Ultra-large cold plate vacuum brazing method and a tool for vacuum brazing

A super-large, cold plate technology, used in welding equipment, metal processing, manufacturing tools, etc., can solve the problems of inability to guarantee large-area flatness, heavy tooling, and difficulty in furnace loading, reducing assembly and furnace loading. The effect of reducing the difficulty of post-weld correction, uniform flatness, and reducing the difficulty of post-weld correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the claims of the present invention is not limited to the content listed in this embodiment.

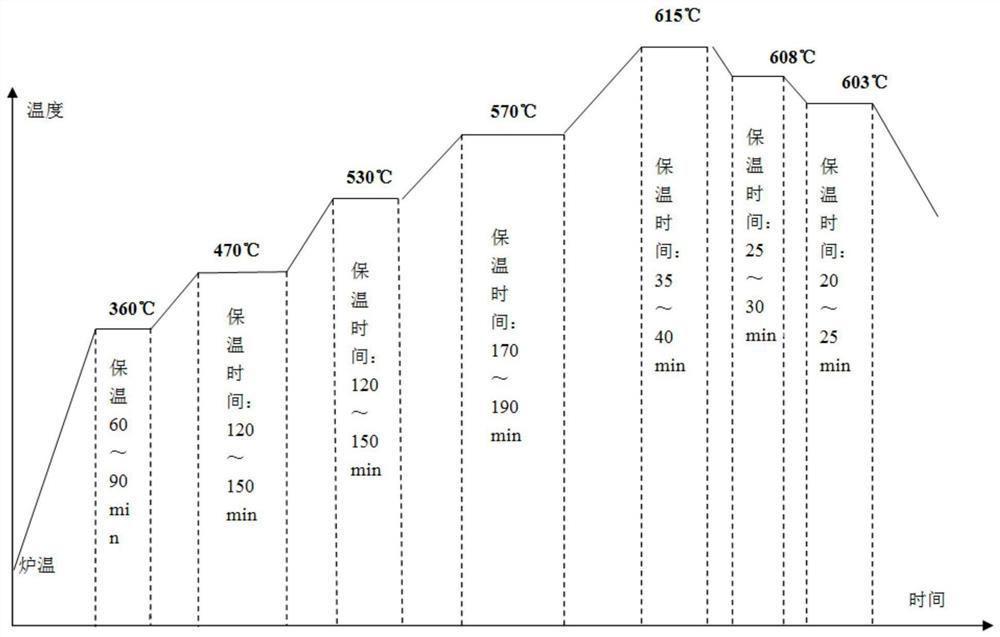

[0060] In this embodiment, a super-large cold plate whose size is 2489 x 950 x 60 mm is taken as an example to describe the vacuum brazing method and vacuum brazing tooling of the present invention in detail.

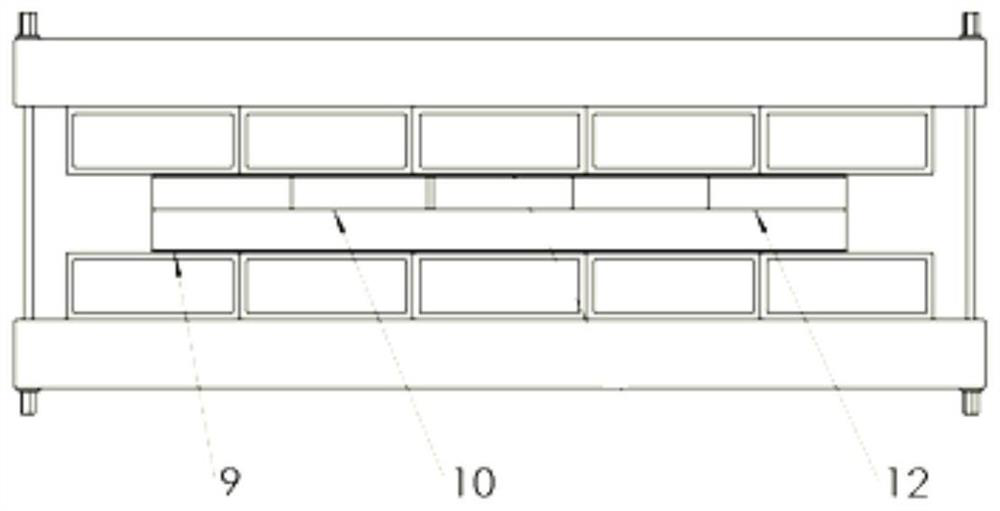

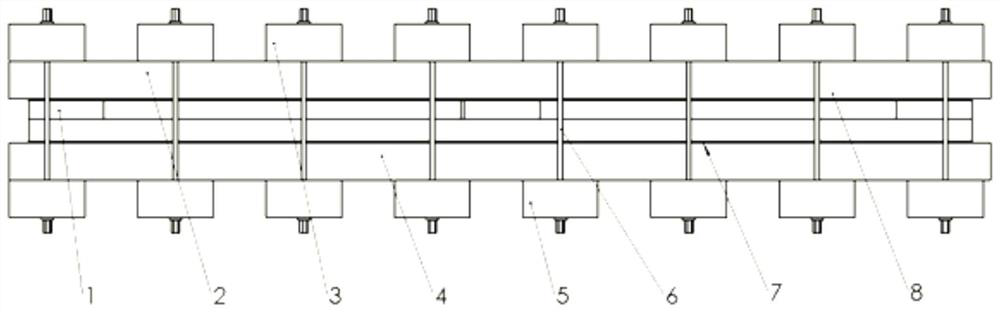

[0061] Vacuum brazing tooling in this embodiment The brazing tooling from top to bottom is the upper clamping plate 3, the upper tube 2, the upper backing plate 8 of the first layer, the elastic device 1, the middle backing plate 10 of the second layer, and the upper graphite paper 12 , lower graphite paper 9, one layer of lower backing plate 7, lower tube 4 and lower clamping plate 5, the elastic device 1 is composed of a plurality of independent cylindrical springs, the tooling is pressurized as a whole, and the middle back...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com