Nylon fiber and protein powder overdyeing method

A technology of nylon fiber and protein powder, which is applied in the field of textile printing and dyeing, can solve the problems of nylon fiber being easily dyed, achieve excellent adsorption performance, avoid excessive concentration, and improve dyeing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

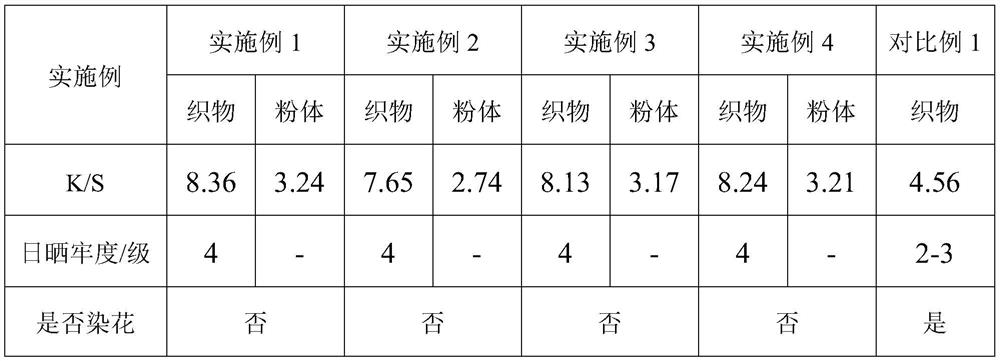

Examples

Embodiment 1

[0044] This embodiment provides a kind of overdyeing method of high-strength nylon 66 fiber and wool powder:

[0045] S1, preparation of dye solution: according to a predetermined ratio, add insoluble vat blue BC to distilled water, and stir, then add sodium hydroxide and thiourea dioxide in sequence to obtain a leuco solution; heat the leuco solution to 90 ℃, stirring at a speed of 250r / min for 15 minutes, adding glacial acetic acid to adjust the pH value to 5-6 to obtain a leuco acid solution; finally adding carrier ethylene glycol phenyl ether to the leuco acid solution, and stirring to prepare Obtain vat dyeing liquor; In described vat dyeing liquor, the concentration of described vat blue BC is 10g / L, and the concentration of described sodium hydroxide is 10g / L, and the concentration of described thiourea dioxide is 10g / L, so The concentration of said ethylene glycol phenyl ether is 70g / L;

[0046] S2, over-dyeing: first put a predetermined proportion of wool powder into...

Embodiment 2

[0049] This embodiment provides a kind of overdyeing method of high-strength nylon 66 fiber and wool powder:

[0050] S1, preparation of dye solution: add insoluble vat blue BC to distilled water according to a predetermined ratio, and stir, then add sodium hydroxide and thiourea dioxide in sequence to obtain a leuco solution; heat the leuco solution to 40 ℃, stirring at a speed of 150r / min for 5 minutes, adding glacial acetic acid to adjust the pH value to 5-6 to obtain a leuco acid solution; finally adding carrier ethylene glycol phenyl ether to the leuco acid solution, and stirring to prepare Obtain vat dyeing liquor; In described vat dyeing liquor, the concentration of described vat blue BC is 4g / L, and the concentration of described sodium hydroxide is 4g / L, and the concentration of described thiourea dioxide is 4g / L, so The concentration of said ethylene glycol phenyl ether is 30g / L;

[0051] S2, over-dyeing: first put a predetermined proportion of wool powder into the ...

Embodiment 3

[0054] This embodiment provides a kind of overdyeing method of high-strength nylon 66 fiber and wool powder:

[0055] S1, preparation of dye solution: according to a predetermined ratio, add insoluble vat blue BC to distilled water, and stir, then add sodium hydroxide and thiourea dioxide in turn to obtain a leuco solution; heat the leuco solution to 60 ℃, stirring at a speed of 200r / min for 10 minutes, adding glacial acetic acid to adjust the pH value to 5-6 to obtain a leuco acid solution; finally adding carrier ethylene glycol phenyl ether to the leuco acid solution, and stirring to prepare Obtain vat dyeing liquor; In described vat dyeing liquor, the concentration of described vat blue BC is 6g / L, and the concentration of described sodium hydroxide is 6g / L, and the concentration of described thiourea dioxide is 6g / L, so The concentration of said ethylene glycol phenyl ether is 40g / L;

[0056] S2, over-dyeing: first put a predetermined proportion of wool powder into the va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com