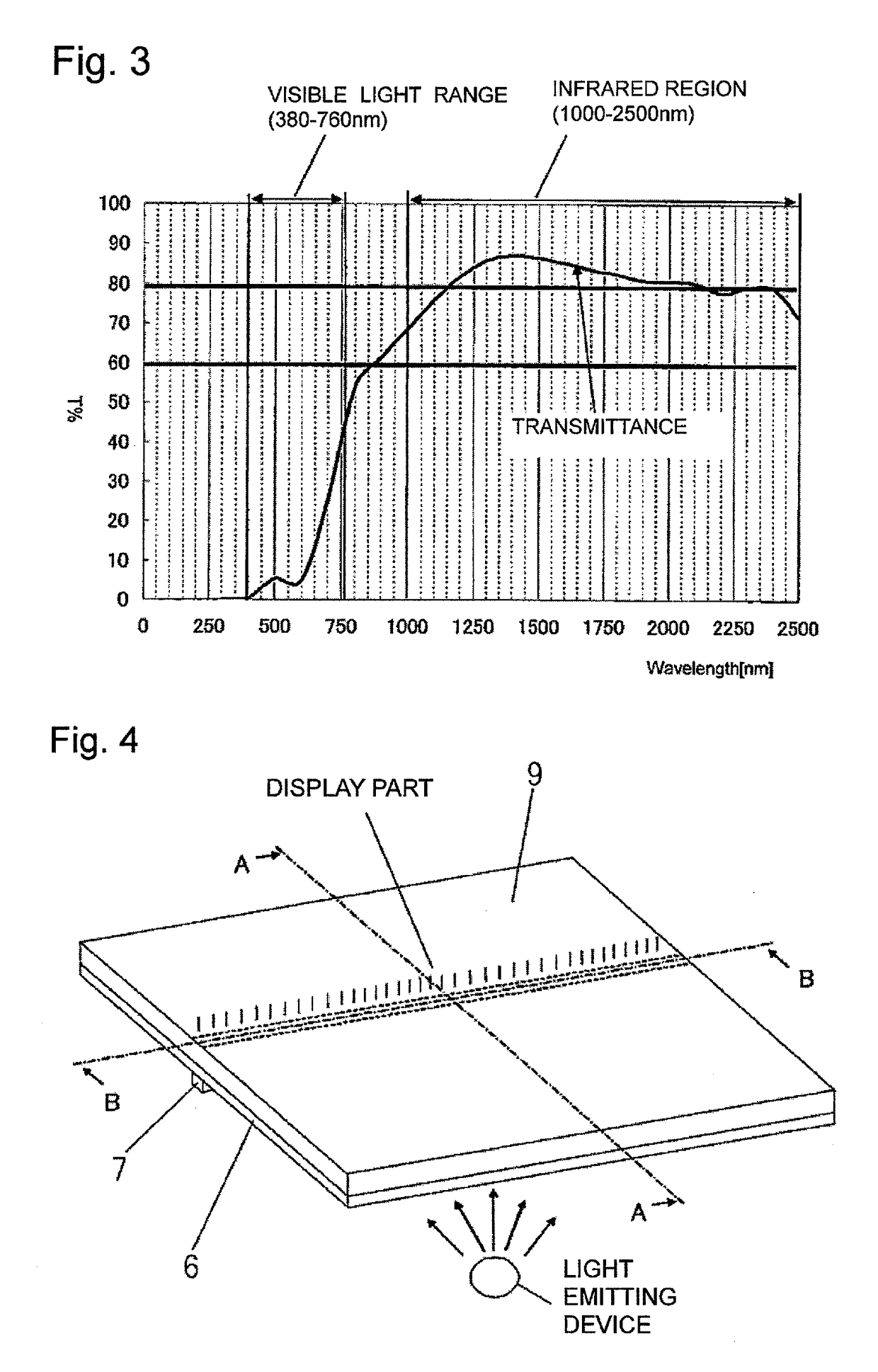

Heating cooker

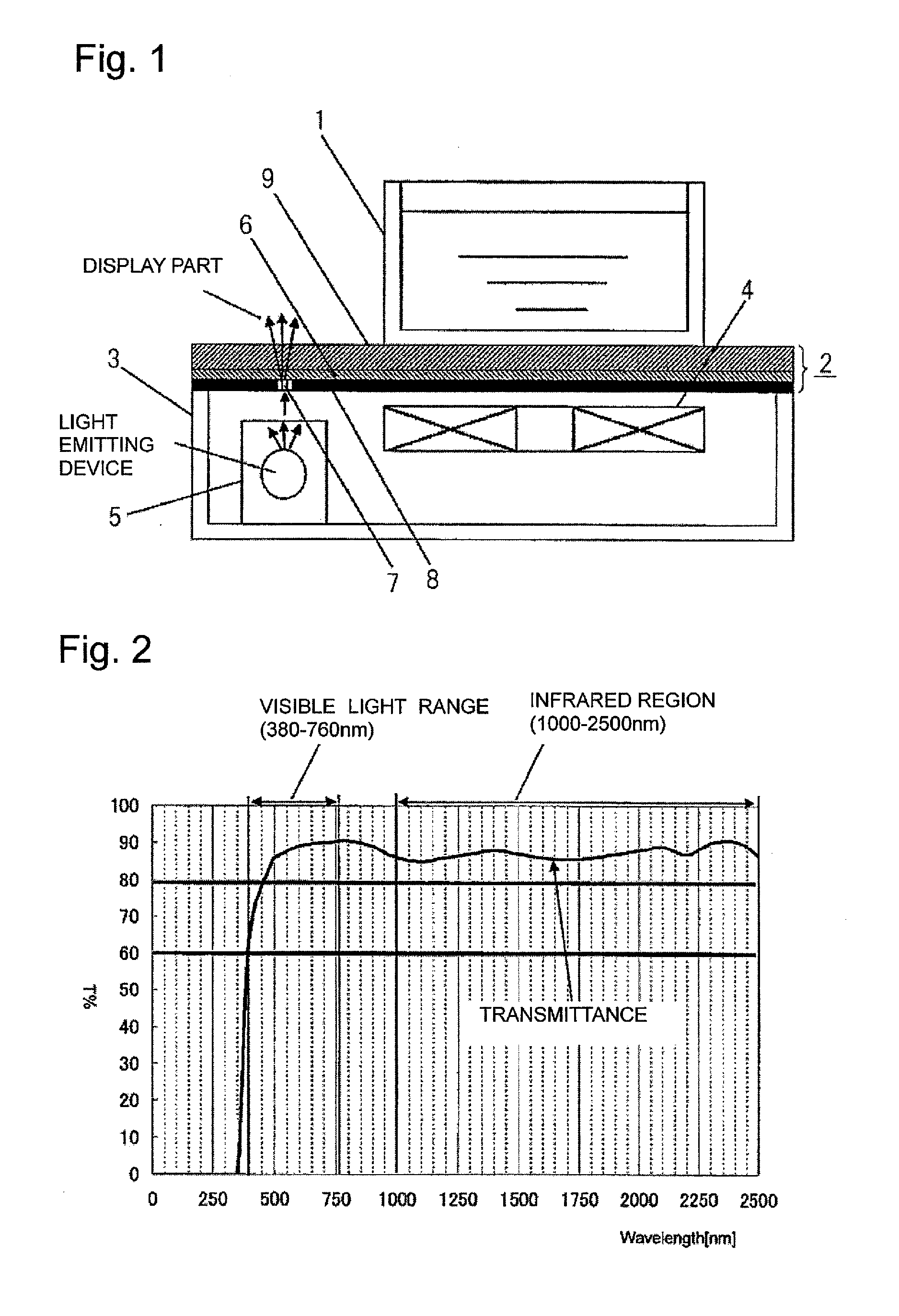

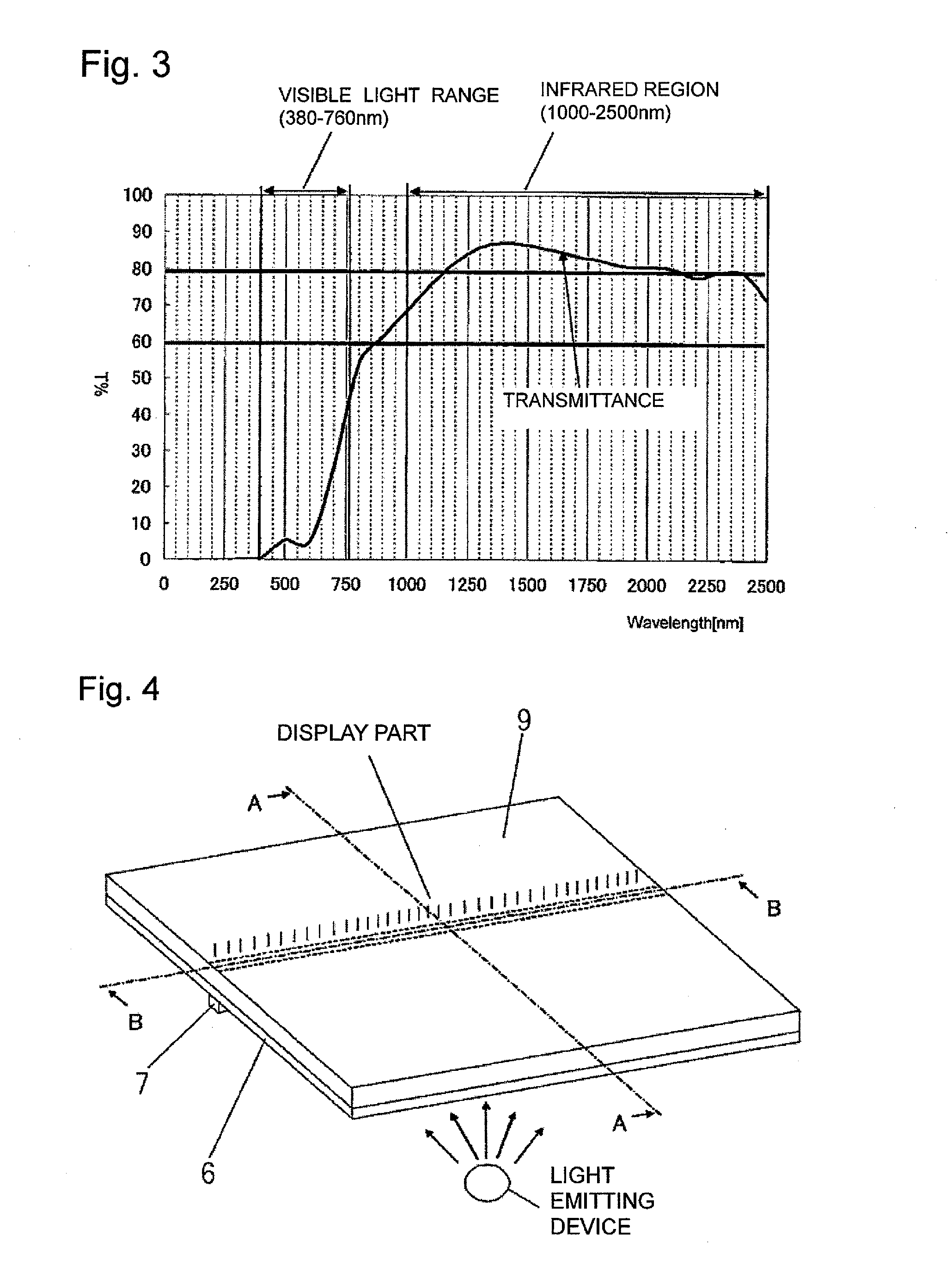

ActiveUS20160258631A1Reduce effectReduce visibilityDomestic stoves or rangesLighting and heating apparatusBlock layerCooker

A heating cooker includes: a top plate on which a cooking container to be heated is placed; an outer case as a main body having an upper surface on which the top plate is placed; a heater heating the cooking container; and a light emitting device disposed in the outer case, for displaying the heating state. The top plate includes: a glass substrate having a transparent light-transmitting low-expansion crystallized glass made mainly of Li2O—AL2O3—SiO2 and having β-quartz solid solution, having a crystal size smaller than the wavelength of visible light; a design layer having a black-based color disposed on an undersurface of the glass substrate; a diffusion region disposed partially on an undersurface of the design layer, for diffusedly emitting light from the light emitting device; and a light-blocking layer disposed on the undersurface of the design layer other than the diffusion region, for blocking light from below.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Environment-friendly curtaining odor-removing PU matted varnish and preparation method thereof

InactiveCN106349920AUniform transparencyUniform flatnessPolyurea/polyurethane coatingsCyclohexanoneFatty acid

The invention relates to an environment-friendly curtaining odor-removing PU matted varnish and a preparation method of the environment-friendly curtaining odor-removing PU matted varnish, and belongs to the technical field of wooden coating manufacturing. The environment-friendly curtaining odor-removing PU matted varnish is prepared by mixing component A, component B, and component C according to the weight ratio of 1: 0.5: 0.4-0.7; the component A is composed of fatty acid modified odor removal alkyd resin, short-oil castor oil alkyd resin, polyamide wax anti-sediment, wetting dispersant, flatting agent, antifoaming agent, modified polyethylene wax powder, matt powder, propylene glycol monomethyl ether acetate, cyclohexanone, ethylene glycol diacetate, 50% by mass of nitrocotton fluid, and n-butyl acetate; the component B is composed of aliphatic series polyisocyanate, TDI tripolymer curing agent, TDI prepolymer, and n-butyl acetate; the component C is composed of xylene, n-butyl acetate, propylene glycol monomethyl ether acetate, acetate, and ethylene glycol diacetate. The coating has strong adhesive force, good transparency, high fullness, good flexibility, good scratching resistance, uniform gloss, stability and impact-resistance, and good waterproof and chemical resistance.

Owner:山东巴德士新材料有限公司

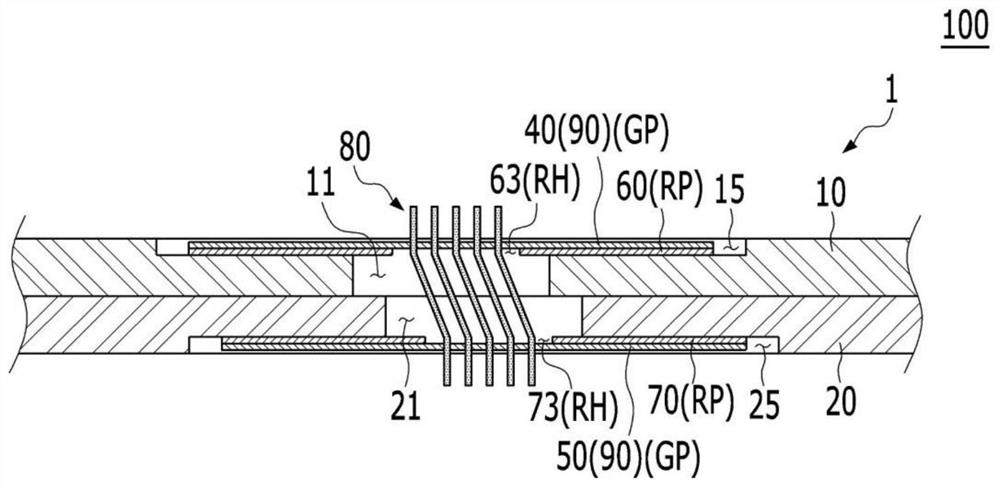

Apparatus for sensing touch pressure

ActiveUS20180300005A1Uniform thicknessThin thicknessConductive layers on insulating-supportsDigital data processing detailsPorous membraneElectrical and Electronics engineering

The present disclosure relates to an apparatus for sensing touch pressure. The apparatus for sensing touch pressure, according to one mode of the present disclosure, includes: a first substrate provided with a first electrode unit formed thereon; a second substrate provided with a second electrode unit formed thereon; and a porous membrane member provided between the first substrate and the second substrate and deformed or restored according to touch pressure applied to the first substrate.

Owner:AMOGREENTECH CO LTD +1

Single-layer polishing pad and method producing the same

ActiveUS7101501B2Reduce rigidityLow compressibilityLaminationFlexible-parts wheelsHigh densityEngineering

A foamed plastic is cut to form a single-layer polishing pad having a desired rigidity and compressibility. A polishing surface of the polishing pad has a higher density than a mounting surface of the polishing pad. The polishing surface and the mounting surface may have different areas having different densities for achieving desired rigidity and compressibility property. Furthermore, methods of making such single-layer polishing pads are also disclosed.

