Colored wide and dense cotton belt and dyeing method thereof

A dyeing method and cotton tape technology, which can be applied in biochemical fiber treatment, textile material processing, bleaching products, etc., can solve problems such as uneven dyeing of wide and dense cotton tapes, dyeing of wide and dense cotton tapes, color difference between head and tail, and achieve High success rate of dyeing at one time, not easy to dye flowers, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A kind of dyeing method of wide dense cotton belt, comprises the following steps:

[0055] (1) Pre-shrinking: Soak the wide-density cotton tape in hot water at 70°C for 30 minutes, with a bath ratio of 1:15 (water can be recycled), and then dehydrate.

[0056] (2) Tape winding: 22Kg pre-shrunk wide dense cotton tape is evenly coiled on the dyeing shaft, the total thickness of the wide dense cotton tape is 5.5cm.

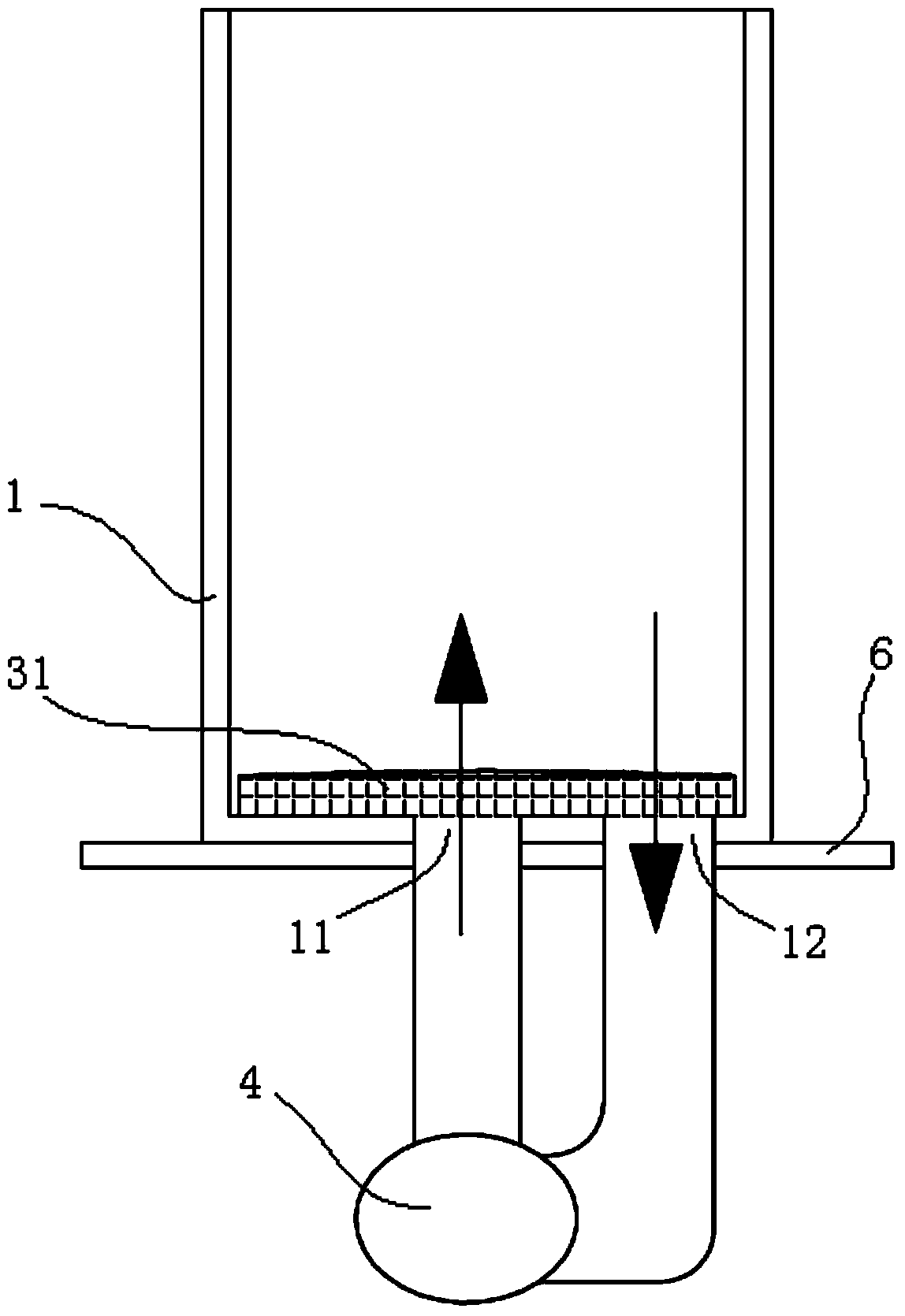

[0057] (3) Pretreatment: Hang the dyeing shaft of the above-mentioned coiled wide dense cotton belt into the dyeing equipment with a capacity of 30KG belt / set for pretreatment, and carry out pretreatment twice.

