Wall aluminum plate system and its installation method

An installation method and aluminum plate technology, applied in covering/lining, building, building structure, etc., can solve the problems of affecting the appearance, difficult to control uniformity, loss of sense of craftsmanship, etc., and achieve the effect of uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

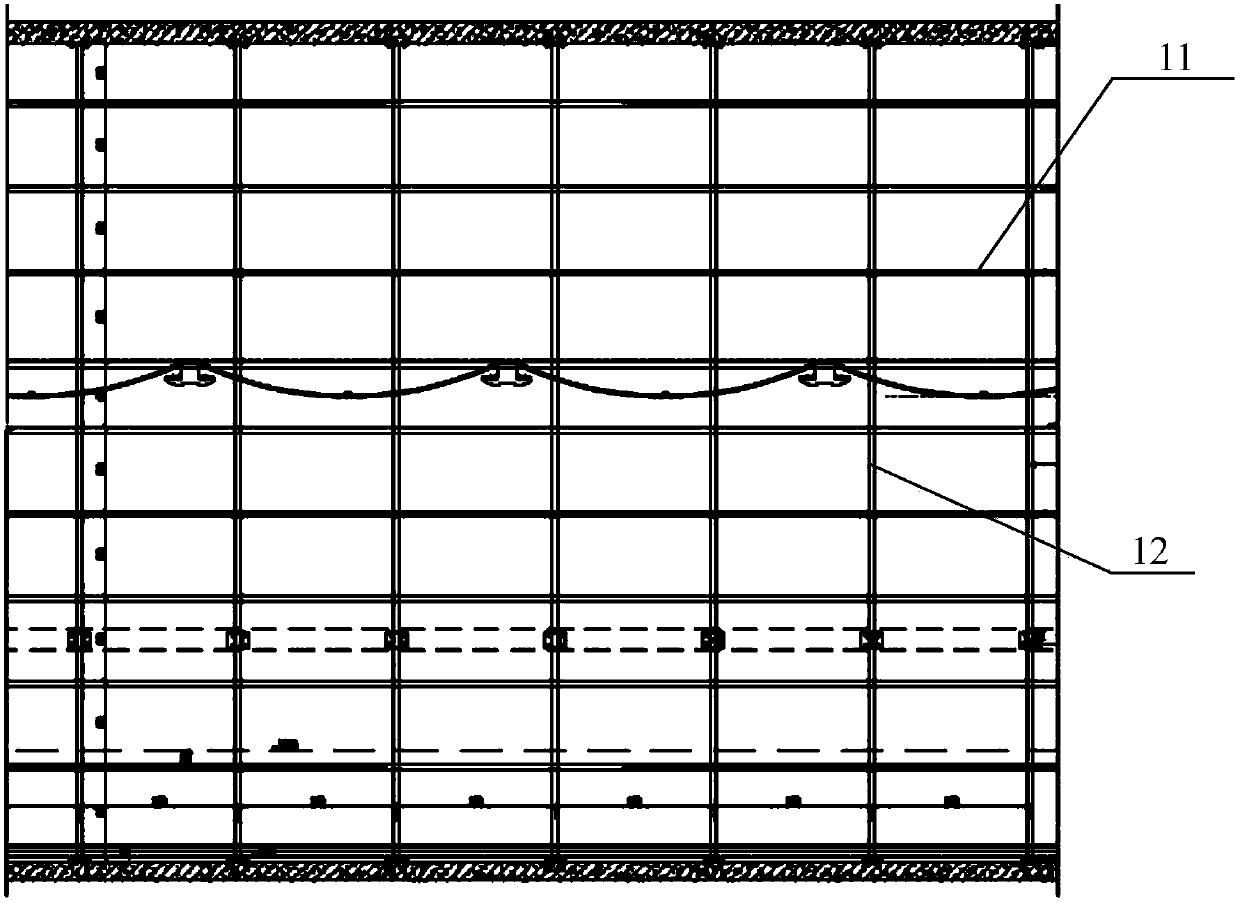

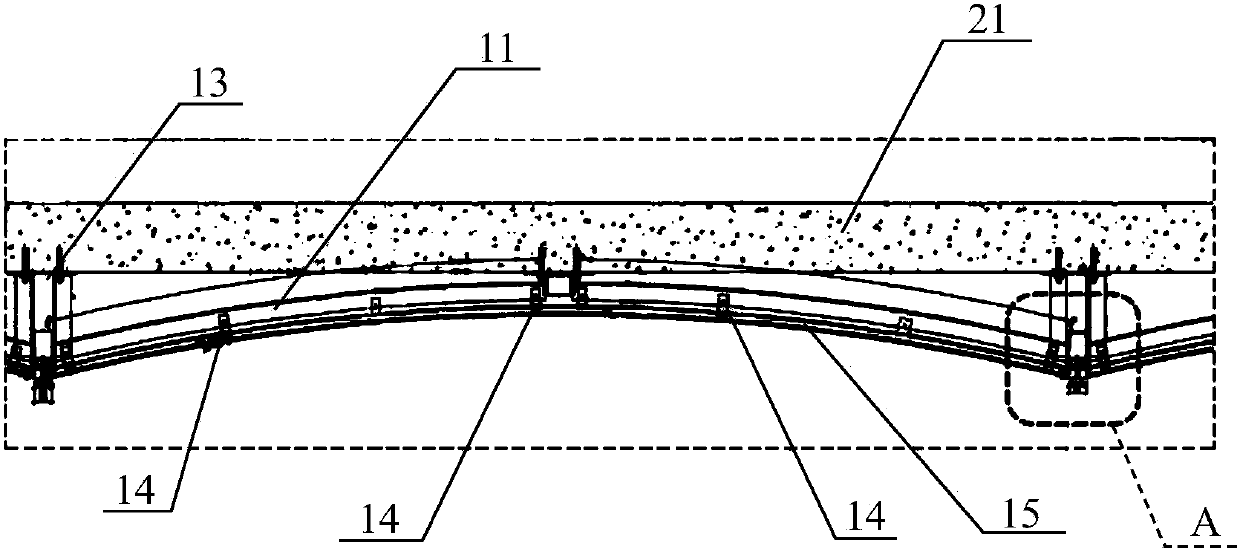

[0029] Such as figure 1 and figure 2 As shown, the wall aluminum plate system includes: rear embedded plate 13, vertical keel 12, horizontal keel 11, F-shaped corner code 14, and curved aluminum plate 15.

