Chemical mechanical grinding processing method and system

A chemical mechanical and grinding process technology, applied in grinding devices, grinding machine tools, manufacturing tools, etc., can solve the problems that chemical mechanical grinding cannot efficiently improve flatness and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

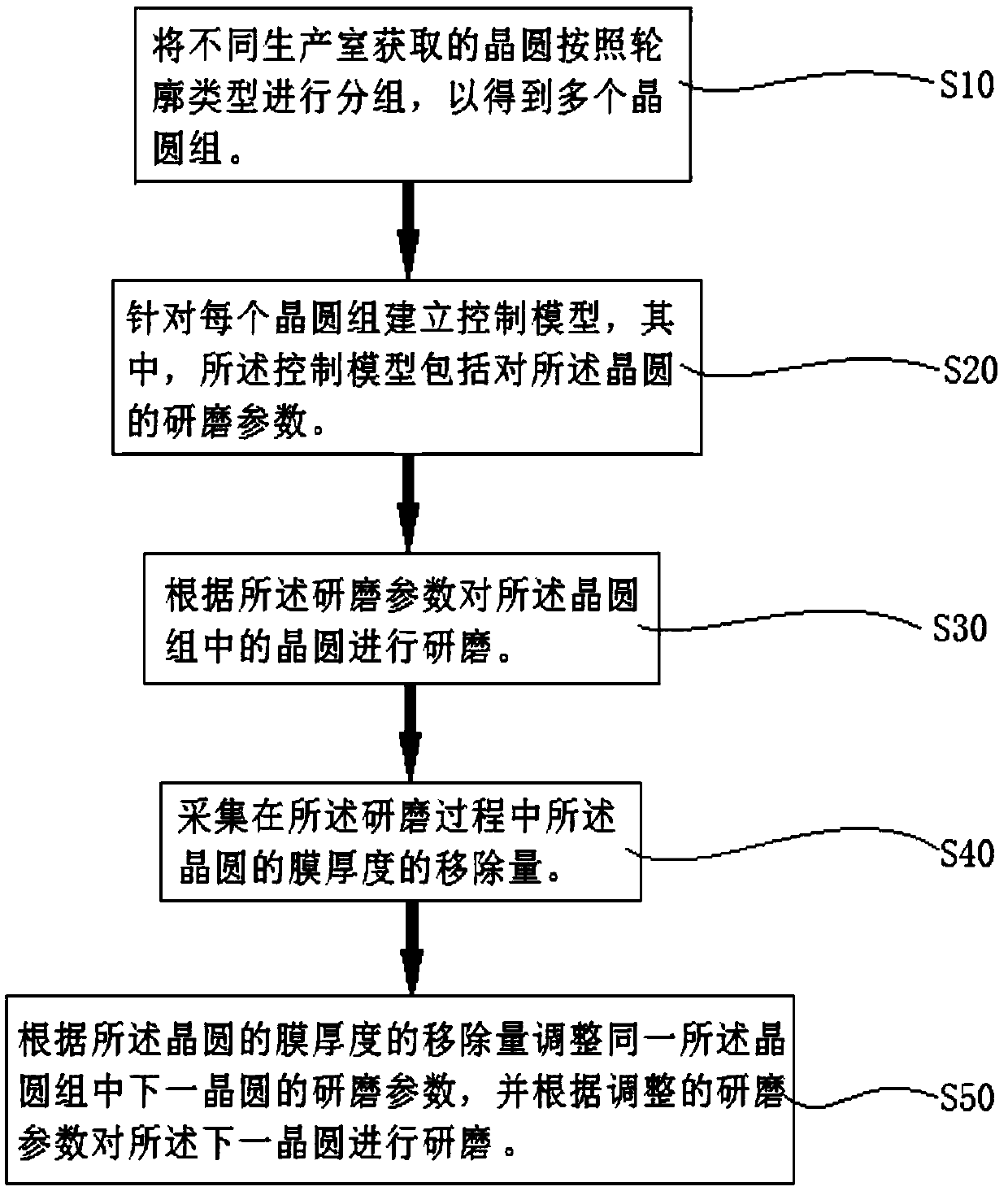

[0053] A kind of chemical mechanical polishing process method of this embodiment, refer to figure 1 As shown, the method includes:

[0054] Step S10: group the wafers obtained from different production rooms according to the outline type to obtain multiple wafer groups.

