Patents

Literature

45results about How to "Avoid uneven staining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

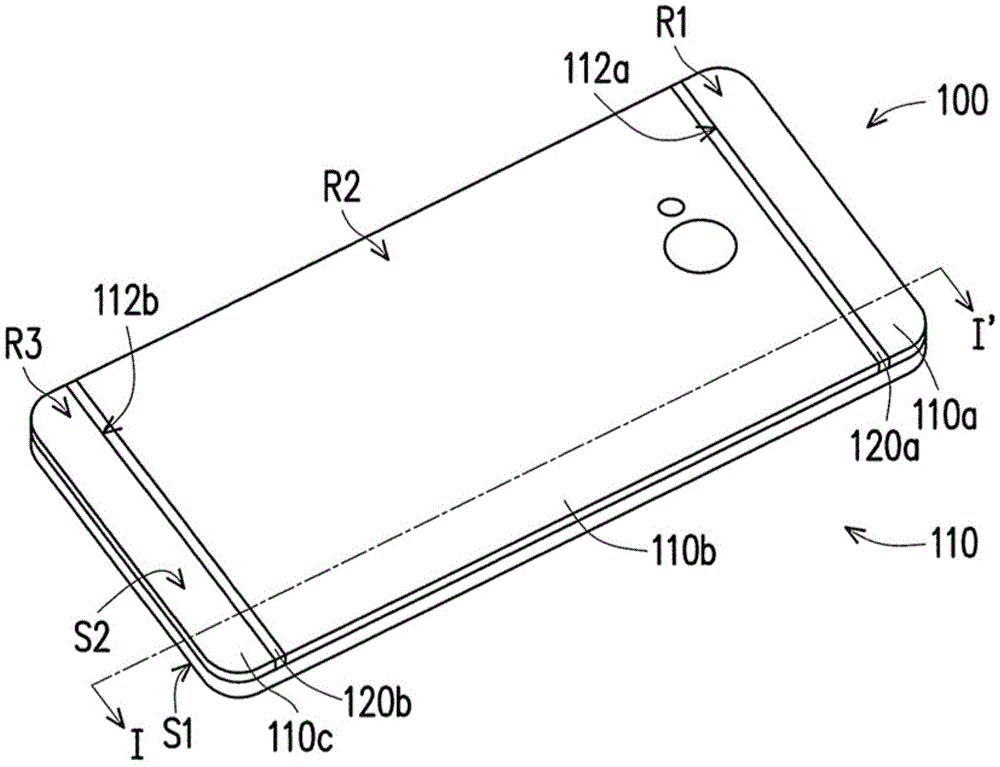

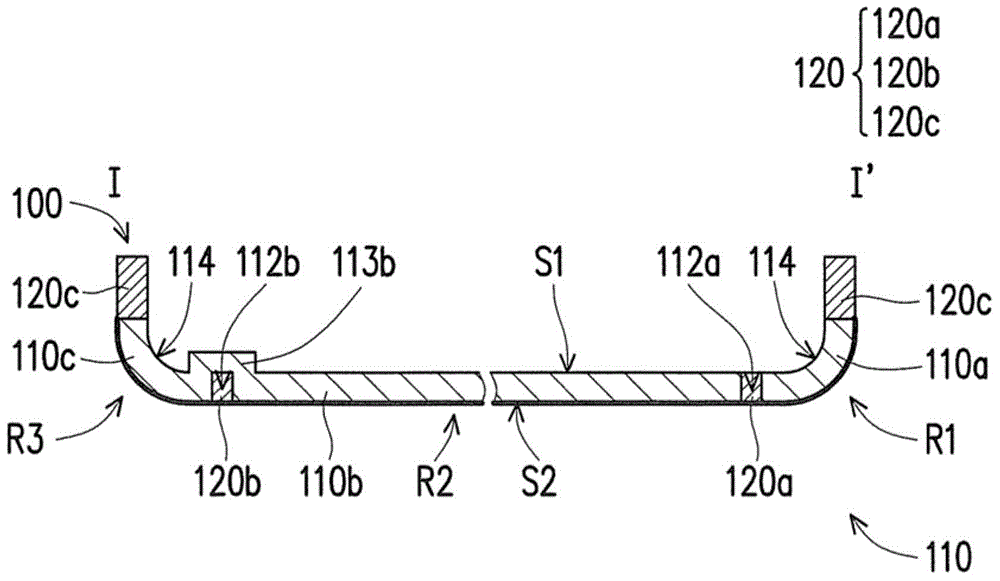

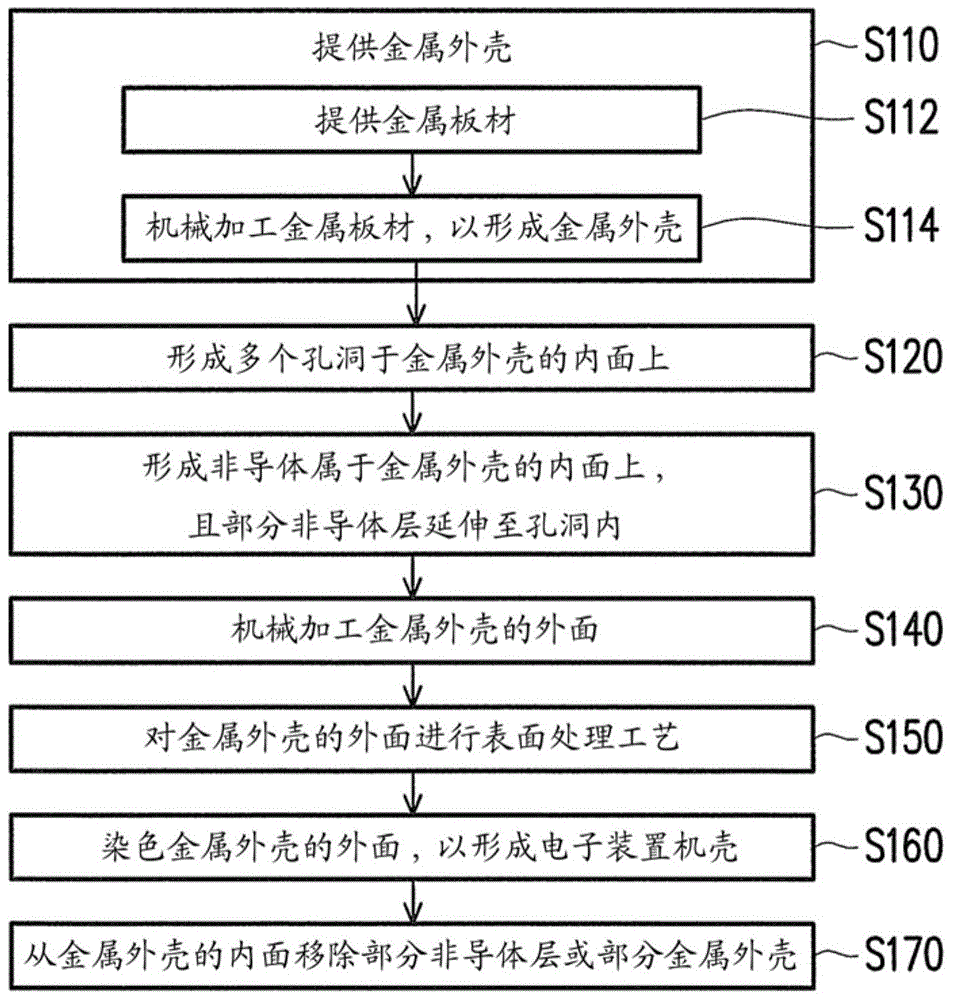

Casing Of Electronic Device And Method Of Manufacturing The Same

ActiveCN104066293AHigh mechanical strengthAvoid uneven stainingMetal casingsEngineeringElectrical conductor

A method of manufacturing a casing of an electronic device is provided. The method of manufacturing the casing of the electronic device includes following steps: providing a metal hosuing provided with an inner face and an outer face opposite to the inner face, forming a plurality of holes in the inner face of the metal housing, forming a non-conductive layer, a part of which extends into the holes, on the inner face of the metal housing, and dyeing the outer face of the metal housing to form the casing of the electronic device. The invention further discloses the casing of the electronic device.

Owner:HTC CORP

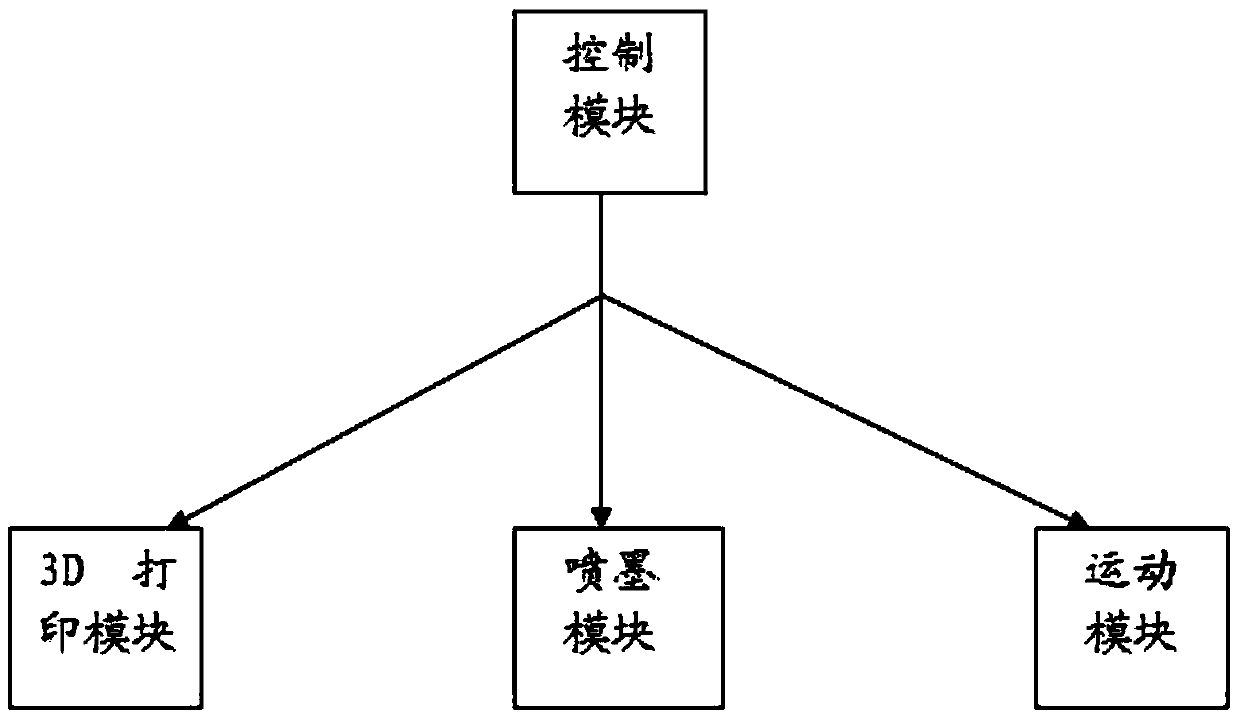

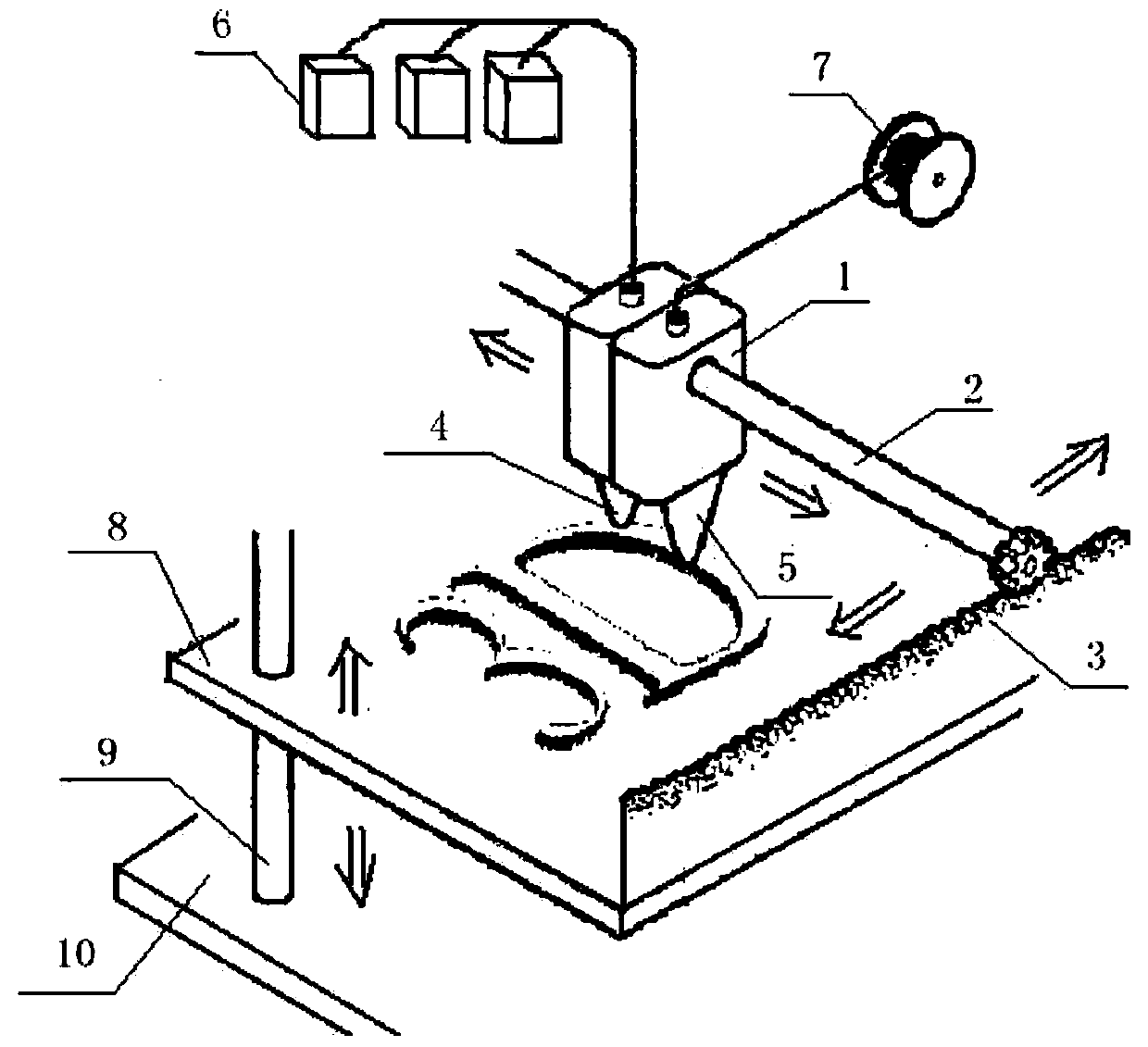

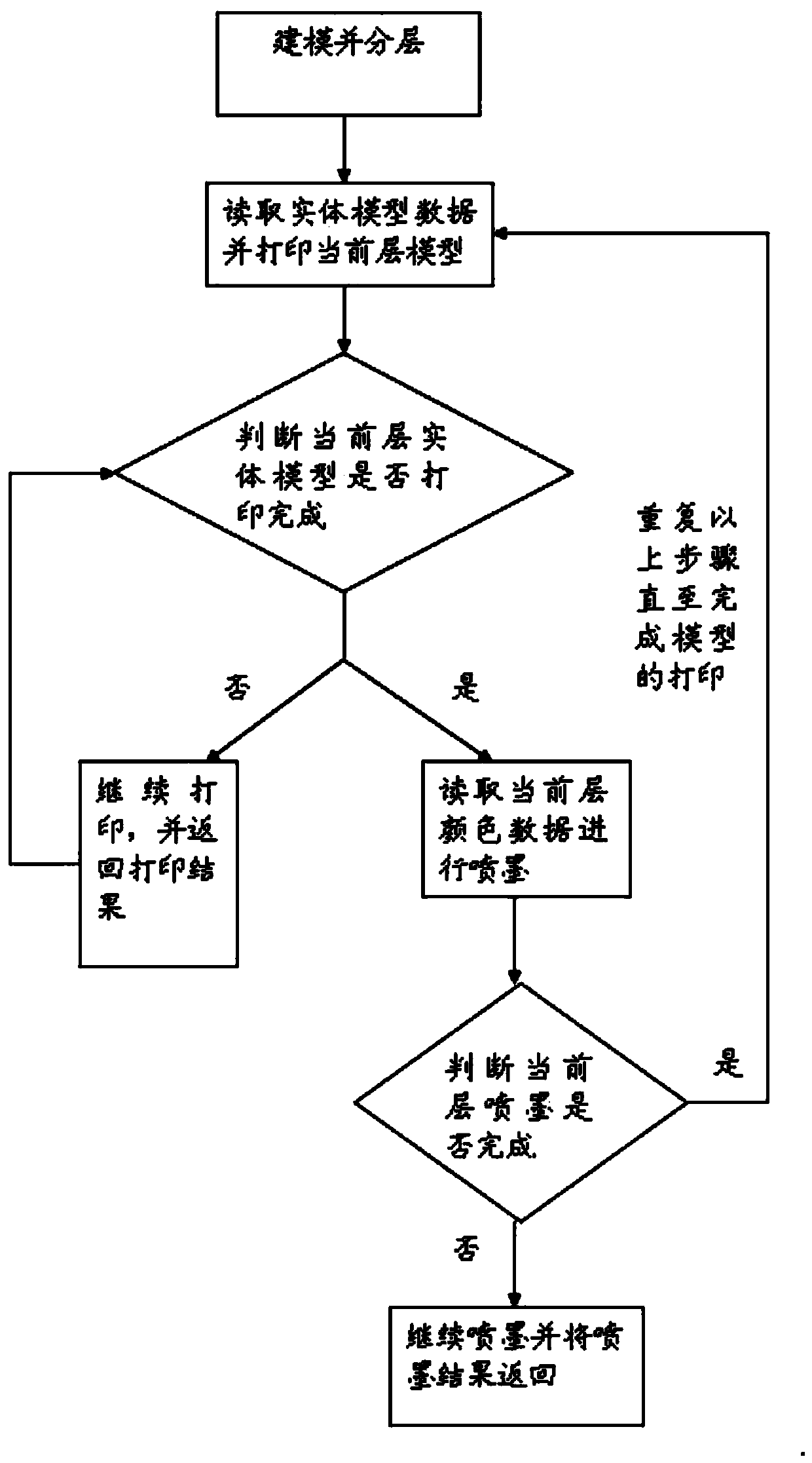

Three-dimensional Ink jetting printing equipment and three-dimensional ink jetting printing method

The invention relates to the field of three-dimensional printing and particularly relates to a three-dimensional ink jetting printing equipment and a three-dimensional ink jetting printing method. The three-dimensional ink jetting printing equipment comprises a control module, a movement module and a three-dimensional printing module, wherein the three-dimensional printing module is used for printing a thermoplastic material by layers according to data read by the control module; the movement module is used for controlling the movement of a printing object in a layered control process under the control of the control module; the three-dimensional ink jetting printing equipment further comprises an ink jetting module; the ink jetting module is connected with the control module and is used for carrying out ink jetting dyeing treatment on a current layer after an entity of the current layer is printed by the three-dimensional printing module; the movement module is used for controlling the movement of the printing object in an ink jetting process under the control of the control module; and the ink jetting module, the movement module and the three-dimensional printing module work independently under the control of the control module. According to the three-dimensional ink jetting printing equipment, a colorful plane printing technology can be applied to a complicated three-dimensional object and the printing cost is low.