Owner:IV TECH CO LTD

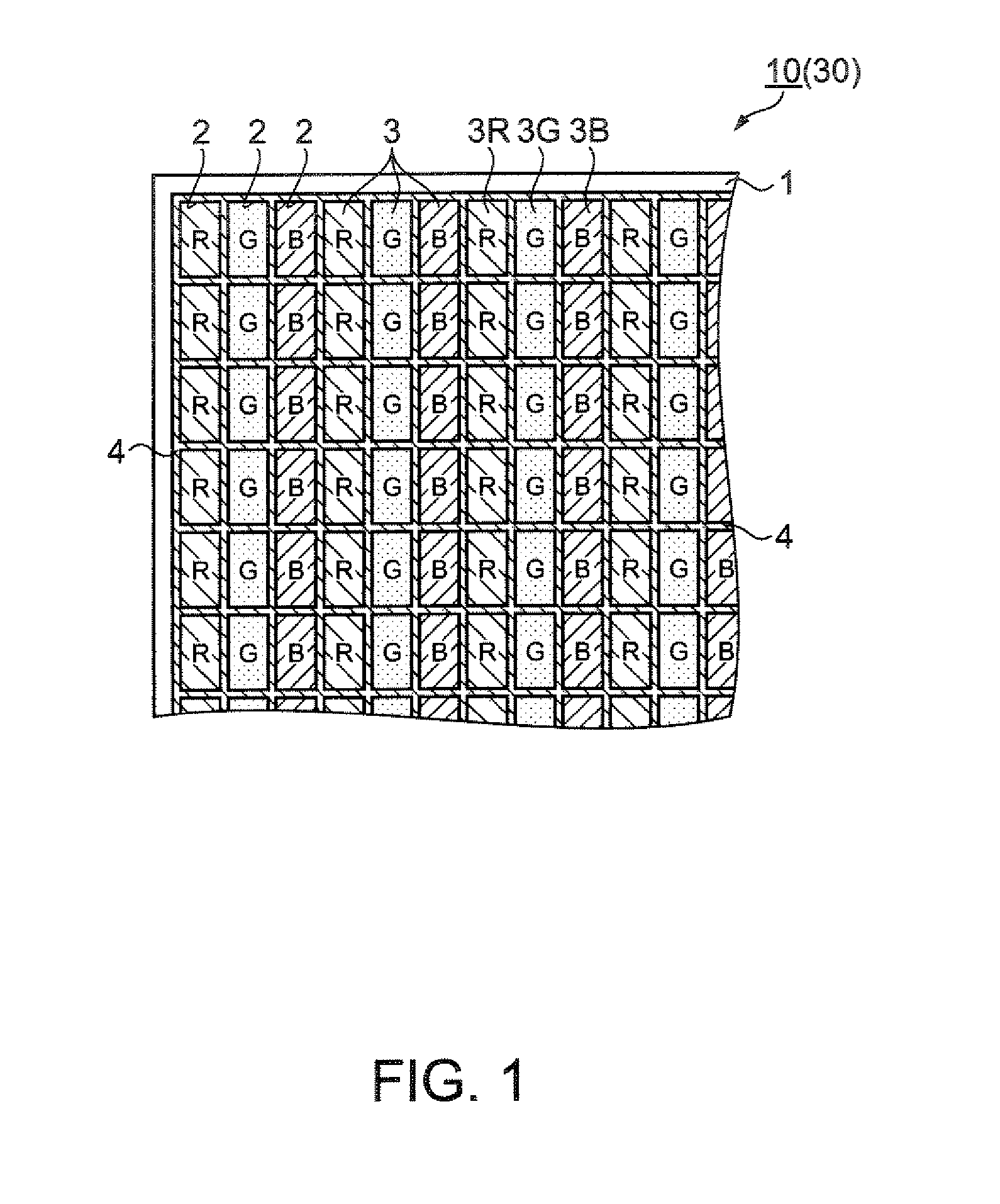

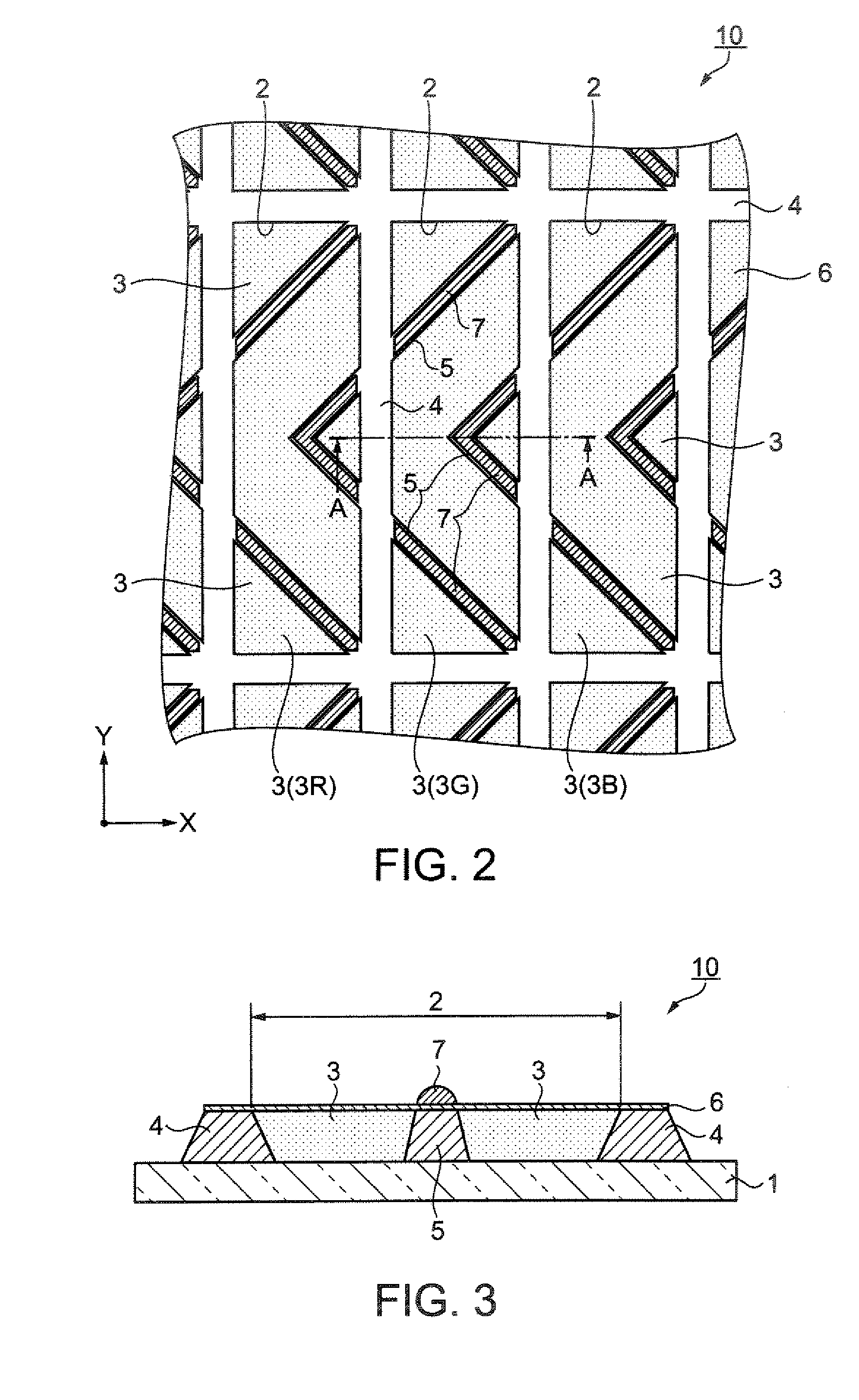

Color filter substrate, liquid crystal display device, electronic apparatus, and methods for manufacturing color filter substrate and liquid crystal display device

InactiveUS20070139588A1Reduce wasteUniform qualityPrintingNon-linear opticsLiquid-crystal displayEngineering

A color filter substrate includes: a first partition wall for partitioning a substrate into a plurality of color element regions; a second partition wall for dividing each of the plurality of color element regions into a plurality of regions; color elements having a plurality of types, being formed on the plurality of color element regions; a transparent electrode covering the first partition wall, the second partition wall, and the color element; and a projection or an aperture formed on the transparent electrode; wherein the second partition wall is arranged in the direction in which the projection or the aperture is extended.

