Non-woven cloth dyeing device and process

A dyeing device and technology for non-woven fabrics, applied in the field of fabric dyeing, can solve the problems of uneven dyeing of non-woven fabrics, weak color and waste, etc., and achieve complete removal of dyeing liquid and impurities, simple dyeing process, and keep clean and hygienic. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

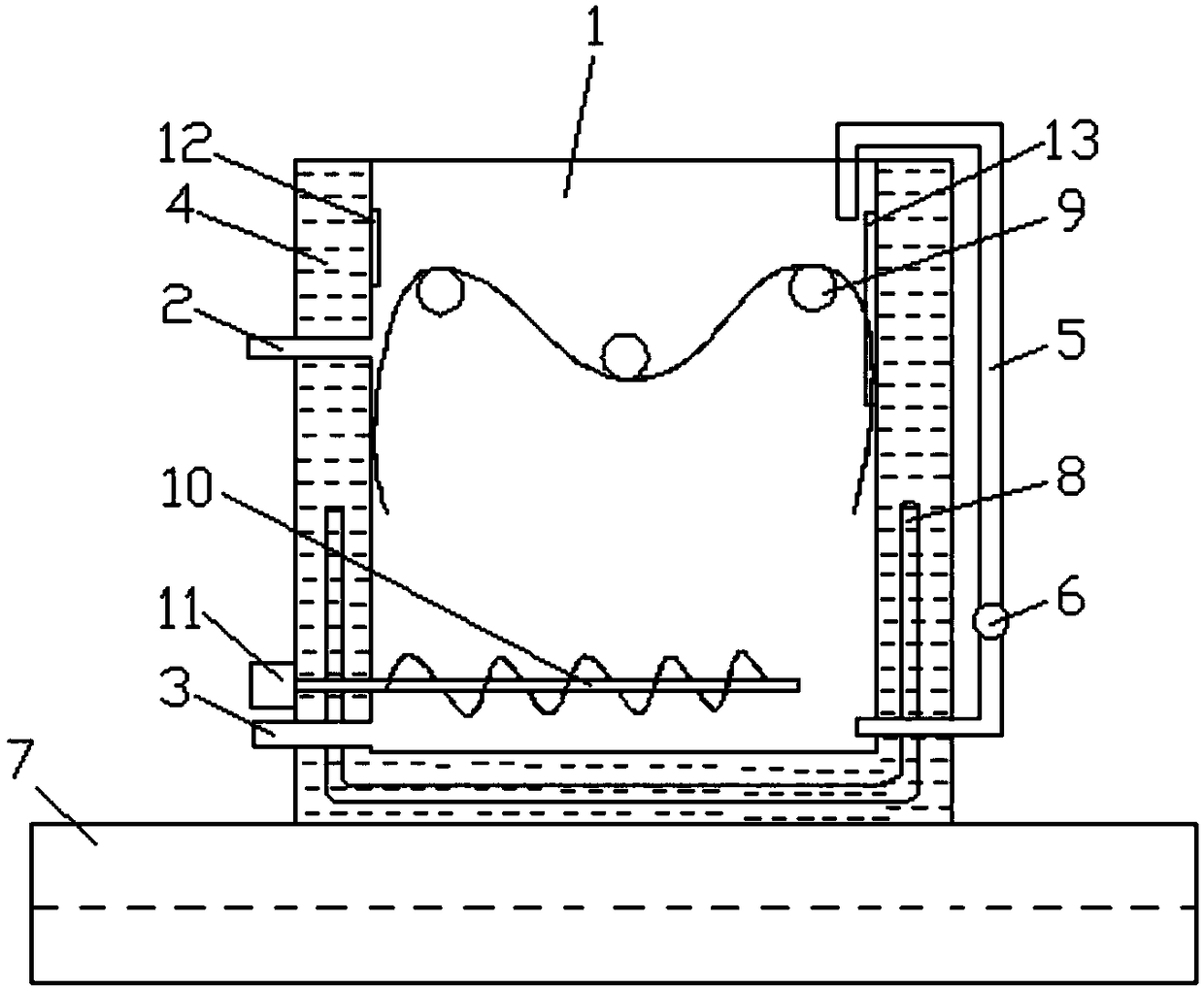

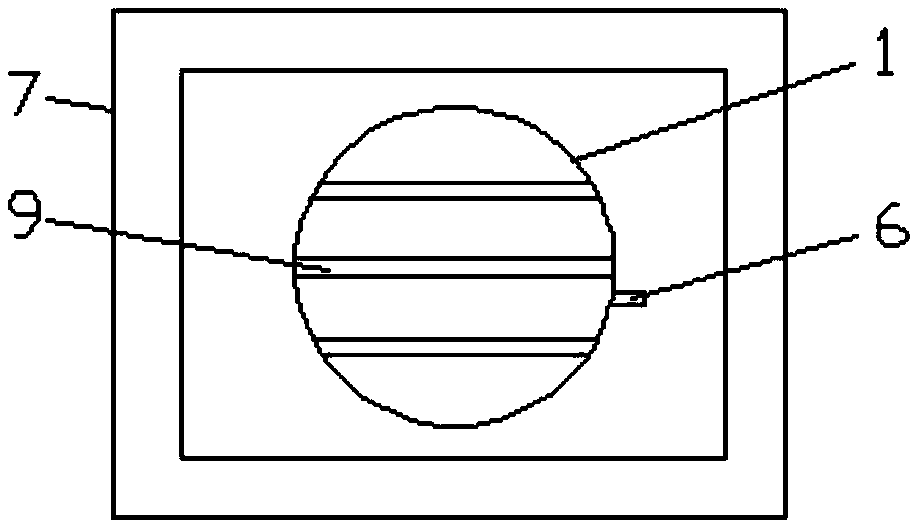

Method used

Image

Examples

Embodiment 1

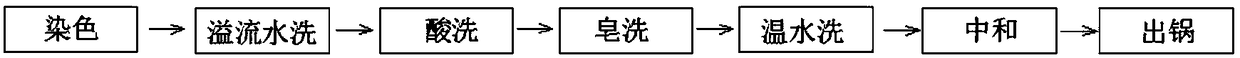

[0052] The present embodiment provides a kind of non-woven fabric dyeing process, comprises the following steps:

[0053] S1: Pour the dyeing solution into the dyeing pot 1, dye the non-woven fabric for 60 minutes, and discharge the dyeing solution. The process of dyeing solution configuration is as follows:

[0054] (1) According to the need, add the dye and water into the batching device according to the bath ratio of 1:8, mix well, heat to 30°C, and keep warm for 10min;

[0055] (2) Continue to heat the mixed solution in the above step (1) to 60°C, add 1 / 2 part of sodium sulfate with a concentration of 15g / L at intervals of 5 minutes and 10 minutes respectively, and then add 2 / 5 parts at intervals of 10 minutes , 3 / 5 parts of soda ash with a concentration of 7g / L, kept for 40 minutes;

[0056] S2: Continuously feed clean water into the dyeing pot 1 to wash the non-woven fabric in step S1 for 5 minutes, remove the impurities distributed on the surface of the non-woven fabri...

Embodiment 2

[0061] The present embodiment provides a kind of non-woven fabric dyeing process, comprises the following steps:

[0062] S1: Pour the dyeing solution into the dyeing pot 1, dye the non-woven fabric for 65 minutes, and discharge the dyeing solution. The process of dyeing solution configuration is as follows:

[0063] (1) According to needs, add the dye and water into the batching device according to the bath ratio of 1:10, mix well, heat to 30°C, and keep warm for 10 minutes;

[0064] (2) Continue to heat the mixed solution in the above step (1) to 60°C, add 1 / 2 part of sodium sulfate with a concentration of 15g / L at intervals of 5 minutes and 10 minutes respectively, and then add 2 / 5 parts at intervals of 10 minutes , 3 / 5 parts of soda ash with a concentration of 7g / L, kept for 40 minutes;

[0065] S2: Continuously feed clean water into the dyeing pot 1 to wash the non-woven fabric in step S1 for 6 minutes, remove the impurities distributed on the surface of the non-woven fa...

Embodiment 3

[0070] The present embodiment provides a kind of non-woven fabric dyeing process, comprises the following steps:

[0071] S1: Pour the dyeing solution into the dyeing pot 1, dye the non-woven fabric for 70 minutes, and discharge the dyeing solution. The process of dyeing solution configuration is as follows:

[0072] (1) According to the need, add the dye and water into the batching device according to the bath ratio of 1:8~12, mix evenly, heat to 30°C, and keep warm for 10min;

[0073] (2) Continue to heat the mixed solution in the above step (1) to 60°C, add 1 / 2 part of sodium sulfate with a concentration of 15g / L at intervals of 5 minutes and 10 minutes respectively, and then add 2 / 5 parts at intervals of 10 minutes , 3 / 5 parts of soda ash with a concentration of 7g / L, kept for 40 minutes;

[0074] S2: Continuously feed clean water into the dyeing pot 1 to wash the non-woven fabric in step S1 for 7 minutes, remove the impurities distributed on the surface of the non-woven ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com