Owner:马驰

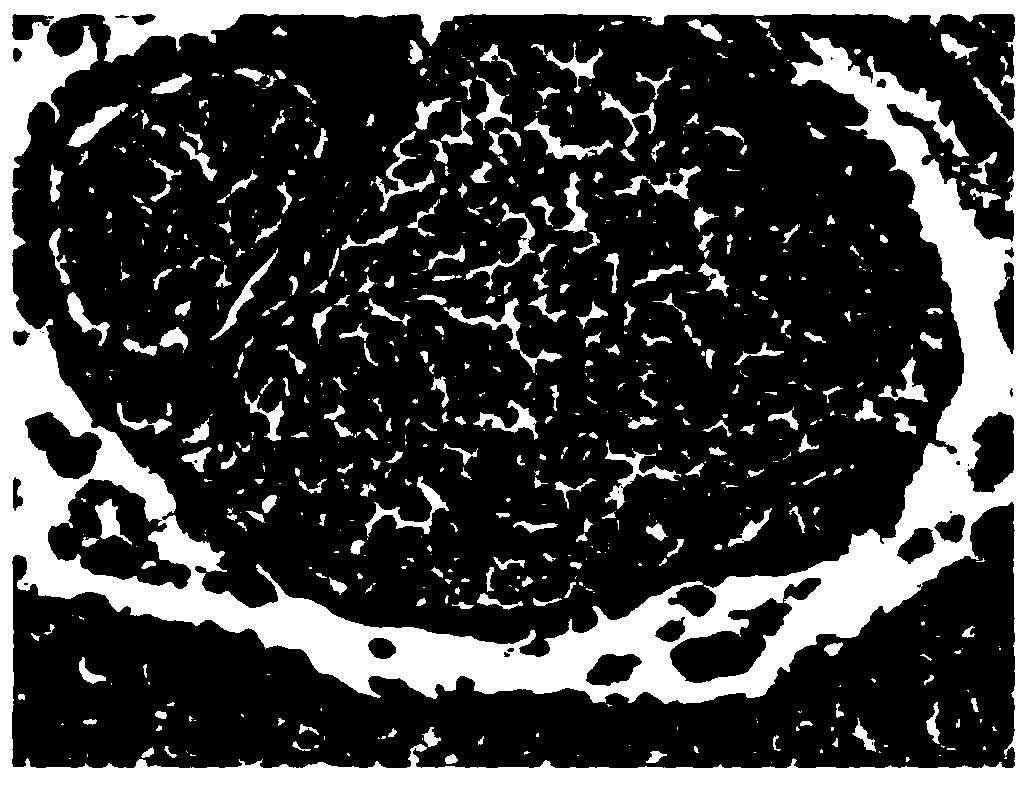

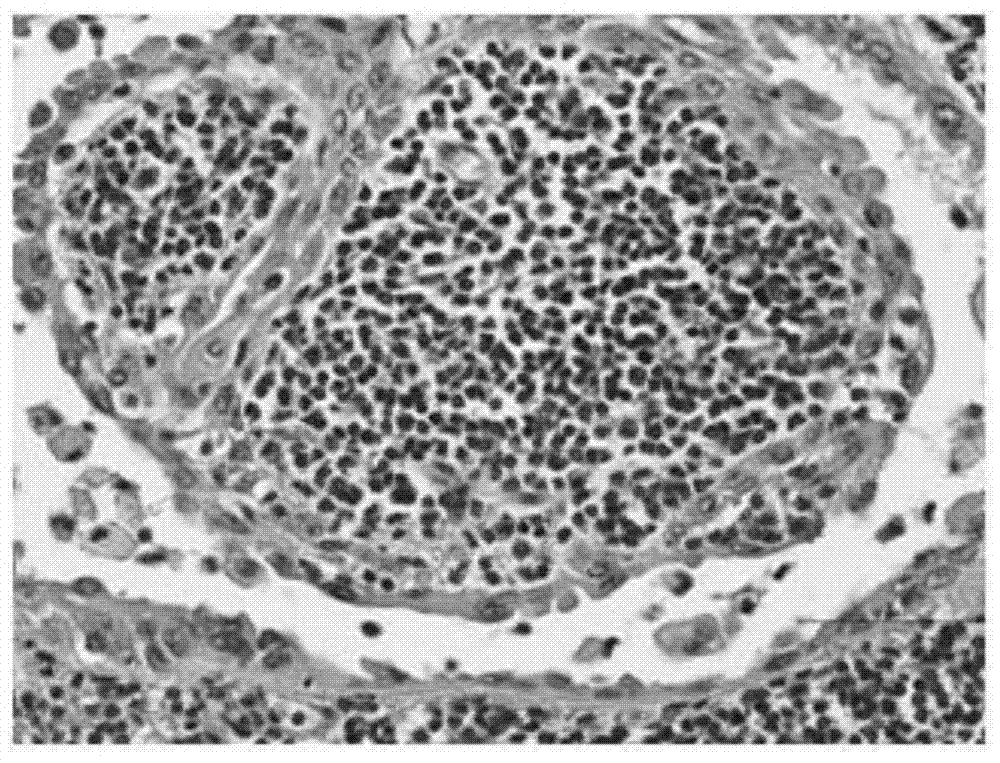

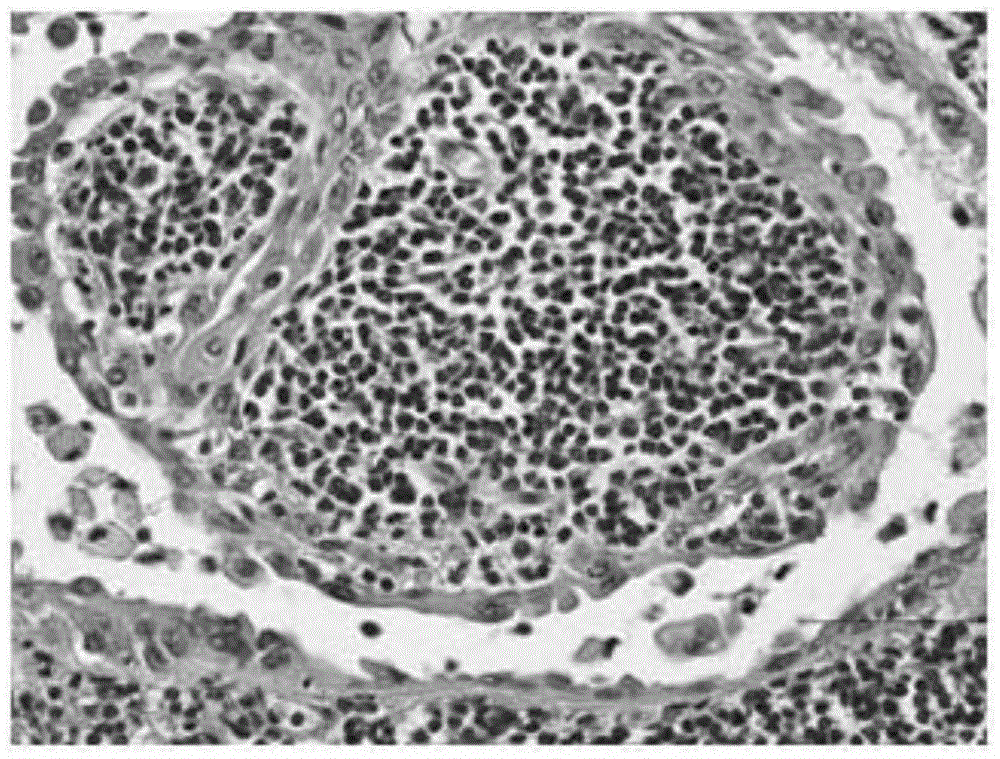

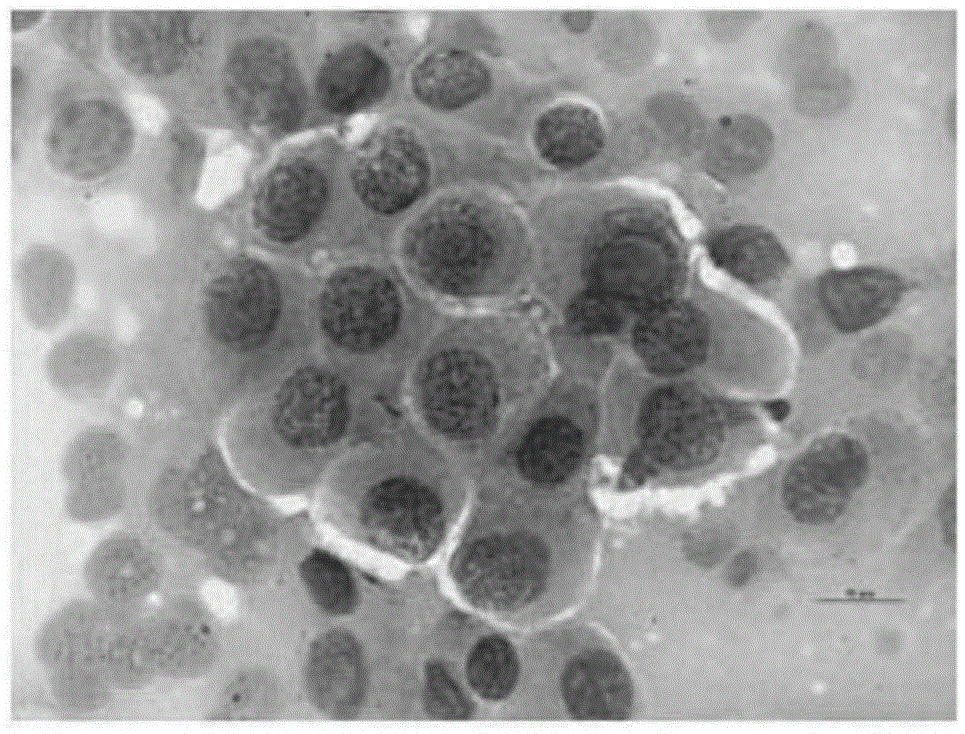

Hematoxylin eosin staining solution and preparation method thereof

ActiveCN103725040ALong validity periodEfficient removalPreparing sample for investigationOrganic dyesHematoxylin stainAlcohol

The invention provides a hematoxylin eosin staining solution, comprising a hematoxylin staining solution and an eosin staining solution, wherein the hematoxylin staining solution comprises hematoxylin, an alumium salt, an oxidizing agent, benzalkonium chloride, an alcohol, a weak acid and water; the eosin staining solution comprises eosin, Biebrich scarlet, flame red B, water and ethanol. The invention also provides a preparation method of the hematoxylin eosin staining solution, and a dyeing method thereof. When the hematoxylin eosin staining solution provided by the invention is used for dyeing slices, the effects of clear background, distinct gradation, good dyeing effect, easy slice reading, not easy fading and convenience for long-term storage can be achieved.

Owner:无锡市江原实业技贸有限公司

Eosin staining solution and HE staining solution containing same

ActiveCN104744967AEasy to operateReduce stepsPreparing sample for investigationOrganic dyesEosinBiebrich scarlet

The invention provides an eosin staining solution comprising the components of eosin, Biebrich scarlet, flame red, ethanol and water. The invention also provides a preparation method of the eosin staining solution, a HE staining solution containing the eosin staining solution and a staining method of the eosin staining solution. When the eosin staining solution provided by the invention is used for staining slices, the background is clear, the gradation is distinct, the staining effect is good, and the slices can be read easily, cannot fade easily and are convenient to store for a long time.

Owner:无锡市江原实业技贸有限公司

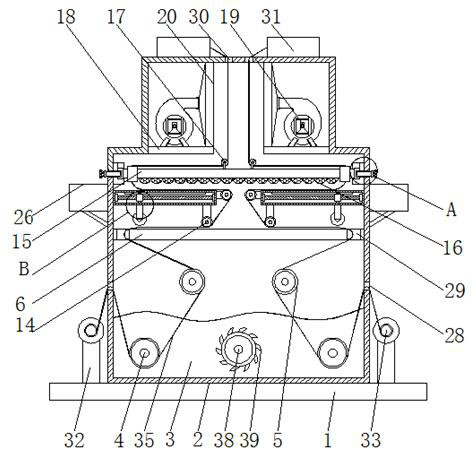

Printing and dyeing device for spinning

ActiveCN109056225AEasy to disassembleRegular cleaningMechanical cleaningPressure cleaningEngineeringCotton material

The invention discloses a printing and dyeing device for spinning. The device comprises a base, a printing and dyeing box is fixedly connected to the top of the base, dye is movably connected to the interior of the printing and dyeing box, two first guide rollers are fixedly connected to the interior of the printing and dyeing box and inside the dye, two second guide rollers are fixedly connectedto the interior of the printing and dyeing box and located over the first guide rollers, a material flattening plate is fixedly connected to the interior of the printing and dyeing box and located over the second guide rollers, the two sides of the inner wall of the printing and dyeing box are each fixedly connected with a material uniform box. The invention relates to the technical field of printing and dyeing. According to the printing and dyeing device for spinning, a material flattening wheel is used for rolling a cloth, then, a hair absorbing ball on a hair suction plate is used for adsorbing hair on a cloth, the cloth dyeing is more uniform, the working efficiency is high, the hair on the surface of the cloth is easily removed clearly, the whole cloth quality is improved, and the whole aesthetic feeling of the cloth is enhanced.

