A high temperature and high pressure gas-liquid dyeing machine and its control method

A high-pressure gas dyeing machine technology, applied in the field of dyeing, can solve the problems of incomplete penetration of dye liquor, high energy consumption of fans, and prolonging dyeing time, so as to improve the dyeing performance of penetrating and penetrating parts, reduce the total amount of COD, and shorten the dyeing time. the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific embodiments, but the following are only preferred examples of the present invention, and if there are components or processes not specifically described in detail, those skilled in the art can refer to conventional techniques to realize.

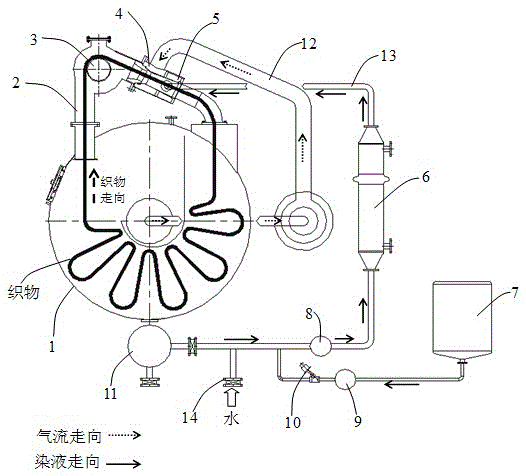

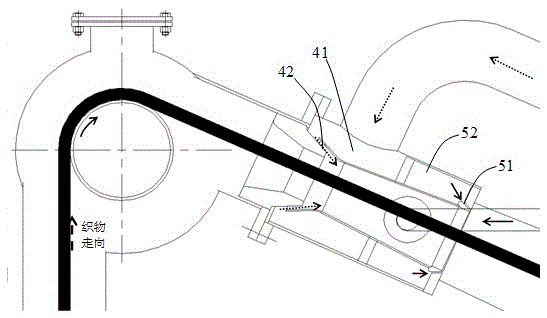

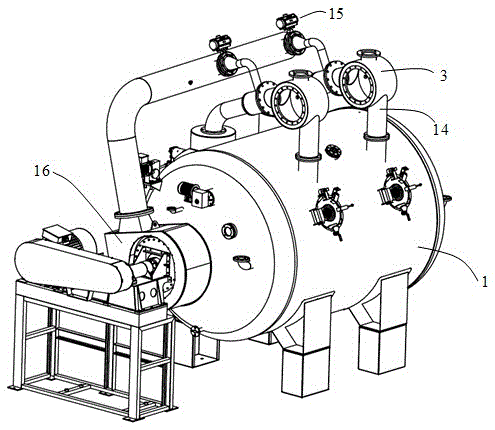

[0022] Such as Figure 1 ~ Figure 3 As shown, a high-temperature and high-pressure gas-liquid split dyeing machine includes a master cylinder 1, a cloth lifting wheel 3, an air flow nozzle 4, a dye liquor nozzle 5, a heat exchanger 6, a feed pump 9, a feed control valve 10, a dye liquor master Main components such as pump 8 and fan assembly 16; the cloth lifting wheel 3 is connected with the main cylinder 1, the air flow nozzle 4 and the dye solution nozzle 5 through the fabric pipe 2 to form a group of dyeing units, and the fabric to be dyed can be dyed through the air flow nozzle. The thrust of the injected airflow can run stably; the main cylinder 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com