Owner:SEIKO EPSON CORP

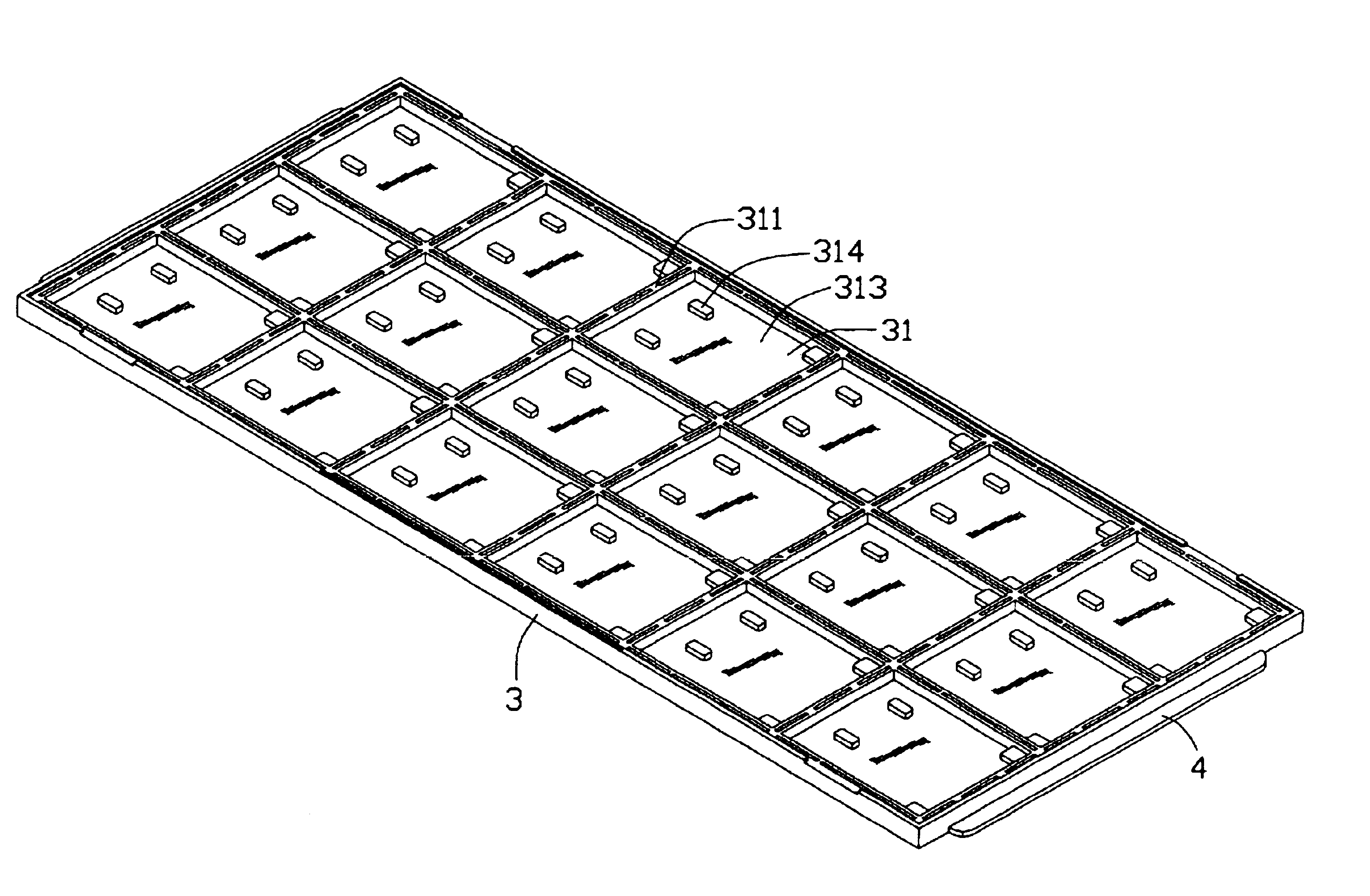

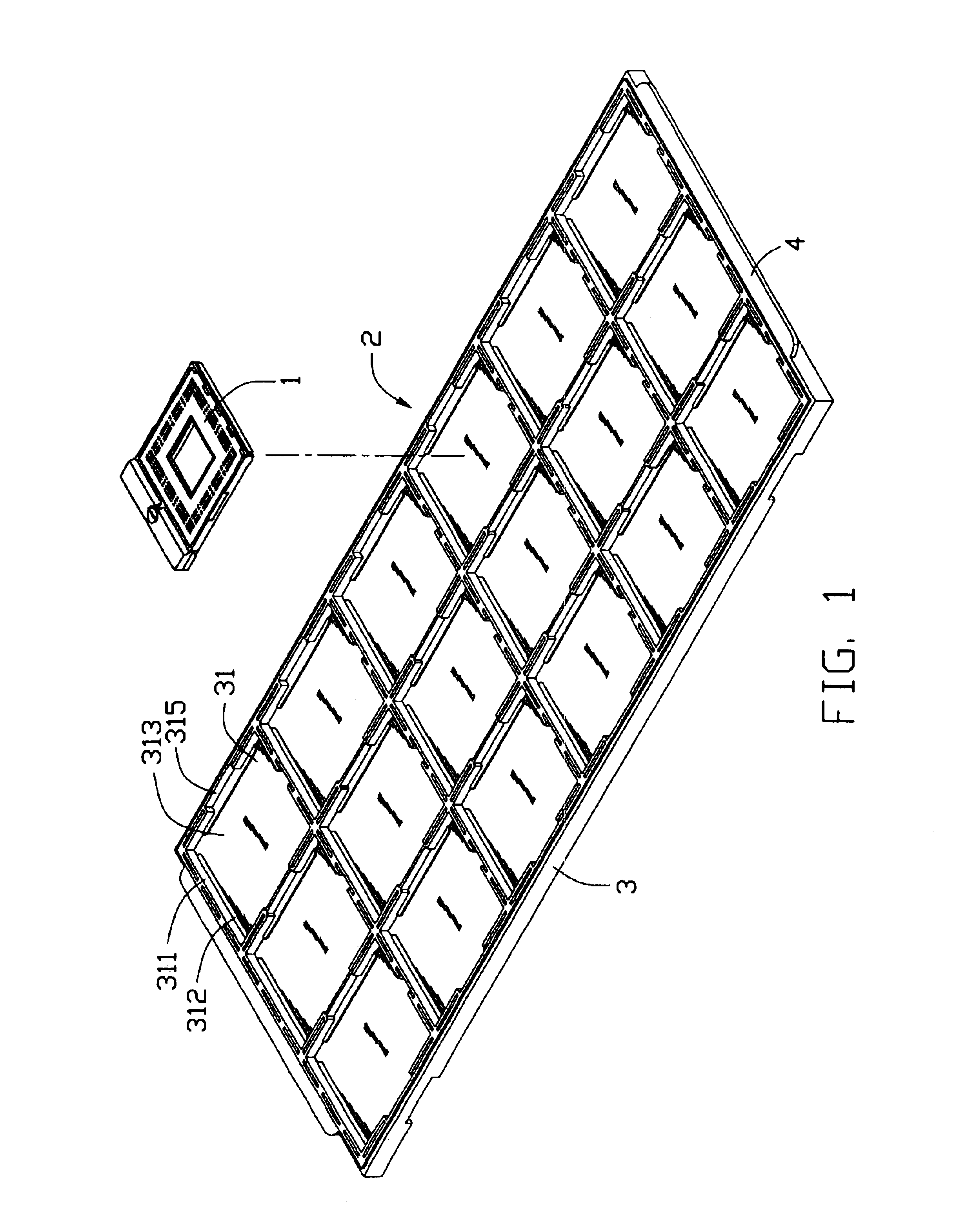

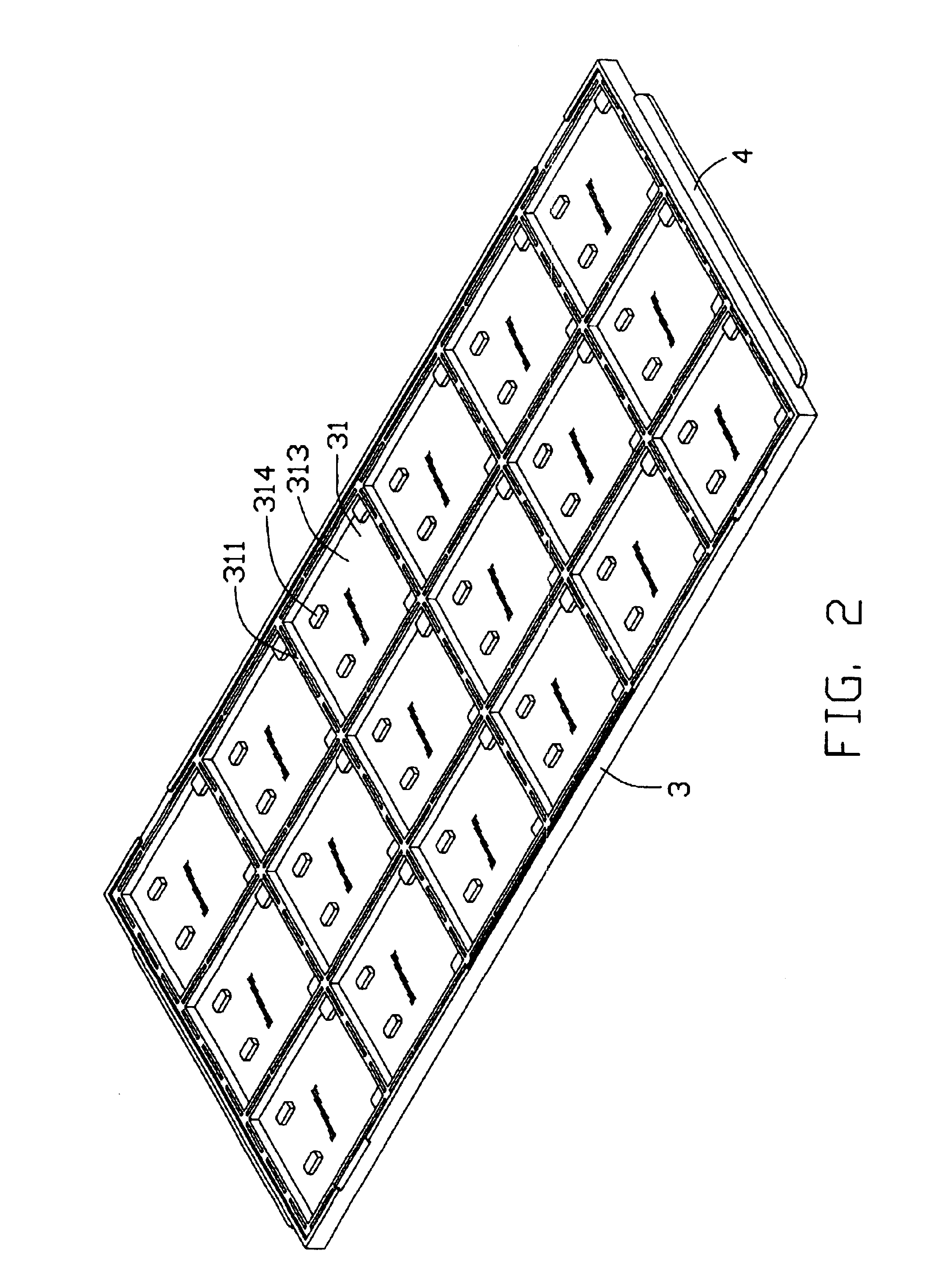

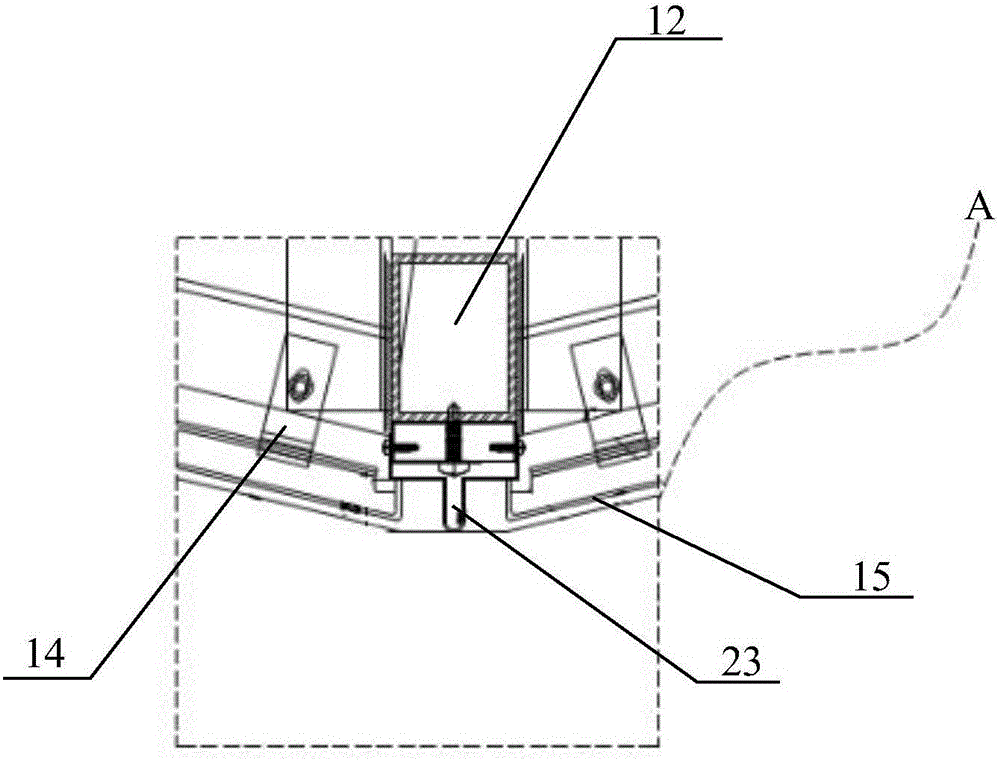

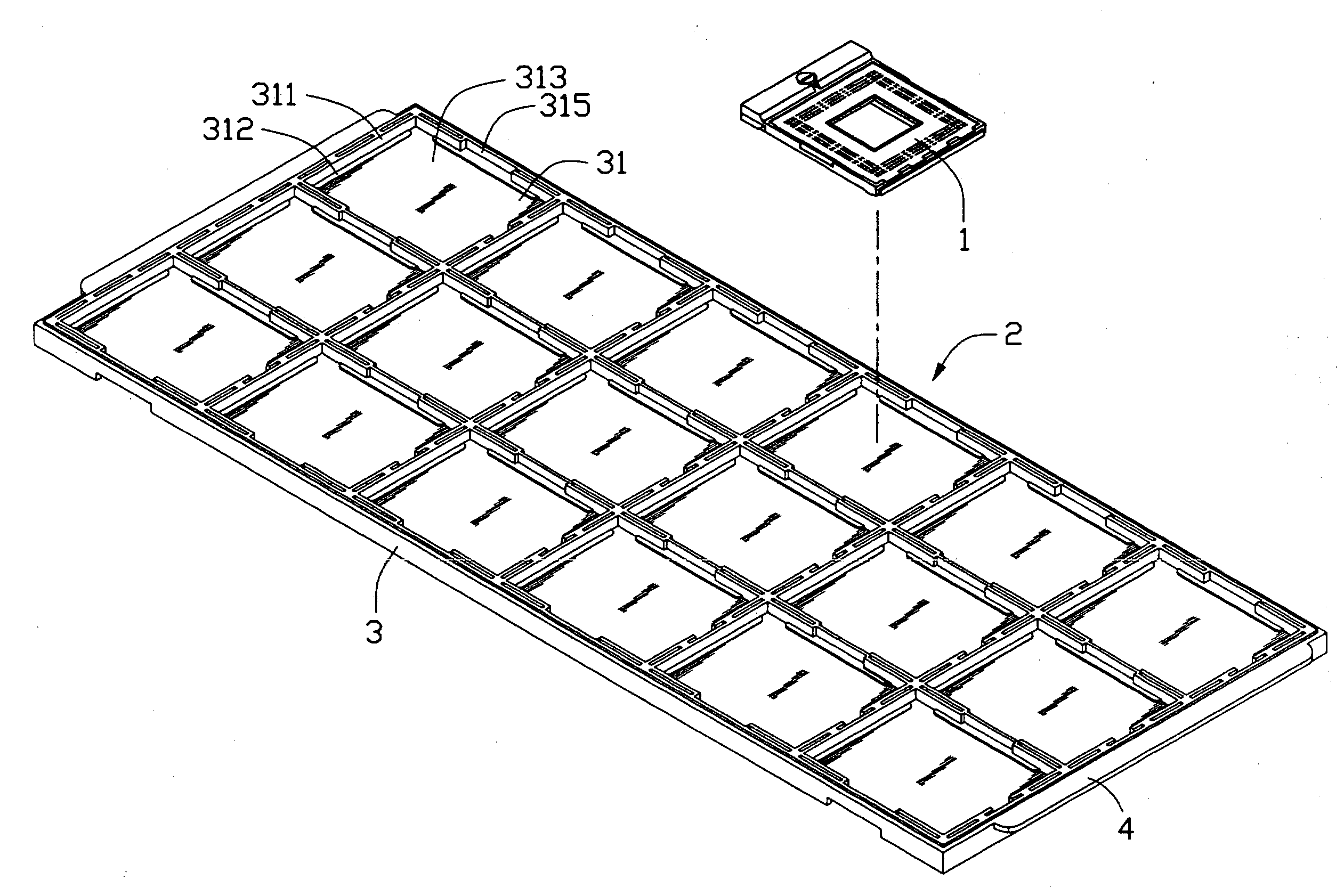

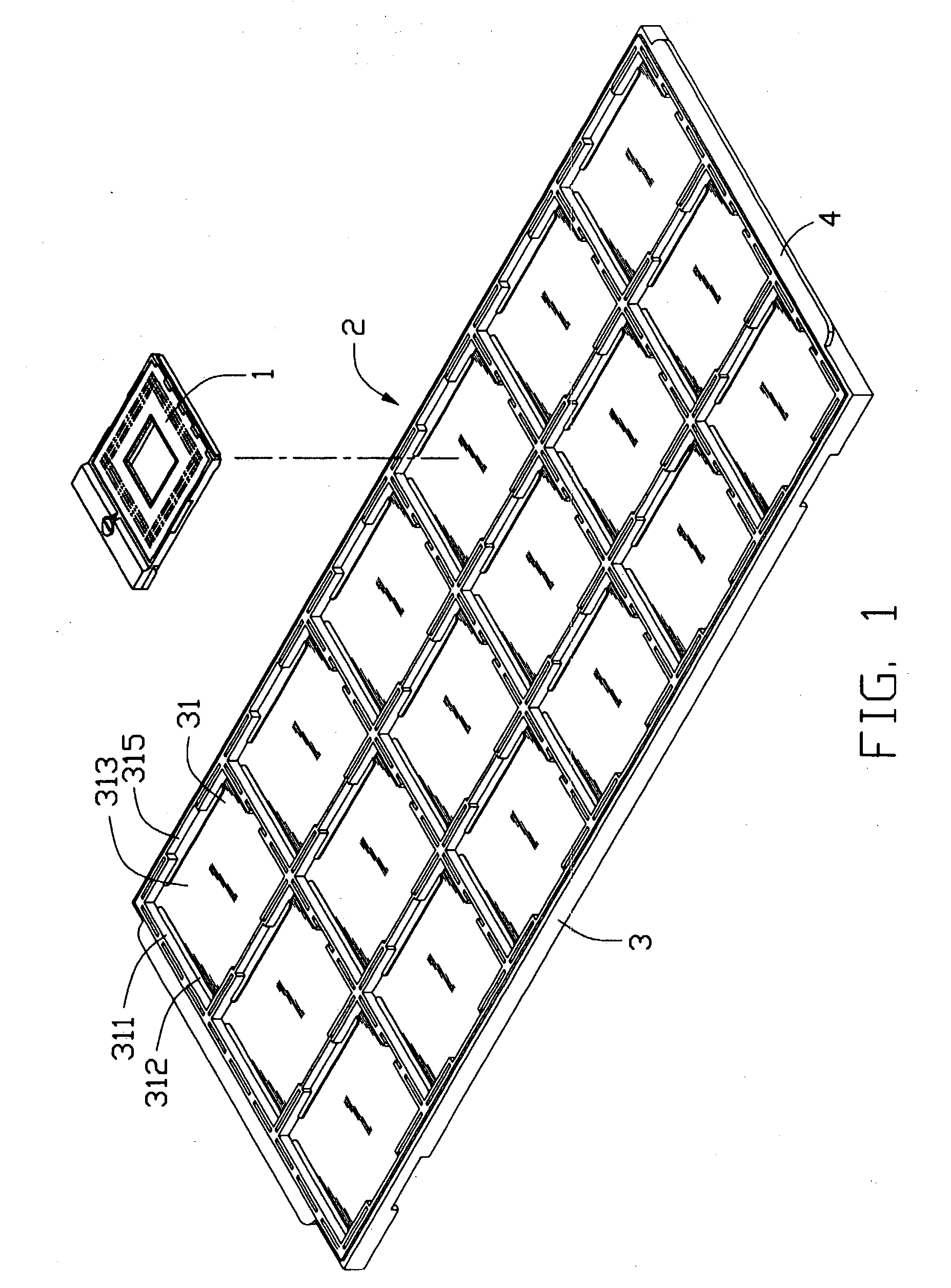

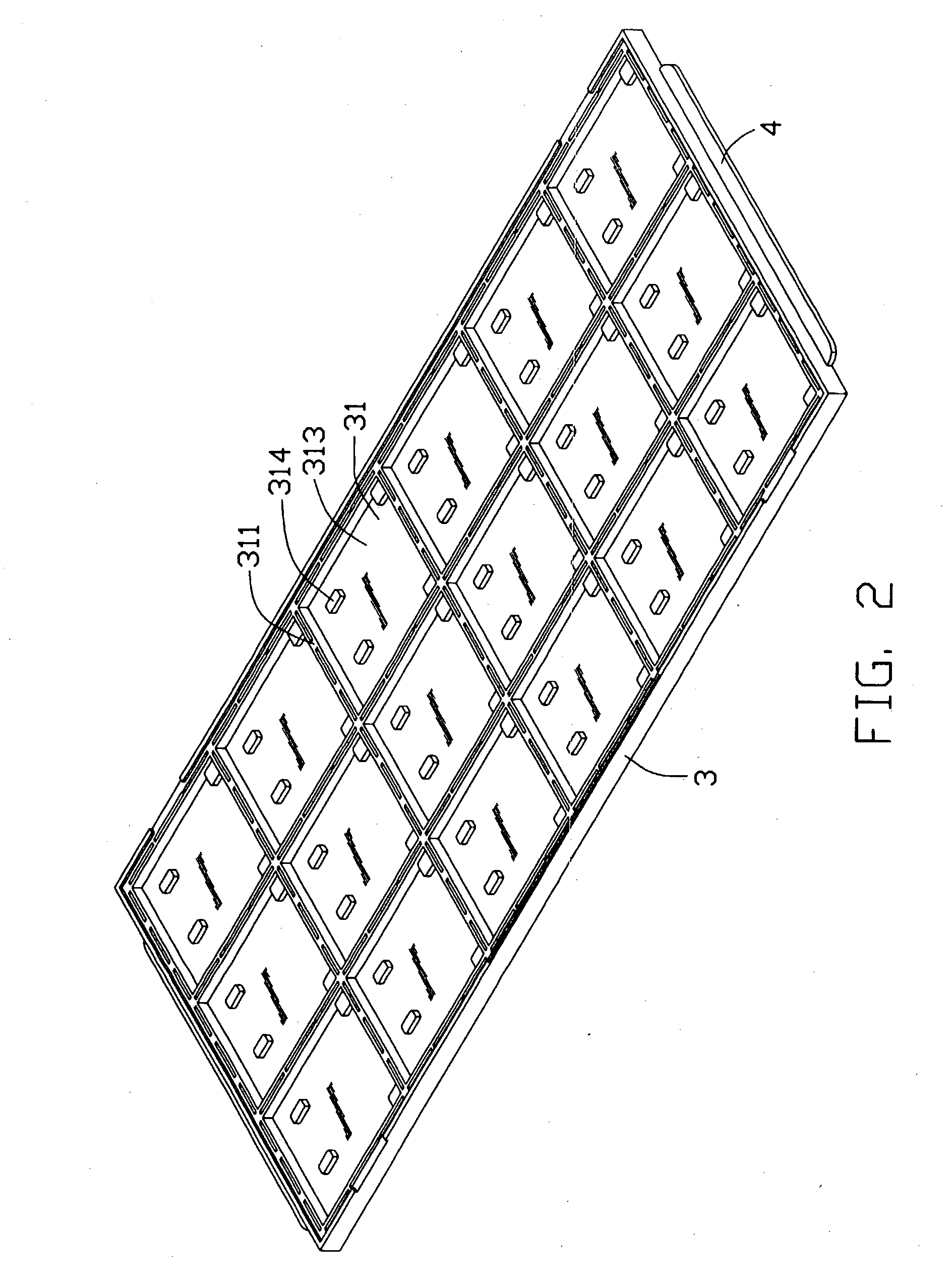

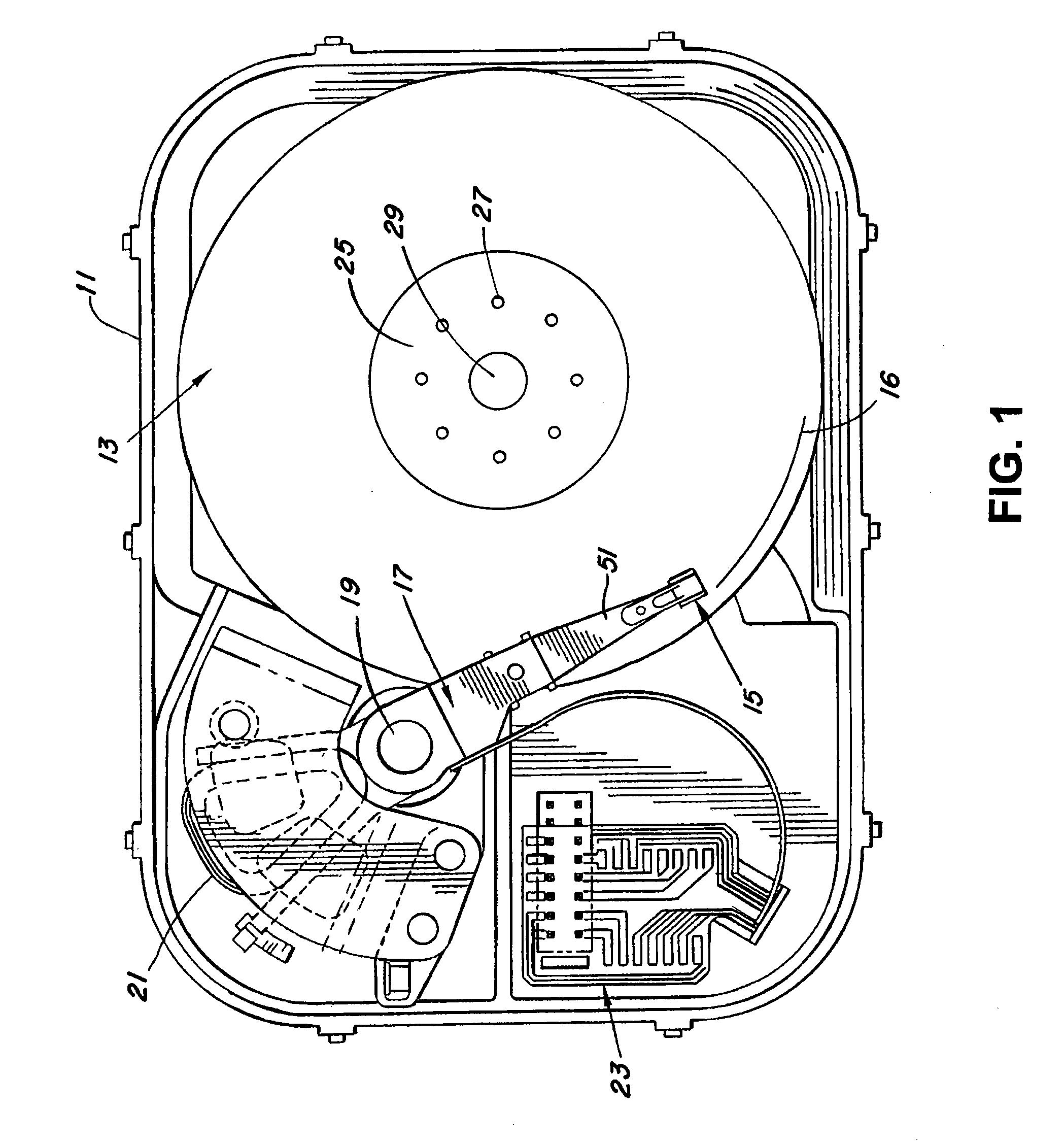

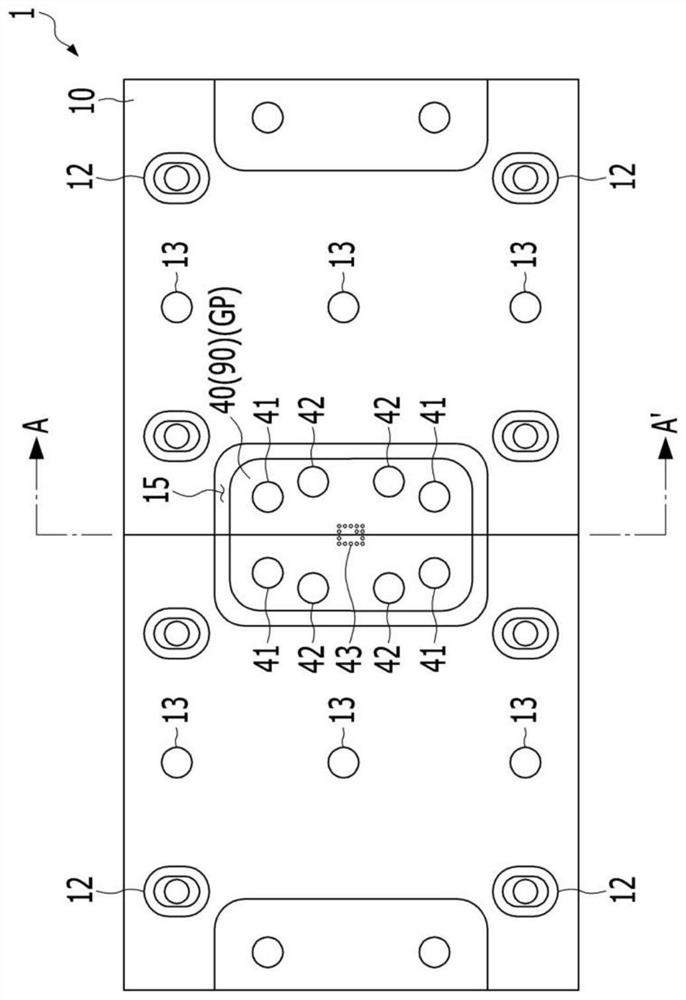

Connector packaging tray with supporting standoffs

InactiveUS6780039B2Reliable inspectionUniform flatnessCoupling device detailsSemiconductor/solid-state device manufacturingCPU socketSolder ball

A packaging tray (2) includes an elongate base (3). The base includes supporting portions (31) for receiving CPU sockets (1) therein. Each supporting portion includes four sidewalls (311), and a bottom wall (313) having an upper surface and a lower surface. Each sidewall forms an inwardly extending rib (312). Four standoffs (314) are formed on the lower surface. When mounting the CPU sockets on the upper surfaces, each CPU socket rests on the corresponding ribs, and solder balls of the CPU socket are supported by the corresponding upper surface. Thus, in handling of the CPU sockets, the solder balls are unlikely to sustain damage. Conversely, the CPU sockets can be reverse mounted on the lower surfaces. The solder balls of each CPU socket are located in a horizontal plane face up, with the standoffs supporting the CPU socket. The solder balls can be accurately inspected by a flatness inspection device.