Owner:周煜皓

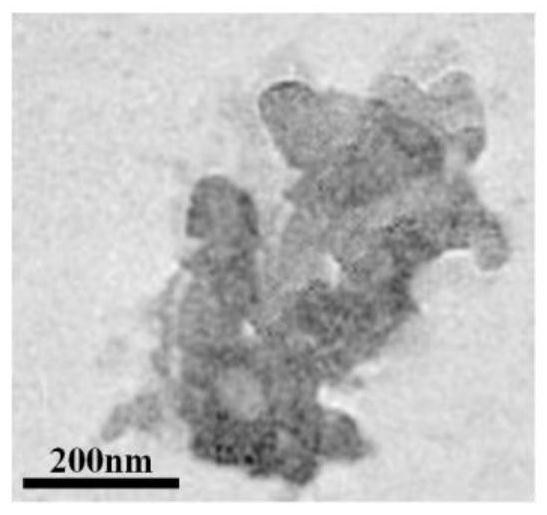

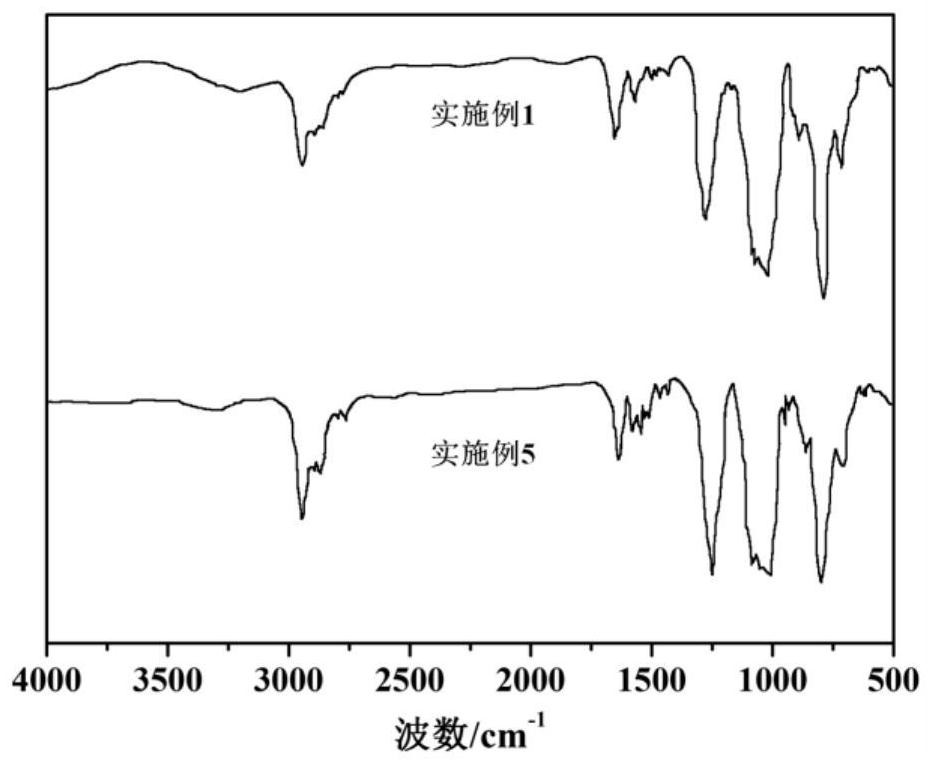

Aluminum alloy dyeing additive and dyeing method

The invention relates to the technical field of aluminum alloy, in particular to an aluminum alloy dyeing additive and a dyeing method. The aluminum alloy dyeing additive comprises the following raw materials of, by weight, 30-35 parts of nickel sulfate, 8-12 parts of stannous sulfate, 18-22 parts of sulfuric acid, 16-20 parts of a coloring stabilizer and 13-18 parts of a synergist. The dyeing additive is used for aluminum alloy dyeing, the dyeing efficiency and uniformity can be improved, the dyeing effect and the product yield are improved, the problems of color flowing, different colors andthe like in the dyeing process are solved, the service life of coloring liquid is prolonged, and aluminum alloy has a good appearance effect, good durability and long service life. An aluminum alloydyeing pretreatment method using the aluminum alloy dyeing pretreatment agent is simple and convenient to operate and easy to control, the dyeing efficiency and uniformity can be remarkably improved,the dyeing effect and the product yield are improved, an aluminum alloy dyeing workpiece with a uniform color and a good appearance effect can be obtained, and the aluminum alloy dyeing pretreatment method is suitable for industrial mass production.

Owner:东莞市新东明科技有限公司

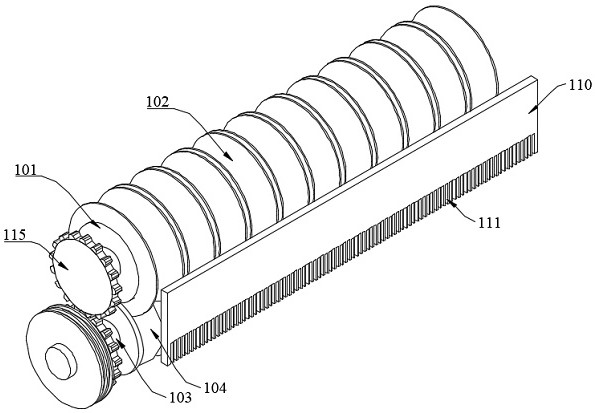

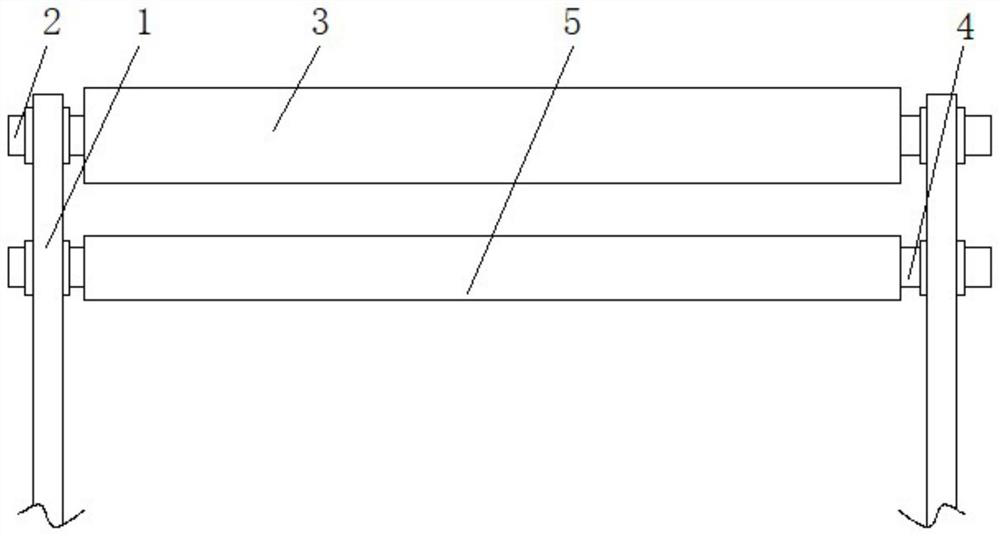

Degradable fiber dyeing equipment

ActiveCN112160086AStrong penetrating powerEasy to replaceLiquid/gas/vapor removalTextile treatment machine arrangementsFiberPolymer science

The invention discloses a degradable fiber dyeing equipment. The degradable fiber dyeing equipment comprises a dyeing pool. The two ends of the bottom of the dyeing pool are rotationally connected with material distribution rollers, and extrusion rollers are arranged below the material distribution rollers. A stirring mechanism comprises a stirring shaft rotationally connected with the dyeing pool, and a plurality of stirring blades are connected to the top end of the stirring shaft. Guide mechanisms comprise guide rollers, the two ends of the guide rollers are rotationally connected with thedyeing pool, and a plurality of guide grooves are axially arrayed in the guide rollers. A drying mechanism is used for quickly drying dyed fibers. A winding mechanism comprises a liftable transfer roller and a pair of winding frames, the transfer roller is arranged between the drying mechanism and the winding frames, and a winding roller is arranged between the winding frames. According the degradable fiber dyeing equipment, bubbles in fibers are discharged during dyeing, dye infiltration is facilitated, soaking time is shortened, dyeing liquid of different depths is fully mixed in the dyeingprocess, uneven dyeing is prevented, square blocks are inserted into grooves during winding roller installation, limiting blocks are assembled in the grooves, winding frames do not need to be moved, and equipment stability is high.

Owner:SHAOXING UNIVERSITY

Novel indigo blue reducing and dyeing method

The invention belongs to the technical field of textile printing and dyeing, and especially relates to an indigo blue reducing and dyeing method. The clean indigo blue reducing and dyeing method is provided to avoid the problems of poor labor environment and excessive amount of sulfate substances in wastewater in the traditional indigo blue reducing and dyeing process. The method provided by the invention has the advantages of no irritating odor in the reducing and dyeing process, mild reaction process, easiness in control, and no sulfur-containing substances in the wastewater. An indigo bluedyed fabric obtained by dyeing using the method has a soft color and a good color fastness.

Owner:CHANGZHOU UNIV

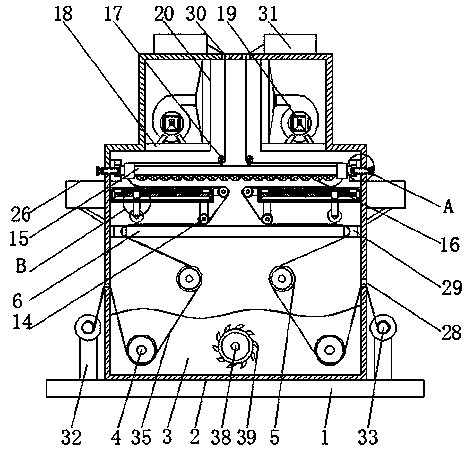

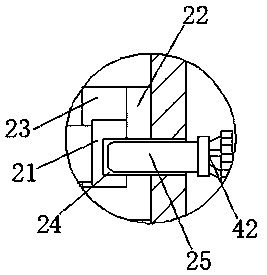

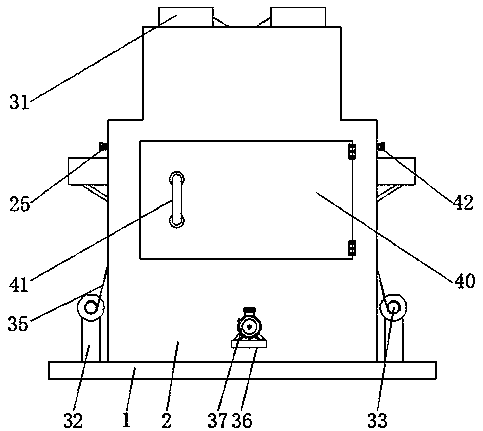

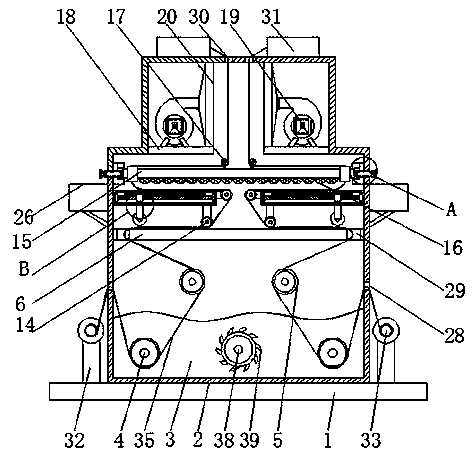

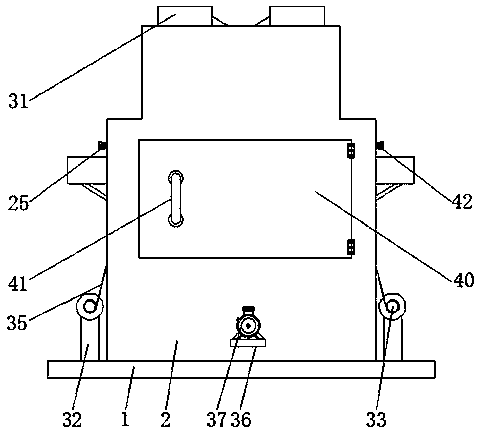

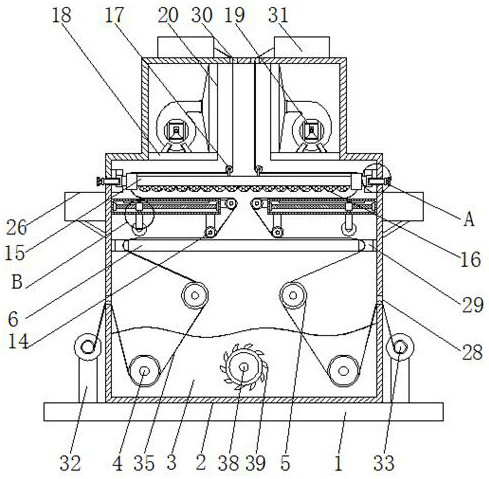

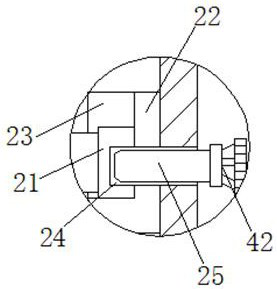

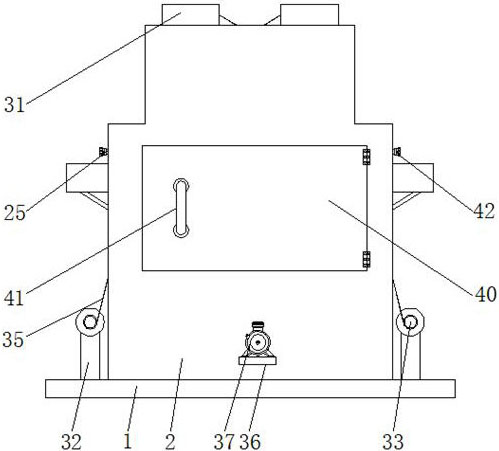

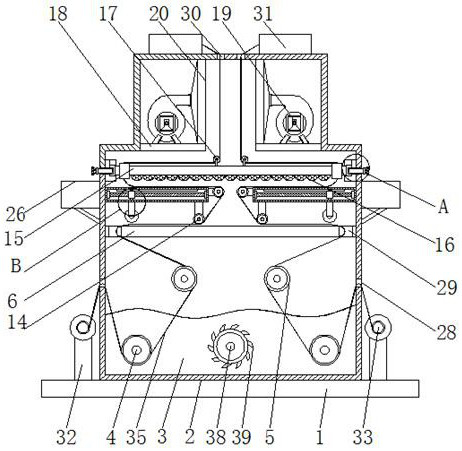

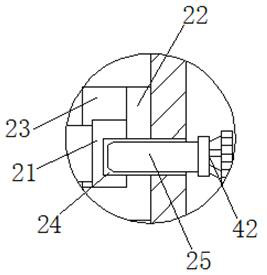

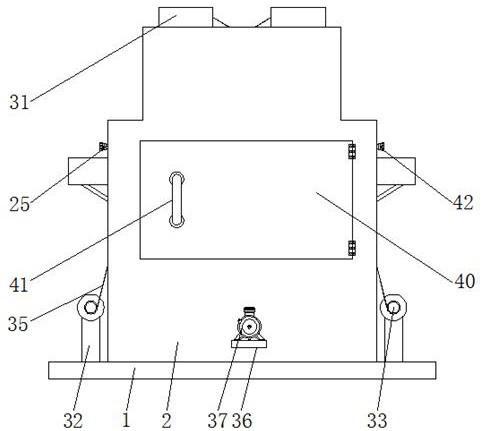

Box type printing and dyeing device for spinning

ActiveCN109056249AEasy to disassembleRegular cleaningMechanical cleaningPressure cleaningEngineeringDyeing

The invention discloses a box type printing and dyeing device for spinning. The device comprises a base, a printing and dyeing box is fixedly connected to the top of the base, dye is movably connectedto the interior of the printing and dyeing box, two first guide rollers are fixedly connected to the interior of the printing and dyeing box and inside the dye, two second guide rollers are fixedly connected to the interior of the printing and dyeing box and located over the first guide rollers, a material flattening plate is fixedly connected to the interior of the printing and dyeing box and located over the second guide rollers, the two sides of the inner wall of the printing and dyeing box are each fixedly connected with a material uniform box. The invention relates to the technical fieldof printing and dyeing. According to the printing and dyeing device for spinning, a material flattening wheel is used for rolling a cloth, then, a hair absorbing ball on a hair suction plate is usedfor adsorbing hair on a cloth, the cloth dyeing is more uniform, the working efficiency is high, the hair on the surface of the cloth is easily removed clearly, the whole cloth quality is improved, and the whole aesthetic feeling of the cloth is enhanced.

