Overturning mechanism of single-sheet printing product and working method of overturning mechanism

A technology of overturning mechanism and working method, which is applied to printing machines, general parts of printing machinery, printing, etc., and can solve problems such as paper damage, waste product reduction of pass rate, belt wear on printed products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

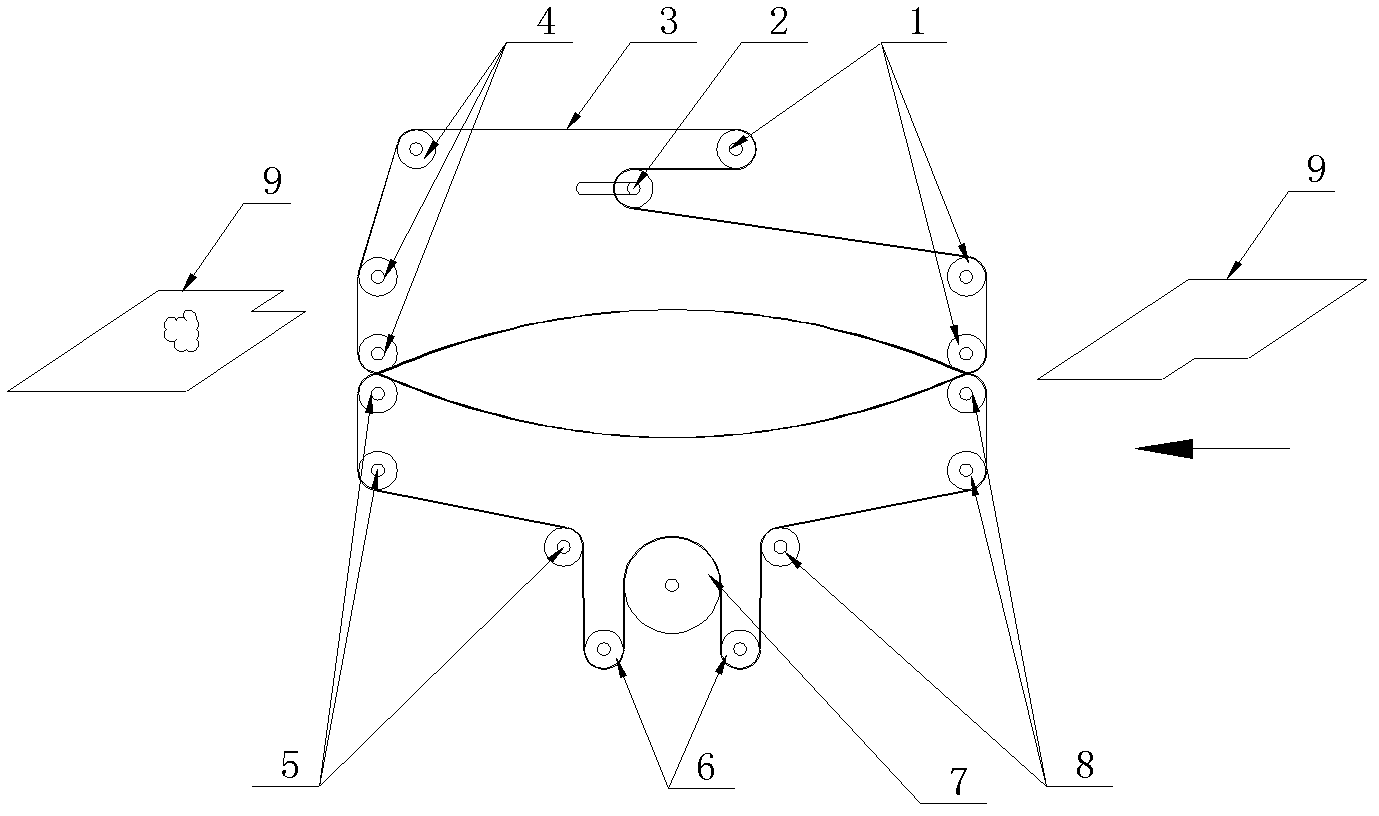

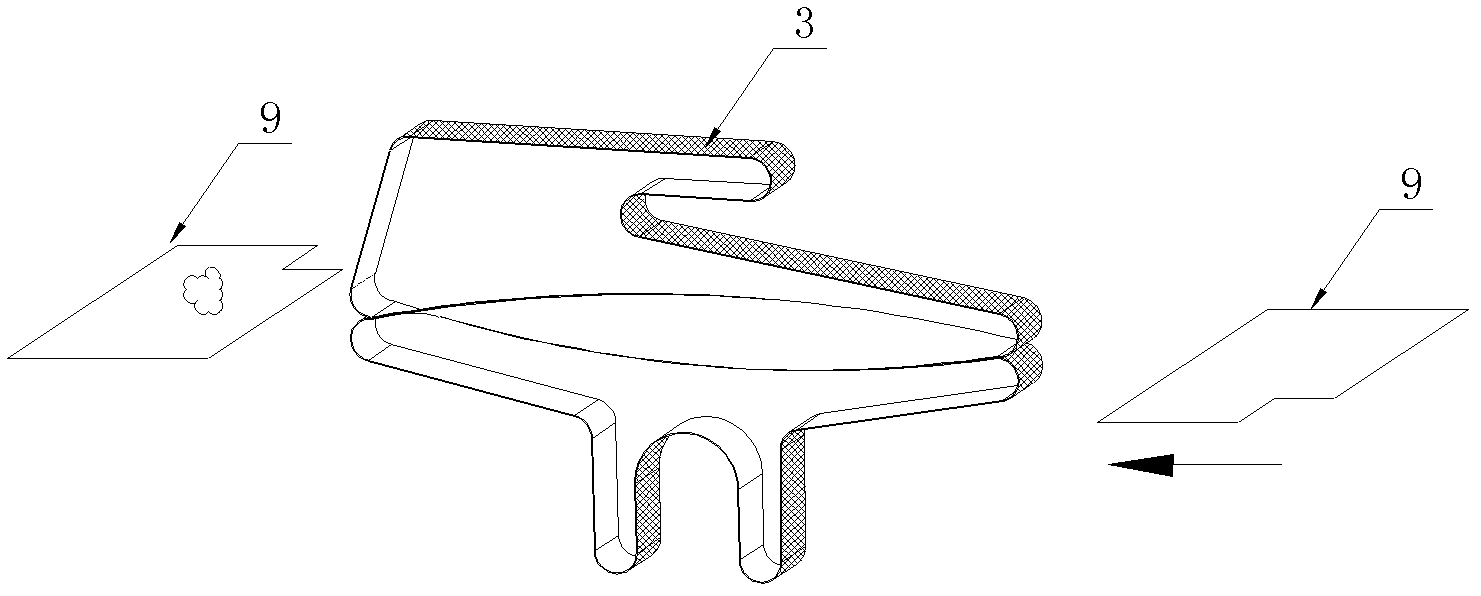

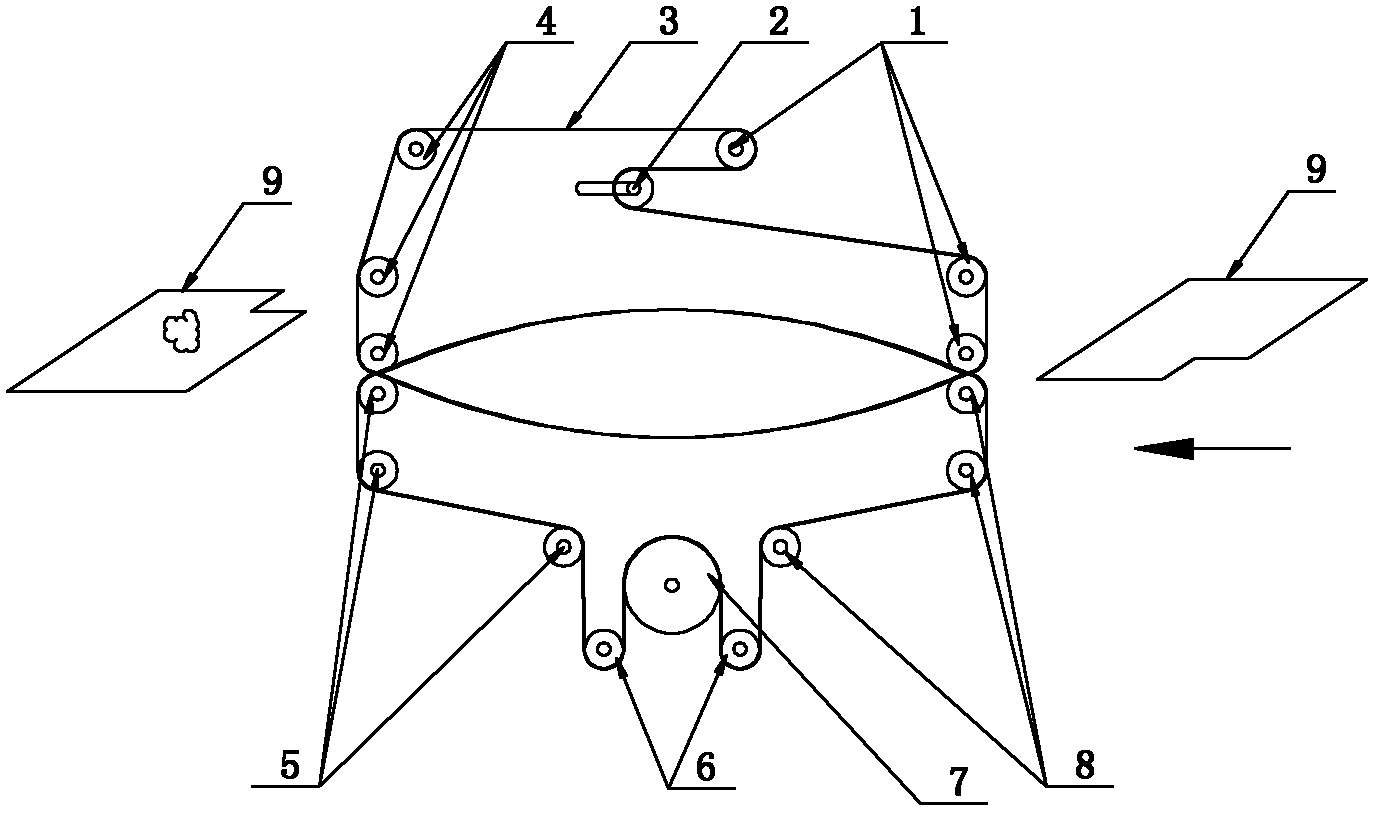

[0016] Embodiment: a kind of sheet-fed product turnover mechanism (see figure 1 , figure 2 ), is characterized in that it comprises upper guide wheel 1 on the right side, tension pulley 2, belt 3, upper guide wheel 4 on the left side, lower guide wheel 5 on the left side, power guide wheel 6, power wheel 7, lower guide wheel on the right side 8. Printed product 9; the left lower guide wheel 5 and the right lower guide wheel 8 are respectively installed on both sides of the power wheel 7; the power guide wheels 6 are installed in pairs on both sides of the power wheel 7; the right Side upper guide wheel 1, tension pulley 2 and left upper guide wheel 4 are installed on the top of power wheel 7; Said belt 3 starts to bypass a power guide wheel 6, left side lower guide wheel 5, right side successively from power wheel 7. Side upper guide wheel 1, tensioning pulley 2, upper guide wheel 4 on the left side, lower guide wheel 8 on the right side and another power guide wheel 6 form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com