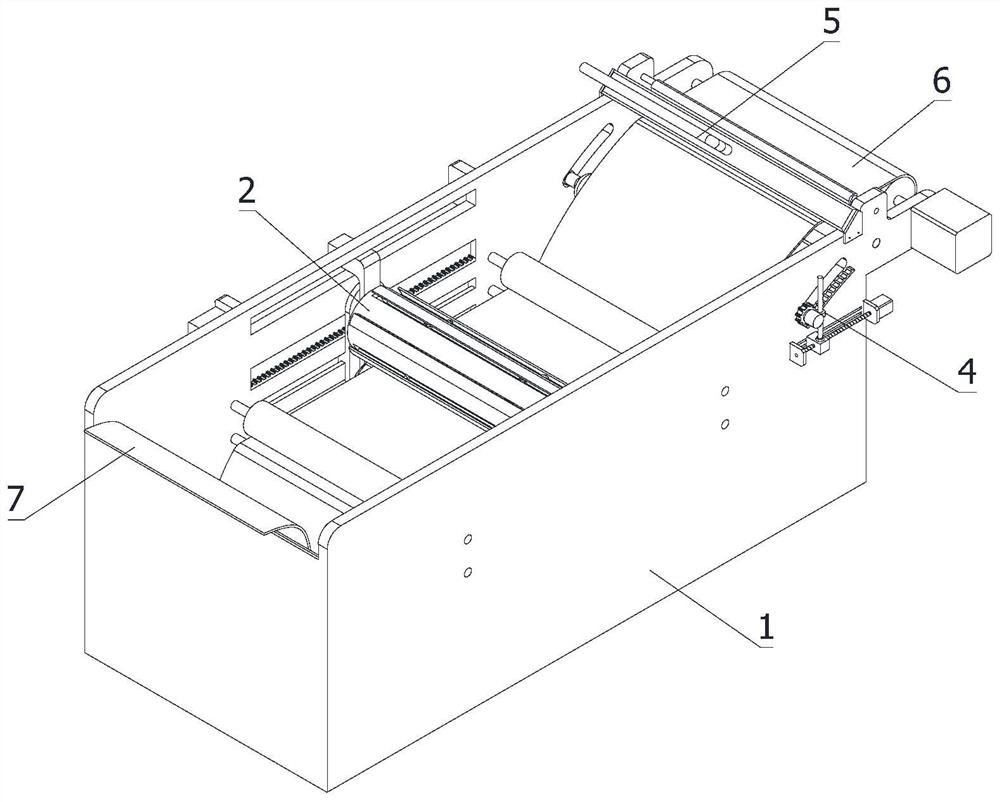

Double-sided uniform rolling type full-automatic intelligent dye vat and method

A roll-pressed, fully automatic technology, applied in high-pressure cleaning, liquid/gas/vapor removal by air jet method, and preservation of rolled textile materials, etc., can solve the problems of affecting the dyeing quality of fabrics, insufficient dyeing, and inconvenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

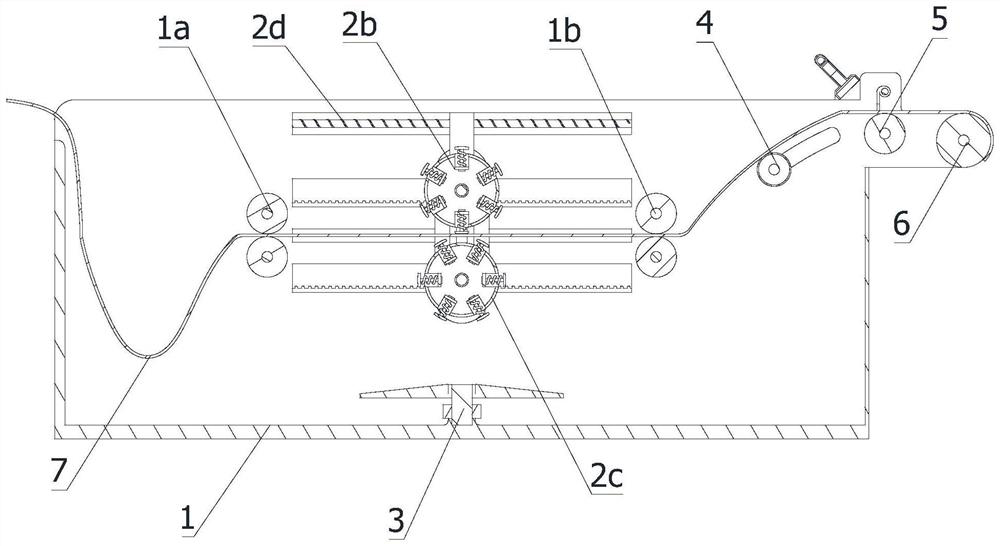

[0074] A method for implementing a fully automatic intelligent dye vat with double-sided uniform roller pressure, comprising the following steps:

[0075]Step 1, the staff pours the dye into the inside of the dye box 1;

[0076] Step 2: One end of the dye-soaked fabric passes sequentially through the first guide wheel set 1a, the output end of the extrusion permeation roller set 2, the second guide wheel set 1b and the hair removal mechanism 5, and finally winds around the winding mechanism 6 output terminal;

[0077] Step 3, the reciprocating drive assembly 2d starts to work, the output end of the reciprocating drive assembly 2d drives the first extrusion wheel 2b and the second extrusion wheel 2c to move through the sliding frame 2a, the first extrusion wheel 2b and the second extrusion wheel 2c moves linearly between the first guide wheel set 1a and the second guide wheel set 1b, and squeezes and relaxes the fabric through the first squeeze wheel 2b and the second squeeze ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com