Owner:周煜皓

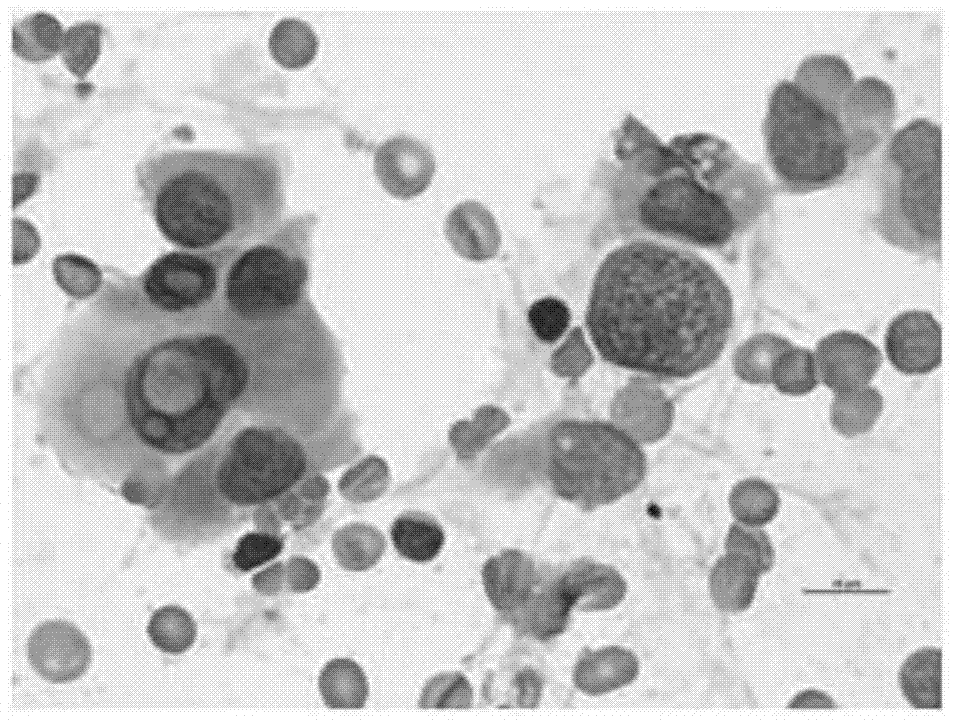

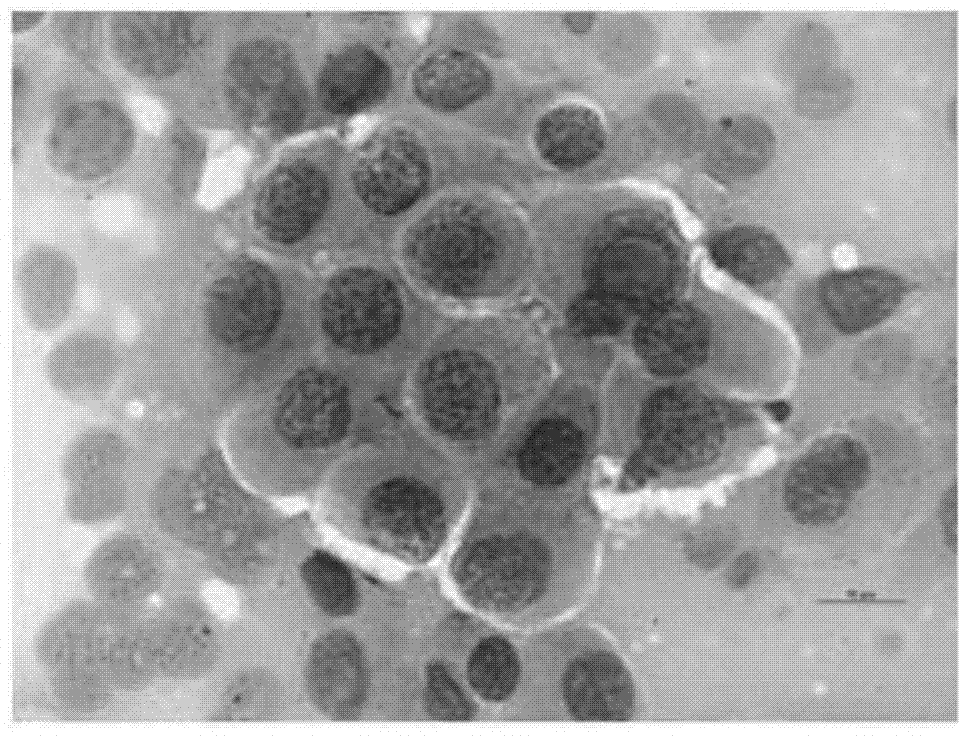

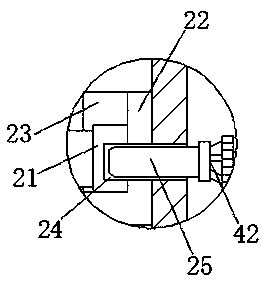

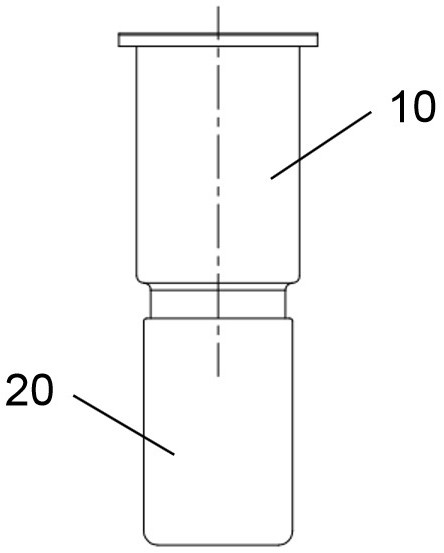

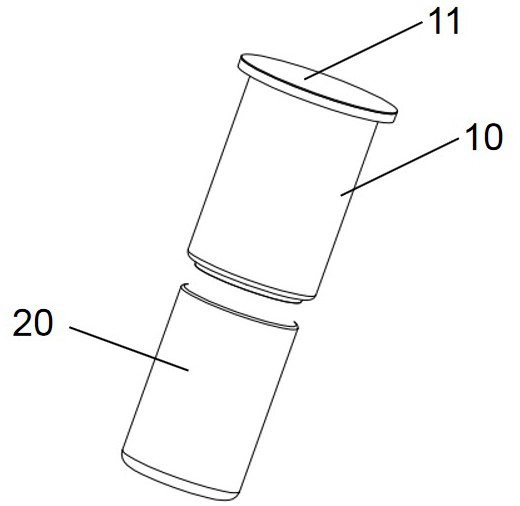

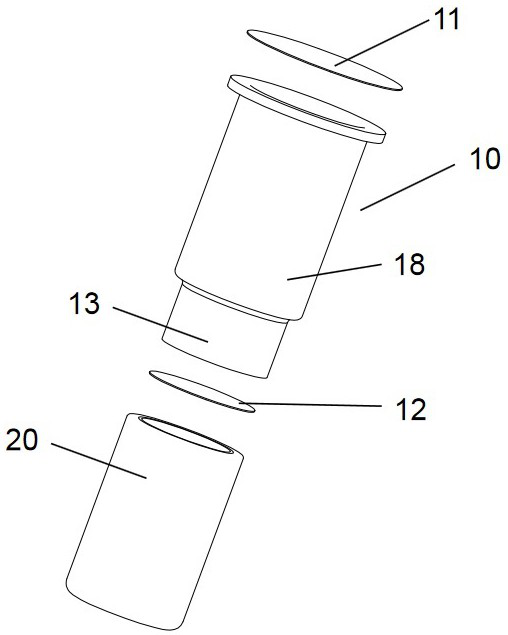

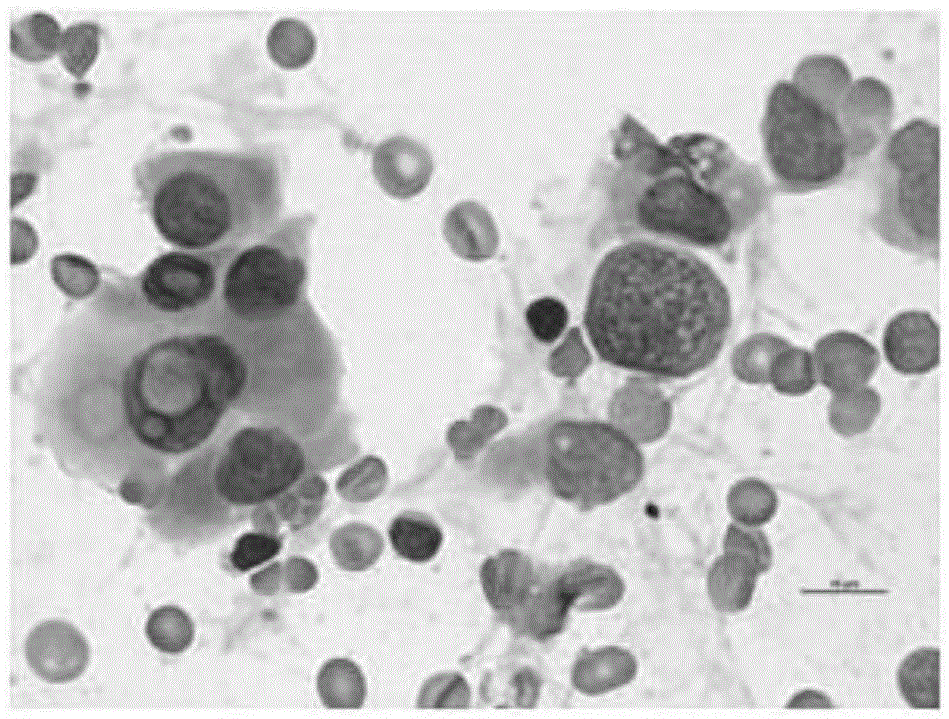

Reagent device and secondary staining method

PendingCN112504795AExtended shelf lifeSimple and ingenious structurePreparing sample for investigationMechanical engineeringMedicine

The invention discloses a reagent device and a secondary staining method. A sampling nozzle in a sampling device punctures a sealing film at the top of a first container after sampling, and a sample is mixed with a first reagent in the first container to finish first staining; the sampling device and the first container are continuously pushed or rotated downwards to enable a piercing device to bein contact with and pierce a bottom sealing film, and the sample mixed solution after the first staining is mixed with a second reagent in a second container to form a sample mixed solution after thesecond staining; and the sampling device is inverted together with the first container and the second container, the sample mixed solution stained for the second time is dropped into a mixed solutionpaving device from a sample outlet nozzle through the second container, the first container, the sampling nozzle and a sample accommodating channel in sequence, and the mixed solution is flattened inthe mixed solution paving device for microscopic examination. The reagent device is simple and ingenious in structure, very convenient to perform efficient secondary staining, simple to operate, goodin cell staining effect, obvious in stained cell characteristics and suitable for cell analysis in a bright field of view.