Owner:HON HAI PRECISION IND CO LTD

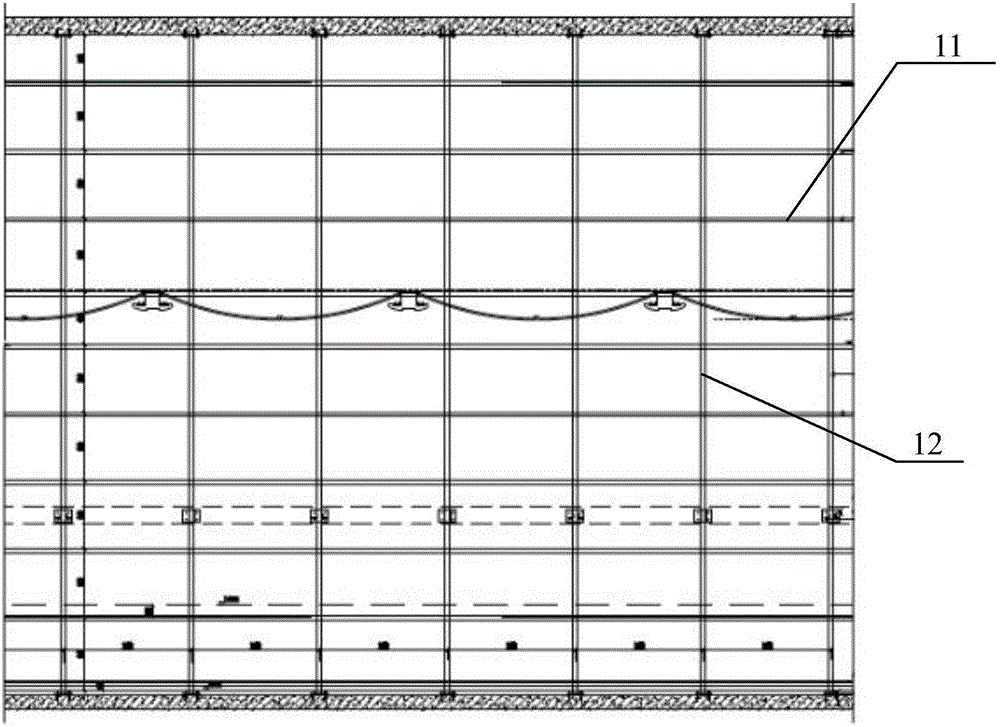

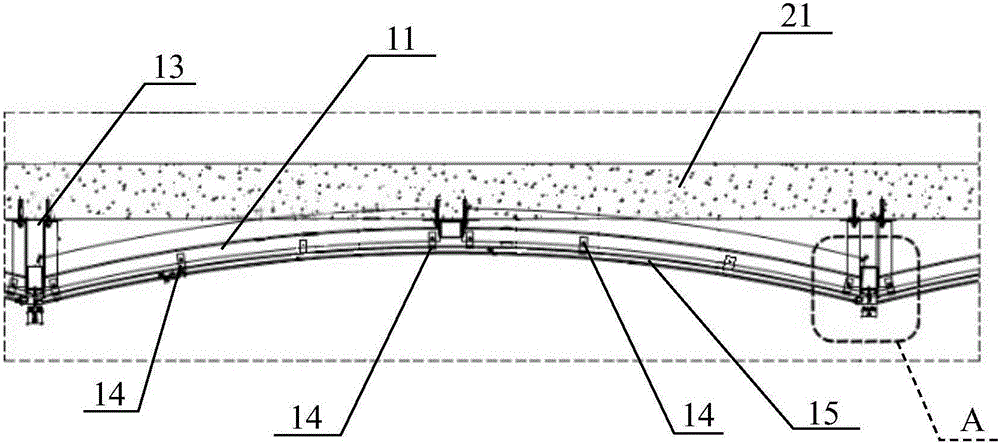

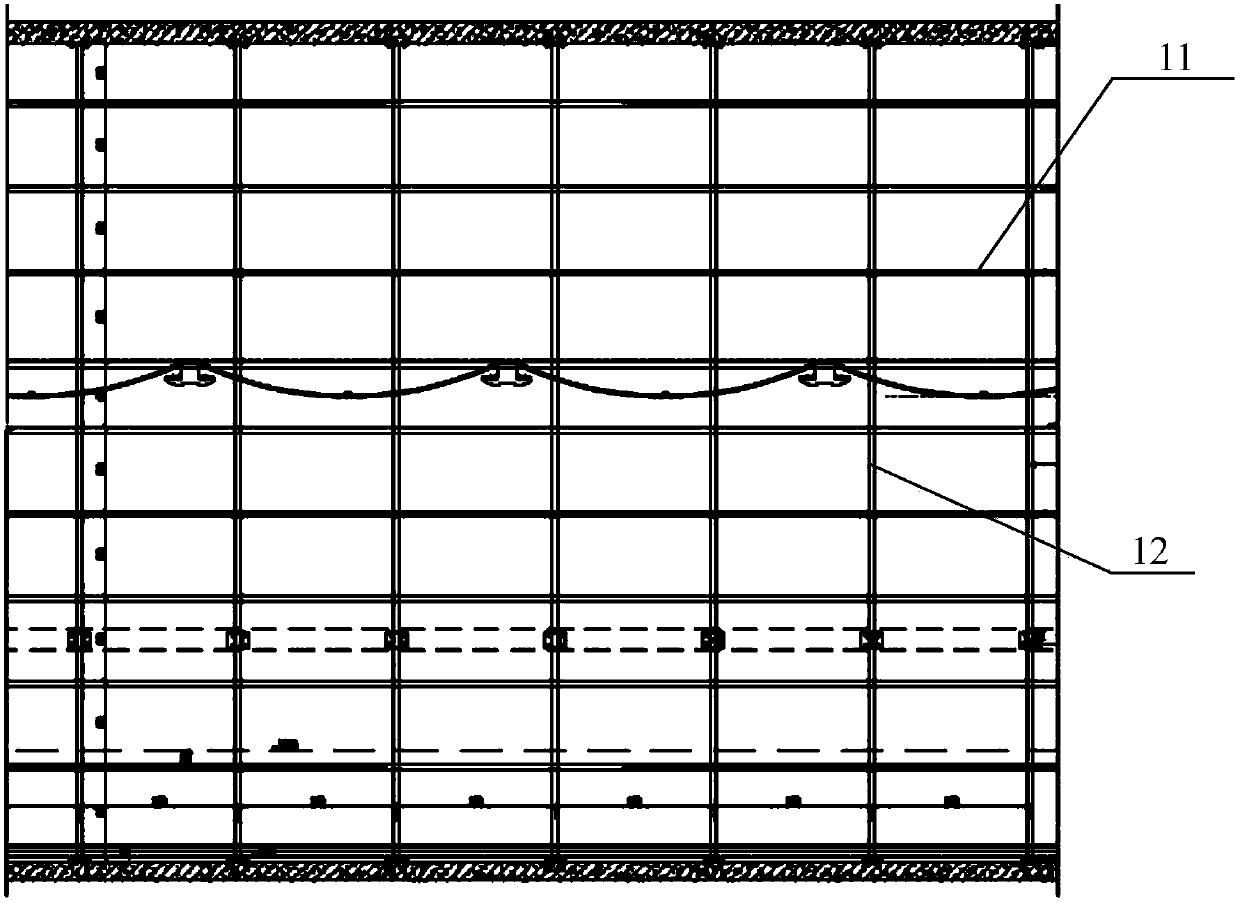

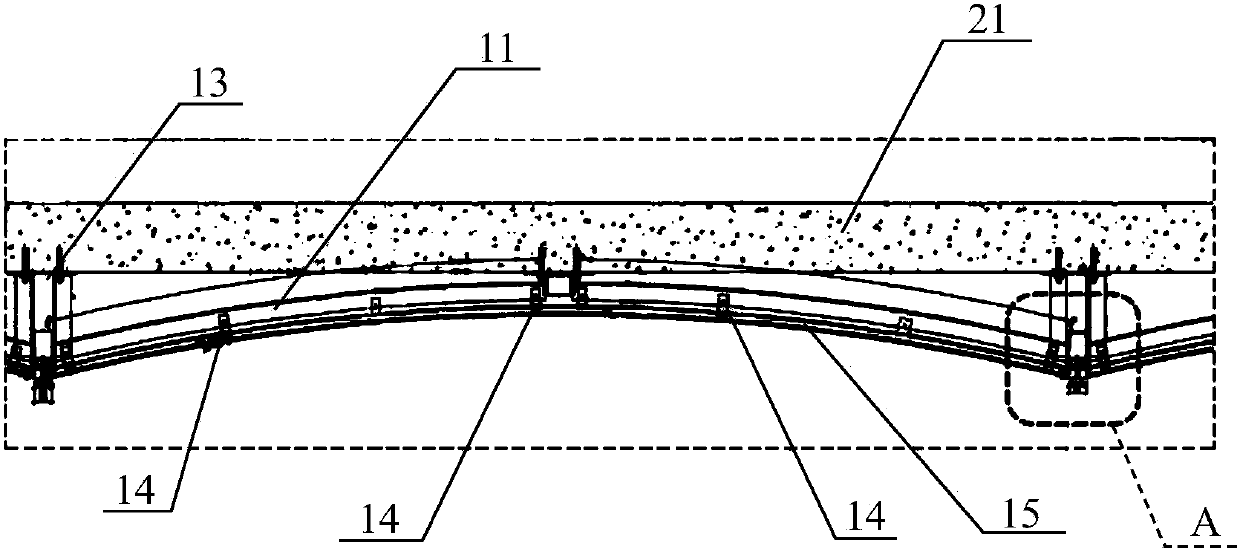

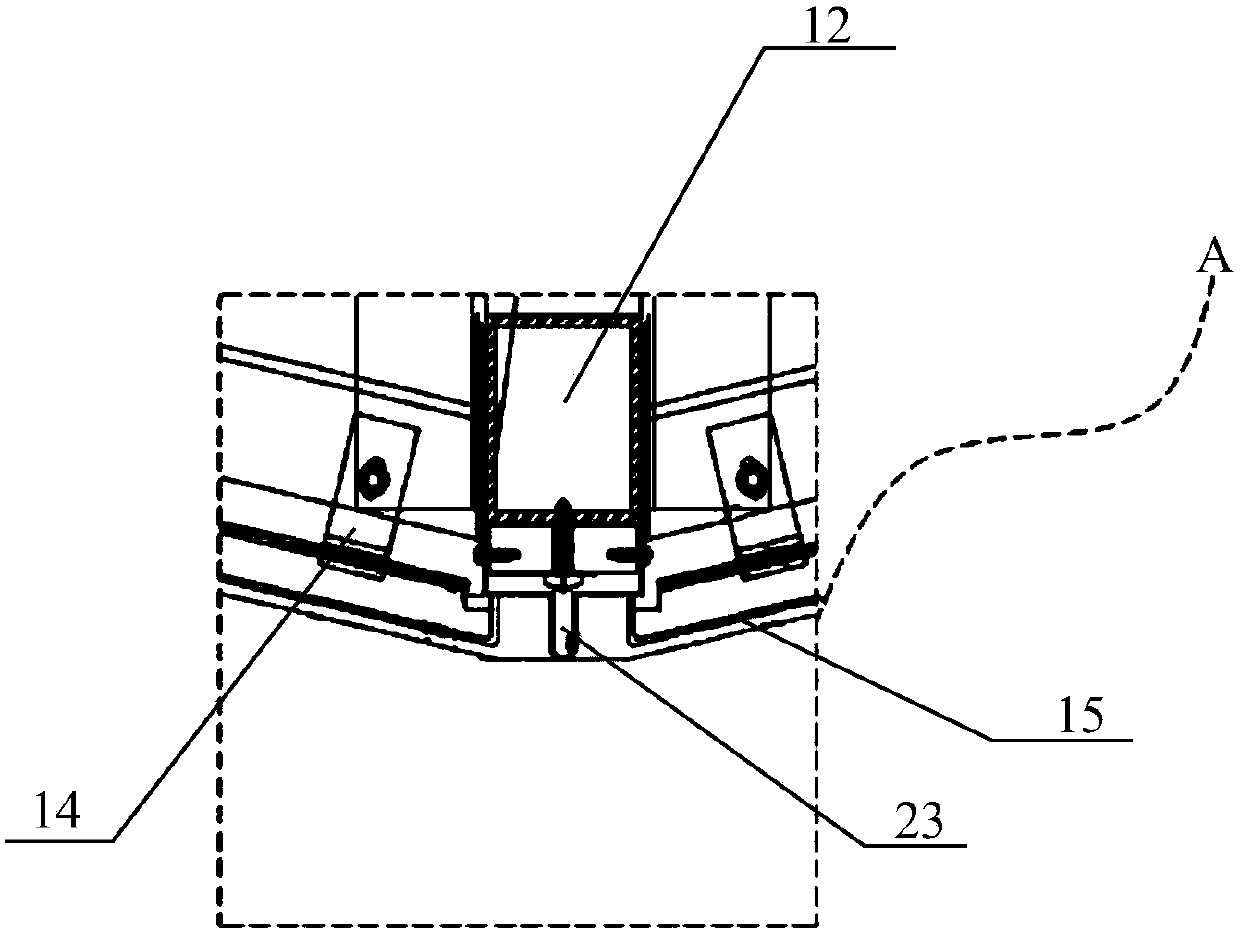

Wall surface aluminum plate system and installing method thereof

The invention provides a wall surface aluminum plate system and an installing method thereof, wherein the wall surface aluminum plate system is arranged on a wall surface, and comprises a postpositive embedded plate, a vertical keel, a transverse keel, a plurality of F-shaped corner connectors and an arc-shaped aluminum plate, wherein the postpositive embedded plate is fixedly connected with the wall surface; the vertical keel is arranged on the postpositive embedded plate; the transverse keel is in an arc shape and is transversely arranged on the vertical keel; the F-shaped corner connectors are arranged on the arc-shaped surface of the transverse keel in a scattered way; the arc-shaped aluminum plate is matched with the shape of the transverse keel; the upper end and the lower end of the arc-shaped aluminum plate are respectively arranged in the F-shaped corner connectors. The wall surface aluminum plate system and the installing method of the wall surface aluminum plate system provided by the invention have the advantages that the upper and lower folding edges of the aluminum plate are made into reverse hook structures; meanwhile, the F-shaped corner connectors are designed; the upper strip edge of the aluminum plate is hung, and the lower strip edge inserter of the aluminum plate is inserted, so that the seam sealing by using a buckle plate is not needed after the installation of the arc-shaped aluminum plate is completed; the flatness and the aluminum plate connecting seam size are uniform; the appearance is attractive.

Owner:中建八局装饰工程有限公司

Connector packaging tray with supporting standoffs

InactiveUS20040115981A1Reliable inspectionUniform flatnessCoupling device detailsSemiconductor/solid-state device manufacturingCPU socketSolder ball

A packaging tray (2) includes an elongate base (3). The base includes supporting portions (31) for receiving CPU sockets (1) therein. Each supporting portion includes four sidewalls (311), and a bottom wall (313) having an upper surface and a lower surface. Each sidewall forms an inwardly extending rib (312). Four standoffs (314) are formed on the lower surface. When mounting the CPU sockets on the upper surfaces, each CPU socket rests on the corresponding ribs, and solder balls of the CPU socket are supported by the corresponding upper surface. Thus, in handling of the CPU sockets, the solder balls are unlikely to sustain damage. Conversely, the CPU sockets can be reverse mounted on the lower surfaces. The solder balls of each CPU socket are located in a horizontal plane face up, with the standoffs supporting the CPU socket. The solder balls can be accurately inspected by a flatness inspection device.

Owner:HON HAI PRECISION IND CO LTD

Photosensitive resin composition, display device using the same

ActiveCN104007616AImprove display qualityHigh resolutionLayered productsSolid-state devicesBoiling pointDisplay device

The invention provides a photosensitive resin composition, and a display device using the same. The photosensitive resin composition comprises about 10 wt % to about 50 wt % of a solute comprising about 100 parts by weight of an acryl-based copolymer and about 5 to about 100 parts by weight of a 1,2-quinonediazide compound; and a solvent comprising a glycol-based material having a boiling point of greater than about 190 DEG C., wherein the acryl-based copolymer is a copolymer of an unsaturated carbonic acid or an anhydride thereof, an epoxy group-containing unsaturated compound, and an olefin-based unsaturated compound.