[0030] The rear embedded board 13 is fixedly connected with the wall surface 21;

[0031] The vertical keel 12 is installed on the rear embedded plate 13;

[0032] The horizontal keel 11 is arc-shaped, and is horizontally installed on the vertical keel 12;

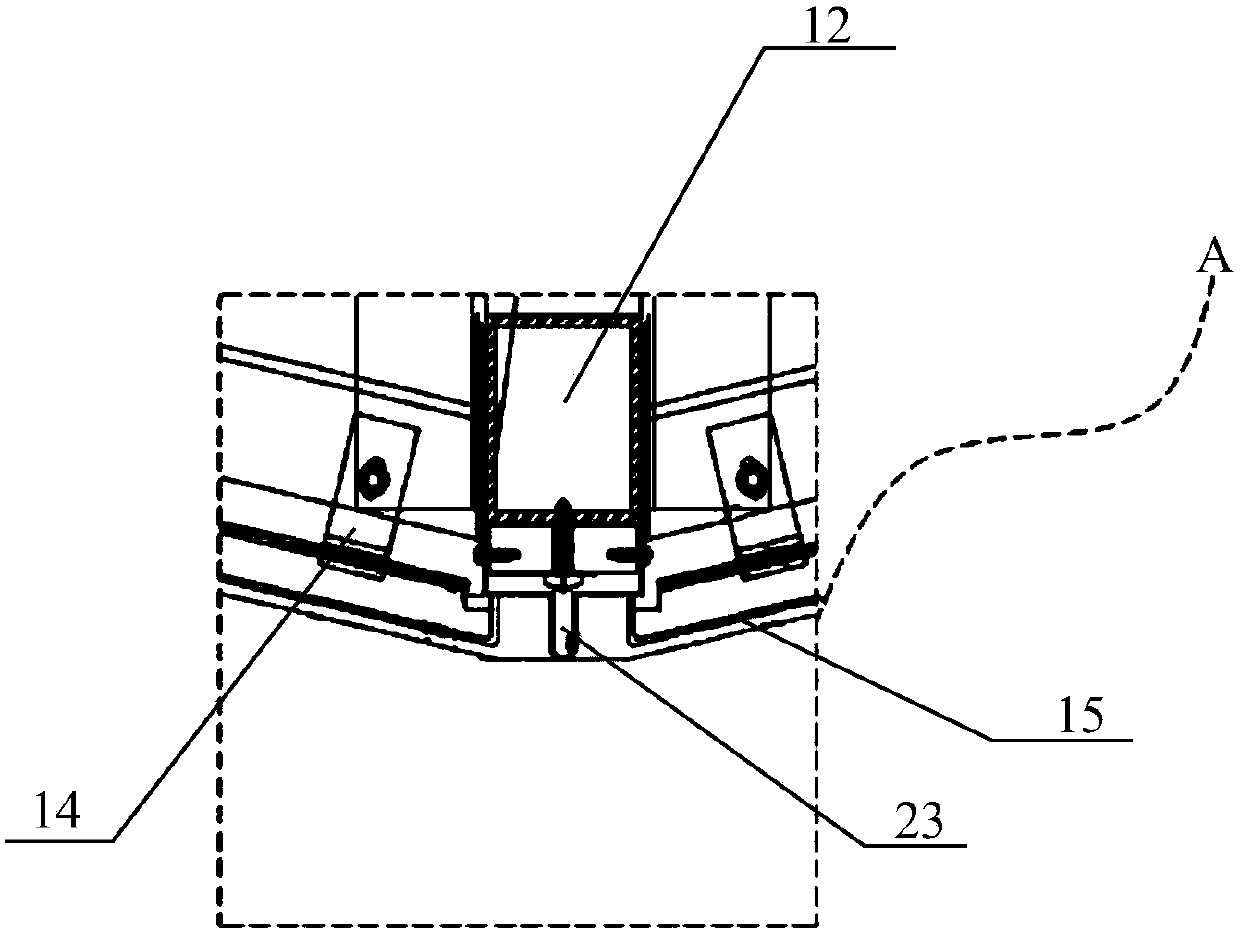

[0033] A plurality of F-shaped corner codes 14 are scattered and installed on the curved surface of the transverse keel; such as Figure 4 and Figure 5 As shown, the F-type corner code is installed horizontally on the inverted L-shaped angle steel, and the notch of the F-type corner code faces upward.

[0034] The arc-shaped aluminum plate 15 matches the shape of the transv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com