Owner:SHENZHEN ANLV MEDICAL TECH CO LTD

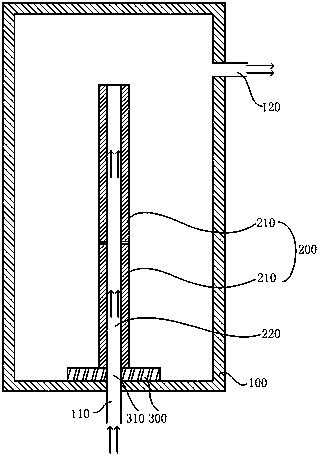

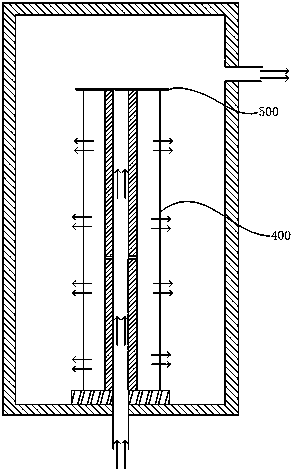

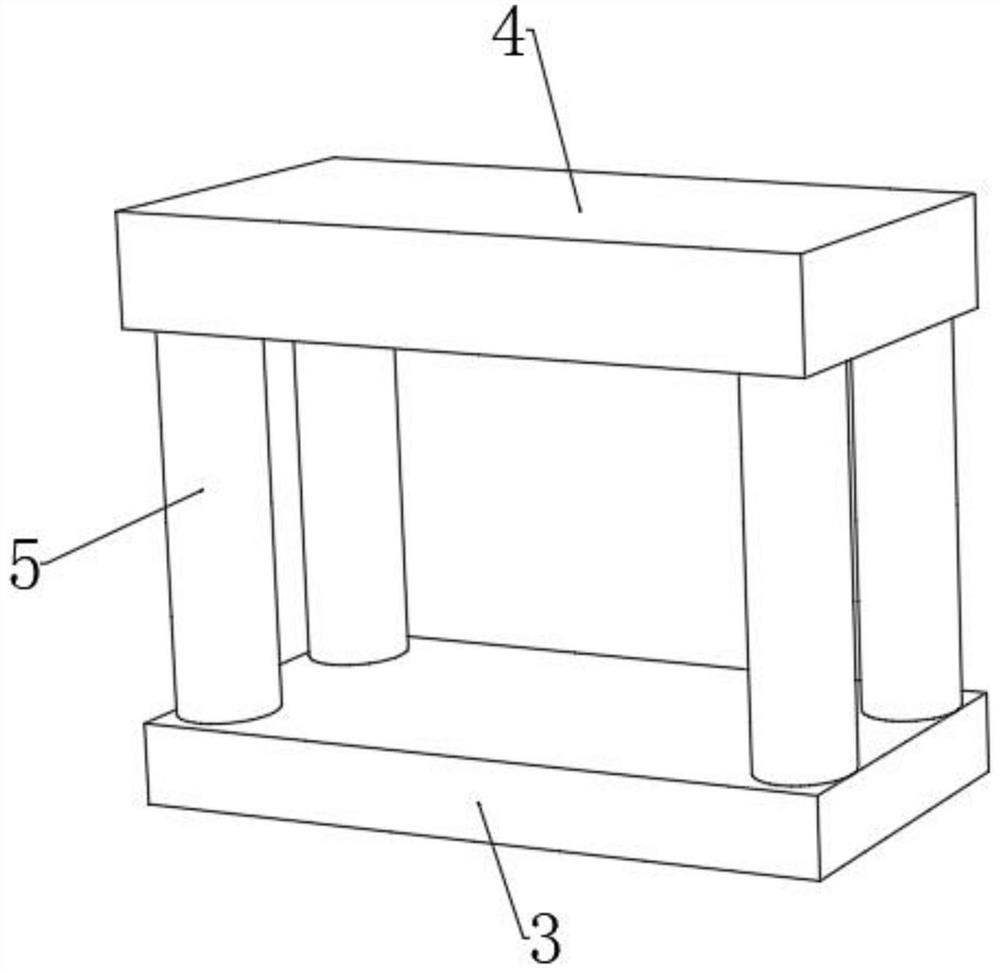

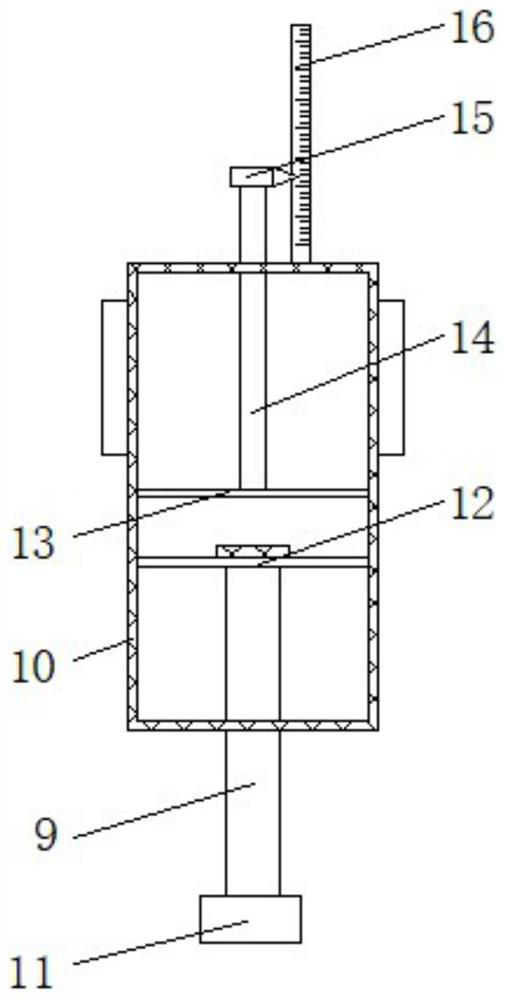

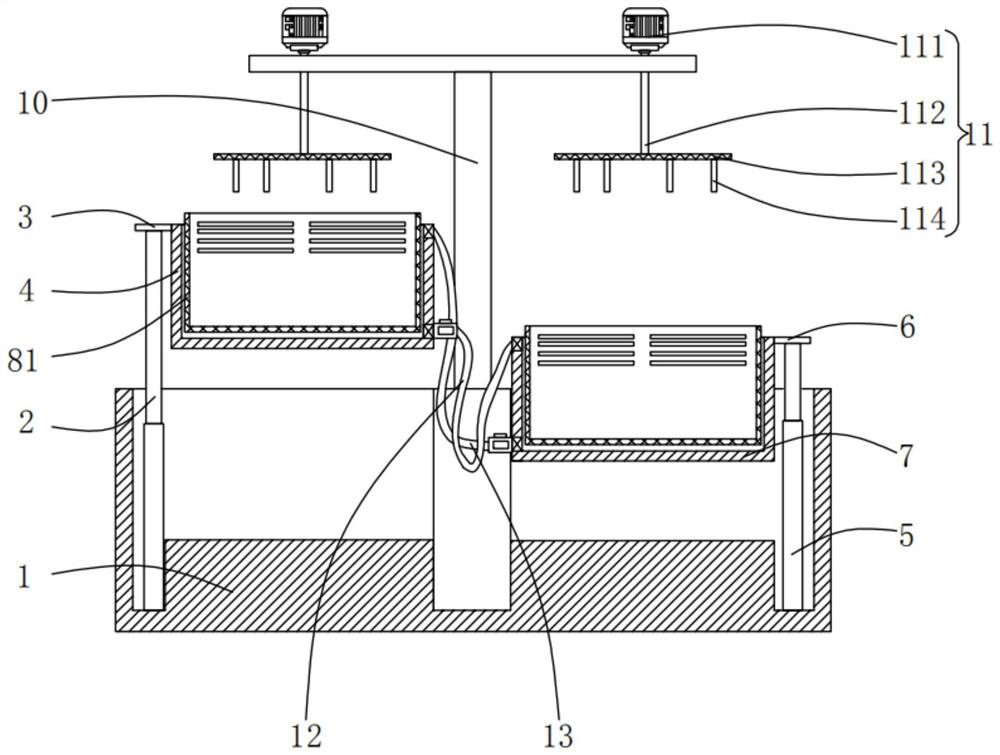

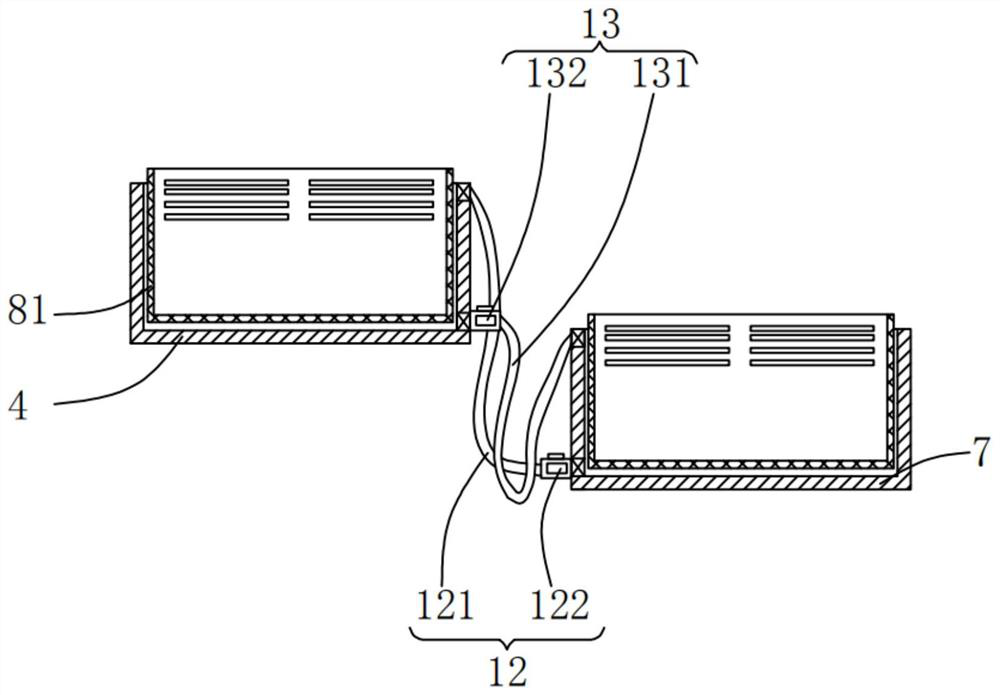

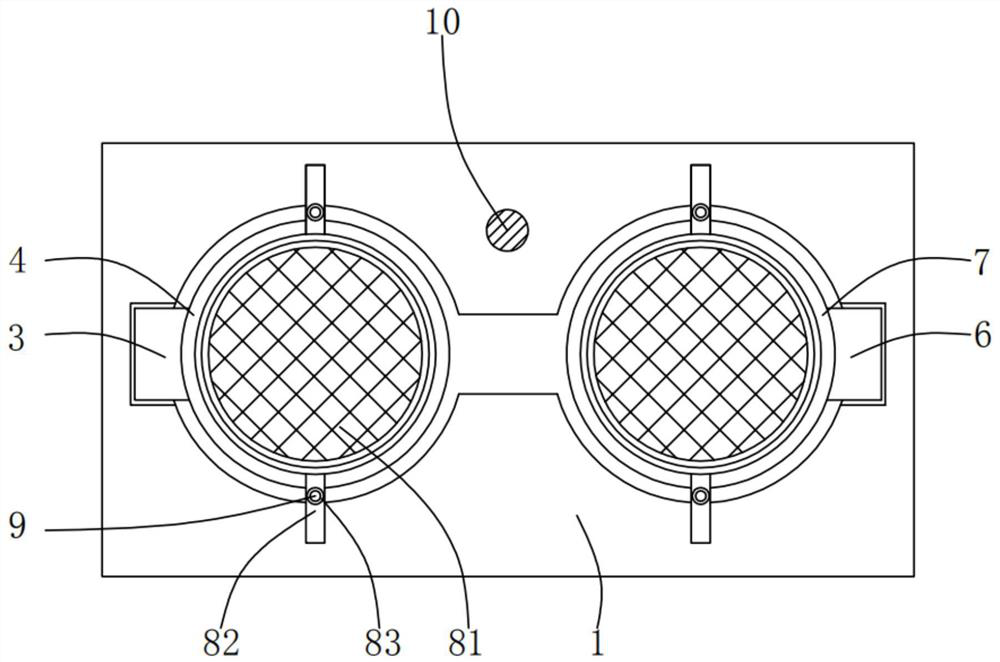

Dyeing kettle and dyeing device for supercritical dyeing

InactiveCN108823866AAvoid contaminationAvoid uneven stainingTextile treatment containersTextile solvent-dyeingYarnOligomer

The invention discloses a dyeing kettle and dyeing device for supercritical dyeing. The dyeing device comprises a hollow dyeing kettle body, wherein the bottom of the dyeing kettle body is provided with an air inlet; the side wall of the dyeing kettle body is provided with an air outlet; the inner part of the dyeing kettle body is provided with a yarn dyeing column; a first through hole is arranged in the yarn dyeing column; the first through hole is communicated with the air inlet. The yarn dyeing column is composed of a plurality of sub yarn dyeing columns in series connection, and the material of the sub yarn dyeing column is a sintered metal porous filtering material. While ensuring that the supercritical carbon dioxide fluid with dye flows from the pores on the side wall of the yarn dyeing column to a cone yarn to dye the yarn, the oligomer and dye separated out from the supercritical carbon dioxide fluid after dyeing during the pressure reduction separation process can be filtered and prevented from sticking to the inner wall of the cone yarn, which causes contamination to the inner layer yarn, and results in uneven dyeing, so that the dyeing is uniform, and the mass production of supercritical carbon dioxide waterless dyeing of the cone yarn is facilitated.

Owner:QINGDAO JIFA GROUP

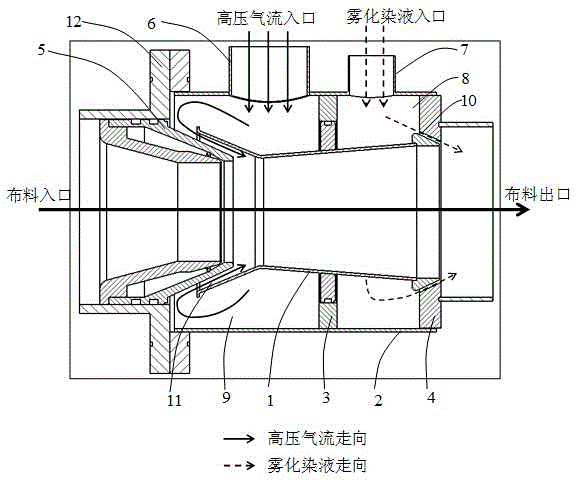

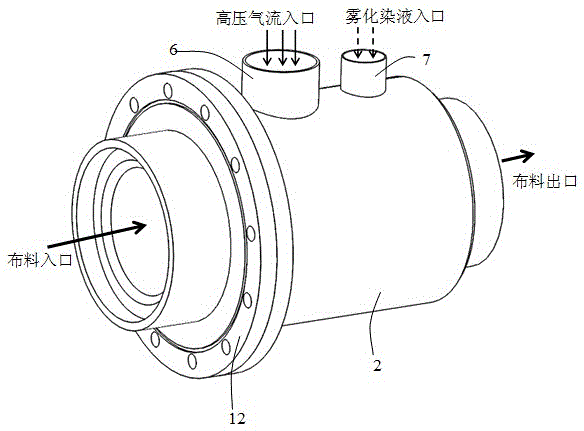

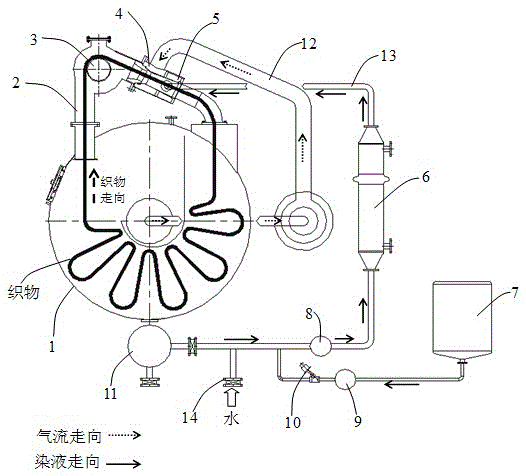

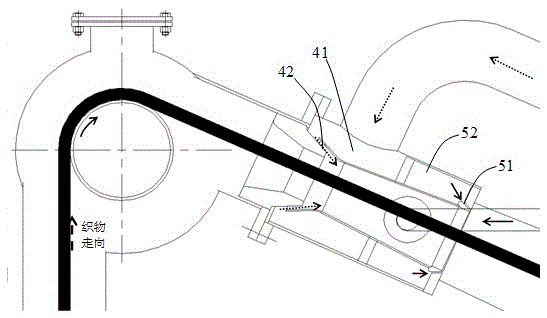

A gas-liquid split nozzle for a dyeing machine

InactiveCN104047135BReduce energy consumptionEasy to control independentlyLiquid spraying apparatusTextile treatment by spraying/projectingProcess engineeringMechanical engineering

The invention discloses a gas-liquid diverting nozzle for a dyeing machine, which includes a nozzle body, a shell, a partition, a terminal positioning seat, a front positioning sleeve, etc., and an air jet flow path, a dye liquor jet flow path, and airflow annular chamber, dye liquor annular chamber; the airflow injection flow path is separated from the dye liquor injection flow path, and the parameters of airflow and dye liquor flow can be independently controlled; the airflow injection flow path is located before the dye liquor injection flow path, and can be first The entangled fabric is fluffy and blown open, and then the dye liquor is sprayed and penetrated, which greatly improves the use efficiency of the dye liquor, improves the leveling performance of the dyeing, the color yield, shortens the dyeing time, and reduces the use of auxiliaries and dyes The total amount can effectively reduce the total amount of COD to achieve the purpose of saving energy, reducing consumption, and being low-carbon and environmentally friendly. The present invention can also prevent uneven dyeing caused by wrinkles of the fabric, fully utilize the impulsive force of the jetting of the dye liquor and the airflow to pull the fabric forward, and reduce the energy consumption of the air-liquid split dyeing machine.

Owner:高勋绿色智能装备(广州)有限公司

Production method of bamboo fiber siro compact spinning finished product fabric

The invention discloses a production method of a bamboo fiber siro compact spinning finished product fabric. The production method sequentially comprises the steps of grey yarn finishing, doubling treatment, color yarn processing, loom beam production, pattern design, grey fabric weaving, finishing and repairing, and dyeing and finishing treatment. The problems that in the bamboo fiber siro compact spinning process, defects such as elastic twisting, untwisting, multiple strands and few strands of plied yarn bobbins, wrong dyed yarn count, cloth cover yarn sinking and yarn skipping frequently occur and cloth cover dyeing is not uniform can be effectively solved.

