Glass curtain wall single body and integrated honeycombed outwards-convex-type irregular curtain wall structure

A glass curtain wall, irregular technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of difficult selection of special-shaped glass curtain wall materials, complicated construction technology, and various material sizes, and achieve good social benefits, mature technology, self-respect light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

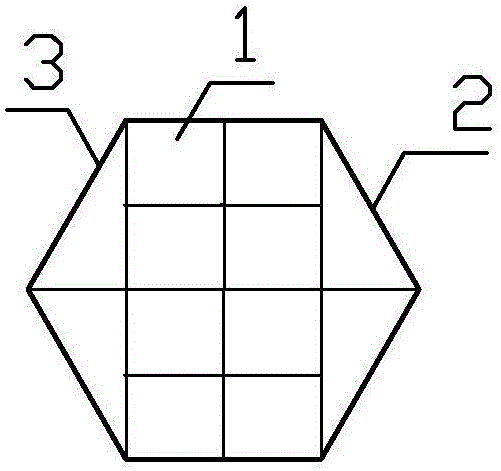

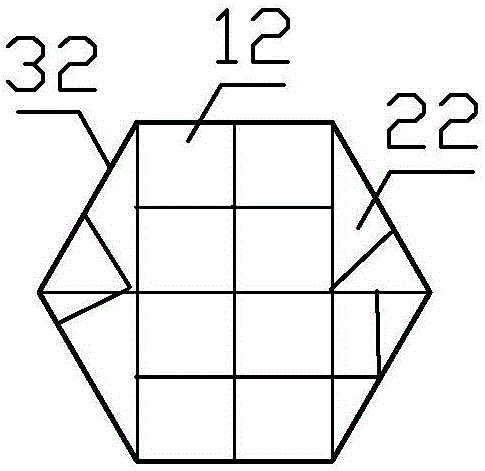

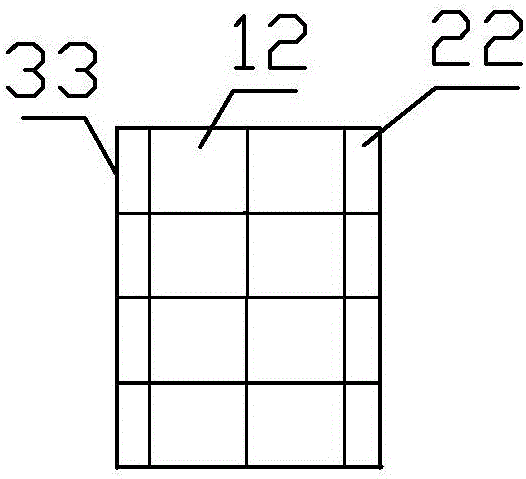

[0064] A glass curtain wall unit, the glass curtain wall unit is composed of m pieces of standard glass 1 and n pieces of non-standard glass 2 and a structural border line 3, each standard glass 1 is in the shape of a rectangle or square, and the structural border line 3 It is a regular hexagon or rectangle, and n pieces of non-standard glass 2 are located between the outer periphery of m pieces of standard glass 1 and the gap formed by the frame line 3 of the structure; the value range of m and n is: m and n are between 4 and 12 even;

[0065] According to the different shapes of standard glass 1, non-standard glass 2 and structural frame line 3 that make up the glass curtain wall monomer, the glass curtain wall monomer has the following different structural methods:

[0066] One of the structure of embodiment one:

[0067] 1. Regular hexagonal glass curtain wall monomer:

[0068] like Figure 2-1 As shown, the regular hexagonal glass curtain wall unit is composed of 4 pie...

Embodiment 2

[0075] Embodiment 2: The structure of the honeycomb planar glass curtain wall - that is: regular hexagonal curtain wall component A:

[0076] like image 3 As shown, the honeycomb planar glass curtain wall is composed of a regular hexagonal curtain wall assembly A: the regular hexagonal curtain wall assembly A is composed of various types of regular hexagonal glass curtain wall monomers as described in Embodiment 1. For the specific structure, refer to the embodiment One structure 1, regular hexagonal glass curtain wall unit, see Figure 2-1 , Figure 2-2 , Figure 2-1 for the bright frame, Figure 2-2 is a hidden frame.

Embodiment 3

[0077] Example 3: Honeycomb-shaped irregular curtain wall:

[0078] The honeycomb convex irregular curtain wall is composed of P pieces of glass curtain wall components; when in use, two large triangular glass curtain walls with unequal planes are connected on equal sides to form the overall structure of the honeycomb convex irregular curtain wall (see Figure 8-1 , Figure 8-2 );

[0079] The glass curtain wall assembly includes a triangular honeycomb glass curtain wall assembly IB (see Figure 4 ), triangular honeycomb glass curtain wall assembly ⅡC (see Figure 5 );

[0080] The triangular honeycomb-shaped glass curtain wall assembly IB and the triangular honeycomb-shaped glass curtain wall assembly IIC are both composed of the glass curtain wall monomer and the keel described in Embodiment 1;

[0081] The triangular honeycomb-shaped glass curtain wall component IB is composed of irregular triangular steel keels 41 and P blocks of regular hexagonal glass curtain wall m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com