[0055] Step S20: establishing a control model for each wafer group, wherein the control model includes grinding parameters for the wafers.

[0056] Step S30: Grinding the wafers in the wafer group according to the grinding parameters.

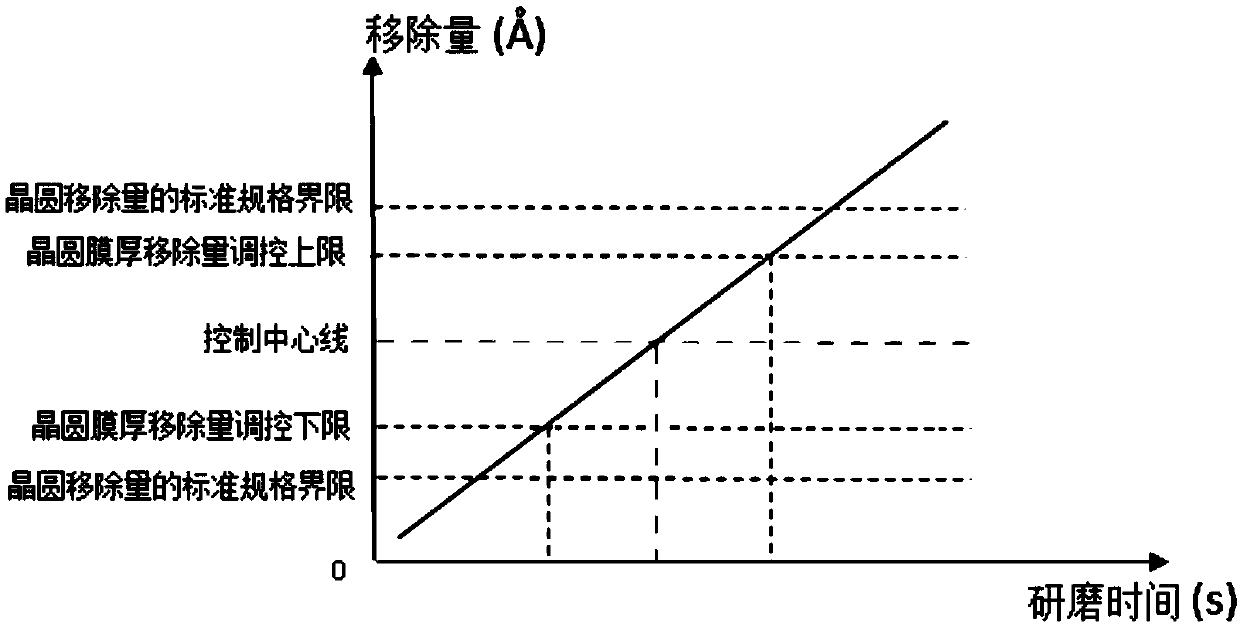

[0057] Step S40: collecting the removal amount of the film thickness of the wafer during the grinding process.

[0058] Step S50: Adjust the grinding parameters of the next wafer in the same wafer group according to the removal amount of the film thickness of the wafer, and grind the next wafer according to the adjusted grinding parameters.