Owner:JIANGSU YUEDA HOME TEXTILE

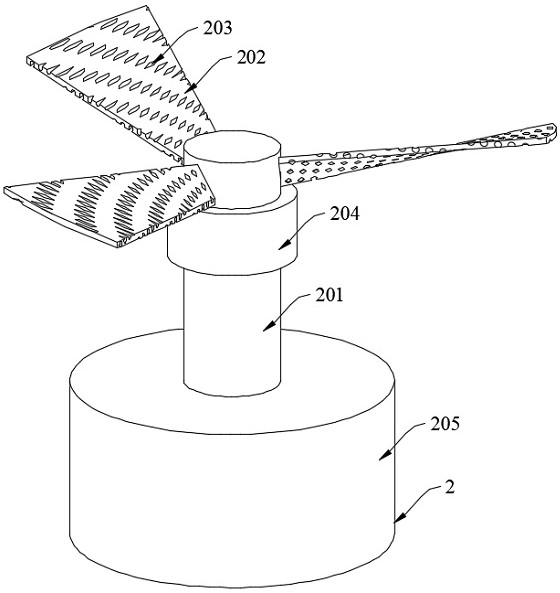

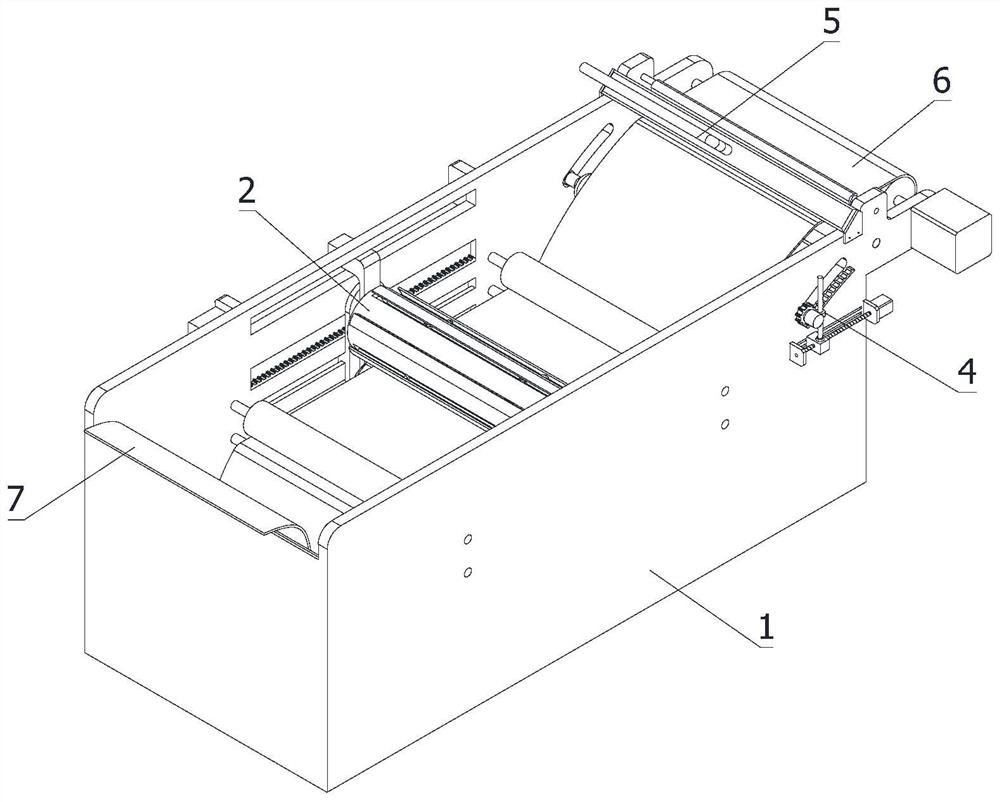

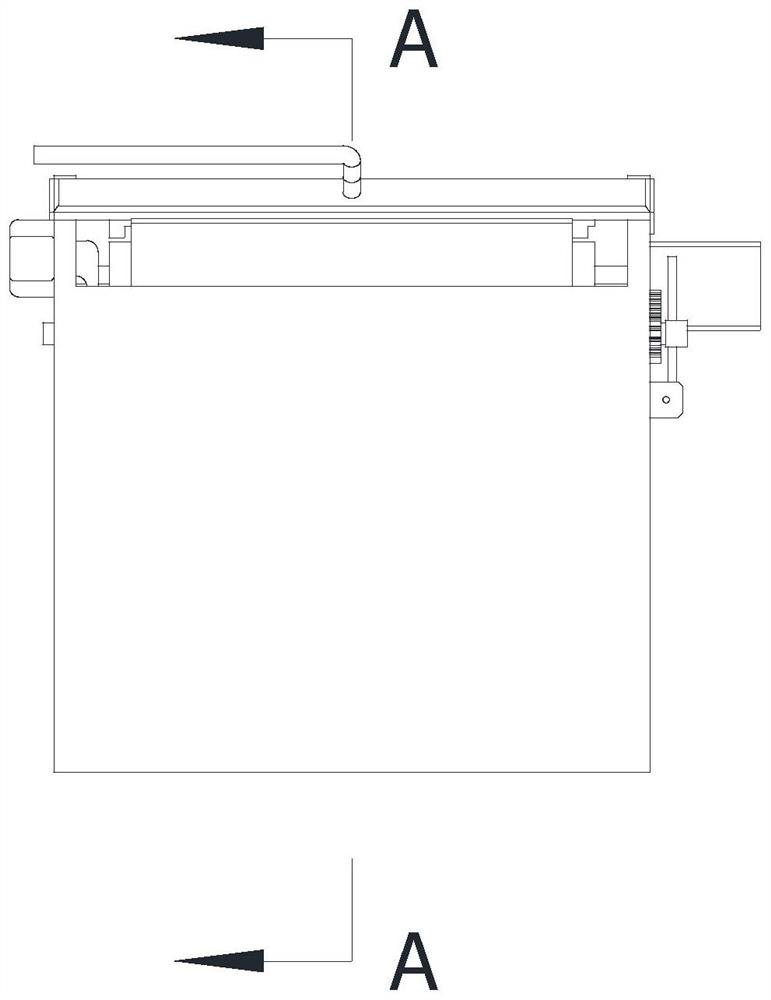

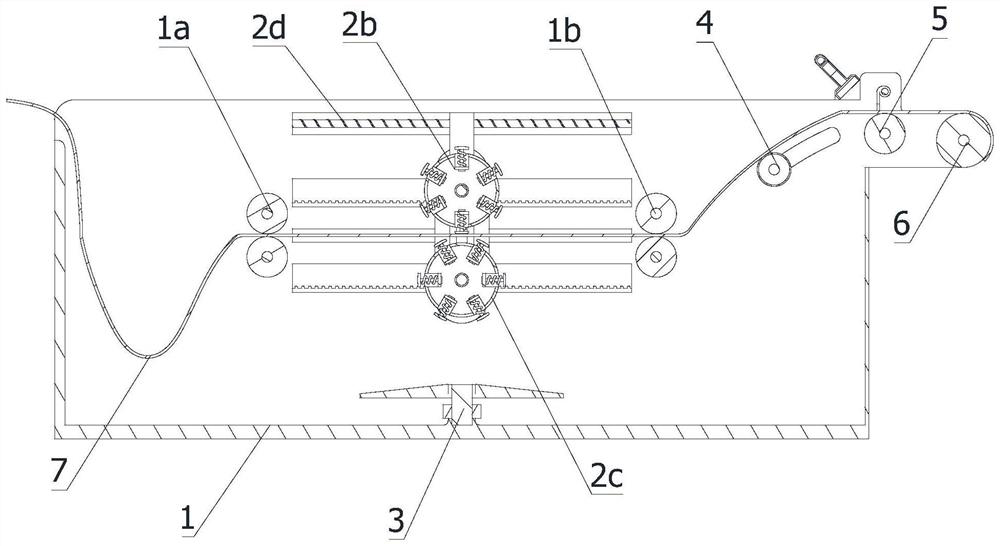

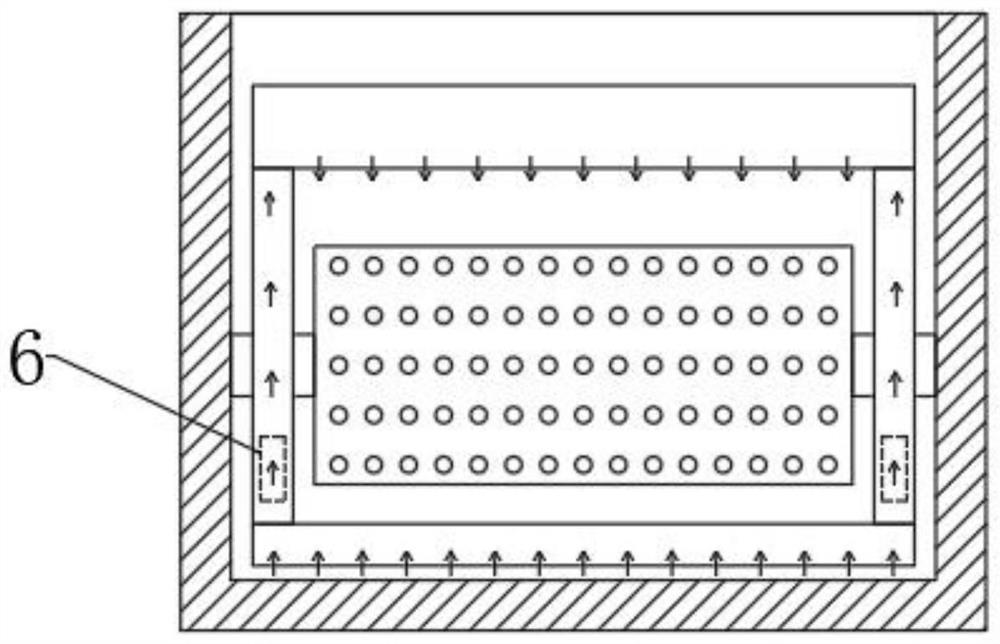

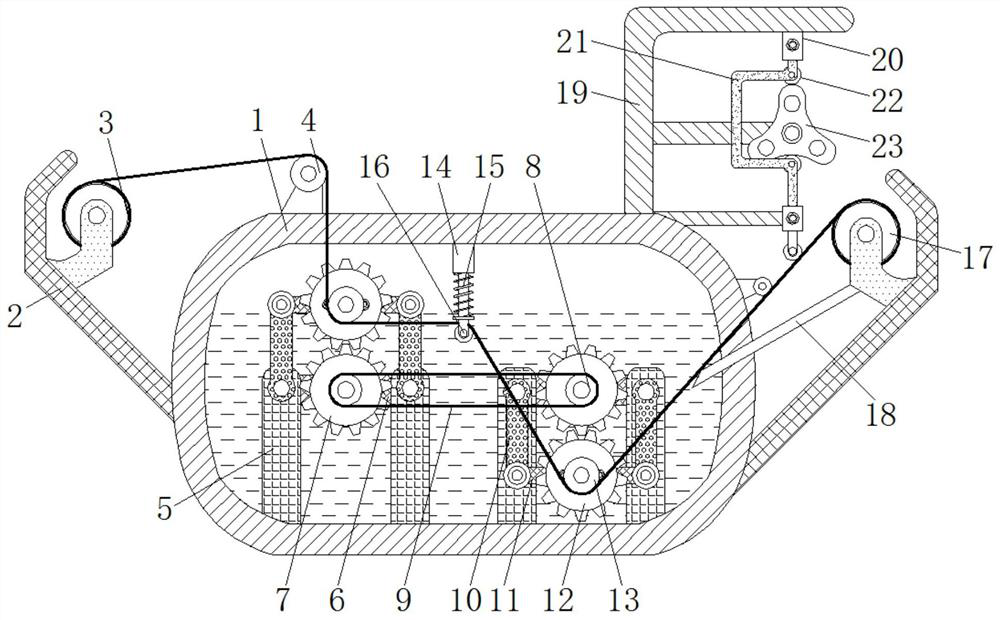

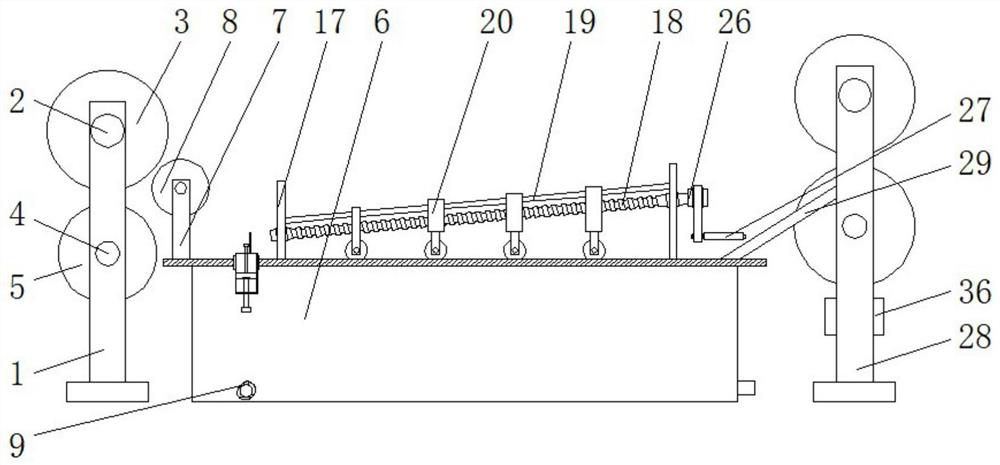

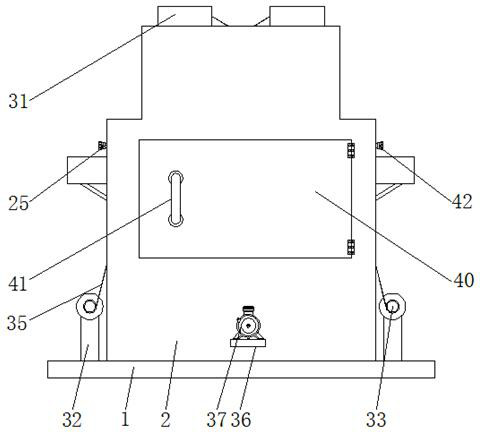

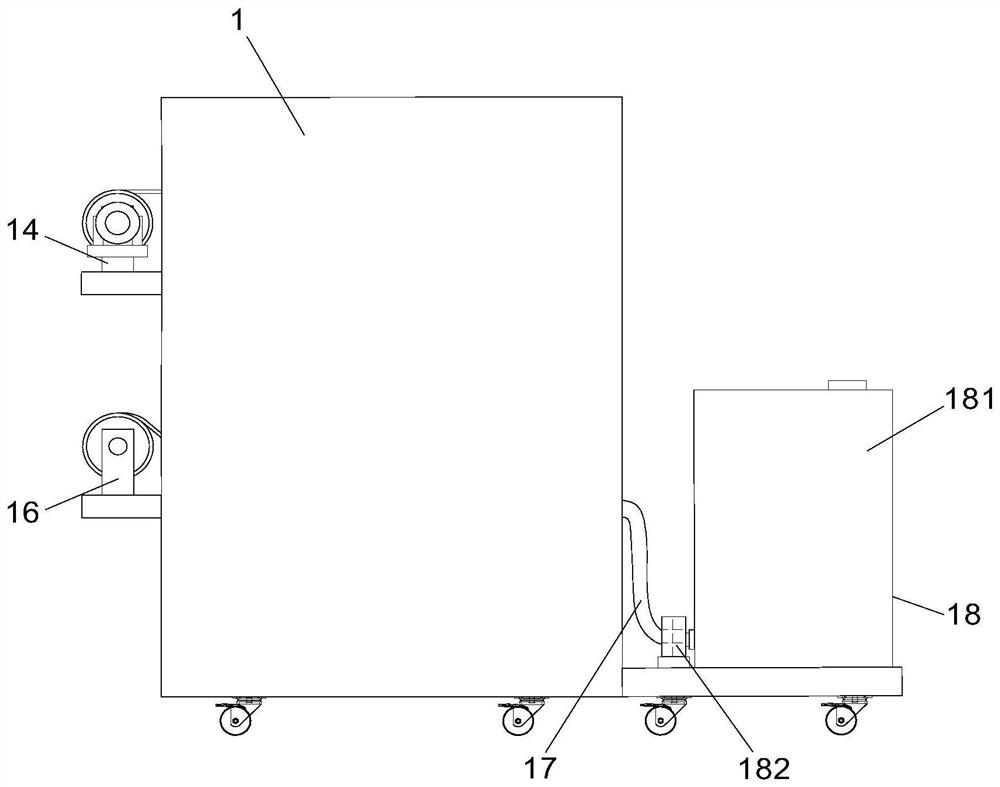

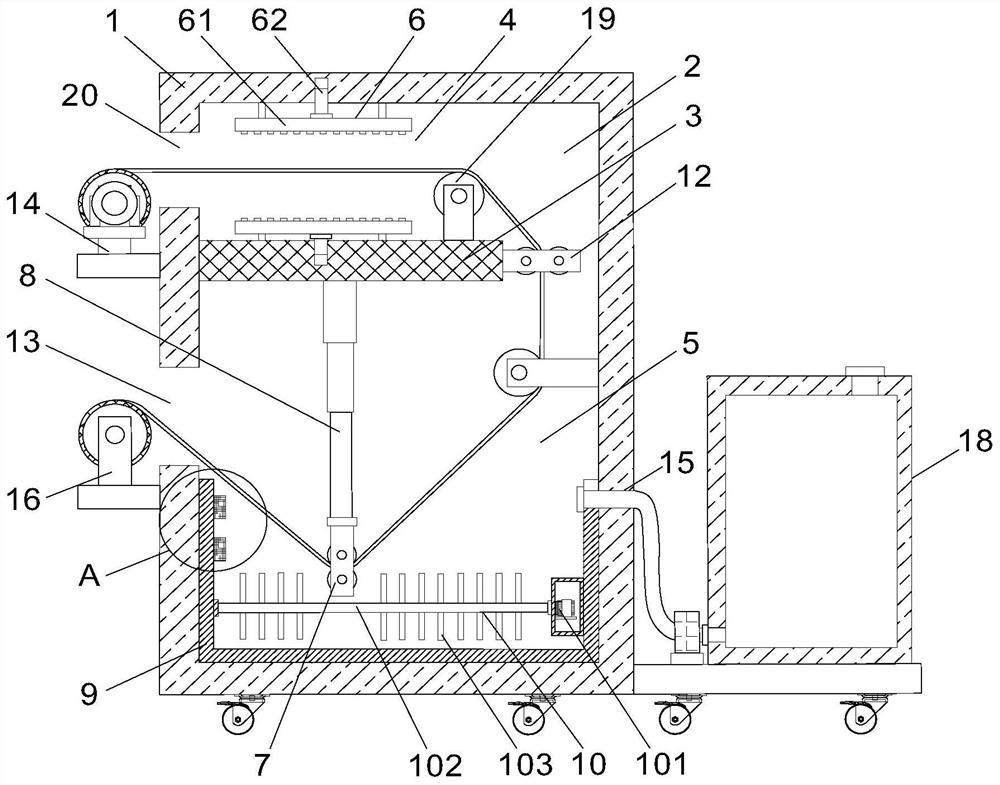

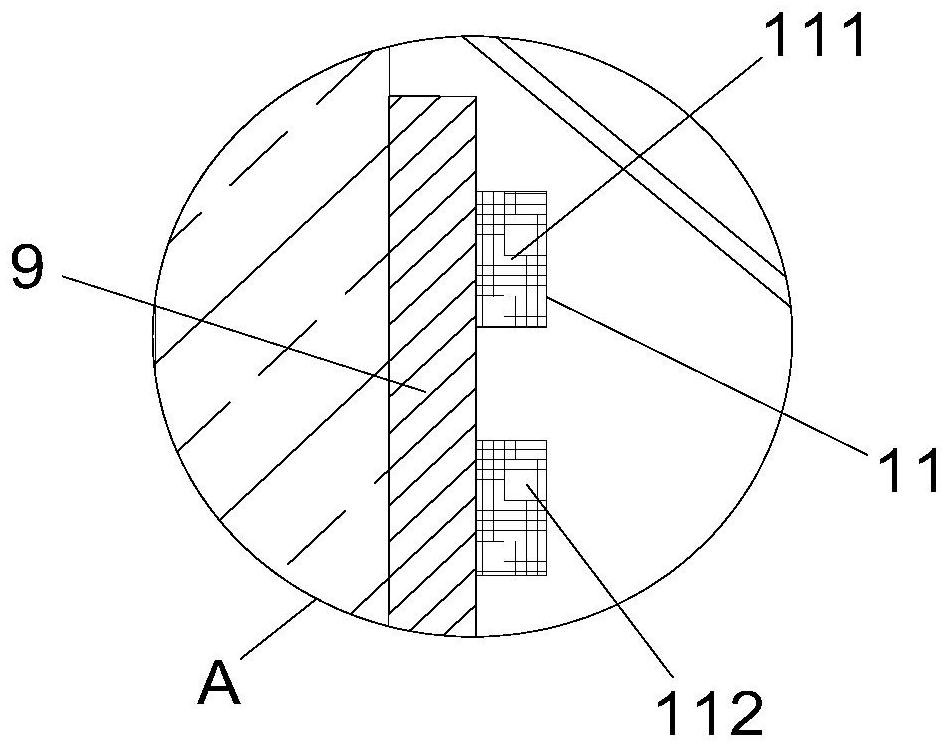

Double-sided uniform rolling type full-automatic intelligent dye vat and method

PendingCN114277532ARemove in timeAvoid uneven stainingMechanical cleaningTextile treatment containersProcess engineeringIndustrial engineering

The invention relates to the technical field of textile fabric processing, in particular to a double-sided uniform rolling type full-automatic intelligent dye vat and a method, and aims to solve the problems of miscellaneous wool, non-uniform dyeing and insufficient dyeing of textile fabrics. The double-sided uniform rolling type full-automatic intelligent dye vat comprises a dye box, an extrusion permeation roller set arranged in the dye box and an anti-precipitation stirring assembly, the anti-precipitation stirring assembly is arranged in the dye box and located below the extrusion permeation roller set, and the stress end of the anti-precipitation stirring assembly is connected with the non-working part of the extrusion permeation roller set; the device comprises a dye box, a rapid drying mechanism, a miscellaneous wool removing mechanism and a winding mechanism, the rapid drying mechanism, the miscellaneous wool removing mechanism and the winding mechanism are sequentially installed at one end of the dye box, the problems of uneven dyeing and insufficient dyeing in the fabric dyeing process can be avoided through the device, and miscellaneous wool on the surface of a fabric can be removed in time.

Owner:芜湖生源纺织科技有限公司

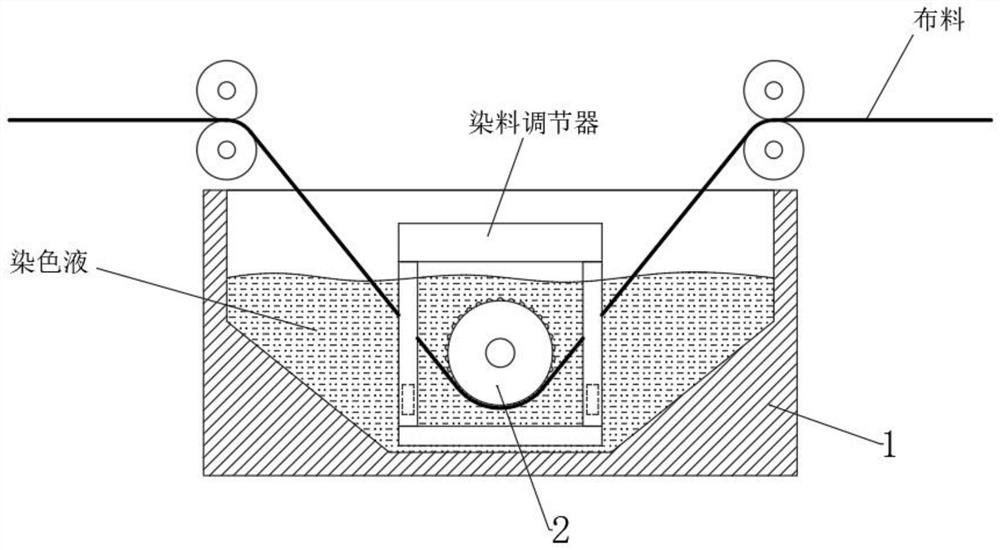

Dyeing device for textile coarse cloth and using method thereof

PendingCN114000289AAvoid uneven stainingImprove dyeing efficiencyTextile treatment containersTextile treatment machine arrangementsProcess engineeringDyeing

The invention discloses a dyeing device for textile coarse cloth and a using method of the dyeing device, and belongs to the field of textile production equipment. The dyeing device is characterized in that a dye regulator is additionally arranged on the basis of an existing dyeing vat to effectively prevent dye from sinking, the dye regulator pumps dyeing liquid located under the cloth into a water falling box through a water pump, and after water enters the water falling box, under the action of buoyancy, a buoyancy releaser ascends, so that the dyeing liquid falls down from a water falling hole, and the dyeing liquid is conveyed from the bottom to the upper part; the problem that dye is deposited to the bottom due to gravity is effectively solved, the dyeing liquid is mixed and stirred, non-uniform dyeing of cloth is effectively prevented, the trouble in mixing stirring by shutdown is also avoided, the dyeing efficiency is effectively improved; and in addition, hole pricking balls are additionally arranged on the basis of a roller to prick the cloth, so that penetration of the dye is effectively improved.