Owner:SAMSUNG DISPLAY CO LTD +1

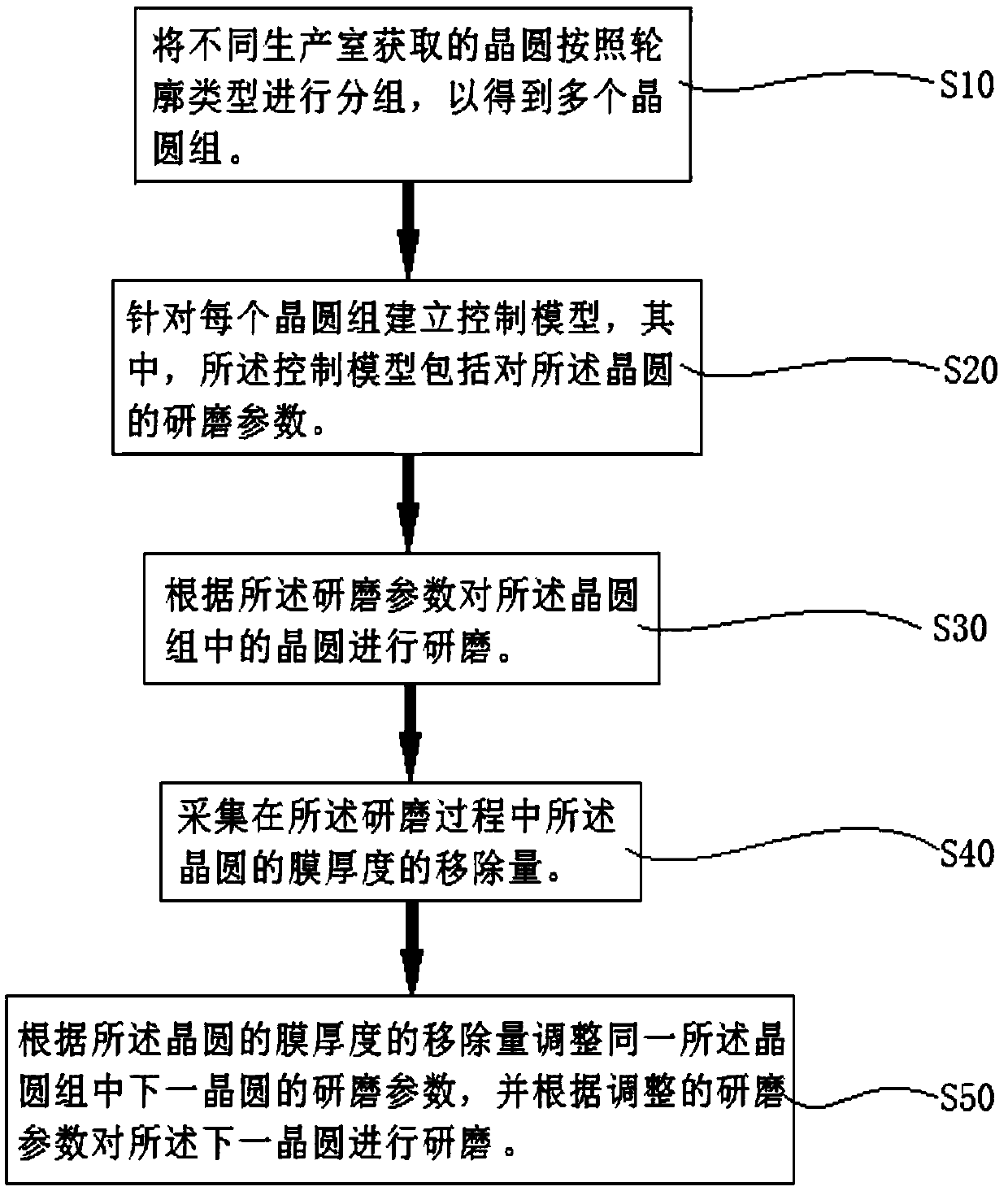

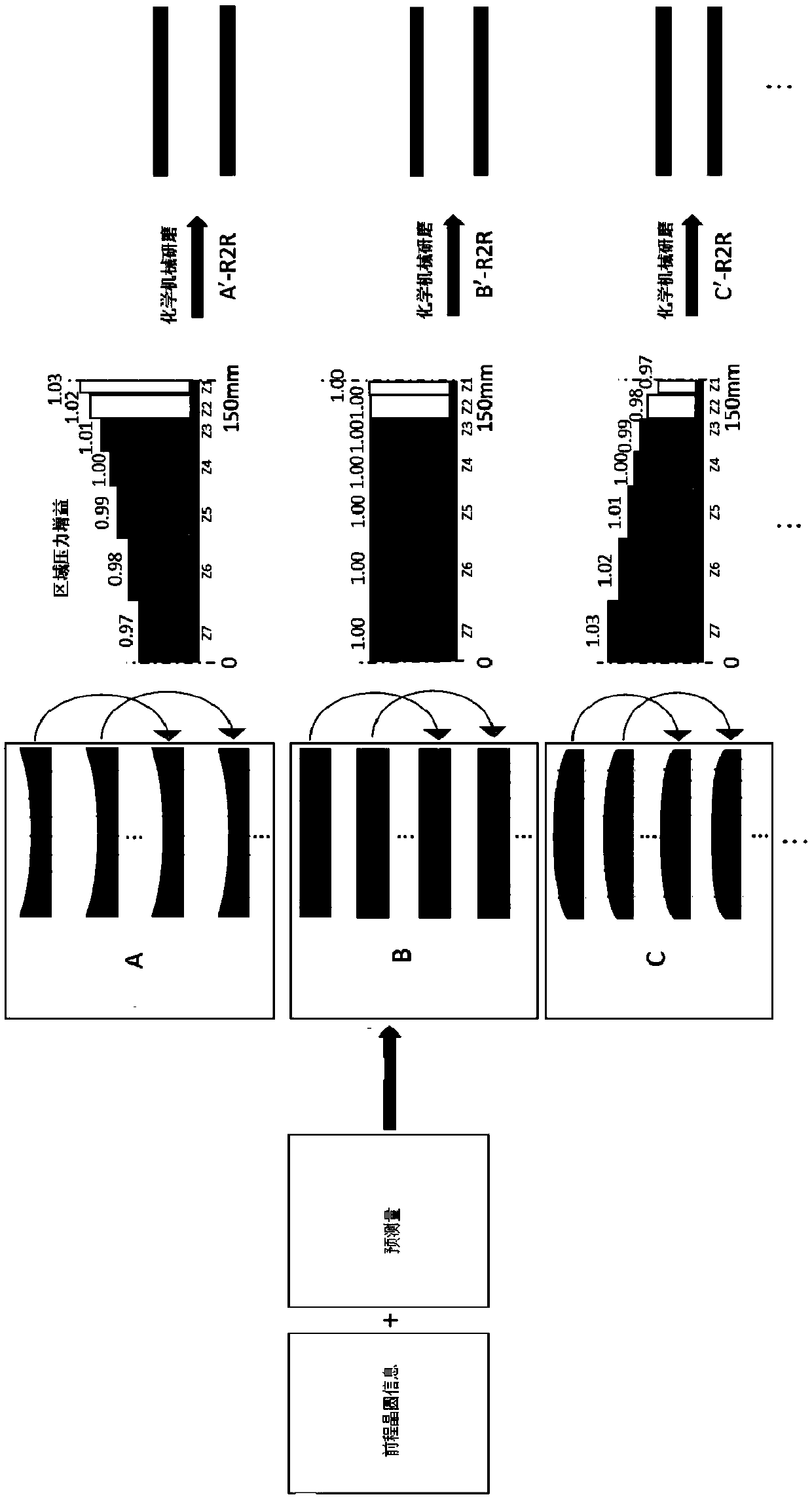

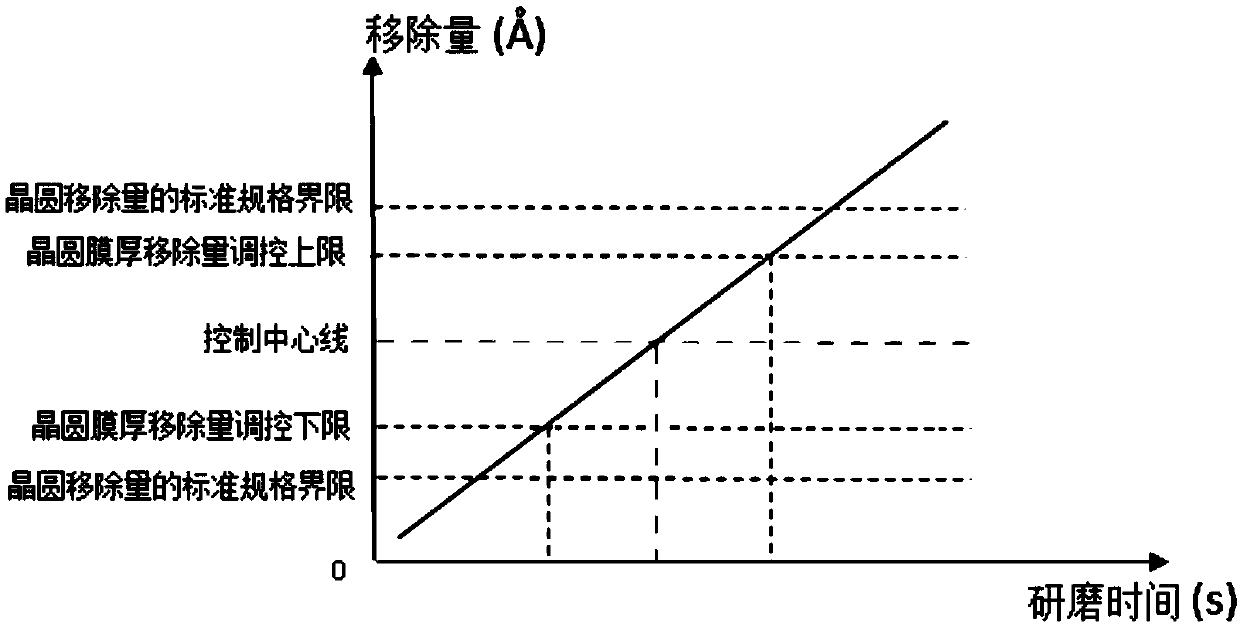

Chemical mechanical grinding processing method and system

PendingCN110497303AEasy to understand implementationEasy to understandLapping machinesControl systemEngineering

The invention provides a chemical mechanical grinding processing method and system. The method comprises the following steps: wafers obtained by different production chambers are grouped according toprofile types to obtain multiple wafer sets; control models are built for each wafer set, and comprise wafer grinding parameters; the wafers in the wafer sets are grinded according to the grinding parameters; wafer film thickness removing quantities are acquired in the grinding process; the grinding parameters of the next wafers in the same wafer sets are adjusted according to the wafer film thickness removing quantities; and the next wafers are grinded according to the adjusted grinding parameters. The system comprises the production chambers and grinding devices; the wafers produced by the different production chambers have different surface profiles; and the grinding devices are used for realizing the chemical mechanical grinding processing method. The wafers with different profiles aregrouped; and one wafer set corresponds to one control system, so that the grinding parameters of chemical mechanical grinding processing are dynamically adjusted, and the wafer flatness in the chemical mechanical grinding processing is improved.

Owner:CHANGXIN MEMORY TECH INC

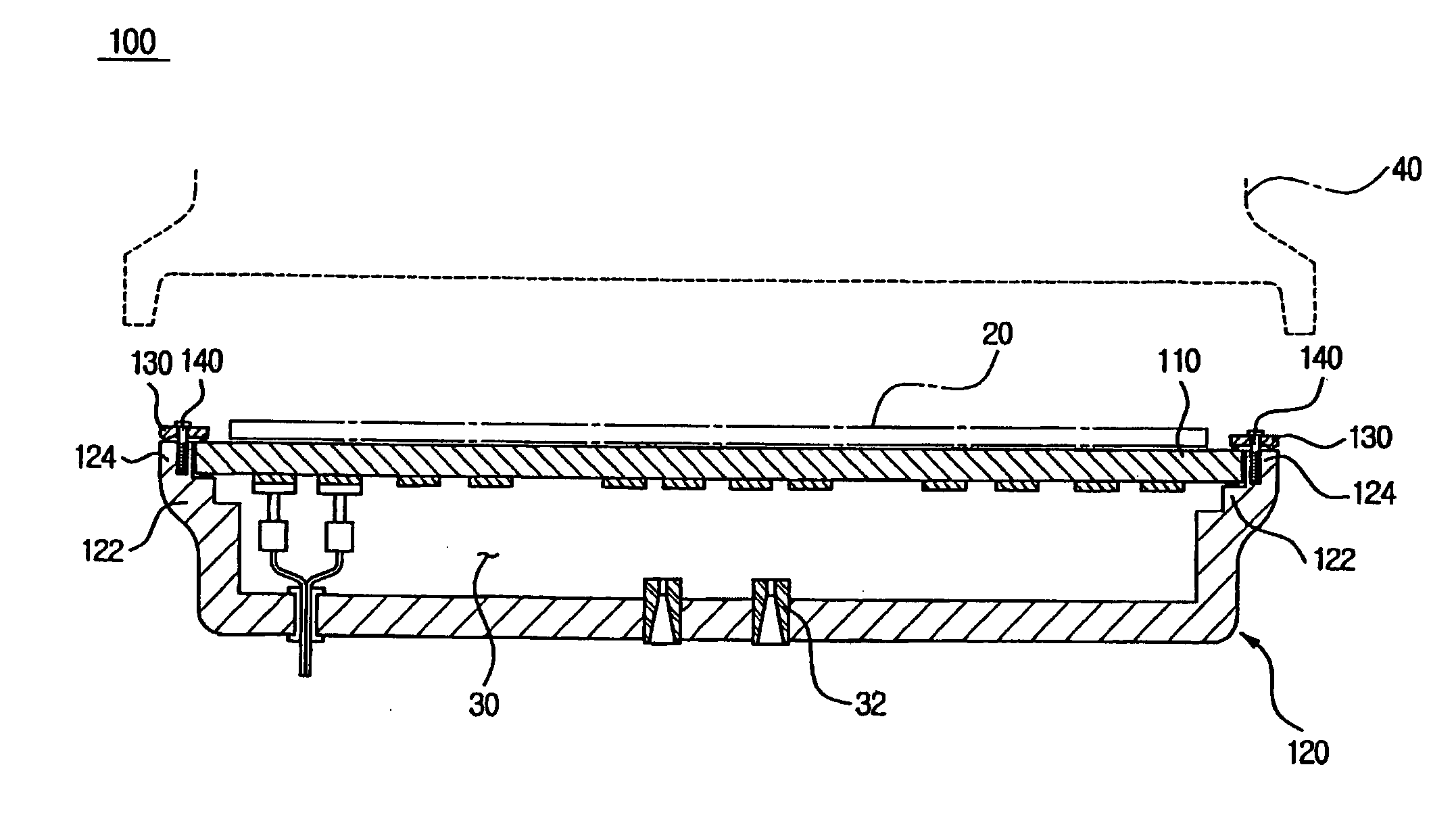

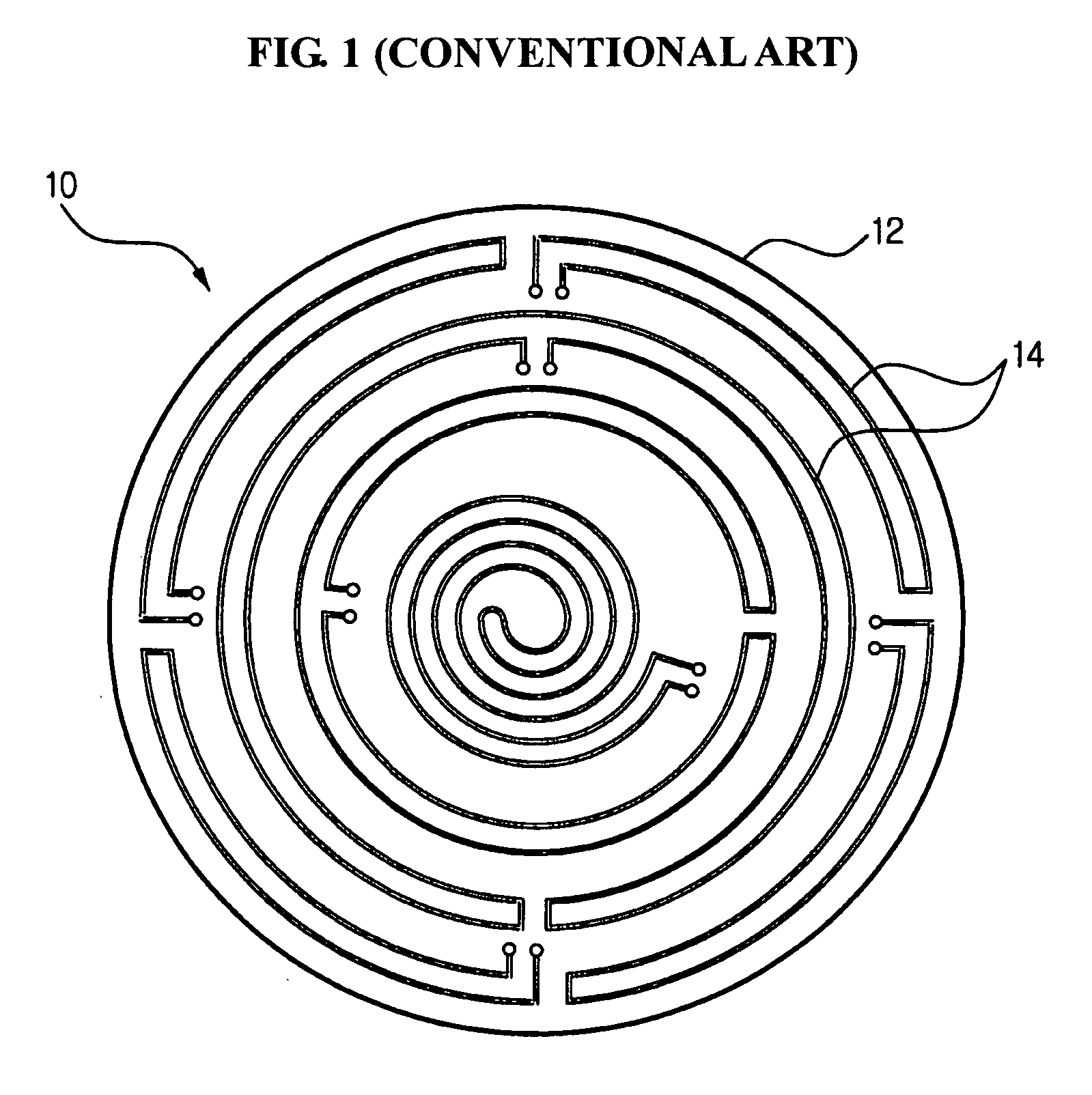

Wafer heating apparatus and method of setting the apparatus

InactiveUS20070025708A1Evenly distributedEasy to correctDrying solid materials with heatSemiconductor/solid-state device manufacturingEngineeringControl unit

A wafer apparatus including a heating plate, a case supporting and containing the heating plate, pressing arms laid across the case and the heating plate, and arm controlling units vertically moving the pressing arm toward the case. A plurality of the pressing arms and the arm controlling units are disposed along the circumference of the heating plate and may compensate a portion protruded upward due to the warpage of the heating plate by pressurizing. The warpage of the heating plate can be effectively compensated, and a wafer can be heated with a uniform temperature.