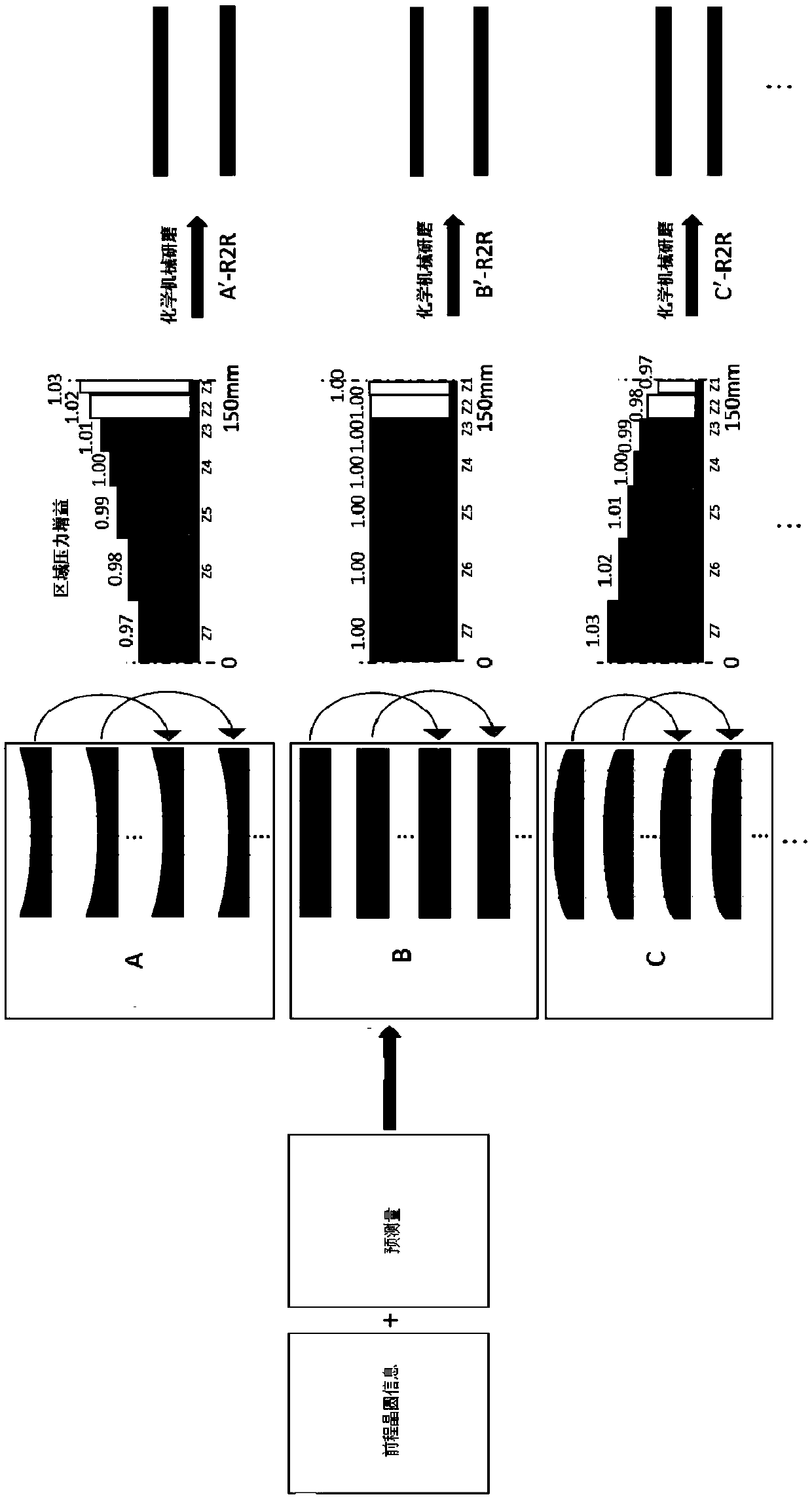

[0059] In a specific embodiment, the previous wafer information (Priorlayers wafer information) and the pre-measure (Pre-measure) pro...

Embodiment 2

[0098] A kind of chemical mechanical polishing process system of this embodiment, refer to Image 6 shown, including:

[0099] a plurality of production chambers 110 for producing wafers, wherein the surfaces of wafers produced by different said production chambers 110 have different profiles; and

[0100] The polishing device 120 is used to realize the chemical mechanical polishing process method as described in the first embodiment.

[0101] In a specific embodiment, the grinding device 120 includes: a front measurement module 121 , a rear measurement module 124 , a control system 122 and a grinding machine table 123 .

[0102] The front measurement module 121 is connected with the production chamber 110, and the front measurement module 121 is used for measuring the first film thickness of the wafer before the chemical mechanical polishing process.

[0103] The post-measurement module 124 is connected to the grinder table 123, and the post-measurement module 124 is used f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com