Method and system for automatic bond arm alignment

A bonding and bonding head technology, which is applied in the direction of tin feeding devices, electrical components, circuits, etc., can solve problems such as time-consuming, mechanical adjustment or misreading of measured values, and achieve risk reduction, time reduction, and complete electrical connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

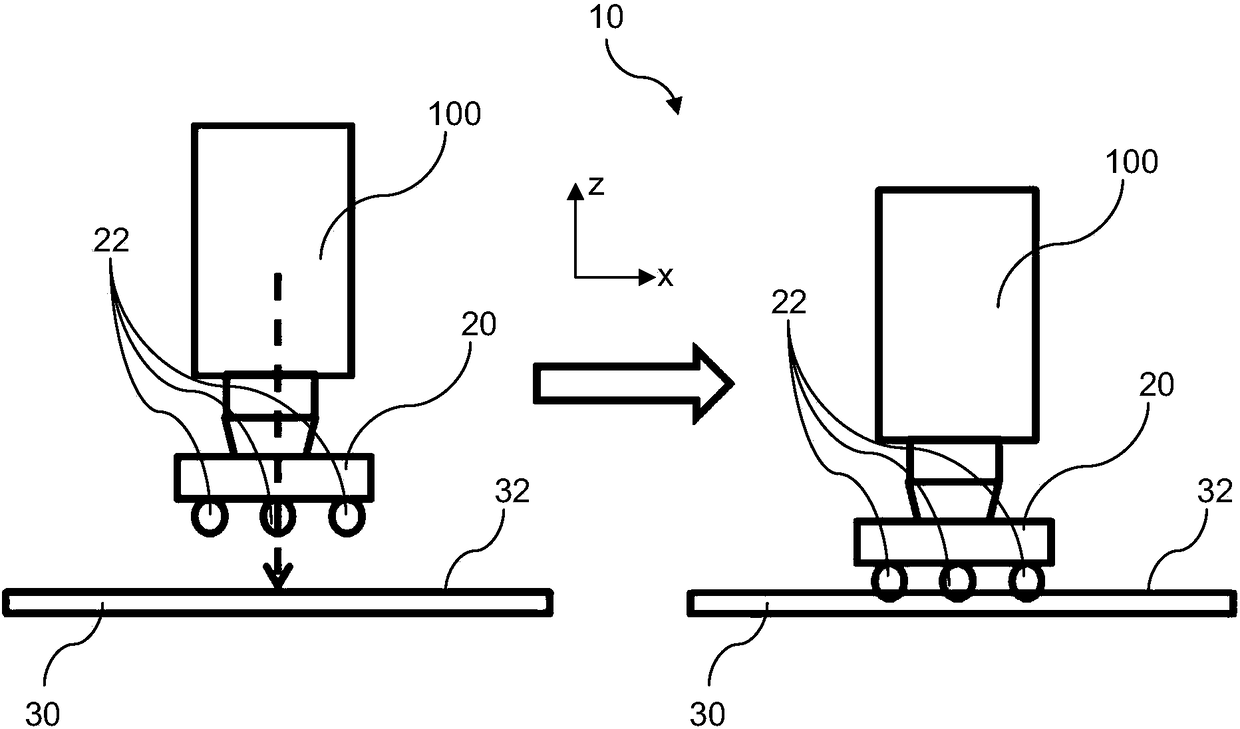

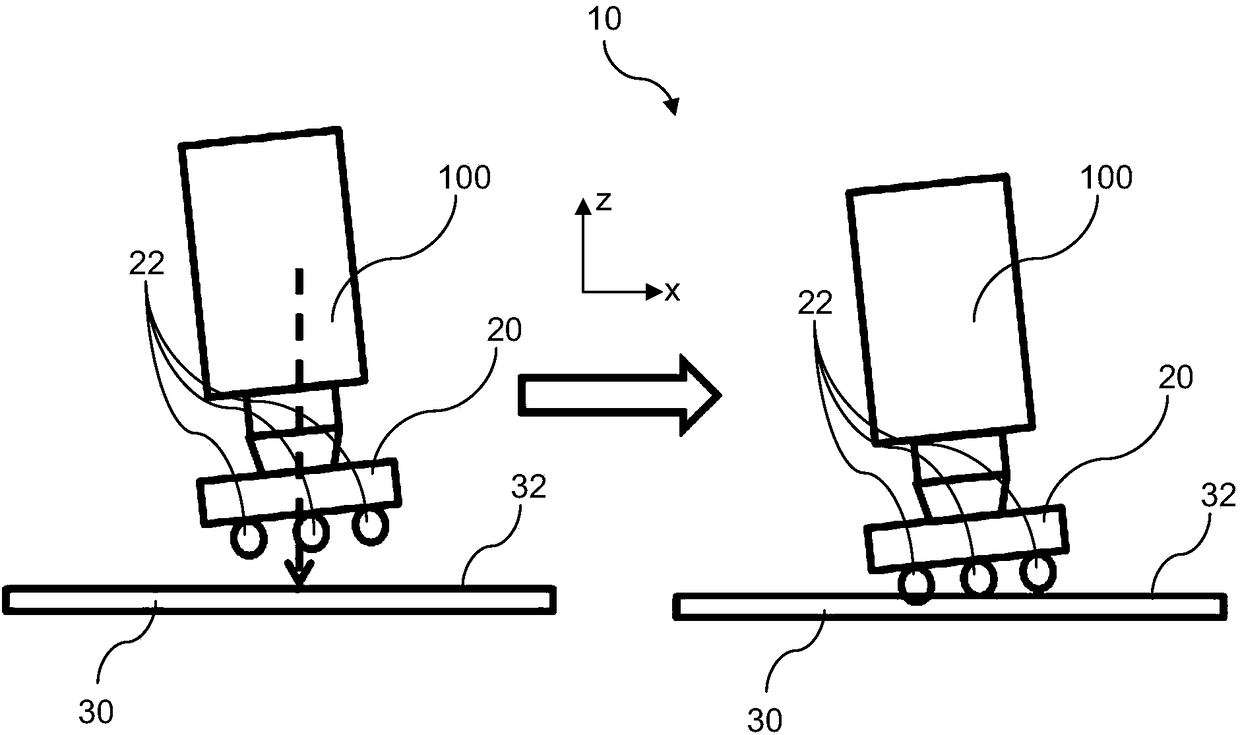

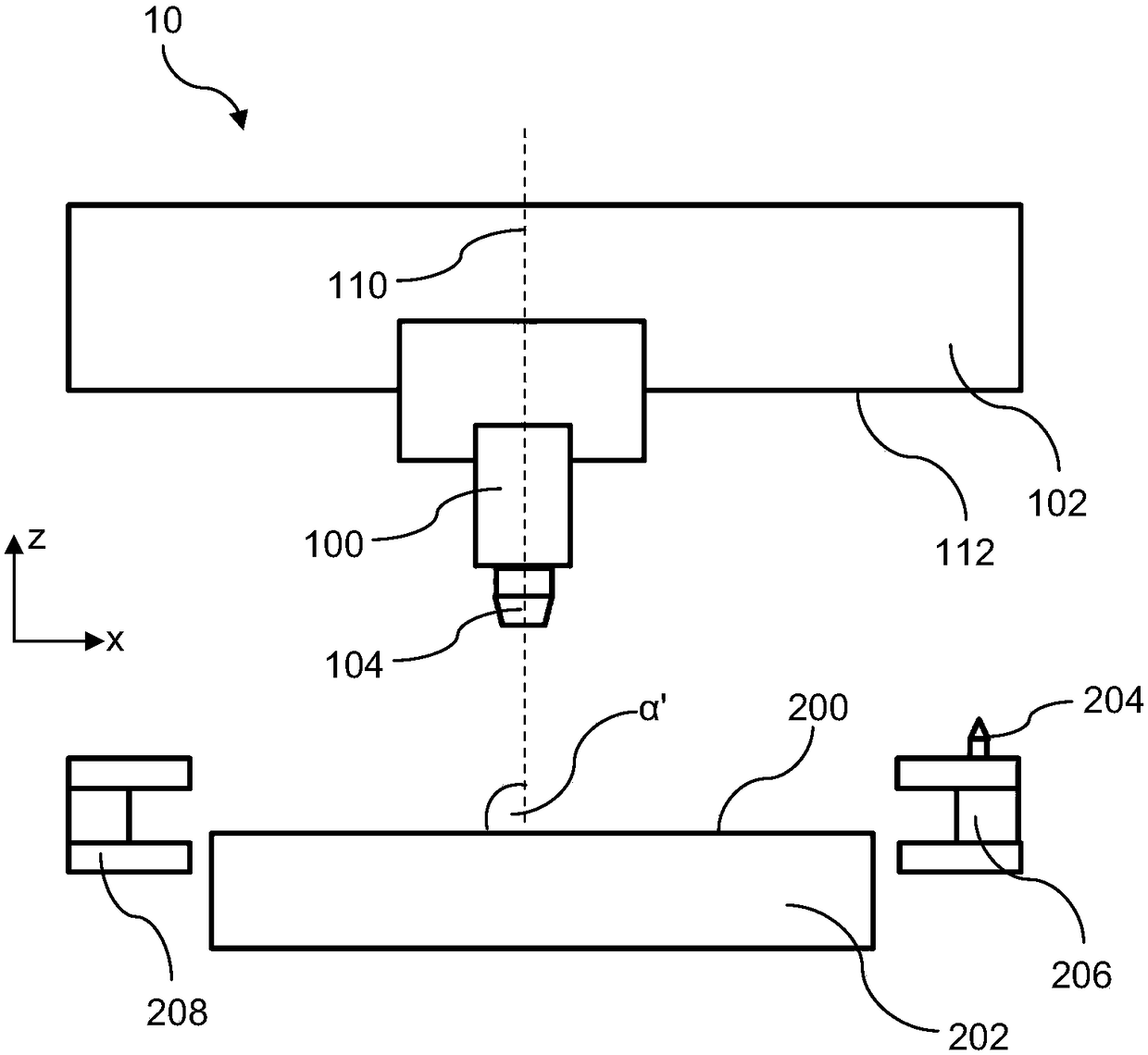

[0031] In the present invention, description of a given element, or consideration or use of a particular element number in a particular figure, or reference thereto in corresponding descriptive material may cover the same, Equivalent or similar elements or element numbers. The use of " / " in a figure or related text should be understood to mean "and / or" unless otherwise indicated. Recitations herein of specific values or ranges of values are understood to include or recitations of approximate values or ranges of values. For brevity and clarity, the description of embodiments of the invention is directed to methods and systems for automatically aligning a bond arm relative to a bond support surface, with reference to the accompanying drawings. It should be understood that the drawings may not be drawn to scale and may not be relied upon to show or determine specific sizes and / or dimensions.

[0032] While various aspects of the invention will be described in conjunction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com