Owner:SAMSUNG ELECTRONICS CO LTD

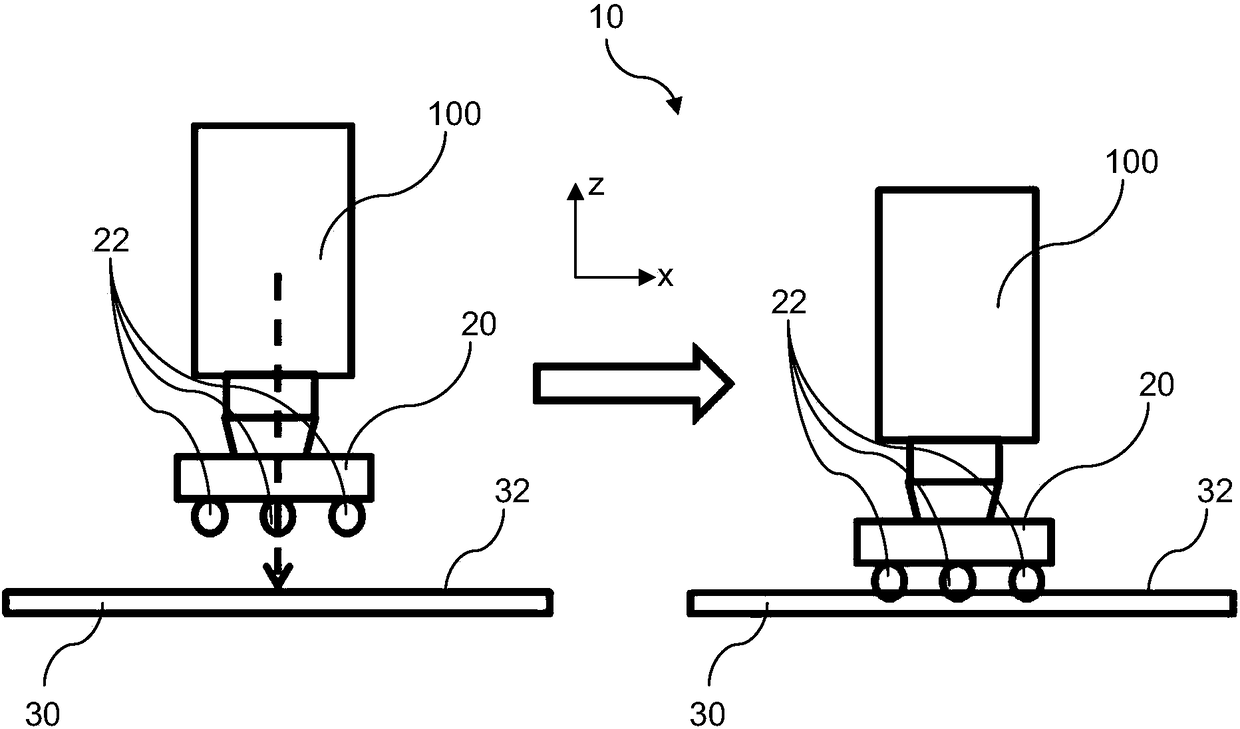

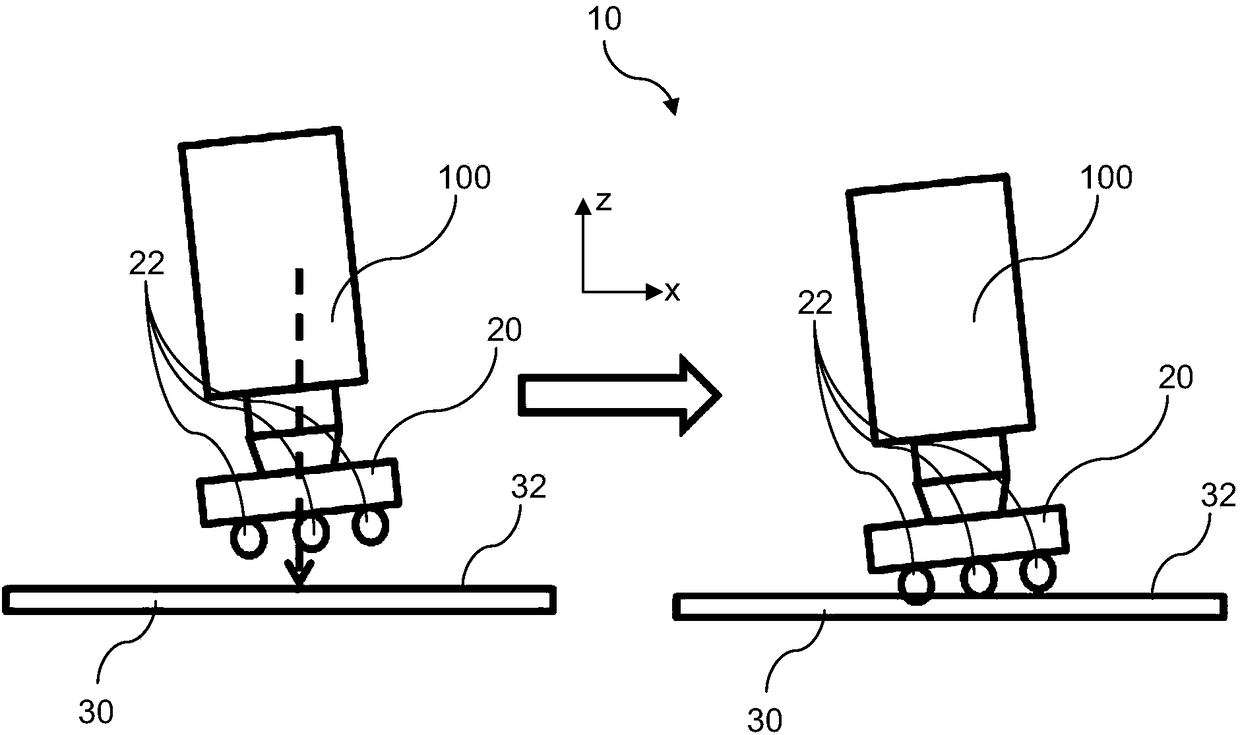

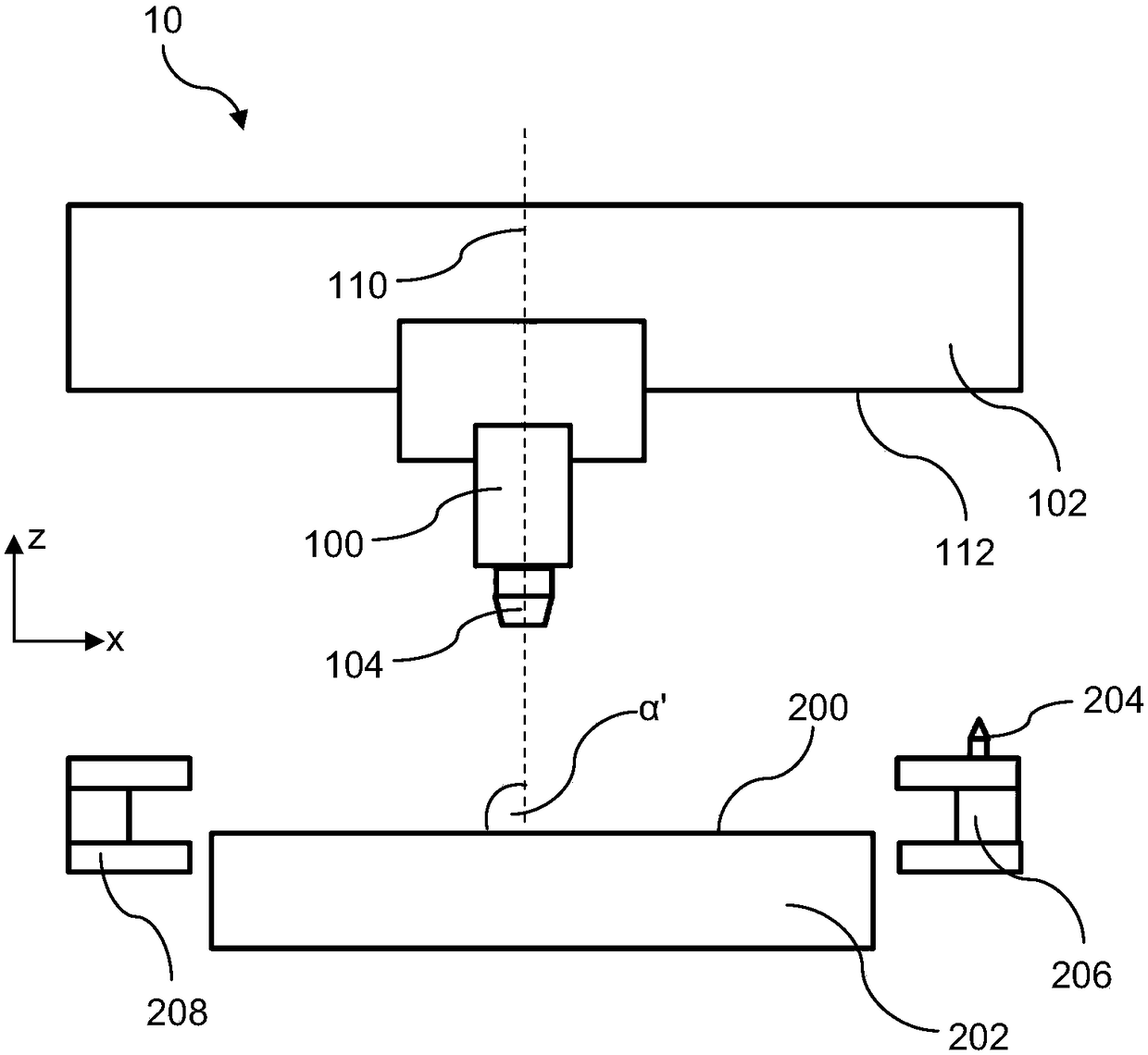

Method and system for automatic bond arm alignment

ActiveCN108346608AUniform flatnessShorten the timeSolid-state devicesSemiconductor/solid-state device manufacturingBonding processEngineering

A method, as well as a system implementing the method, for automatically aligning a bond arm with respect to a bonding support surface for supporting a substrate during a bonding process. The method comprises: rotating the bond arm for a first revolution around a longitudinal axis through a bond head moveably coupled to the bond arm, the first revolution including a plurality of predefined rotaryangular positions; pausing the rotation of the bond arm at each of the plurality of rotary angular positions; determining a tilt angle of the bond arm relative to the bonding support surface during each pause at the respective rotary angular position; and selecting the rotary angular position of the bond arm which has a tilt angle that satisfies a predefined specification such that the bond arm isaligned substantially perpendicular to the bonding support surface.

Owner:ASM TECH SINGAPORE PTE LTD

Automatic winding and roll changing system for wet-process lithium battery diaphragm

PendingCN114212584AImprove flatnessRealize automatic roll changeCell component detailsWebs handlingDrive wheelEngineering

The invention discloses a wet-process lithium battery diaphragm automatic winding and roll changing system which comprises a guide roller and a tension roller which are vertically arranged at an interval, a tension bearing is installed at the end of the tension roller, a pair of shearing rollers which are vertically arranged at an interval are arranged behind the guide roller and the tension roller in the advancing direction of a diaphragm, and the upper side and the lower side of the diaphragm are attached to the two shearing rollers respectively. A moving roller is arranged behind the shearing roller, a winding and reel changing mechanism is arranged behind the moving roller and comprises a driving wheel and a driven wheel driven by the driving wheel to rotate, two winding rollers with the same height position are arranged on the two sides of the axis of the driven wheel respectively, and a film scratching mechanism is arranged below the winding roller close to the driven wheel. The membrane scratching mechanism comprises a support and a driving mechanism for driving the support to move up and down, an electrostatic generator, a rotating brush, a cutter and a pressing roller are installed on the support, the driven wheel rotates during roll changing, the positions of the two winding rollers are exchanged, and a membrane sequentially bypasses the positions below the two winding rollers; when the diaphragm is scratched, the driving mechanism drives the support to move upwards, and the cutter cuts off the diaphragm.

Owner:SINOMA LITHIUM BATTERY SEPARATOR CO LTD

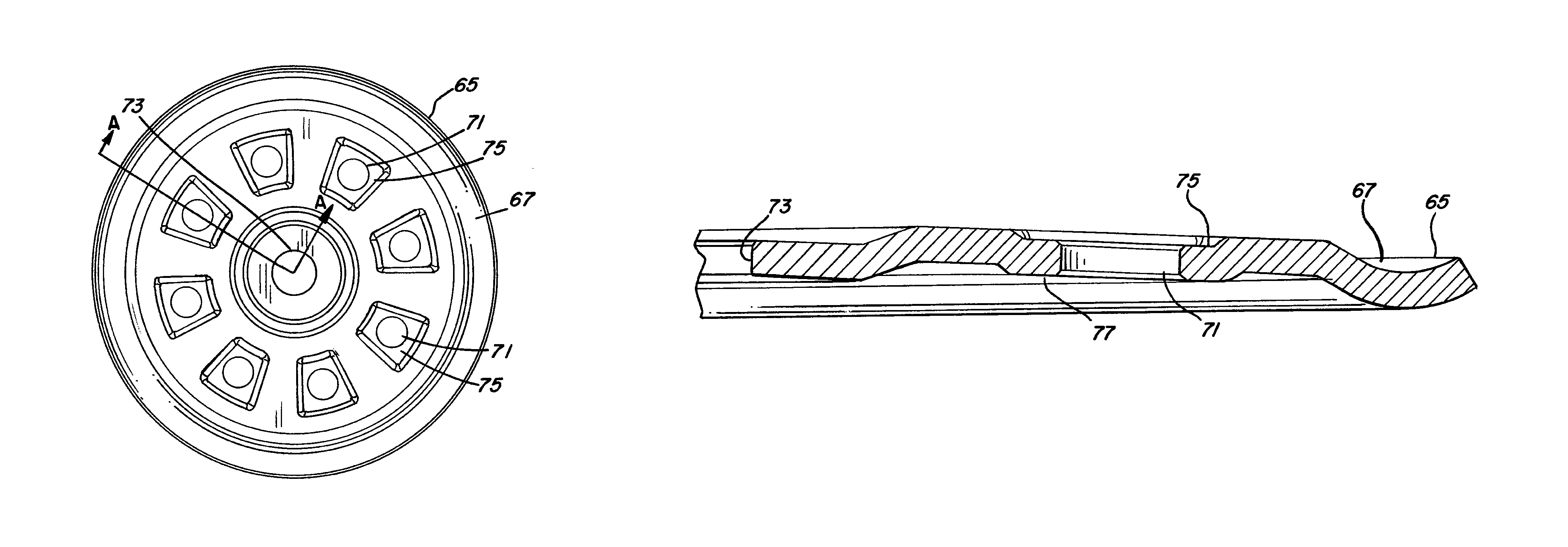

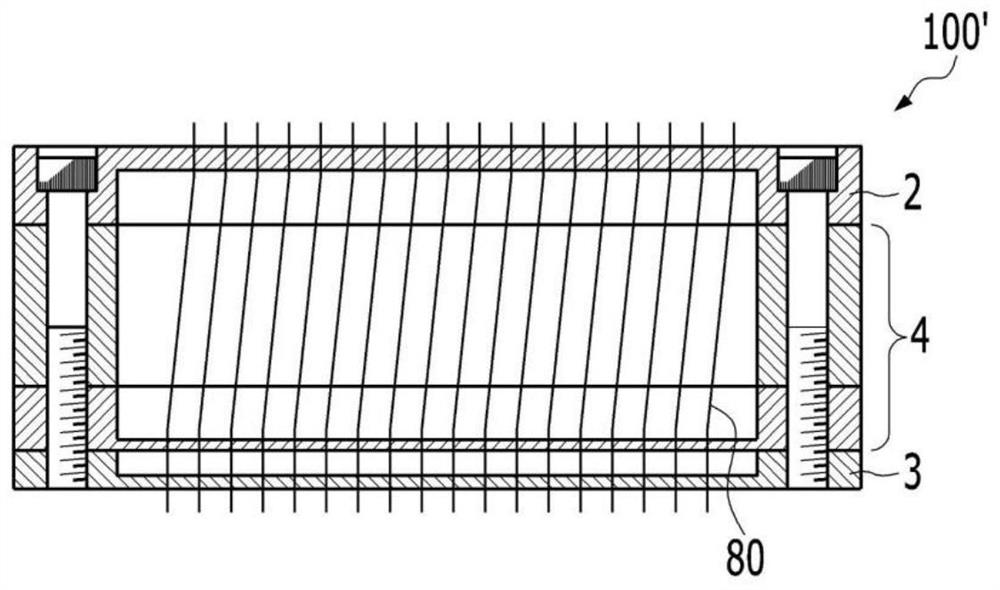

Disk clamp having uniform clamping load and index mark

ActiveUS8824099B2Uniform flatnessUniform forceRecord information storagePackagingRefractive indexEngineering

Owner:INTRL PLEX TECH INC

Probe card

ActiveUS20210102975A1Small sizeDecrease pitchElectronic circuit testingElectrical measurement instrument detailsProbe cardWafering

Proposed is a probe card for performing a circuit test on a wafer and, more particularly, a probe card capable of realizing a reduction in size and pitch of probe insertion holes.