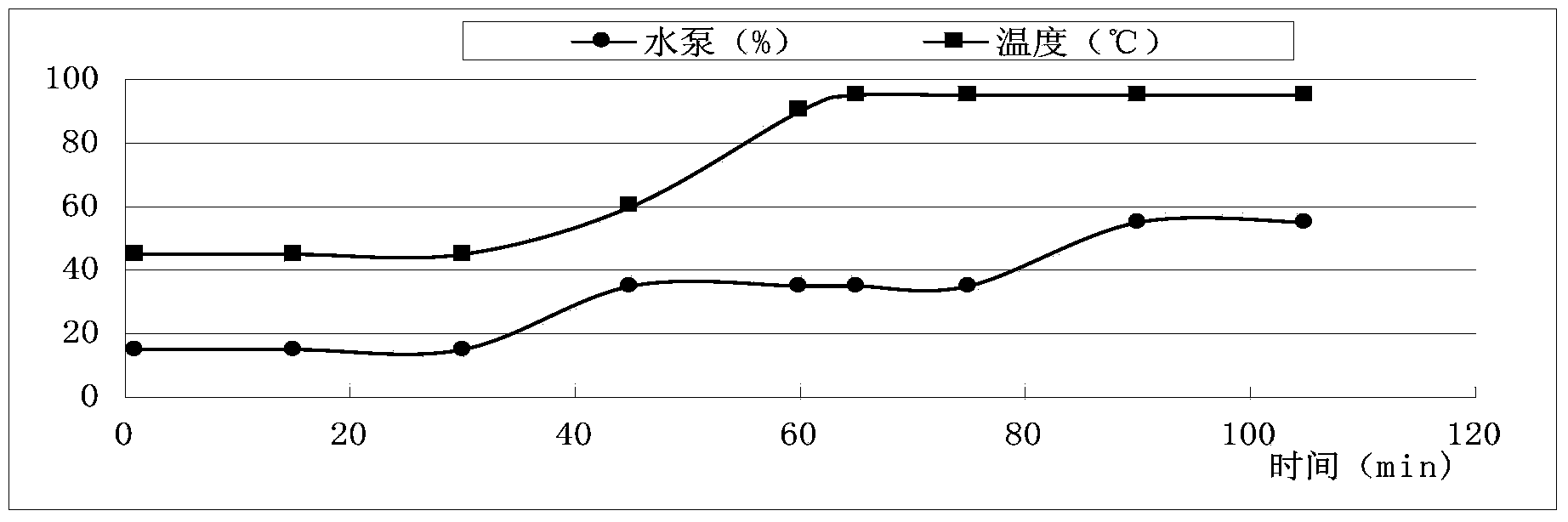

[0058] The first pre-treatment is: 80L of water, start the water pump, and adjust the pump speed of the water pump to be 15% of the maximum pump speed. In this embodiment, the maximum speed of the water pump of the dyeing equipment is 2900 rpm, and the power is 7.5KW . Add penetrating agent SUNMORL 66EG, 0.16Kg from the attached cylinder; degreasing...

Embodiment 2

[0072] A kind of dyeing method of wide dense cotton belt, comprises the following steps:

[0073] (1) Pre-shrinking: soak the wide-density cotton tape in hot water at 50°C for 50 minutes, the bath ratio is 1:20 (water can be recycled), and dehydrate;

[0074] (2) Tape wrapping: the 13KG pre-shrunk wide dense cotton tape is evenly coiled on the dyeing shaft, the total thickness of the wide dense cotton tape is 4cm.

[0075] (3) Pretreatment: Hang the dyeing shaft of the above-mentioned coiled wide dense cotton belt into the dyeing equipment with a capacity of 15KG belt / set for pretreatment, and carry out pretreatment twice.