Owner:南通唯诺思家纺科技有限公司

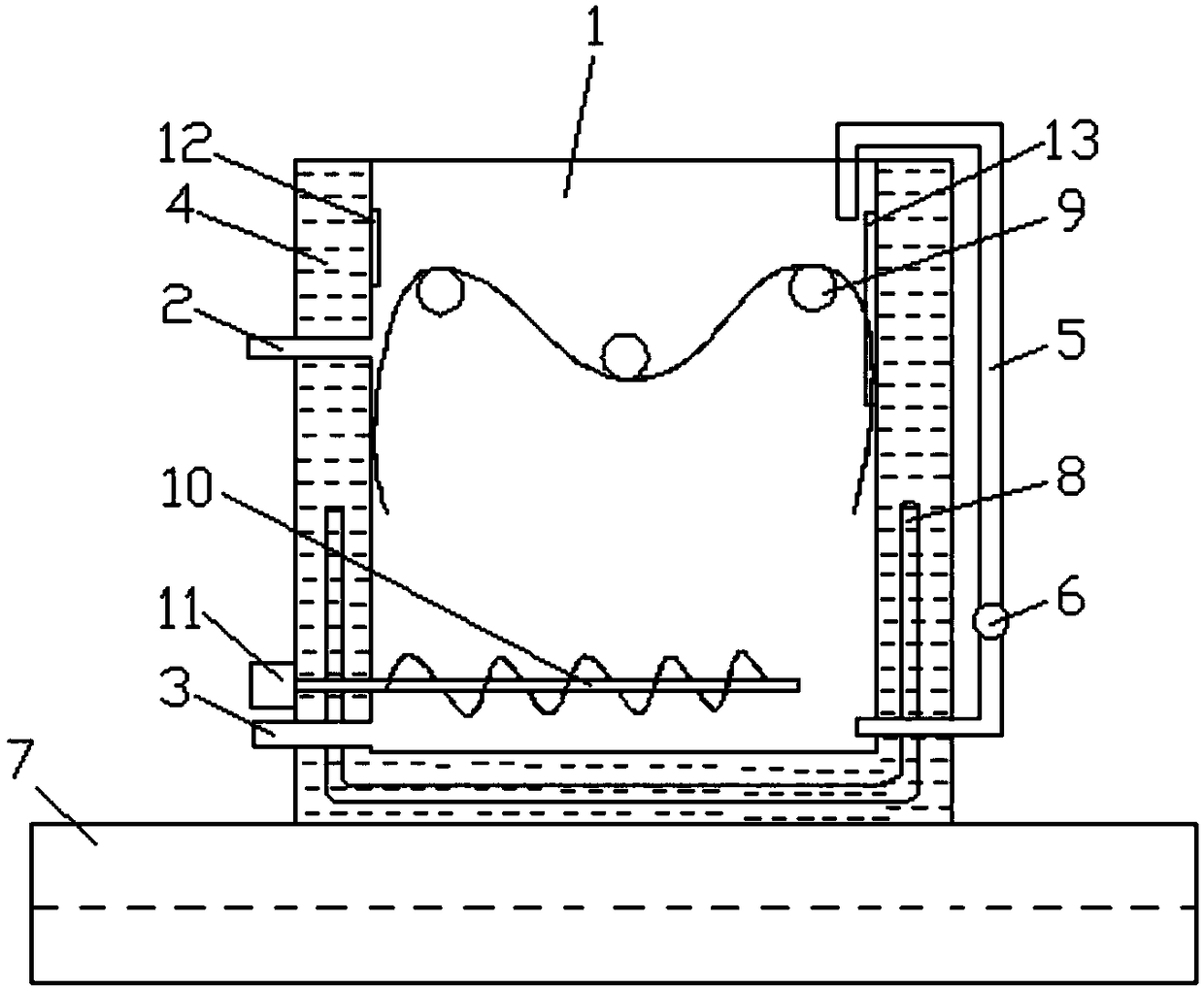

Non-woven cloth dyeing device and process

ActiveCN108754942AUniform dyeingKeep cleanTextile treatment machine arrangementsDyeing processDyeingEngineering

The invention relates to a non-woven cloth dyeing device which comprises a dyeing pot, wherein the top of the dyeing pot is opened; a liquid inlet and a liquid discharge hole are respectively formed in the upper part and the lower part of the side wall of the dyeing pot; a liquid bath heating layer is arranged on the side wall of the dyeing pot; a heating mechanism is arranged inside the liquid bath heating layer; a suspension mechanism for suspending cloth and a stirring mechanism are sequentially arranged from top to bottom inside the dyeing pot; a bent tube is arranged on one side of the dyeing pot; the lower end of the bent tube is communicated with the interior of the dyeing pot; the upper end of the bent tube is positioned above the top of the dyeing pot; a water pump is arranged onthe bent tube; a base is arranged at the bottom of the dyeing pot; the edge of the upper surface of the base concaves inwards to form a recycling groove; the recycling groove is communicated with a recycling tank through a pipeline. The invention further provides a non-woven cloth dyeing process. The dyeing process is simple. The non-woven cloth dyeing device has the beneficial effects that a dyeing liquid can be effectively prevented from deposition or layering, the dyeing liquid in the dyeing pot can be uniformly distributed, non-woven cloth can be dyed uniformly and brightly, and color fastness can be achieved.

Owner:稳健医疗用品(荆门)有限公司

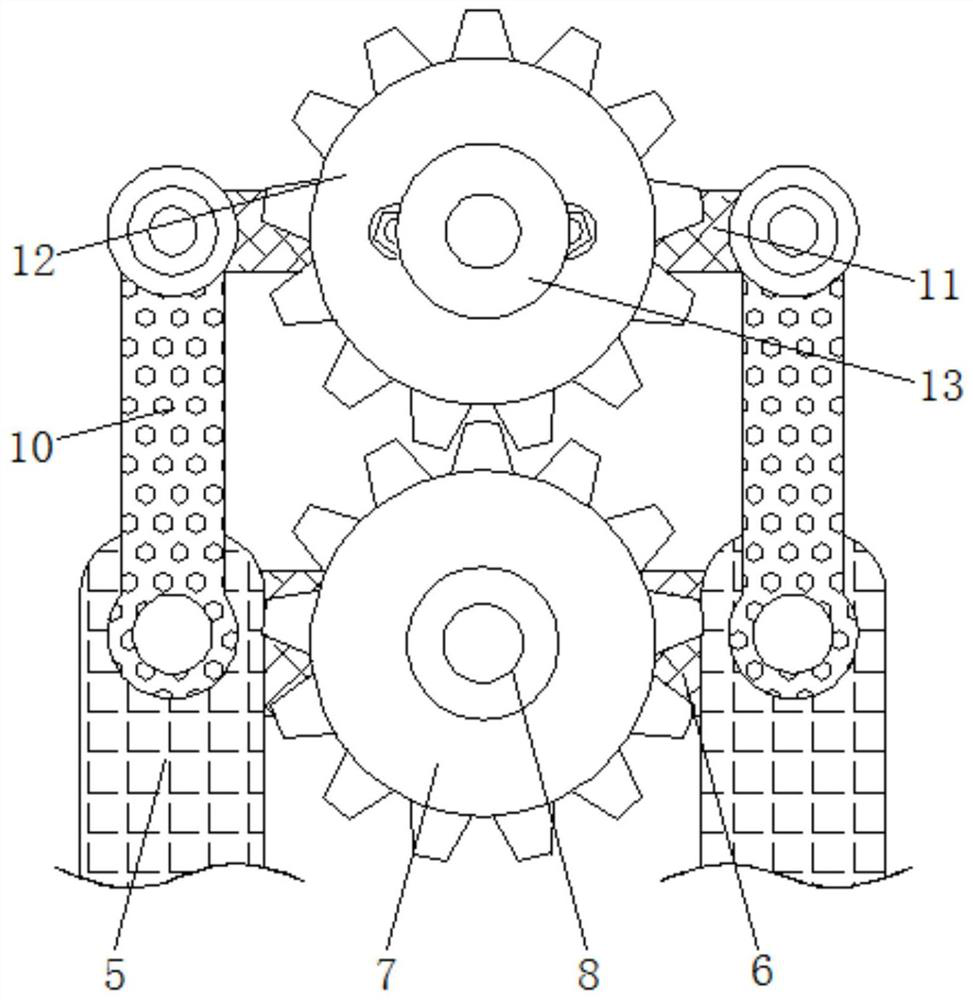

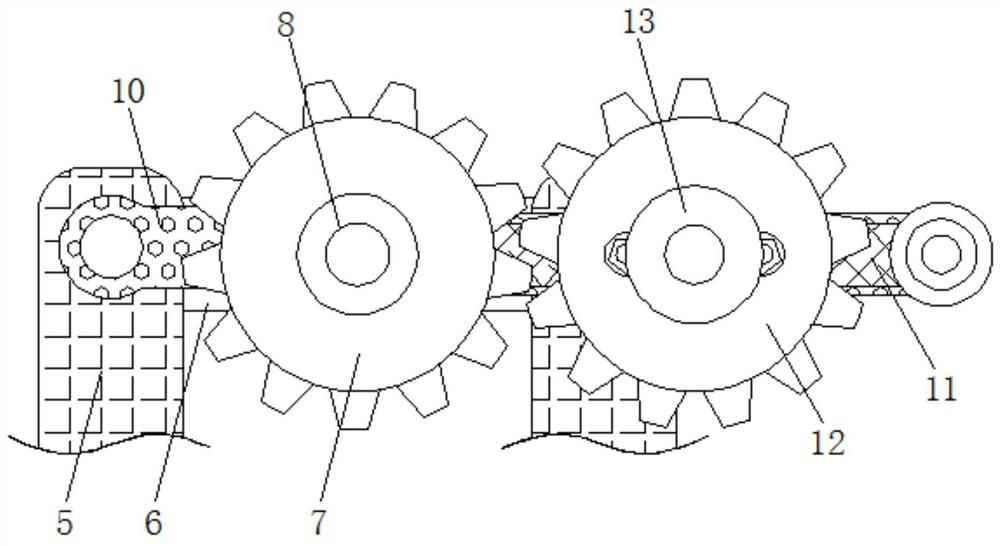

Cloth dyeing auxiliary device capable of avoiding uneven dyeing caused by dye precipitation

InactiveCN112899938AAvoid uneven stainingCause uneven dyeingLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsPolymer scienceEngineering

The invention relates to the technical field of cloth dyeing equipment, and discloses a cloth dyeing auxiliary device capable of avoiding uneven dyeing caused by dye precipitation. The cloth dyeing auxiliary device includes a box body, wherein a bracket is fixedly mounted on the outer side of the box body, a cloth unwinding roller is fixedly mounted on one side, close to the box body, of the bracket, and a roller is fixedly mounted at the top of the box body. According to the cloth dyeing auxiliary device capable of avoiding uneven dyeing caused by dye precipitation, a driven gear is driven to rotate through a driving gear, the effect of stirring dye is achieved while cloth is dyed, and the cloth on the upper layer and the cloth on the lower layer can make contact with the dye at different positions in a dyeing box, so that the cloth is dyed more evenly, meanwhile, damage to the cloth in a stirring process of a stirring device is avoided, the dyeing quality of the cloth is improved to a certain degree; and the roller is driven by a special-shaped wheel to shake up and down, so that the redundant dye on the dyed cloth is shaken out, and waste of the dye is greatly reduced.

Owner:上海瑞晋贸易有限公司

Box type printing and dyeing device for textile

InactiveCN111733554AGood removal effectEasy to removeMechanical cleaningPressure cleaningPolymer scienceEngineering

Owner:周煜皓

Method for preparing fancy cashmere yarns by using colored spun fibers

PendingCN113755025AImprove mechanical propertiesImprove shipping efficiencyOrganic dyesGrip property fibresYarnFiber

The invention discloses a method for preparing fancy cashmere yarns by using colored spun fibers, and relates to the technical field of spinning. The method specifically comprises the following steps: S1, dyeing cashmere wool to prepare uniform wool tops, putting the wool tops into production, and making the wool tops into rough yarns through worsted spinning or semi-worsted spinning; S2, conducting fancy twisting PAFA production, namely carrying out fancy yarn production on the rough cashmere yarns by adopting a fancy twisting machine to obtain fancy cashmere yarns; S3, conducting napping on the made fancy cashmere yarns; S4, performing yarn steaming on the napped yarns; and S5, rewinding the steamed yarns into cone yarns to obtain a product. According to the method provided by the invention, a technological process is greatly shortened, cost is reduced, yarn delivery efficiency is improved, the problem of chromatic aberration is avoided, and the method has the advantages of energy conservation and emission reduction; and the prepared fancy cashmere yarns are excellent in mechanical property and good in softness, the color fastness of pigment on a fabric is high, and dye uptake is better.

Owner:康宝莱(宁波)织造有限公司

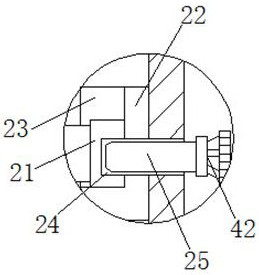

Pigment printing and dyeing device for textile industry

InactiveCN112030418AUniform dyeingAvoid uneven stainingTextile treatment carriersLiquid/gas/vapor textile treatmentWoven fabricDyeing

The invention relates to the technical field of textile processing equipment, and discloses a pigment printing and dyeing device for the textile industry. The device comprises a first support frame, wherein a first rotating shaft is movably arranged in the top end of the first support frame in a sleeved mode, a first winding drum located in the first support frame fixedly sleeves the outer wall ofthe first rotating shaft, a second rotating shaft located in the middle of the first support frame is movably sleeved with the lower portion of the first rotating shaft, a second winding drum locatedin the first support frame fixedly sleeves the outer wall of the second rotating shaft, a dye pool is arranged on one side of the first support frame, and a first mounting support is fixedly connected to one side of the top end of the dye pool. According to the pigment printing and dyeing device for the textile industry, by arranging a guide pipe, a mounting box, a steering pipe, a fixed plate, afloating plate, an ascending rod, a pointer and a ruler, the water amount in the dye pool can be monitored, so that a worker knows the concentration of dye in the dye pool, and uniform dyeing of cloth is guaranteed.

Owner:东阳市刚刚电器销售有限公司

A box-type printing and dyeing device for textile

ActiveCN109056249BUniform dyeingImprove work efficiencyMechanical cleaningPressure cleaningSpinningIndustrial engineering

Owner:周煜皓

Yarn dyeing pretreatment process

InactiveCN110258050AImprove qualityHigh densityLiquid/gas/vapor removalLiquid/gas/vapor yarns/filaments treatmentYarnEngineering

The invention provides a yarn dyeing pretreatment process, which includes the following steps: step I. cleaning a yarn to be dyed, and steaming the cleaned yarn; step II. dehydrating the yarn after steaming; step III. after the dye is filtered and screened, screening out impurities in the dye; step IV. putting the dehydrated yarn into the dye for dyeing; and step V. drying and packaging the dyed yarn. The yarn quality and yarn density are improved by cleaning and cooking the yarn, which is beneficial to improving the dye uptake of the yarn; and the yarn is dehydrated to prevent uneven dyeing caused by excessive water supply to the yarn, and the dyeing quality of the yarn is greatly improved by detecting the dye.

Owner:WUHU FUCHUN DYEING & WEAVING

A box-type printing and dyeing device for textile

ActiveCN109056225BGood removal effectEasy to removeMechanical cleaningPressure cleaningPolymer scienceEngineering

The invention discloses a printing and dyeing device for textile. The printing and dyeing device for textile comprises a base, a printing and dyeing box is fixedly connected to the top of the base, dye is movably connected to the interior of the printing and dyeing box, two first guide rollers are fixedly connected to the position, located in the dye, of the interior of the printing and dyeing box, and two second guide rollers are fixedly connected to the position, located over the first guide rollers, of the interior of the printing and dyeing box; a material leveling flattening plate is fixedly connected to the position, located over the second guide rollers, of the interior of the printing and dyeing box, and material homogenizing boxes are fixedly connected to the two sides of the inner wall of the printing and dyeing box correspondingly. The printing and dyeing device for the textile relates to the technical field of printing and dyeing, material flattening wheels are used for rolling cloth, and wool sucking balls on a wool sucking plate are used for adsorbing wool on the cloth, so that cloth dyeing is more uniform, the working efficiency is high, the wool on the surface of the cloth can be easily removed, the quality of the whole cloth is improved, and the overall aesthetic feeling of the cloth is enhanced.

