A gas-liquid split nozzle for a dyeing machine

A dyeing machine and air jet technology, applied in the field of dyeing, can solve the problems of incomplete penetration of dye liquor, prolonged dyeing time, poor leveling performance, etc. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific examples, but the implementation and protection of the present invention are not limited thereto.

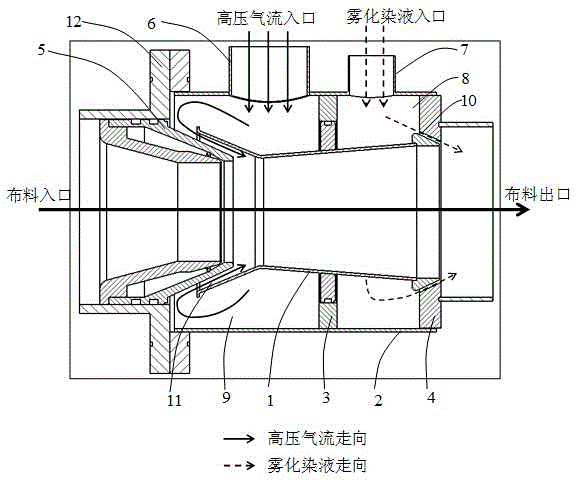

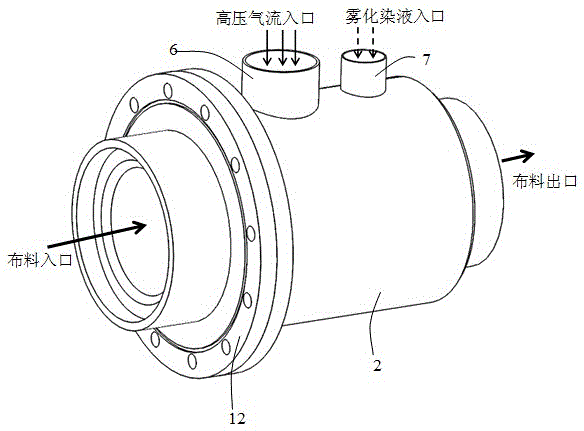

[0023] Such as Figure 1 ~ Figure 2 As shown, a gas-liquid diverting nozzle for a dyeing machine includes a nozzle body 1, a casing 2, a partition 3, an end positioning seat 4, a front positioning sleeve 5, an air inlet pipe 6, and a dye liquor inlet pipe 7; The nozzle body 1 cooperates with the front end positioning sleeve 5 to form a circular frustum-shaped air flow injection channel 11; the nozzle body 1 and the end positioning seat 4 form a circular frustum-shaped dye solution injection flow channel 10; the air flow injection channel 11 and the The injection direction of the dye liquor injection channel 10 forms an included angle of less than 90 degrees with the forward direction of the fabric; the nozzle body 1 is located in the casing 2, and the casing 2, the nozzle body 1, the partit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com