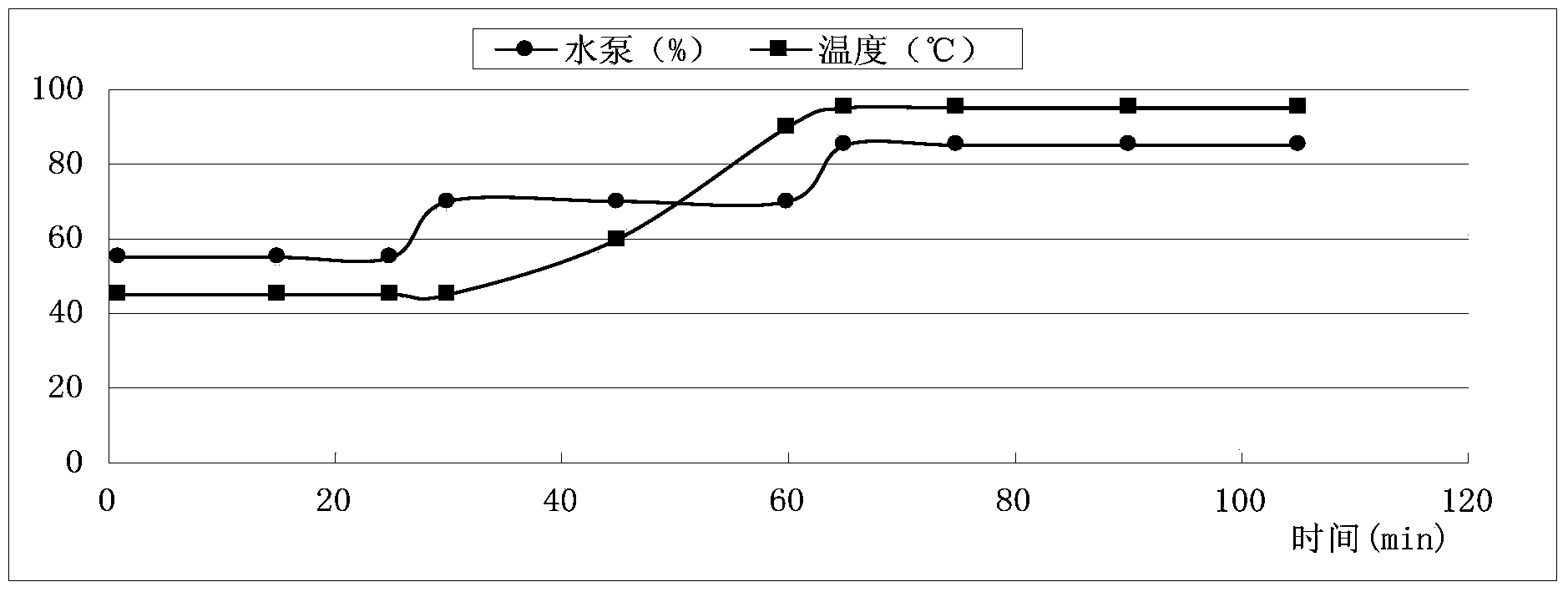

[0076] The first pre-treatment is: 60L of water intake, start the water pump, and adjust the pump speed of the water pump to be 10% of the maximum pump speed. In this embodiment, the maximum speed of the water pump of the dyeing equipment is 2900 rpm, and the power is 5KW. Add penetrant SUNMORL 66EG from the attached tank, 0.k24Kg; degreasing agent (LCF-1...

Embodiment 3

[0081] A kind of dyeing method of wide dense cotton belt, comprises the following steps:

[0082] (1) Pre-shrinking: soak the wide-density cotton tape in hot water at 90°C for 15 minutes, with a bath ratio of 1:5 (water can be recycled), and then dehydrate;

[0083] (2) Tape winding: 15 kg of pre-shrunk wide dense cotton tape is evenly coiled on the dyeing shaft. The total thickness of the wide dense cotton tape is 4.5 cm.

[0084] (3) Pretreatment: Hang the dyeing shaft of the above-mentioned coiled wide dense cotton belt into the dyeing equipment with a capacity of 20KG belt / set for pretreatment, and carry out pretreatment twice.

[0085] The first pretreatment is: 70L of water intake, start the water pump, and adjust the pump speed of the water pump to be 15% of the maximum pump speed. In this embodiment, the maximum speed of the water pump of the dyeing equipment is 2500 rpm, and the power is 5KW. Add penetrating agent SUNMORL 66EG, 0.15Kg from the attached tank; degreasi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com