Owner:周煜皓

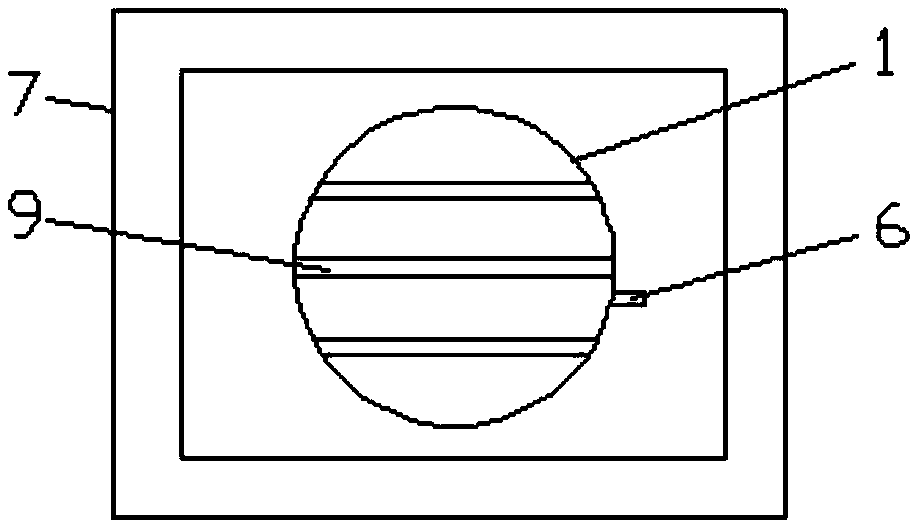

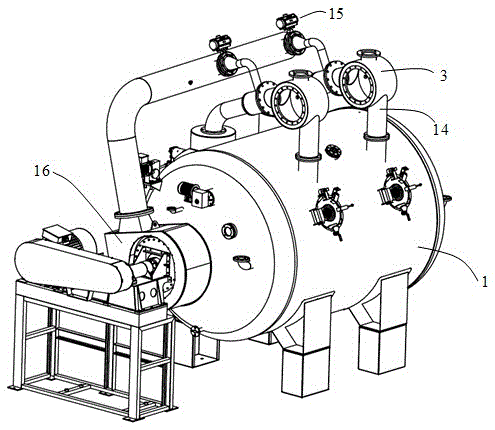

A high temperature and high pressure gas-liquid dyeing machine and its control method

InactiveCN104099734BReduce energy consumptionEasy to control independentlyTextile treatment machine arrangementsTextile treatment by spraying/projectingSpray nozzleProcess engineering

The invention discloses a high-temperature high-pressure gas-liquid dyeing machine and a control method thereof. The high-temperature high-pressure gas-liquid dyeing machine comprises a main cylinder, a cloth lifting wheel, an airflow nozzle, a dyeing liquid nozzle, a heat exchanger, a main dyeing liquid pump and a fan component, and the airflow nozzle and the dyeing liquid nozzle are separated and can conveniently and quickly control parameters of airflow and dyeing liquid flow independently according to characteristics of to-be-dyed fabric. The airflow nozzle is positioned in front of the dyeing liquid nozzle, so that the wound fabric can be blown fluffily by high-pressure airflow, dyeing liquid spraying and penetrating is performed afterwards, using efficiency of dyeing liquid is improved greatly, leveling performance and dye yield rate of dyeing are improved, dyeing time is reduced, total consumption of auxiliaries and dye is lowered, and total COD quantity is lowered effectively. By the high-temperature high-pressure gas-liquid dyeing machine, more uniformity in dyeing can be realized, energy consumption of a gas-liquid split-flow dyeing machine is lowered, and the objectives of energy conservation and environment protection are achieved.

Owner:高勋绿色智能装备(广州)有限公司

A kind of hematoxylin eosin staining solution and preparation method thereof

ActiveCN103725040BLong validity periodEfficient removalPreparing sample for investigationOrganic dyesHematoxylin stainAlcohol

The invention provides a hematoxylin eosin staining solution, comprising a hematoxylin staining solution and an eosin staining solution, wherein the hematoxylin staining solution comprises hematoxylin, an alumium salt, an oxidizing agent, benzalkonium chloride, an alcohol, a weak acid and water; the eosin staining solution comprises eosin, Biebrich scarlet, flame red B, water and ethanol. The invention also provides a preparation method of the hematoxylin eosin staining solution, and a dyeing method thereof. When the hematoxylin eosin staining solution provided by the invention is used for dyeing slices, the effects of clear background, distinct gradation, good dyeing effect, easy slice reading, not easy fading and convenience for long-term storage can be achieved.

Owner:无锡市江原实业技贸有限公司

Textile raw material coloring equipment and use method thereof

PendingCN114182459AImprove efficiencyAvoid uneven stainingLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsProcess engineeringWoven fabric

The invention relates to textile raw material coloring equipment and a using method thereof, and belongs to the technical field of textile raw material coloring. The equipment comprises a shell, the interior of the shell is divided into a drying bin and a dyeing bin through a partition plate, a drying device is arranged in the drying bin, and a dyeing device is arranged in the dyeing bin; the dyeing device is installed at the bottom of the partition plate through a height adjusting frame, a dyeing pool is arranged below the dyeing device, a stirring device and a water level monitoring device are arranged in the dyeing pool, an extrusion device is arranged at one end of the partition plate, the discharging port corresponds to the drying bin, and an active cloth rolling device is arranged on the outer side of the discharging port. The feeding port corresponds to the dyeing bin, an auxiliary cloth rolling device is arranged on the outer side of the feeding port, the water inlet corresponds to the dyeing pool, and the water inlet is connected with a feeding device through a water pipe. The problems of dyeing belt breakage and uneven dyeing are solved, and the textiles are extruded and dried step by step, so that drying is more thorough.

Owner:含山县光乾纺织有限公司

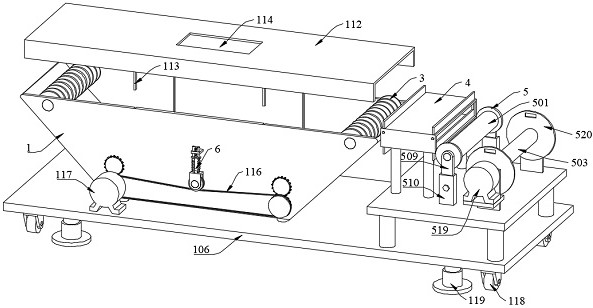

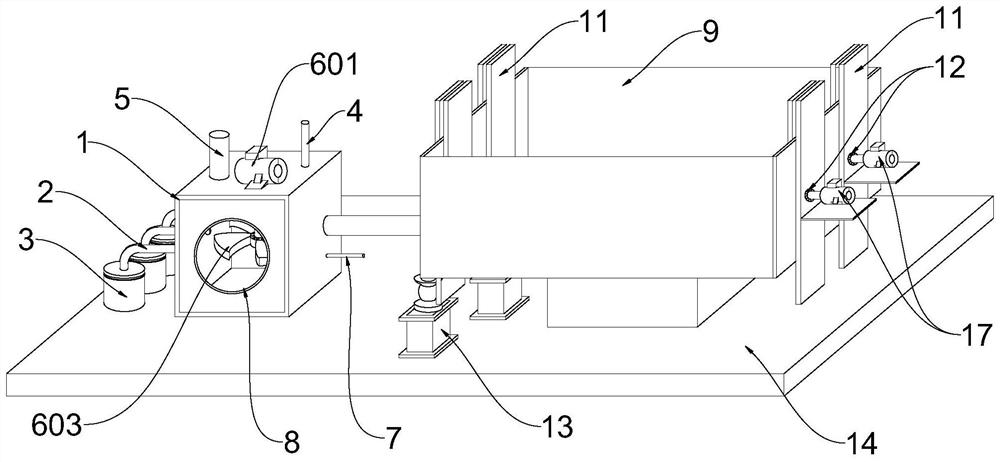

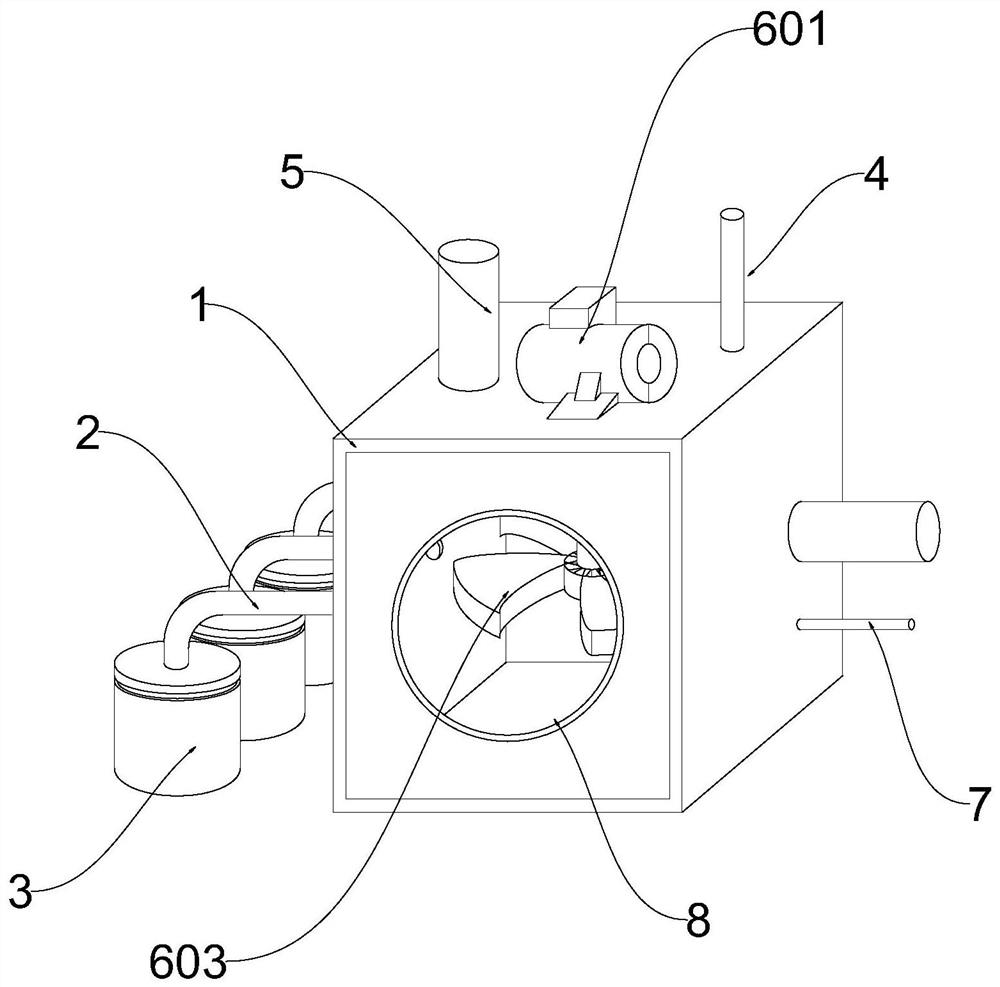

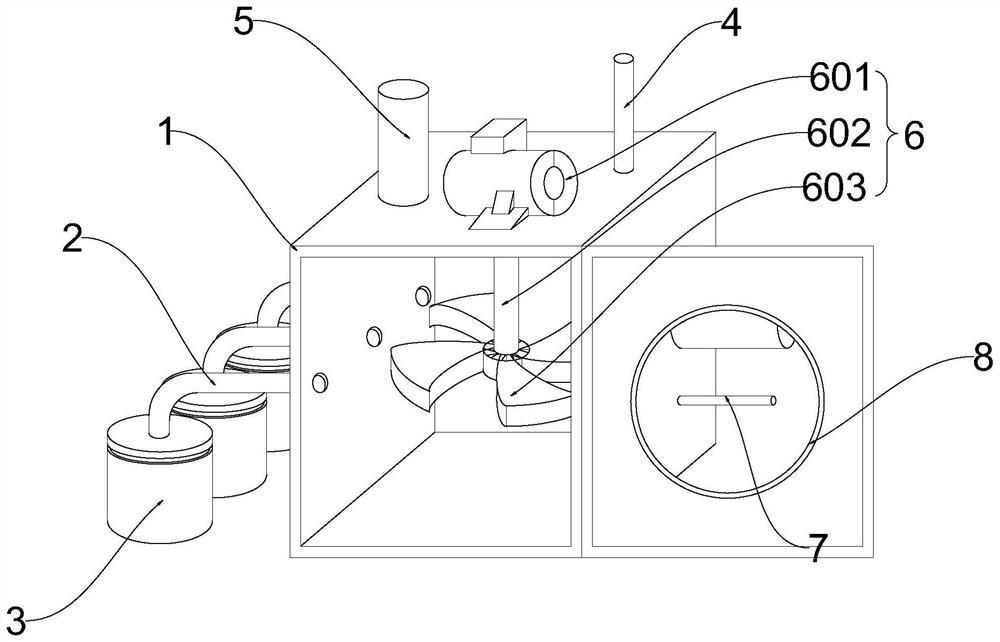

Material preparation and dyeing integrated printing and dyeing equipment for cloth spinning

PendingCN113622120AVersatileAvoid the problem of uneven dyeingTextile treatment machine arrangementsMaterials preparationPolymer science

The invention relates to the technical field of printing and dyeing equipment, in particular to material preparation and dyeing integrated printing and dyeing equipment for cloth spinning. The equipment is characterized in that at least one feeding pipe is mounted on a material preparation container; an auxiliary feeding pipe, a solvent feeding pipe and a stirrer are further mounted on the material preparation container; a dye pool is connected with the material preparation container through a pipeline; the dye pool is in sliding connection with a first stirring shaft and a second stirring shaft through slideways; the first stirring shaft and the second stirring shaft are connected with a partition plate through bearings; the partition plate is attached to the slideways; and the first stirring shaft and the second stirring shaft are connected with a pneumatic telescopic rod of a telescopic cylinder through second bearings. The problem that in the prior art, cloth printing and dyeing are low in printing and dyeing efficiency is solved. A stirring roller of the first stirring shaft and the second stirring shaft form a cloth dyeing rotary device, so that dyeing is more uniform, the dyeing efficiency can be effectively improved, and the printing and dyeing efficiency is high.

Owner:上海艾纺纺织品有限公司

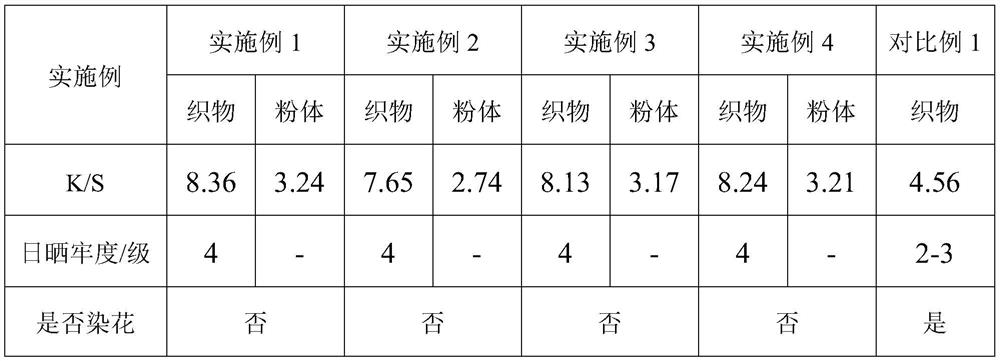

Nylon fiber and protein powder overdyeing method

The invention provides a nylon fiber and protein powder overdyeing method. The method comprises the following steps: sequentially adding vat dye, sodium hydroxide, thiourea dioxide, glacial acetic acid and a carrier according to a preset concentration to prepare vat dye liquor; then adding a mixture of nylon fibers and protein powder into the dye liquor for an overdyeing process to finish respective dyeing of the nylon fibers and the protein powder; and finally, washing the dyed protein powder and nylon fibers in circulating water, cleaning flooding and separating to respectively obtain dyed nylon fibers and dyed protein powder. According to the overdyeing method, the dyeing efficiency of the nylon fibers difficult to dye can be remarkably improved, the uneven dyeing phenomenon of the nylon fibers is effectively improved through the excellent adsorption performance and the gradual release effect of the protein powder on vat dyes while the protein powder is overdyed, and the dyed nylonfibers and protein powder have excellent light fastness.

Owner:WUHAN TEXTILE UNIV +1

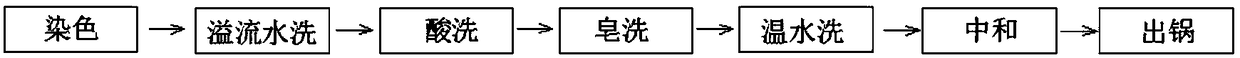

Dyeing process of twill polyester peach skin fabric

InactiveCN110938998AGood colorNo creasesDyeing processLiquid/gas/vapor textile treatmentPolyesterPolymer science

The invention discloses a dyeing process of twill polyester peach skin fabric. The process comprises the steps of step one, performing primary processing before dyeing on the twill polyester peach skin fabric; step two, performing cloth relaxation finishing on the twill polyester peach skin fabric after treating in the step one; step three, performing dyeing treatment on the fabric after the clothrelaxation is finished; step four, performing sampling and color contrast on the fabric after dyeing in the step three; step five, dehydrating the fabric after dyeing and color contrast; and step six, shaping, air-drying and storing the fabric. Through the dyeing process disclosed by the invention, the fabric cannot produce fold when dyeing the twill polyester peach skin fabric, and the dyeing isuniform; and the fabric is good in color rendering index, hard to fade and good in color fixing performance after being dyed.

Owner:苏州育时纺织整理有限公司

A kind of indigo blue bamboo crafts

ActiveCN112621938BNatural textureVariety of colorsClimate change adaptationCane mechanical workingIndigo colorPolymer science

Owner:赤水市牵手竹艺发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com