Method for preparing fancy cashmere yarns by using colored spun fibers

A technology of color spinning fiber and cashmere yarn, which is applied in dyeing method, fiber treatment, animal fiber, etc. It can solve the problems of energy saving, heavy emission reduction tasks, limited textile fiber resources, etc., and achieves the avoidance of yarn count deviation and the stability of ultrasonic dispersion Reinforcement, crockfastness and wash-fading fastness grade-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

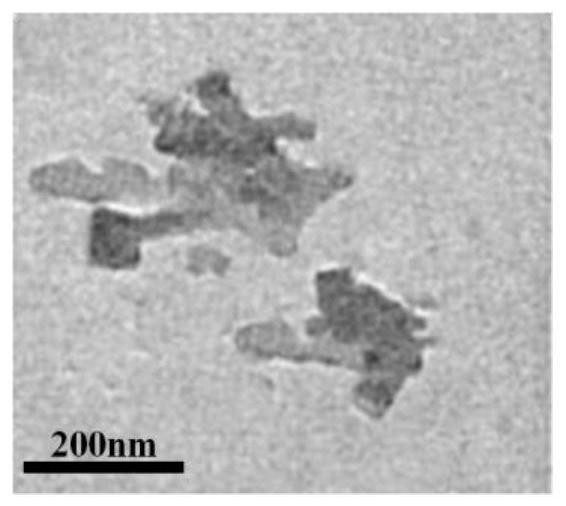

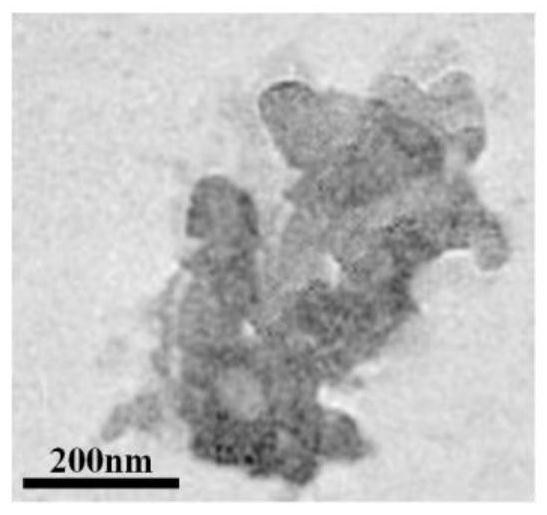

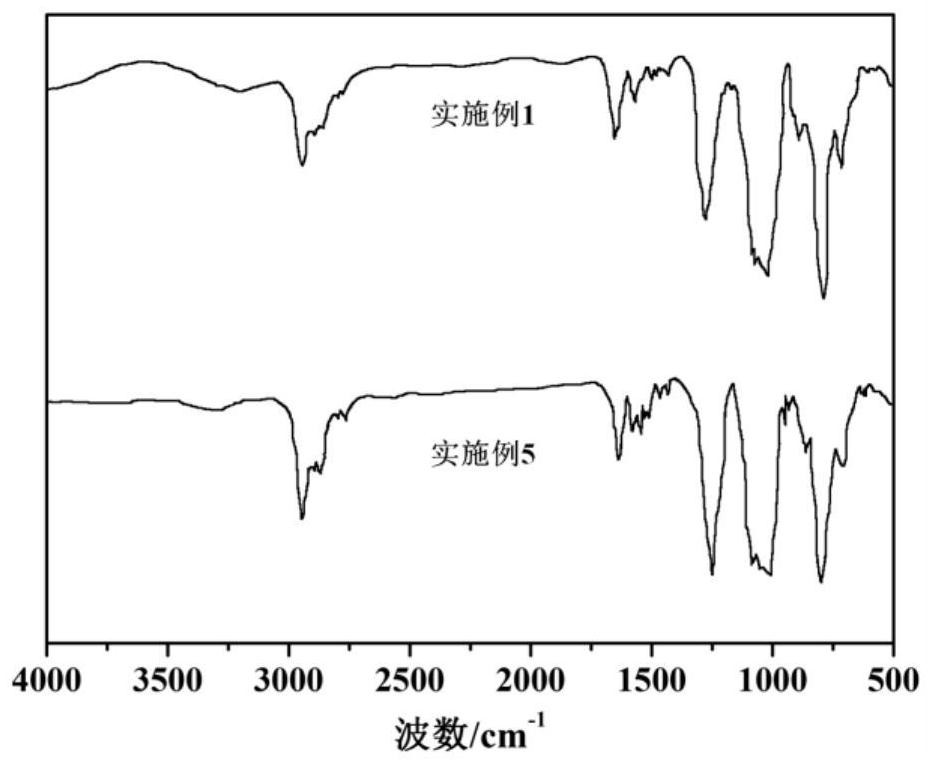

[0052] Preparation of polymer hybrid pigments:

[0053] 1) Use the washing method to remove the salt and other substances of the industrial-grade pigment crystals, specifically: the pigment crystal dispersion liquid is subjected to centrifugation washing at 10000r / min, 8000r / min, and 5000r / min in sequence, and centrifuged for 8 minutes each time;

[0054] 2) Take the washed pigment crystal dispersion, emulsifier OP-10 and water (the mass ratio of the three is 1:0.28:64) and mix and stir for 30 minutes, add St, BA and 4-[(2R)-3,4- Dihydro-7-hydroxyl-2H-1-benzopyran-2-yl]-3-(3-methyl-2-buten-1-yl)-1,2-benzenediol (three The mass ratio is 1:1.2:1), wherein the ratio of the total mass of the pigment crystal dispersion liquid to the monomer is 1:3.1, and then HD and SDS are added (the mass ratio of St, HD and SDS is 1:0.11:0.06), Mixing and stirring for pre-emulsification for 1 hour, then ultrasonication at 150W for 20 minutes; then adding the initiator KPS, stirring and reacting ...

Embodiment 2

[0071] The difference between the preparation of the polymer hybrid pigment and Example 1 is that the mass ratio of the pigment crystal dispersion, OP-10, and water is 1:0.22:62.5; St, BA and 4-[(2R)-3, The mass of 4-dihydro-7-hydroxy-2H-1-benzopyran-2-yl]-3-(3-methyl-2-buten-1-yl)-1,2-benzenediol The ratio is 1:1.3:0.84; the mass ratio of St, HD and SDS is 1:0.06:0.07; the ratio of pigment crystal dispersion liquid to the total mass of monomer is 1:2.4.

[0072] The preparation of silicone oil is the same as in Example 1.

[0073] A method for preparing fancy cashmere yarns using color-spun fibers is the same as in Example 1.

Embodiment 3

[0075] The difference between the preparation of the polymer hybrid pigment and Example 1 is that the mass ratio of the pigment crystal dispersion, OP-10, and water is 1:0.32:61.5; St, BA and 4-[(2R)-3, The mass of 4-dihydro-7-hydroxy-2H-1-benzopyran-2-yl]-3-(3-methyl-2-buten-1-yl)-1,2-benzenediol The ratio is 1:0.95:1.1; the mass ratio of St, HD and SDS is 1:0.14:0.05; the ratio of pigment crystal dispersion liquid to the total mass of monomer is 1:1.6.

[0076] The preparation of silicone oil is the same as in Example 1.

[0077] A method for preparing fancy cashmere yarns using color-spun fibers is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com