Positioning clamp assembly for notching machine

A positioning type, assembly technology, applied in manufacturing tools, workpiece clamping devices, preparation of test samples, etc., can solve problems affecting the accuracy and precision of test data, difficult to ensure spline notch parallelism, notch error Increase and other problems, to achieve the effect of firm fixing, ensuring accuracy and precision, and eliminating notch errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

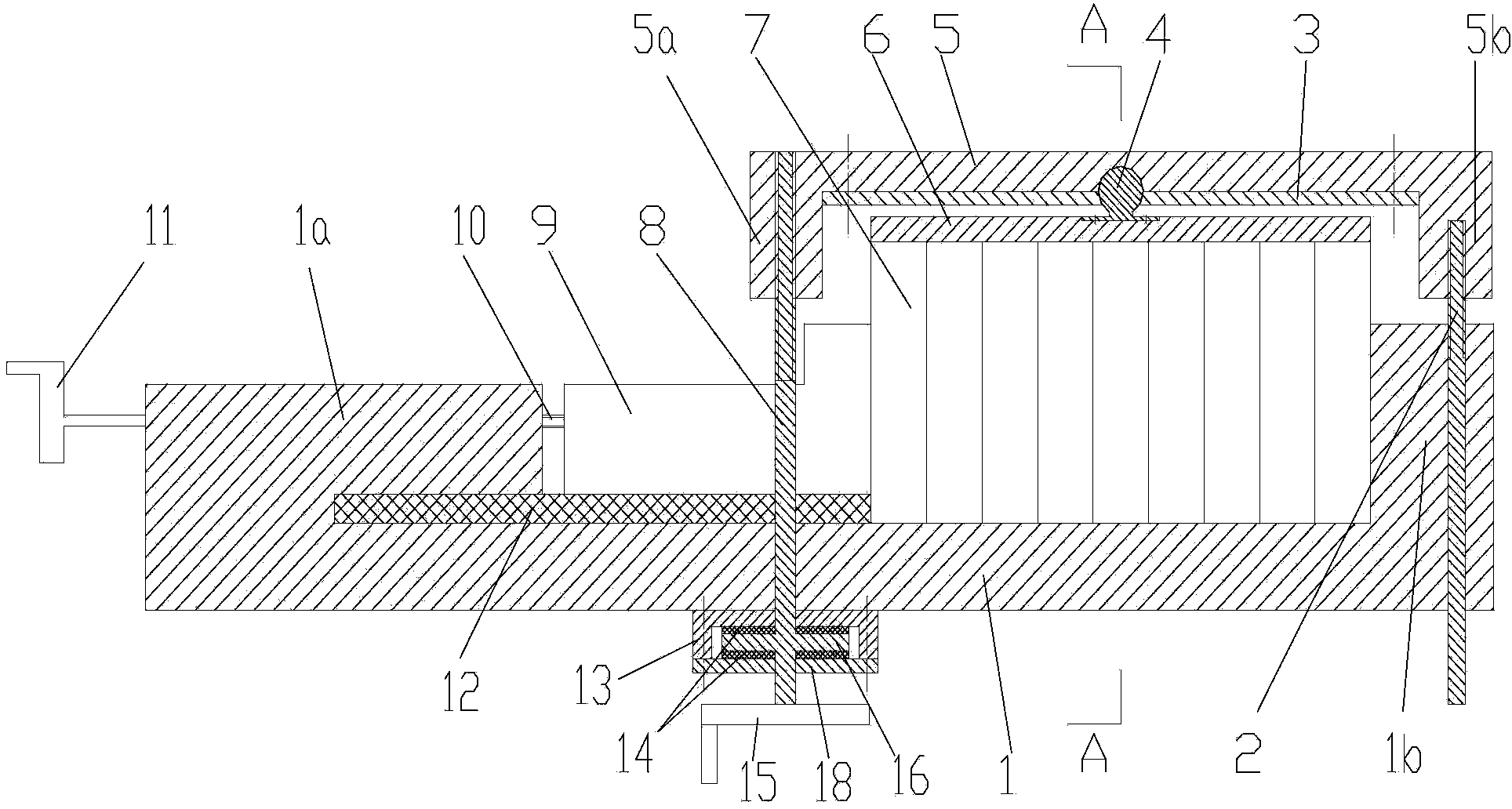

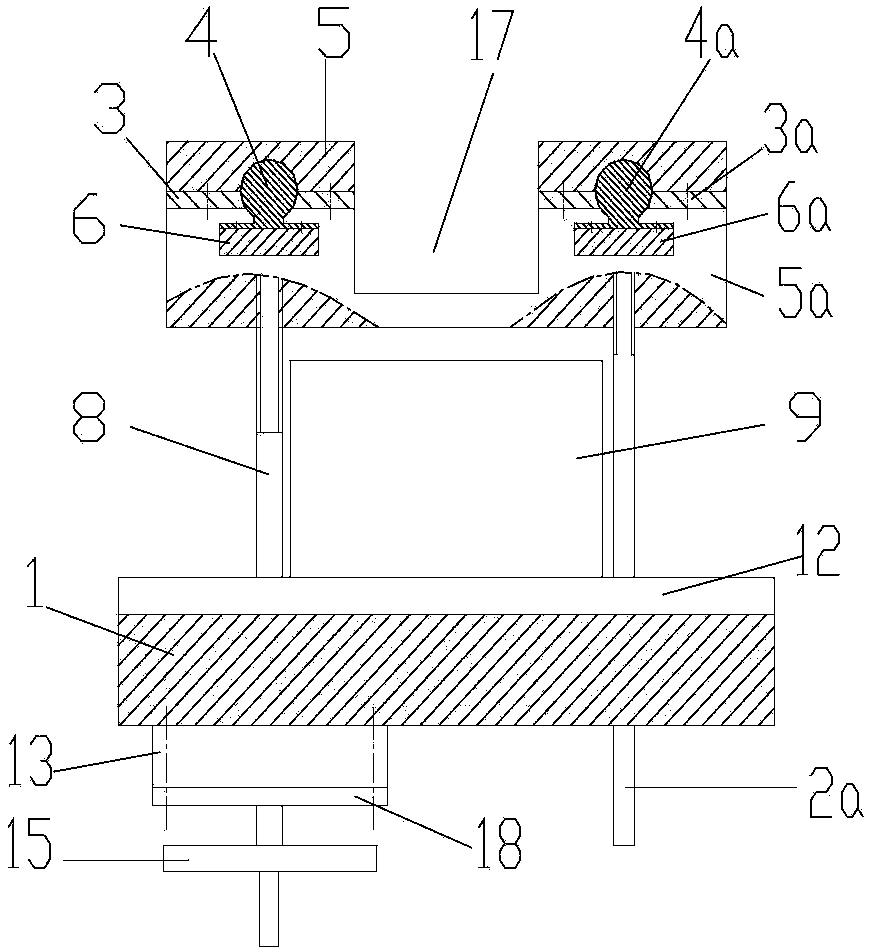

[0022] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 A sectional view along the A-A direction, as shown in the figure: the notch machine positioning fixture assembly of this embodiment includes a base 1, a horizontal pressing assembly and a vertical pressing assembly, and the horizontal pressing assembly includes a The horizontal pressing block 9 that reciprocates in the horizontal pressing direction and the horizontal driving device for driving the horizontal pressing block 9 to move back and forth; the base 1 is provided with a horizontal positioning boss that is fixed at least in the pressing direction 1b, the horizontal positioning boss 1b, the upper surface of the base 1 and the horizontal pressing block 9 jointly form a sample pressing and positioning space; that is, the horizontal driving device drives the horizontal pressing block 9 to be horizontal on the upper surface of the base 1 Move and press the sample 7 (one or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com