Owner:POINT ENG

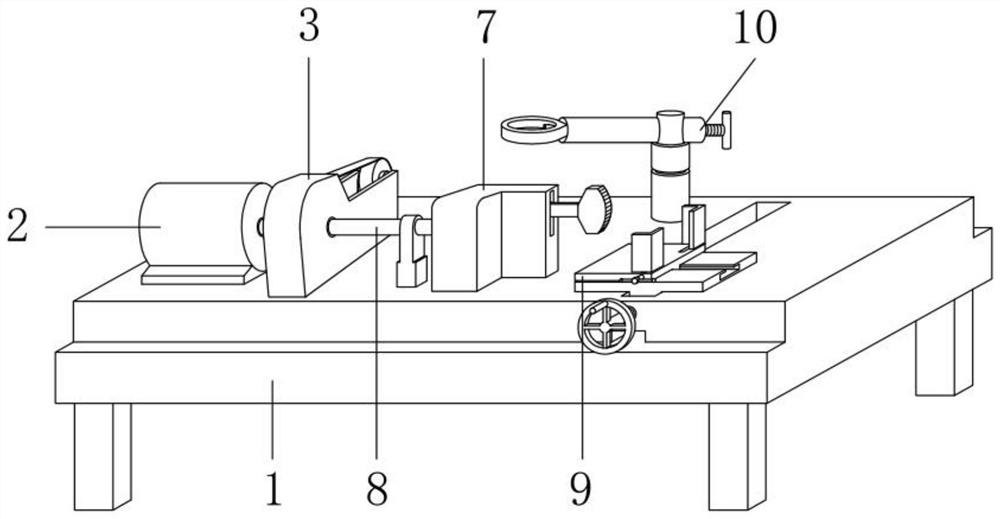

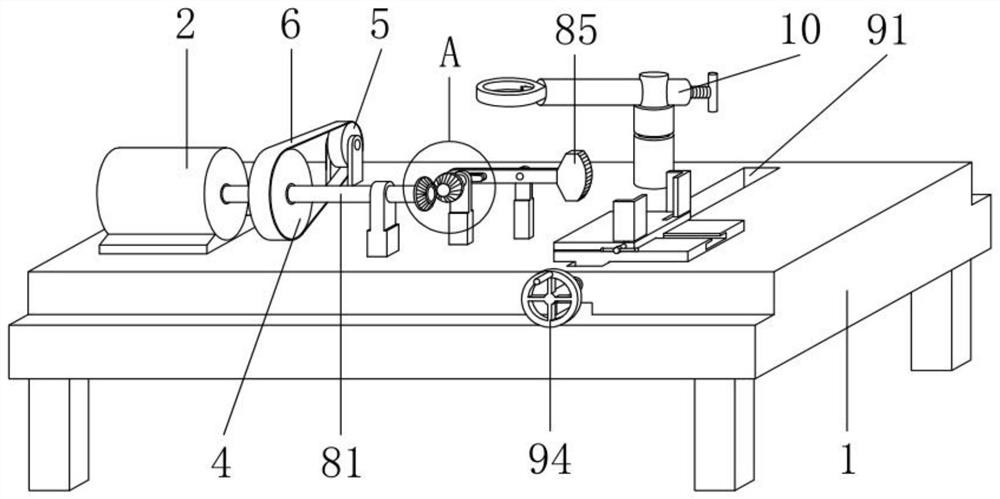

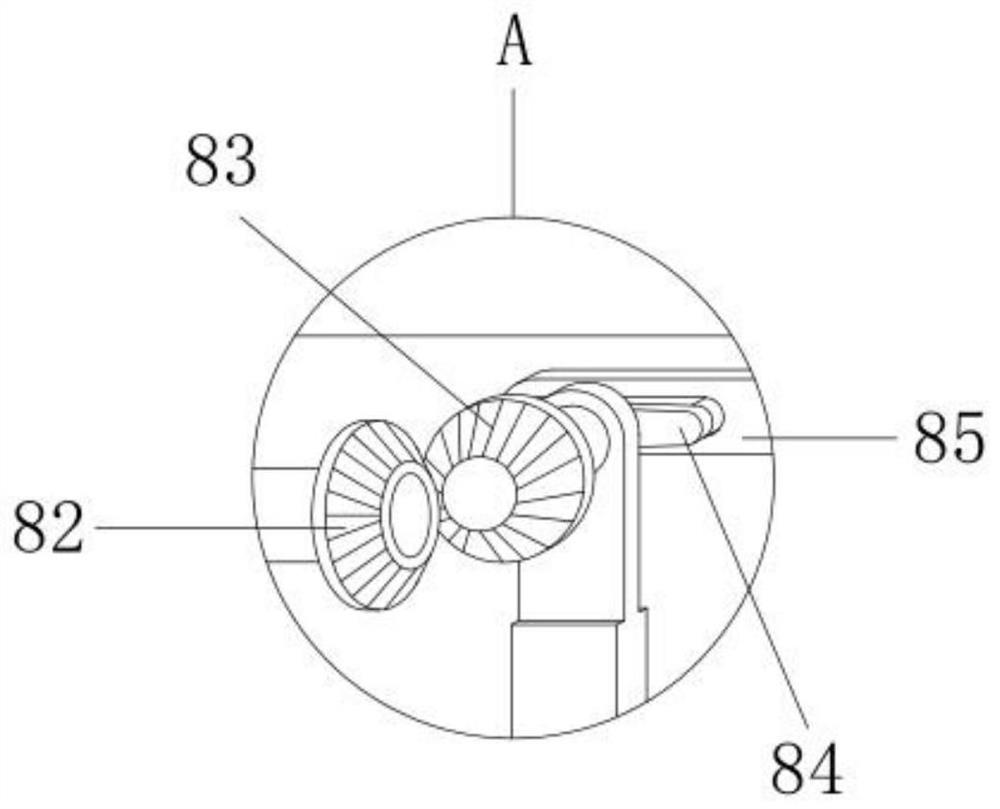

Metal workpiece heat treatment detection polishing device

InactiveCN112091783AAvoid damageReduce the difficulty of detectionGrinding carriagesGrinding drivesPolishingElectric machinery

The invention discloses a metal workpiece heat treatment detection polishing device which comprises a base, a motor, a first shell, a first rotating wheel and a second rotating wheel. Supports are arranged at all the four corners of the bottom end of the base. The motor is in screw connection with the left side of the top end of the base in the left-right direction, and the first shell is locatedon the right side of the motor and is in screw connection with the upper surface of the base in the front-back direction. The first rotating wheel is in key connection with the output end of the motor, and the second rotating wheel is located on the rear side of an inner cavity of the first shell and connected with the upper surface of the base through a bearing. According to the metal workpiece heat treatment detection polishing device, the problem that a workpiece is damaged due to misoperation caused by manual operation of workers is avoided, and the surface of the workpiece is polished more completely. The surface residue is avoided, the polishing flatness is uniform, the detection result is more accurate, workpieces of different shapes and sizes can be ground, and the use is more flexible. The detection difficulty of the workpieces is reduced.

Owner:刘雄

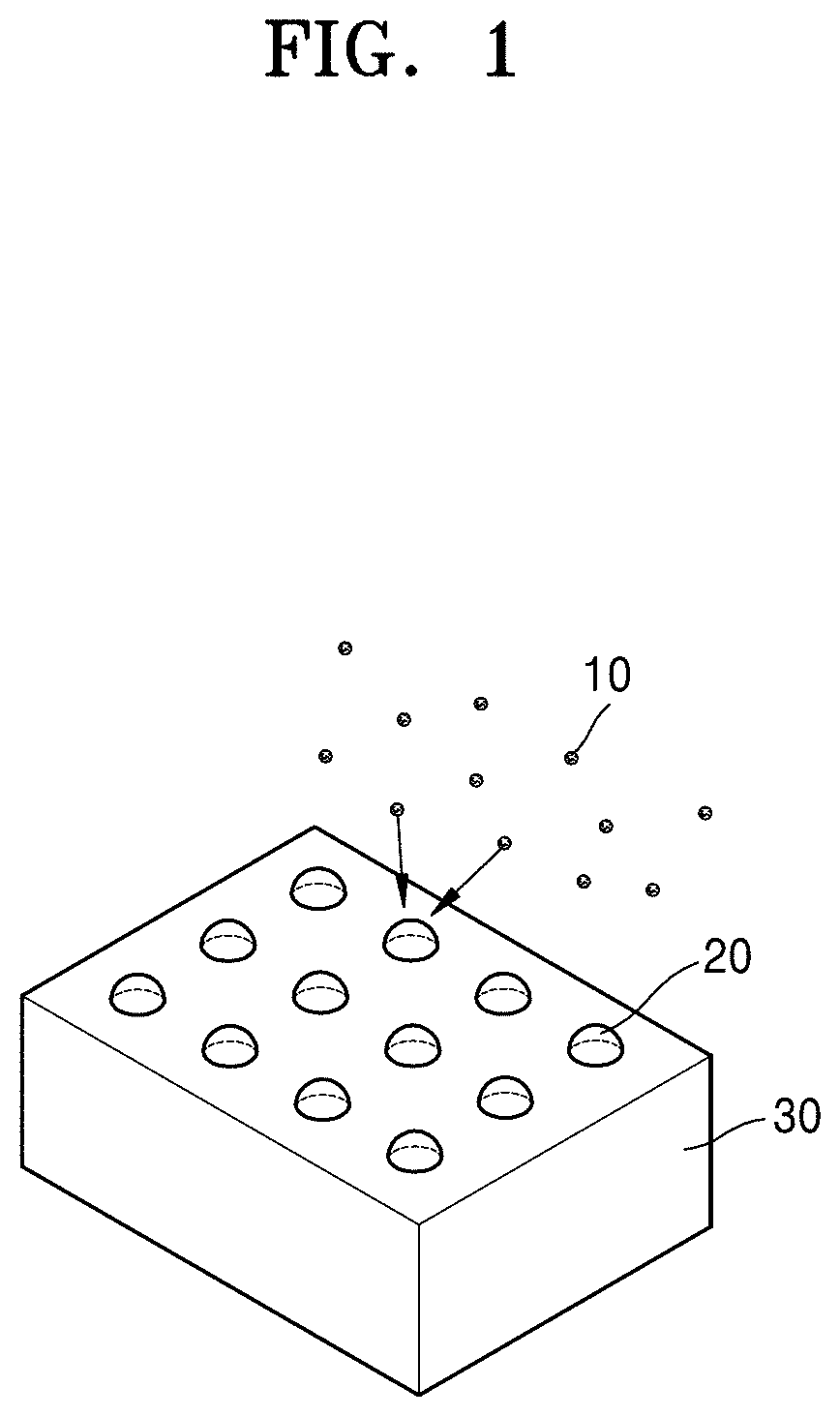

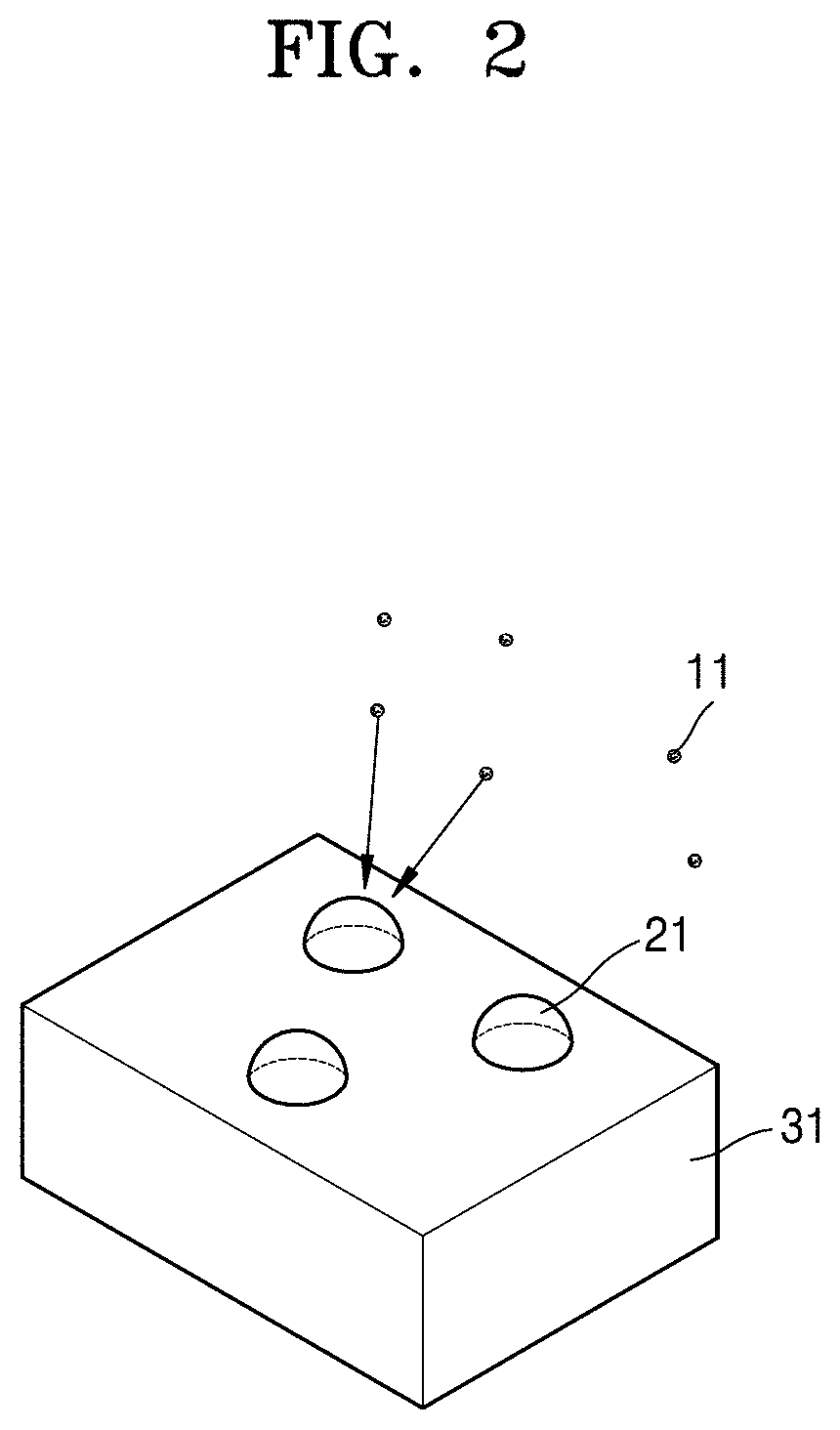

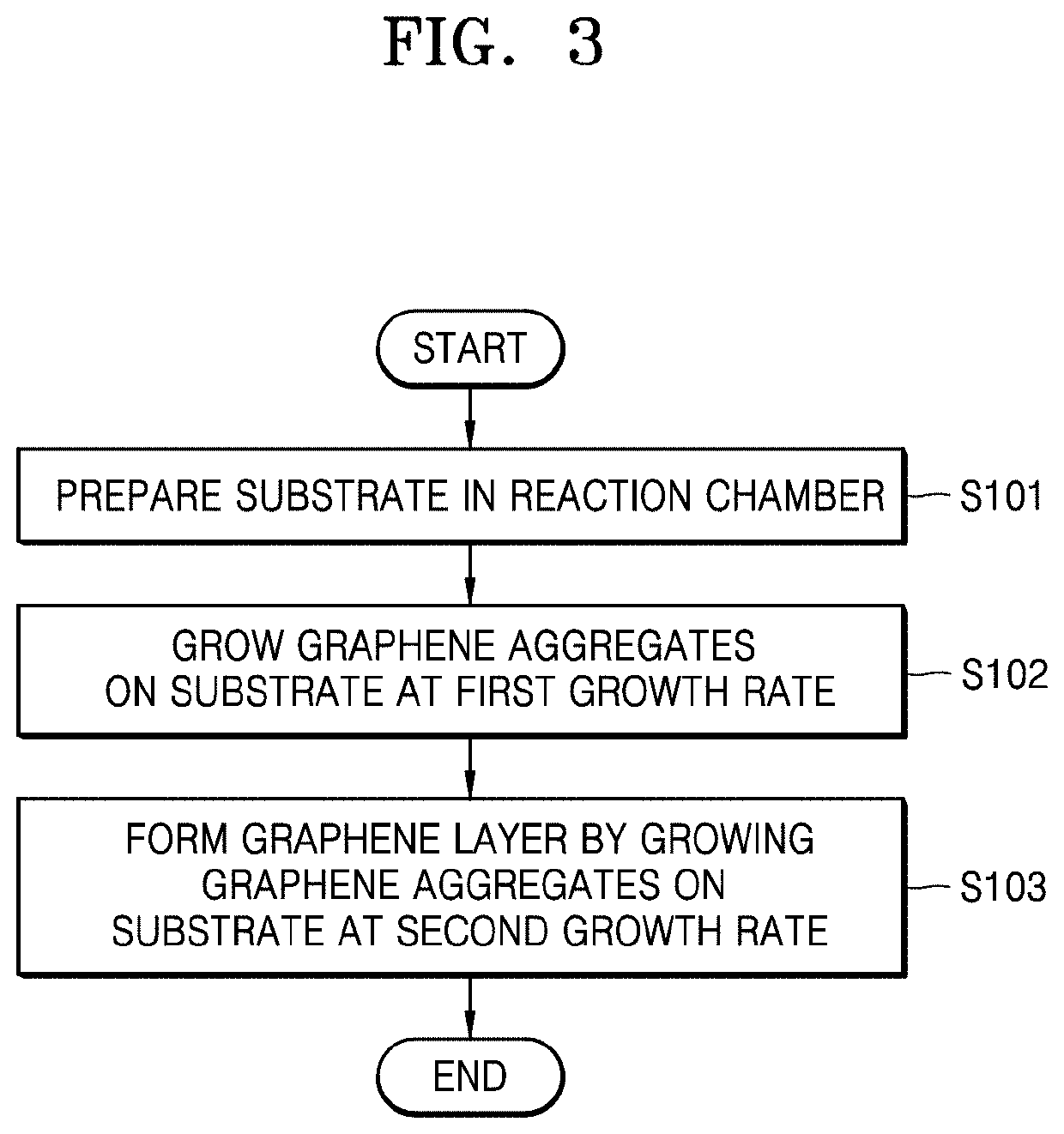

Method of forming graphene

PendingUS20210163296A1Uniform flatnessQuality improvementGrapheneSemiconductor/solid-state device manufacturingGraphiteGraphene

A method of forming graphene includes: preparing a substrate in a reaction chamber; performing a first growth process of growing a plurality of graphene aggregates apart from each other on the substrate at a first growth rate by using a reaction gas including a carbon source; and performing a second growth process of forming a graphene layer by growing the plurality of graphene aggregates at a second growth rate slower than the first growth rate by using the reaction gas including the carbon source.

Owner:SAMSUNG ELECTRONICS CO LTD

Wall aluminum plate system and its installation method

The invention provides a wall surface aluminum plate system and an installing method thereof, wherein the wall surface aluminum plate system is arranged on a wall surface, and comprises a postpositive embedded plate, a vertical keel, a transverse keel, a plurality of F-shaped corner connectors and an arc-shaped aluminum plate, wherein the postpositive embedded plate is fixedly connected with the wall surface; the vertical keel is arranged on the postpositive embedded plate; the transverse keel is in an arc shape and is transversely arranged on the vertical keel; the F-shaped corner connectors are arranged on the arc-shaped surface of the transverse keel in a scattered way; the arc-shaped aluminum plate is matched with the shape of the transverse keel; the upper end and the lower end of the arc-shaped aluminum plate are respectively arranged in the F-shaped corner connectors. The wall surface aluminum plate system and the installing method of the wall surface aluminum plate system provided by the invention have the advantages that the upper and lower folding edges of the aluminum plate are made into reverse hook structures; meanwhile, the F-shaped corner connectors are designed; the upper strip edge of the aluminum plate is hung, and the lower strip edge inserter of the aluminum plate is inserted, so that the seam sealing by using a buckle plate is not needed after the installation of the arc-shaped aluminum plate is completed; the flatness and the aluminum plate connecting seam size are uniform; the appearance is attractive.

Owner:中建八局装饰工程有限公司

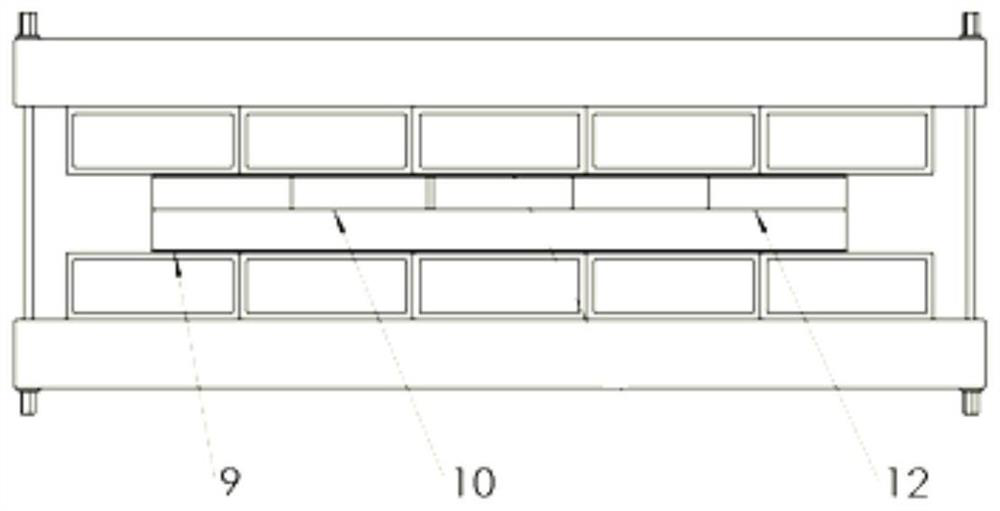

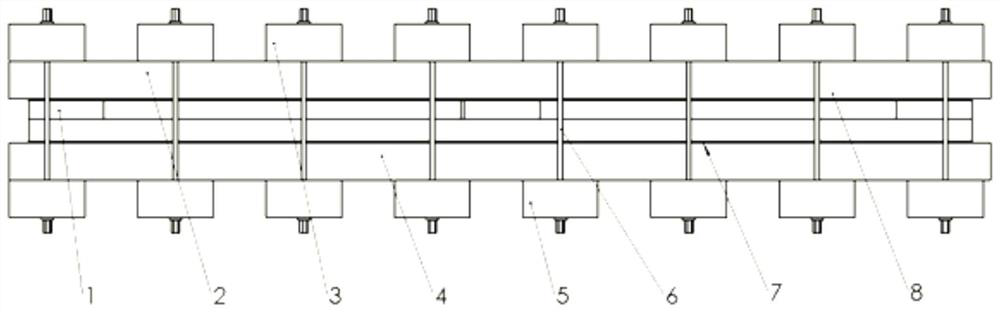

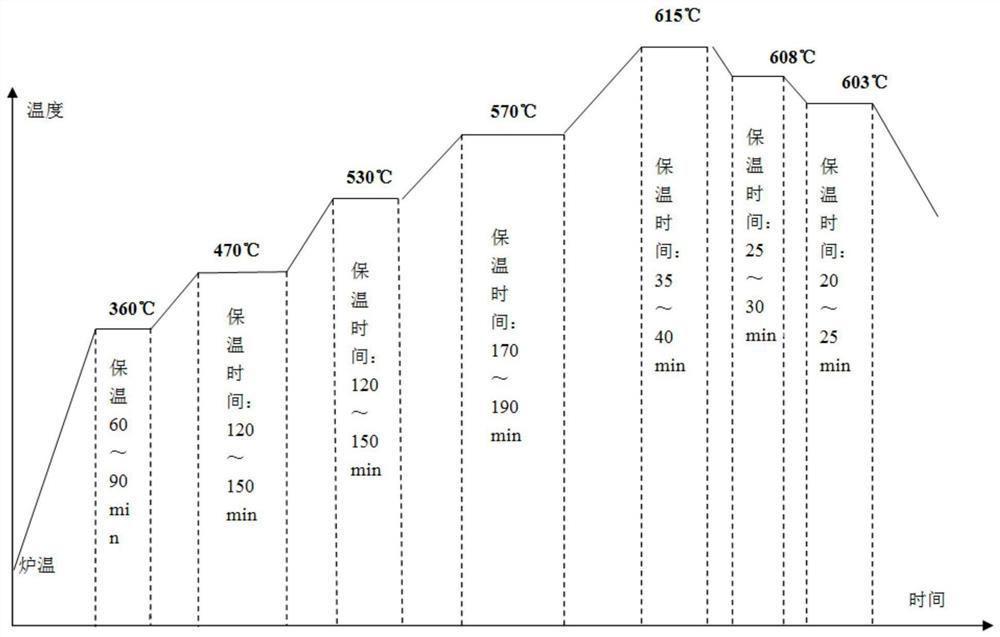

Ultra-large cold plate vacuum brazing method and a tool for vacuum brazing

ActiveCN113732429AAchieve productionReduce the difficulty of productionMetal working apparatusSoldering auxillary devicesFurnace temperatureGraphite

The invention provides an ultra-large cold plate vacuum brazing method and a tool for vacuum brazing. The tool sequentially comprises an upper clamping plate, an upper square pipe, an upper base plate, an elastic device, a middle base plate, upper graphite paper, lower graphite paper, a lower base plate, a lower square pipe and a lower clamping plate from top to bottom, the elastic device is formed by combining a plurality of independent cylindrical springs, and the tool is integrally pressurized. Existing vacuum equipment is used for welding an ultra-large cold plate, and brazing is conducted according to the route of the furnace temperature to 360 DEG C to 470 DEG C to 530 DEG C to 570 DEG C to 615 DEG C to 608 DEG C to 603 DEG C. According to the brazing tool, the assembly difficulty of the ultra-large cold plate is reduced, the welding quality of the large-area cold plate is improved, the welding technical problem of the ultra-large cold plate is solved through successful application of the brazing tool, and meanwhile the industry image of an enterprise is improved.

Owner:贵州永红换热冷却技术有限公司

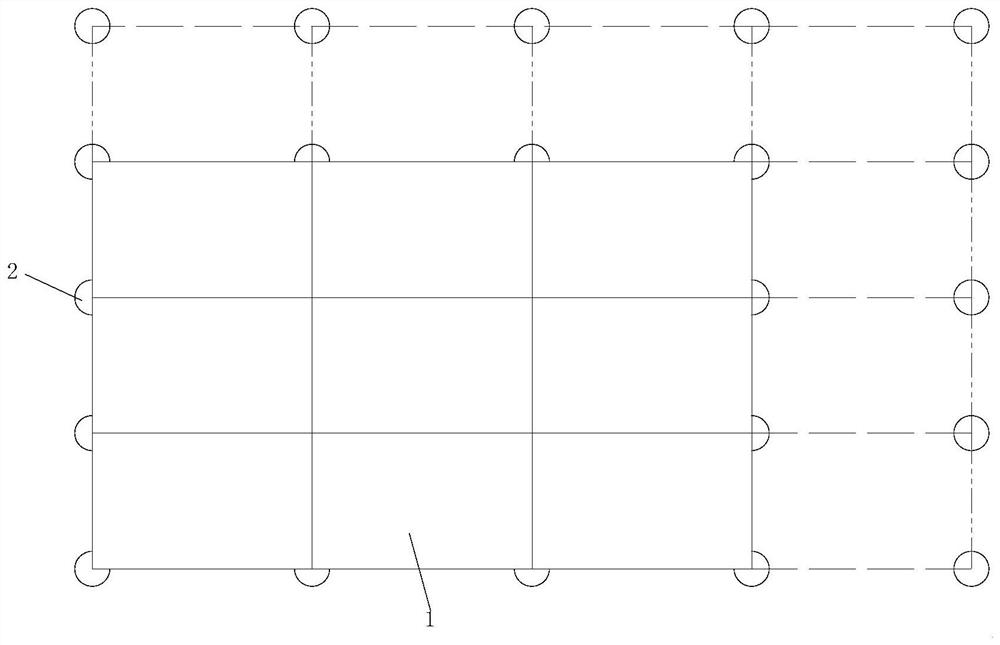

Overhead mounted waterless spliced floor tile and preparation and mounting method thereof

InactiveCN113356516APlay a role in strengthening the supportEasy to fixFalse floorsEngineeringStructural engineering

The invention discloses an overhead mounted waterless spliced floor tile. The overhead mounted waterless spliced floor tile comprises a tile body and a leveling support leg, wherein the leveling support leg comprises a base and a panel, nuts are respectively fixed in the base and the panel, and a stud is in threaded connection between the two nuts. The invention further discloses a preparation method of the overhead mounted waterless spliced floor tile. The preparation method comprises the following steps of (S1) forming side grooves in the side surfaces of a reinforcing bottom plate; and (S2) after the reinforcing bottom plate and a tile plate are bonded through a bonding layer, applying external force to press the reinforcing bottom plate and the tile plate so as to form a tile body. The invention further discloses a mounting method of the overhead mounted waterless spliced floor tile. According to the overhead mounted waterless spliced floor tile and the preparation and mounting method, the reinforcing bottom plate is bonded to the bottom surface of the fragile tile plate so as to reinforce and support the tile plate, the side grooves are formed in the side surfaces of the reinforcing bottom plate on the basis, compared with a preparation method that the side grooves are formed in the fragile tile plate, the machining is simple, two tile bodies are fixed firmly through splicing of splicing strips and the side grooves, and the stability is high.

Owner:上海品宅装饰科技有限公司

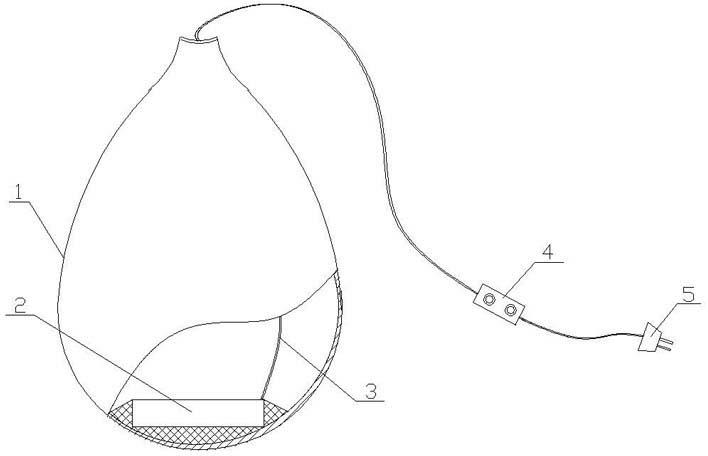

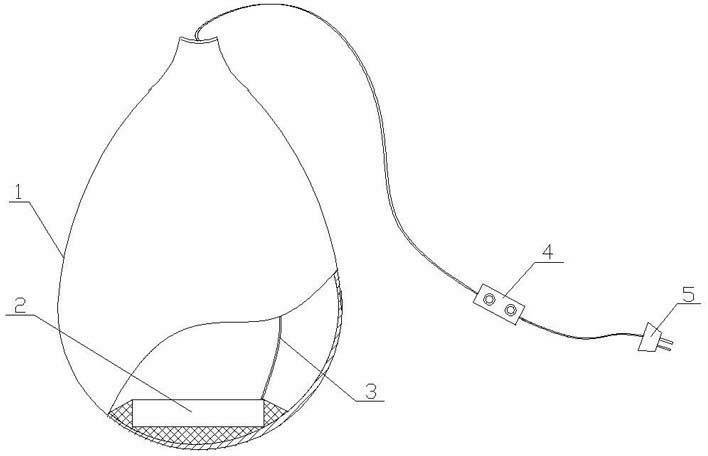

Multifunctional junporcelain massage tank

InactiveCN102319178ASimple structureHas a health effectDevices for heating/cooling reflex pointsDevices for pressing relfex pointsHollow coreElectricity

The invention discloses a multifunctional junporcelain massage tank, which comprises a junporcelain tank body with a hollow structure, wherein an electromagnetic vibrator is fixedly arranged in an inner cavity of the junporcelain tank body; an iron core of the electromagnetic vibrator is made of a silicon steel sheet; and a control lead of the electromagnetic vibrator is led out of a tank opening of the junporcelain tank body and is electrically connected with a power supply plug by a control switch; the lower part of the junporcelain tank body has a hemispheroid structure; and the vibration frequency of the electromagnetic vibrator is 183 revolutions / minute. The multifunctional junporcelain massage tank has the advantages that a junporcelain tank fired in Shenhou town, Yuzhou city, Henan province is used as a matrix tank, patients energize the electromagnetic vibrator in the junporcelain tank body under the guidance of medical care personnel, so that the iron core is heated to generate far infrared rays, and the tank body is placed at treatment acupoints, main and collateral channels or pathological change sites, so that a trace element, namely copper, in junporcelain enamel acts on human bodies to replenish the copper element to the human bodies. The multifunctional junporcelain massage tank has a simple structure, the copper element in the enamel acts on the human bodies under the vibrating action of the electromagnetic vibrator in the tank body after the electromagnetic vibrator is energized, so the massage tank has a certain health care effect.

Owner:李高申

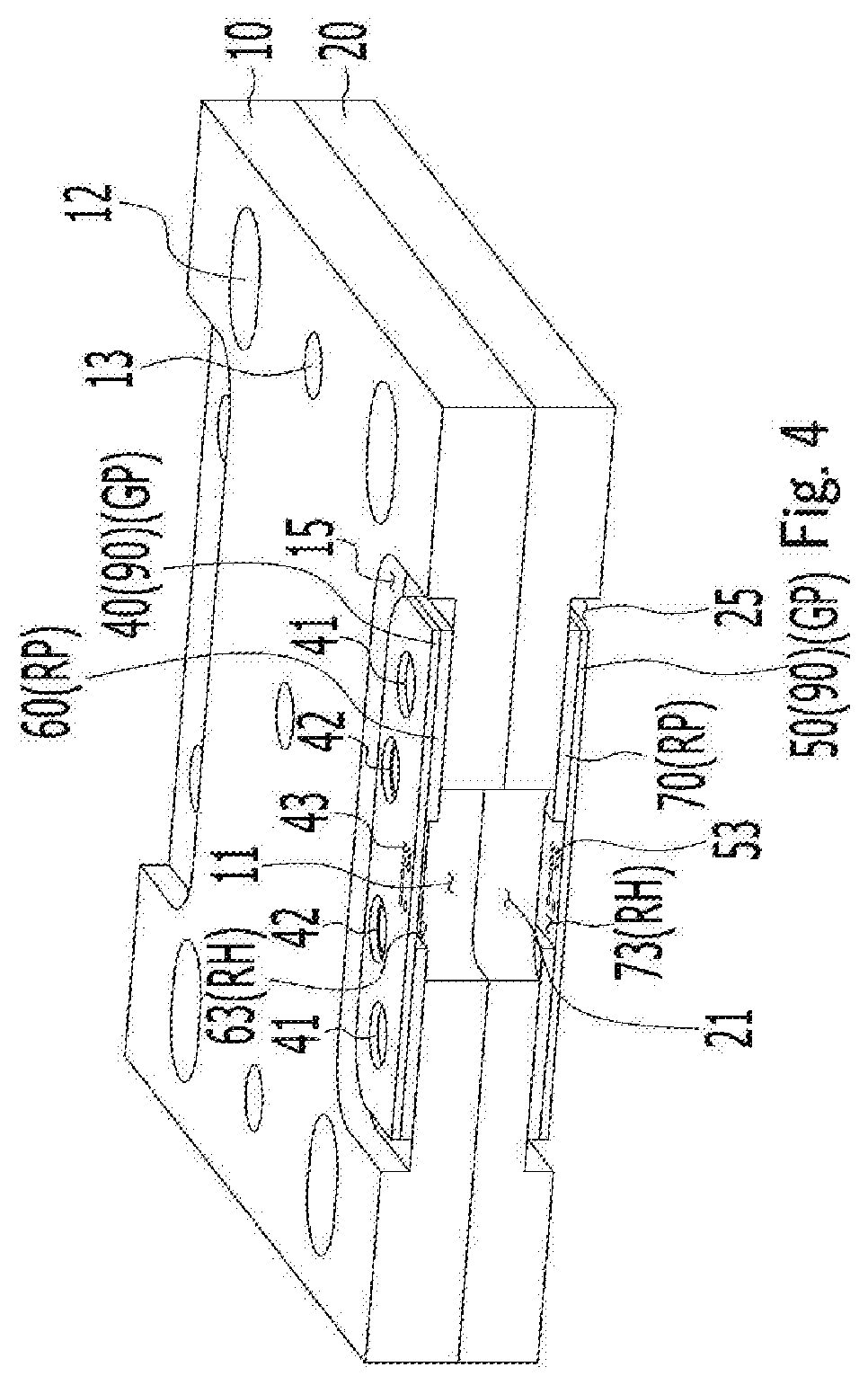

Positioning clamp assembly for notching machine

ActiveCN102990557BPrecise positioningAdaptablePreparing sample for investigationWork holdersEngineeringSelf adaptive

The invention discloses a positioning clamp assembly for a notching machine. The positioning clamp assembly comprises a base, a horizontal compression assembly and a vertical compression assembly, wherein the vertical compression assembly comprises a compression assembly which can move vertically in a reciprocating way and a vertical driving device for driving the compression assembly to move vertically in the reciprocating way; and the compression assembly comprises a horizontally-arranged substrate and a vertical compression plate spherically articulated on the substrate. A simultaneous horizontal and vertical fixed clamping structure is adopted, and a self-adaptive pressure plate structure is adopted in the vertical direction, so that the positioning clamp assembly is suitable for processing a plurality of samples simultaneously and has uniform flatness; during notch processing, the samples can be fastened and positioned comprehensively and are fixed firmly, and each sample has a uniform standard; and the positioning clamp assembly has higher adaptability to sample height errors, i.e., a plurality of samples are positioned in a standard way, so that deviation in a processing process is avoided, the gap manufacturing parallelism of the samples is ensured, gap errors are reduced and even eliminated, and the accuracy and precision of test data are ensured.

Owner:CHONGQING YUNTIANHUA HIGH END NEW MATERIALS DEV CO LTD +1

Probe card

PendingCN112611949AMiniaturizationEasy to handleElectronic circuit testingElectrical measurement instrument detailsProbe cardEngineering

The present invention relates to a probe card comprising: a first plate; a second plate coupled to a lower portion of the first plate; an upper guide plate provided on the upper surface of the first plate; and a lower guide plate provided to the lower surface of the second plate. At least one of the upper guide plate and the lower guide plate includes an anodic oxide film material, and the area of the upper guide plate and the area of the lower guide plate are smaller than the area of the first plate and the area of the second plate, so that the surfaces of the first plate and the second plate are exposed.

Owner:POINT ENG

Heating cooker

ActiveUS9863643B2Reduce additionalReduce thermal effectsDomestic stoves or rangesLighting and heating apparatusEngineeringSolid solution

A heating cooker includes: a top plate on which a cooking container to be heated is placed; an outer case as a main body having an upper surface on which the top plate is placed; a heater heating the cooking container; and a light emitting device disposed in the outer case, for displaying the heating state. The top plate includes: a glass substrate having a transparent light-transmitting low-expansion crystallized glass made mainly of Li2O—AL2O3—SiO2 and having β-quartz solid solution, having a crystal size smaller than the wavelength of visible light; a design layer having a black-based color disposed on an undersurface of the glass substrate; a diffusion region disposed partially on an undersurface of the design layer, for diffusedly emitting light from the light emitting device; and a light-blocking layer disposed on the undersurface of the design layer other than the diffusion region, for blocking light from below.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com