Anti-bleeding water-borne wood coating structure and application thereof

A coating, water-based technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of deterioration, coating discoloration and adhesion, affecting the effect of coating, etc., to achieve low water permeability, improve polishing Durable, easy-to-polish effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

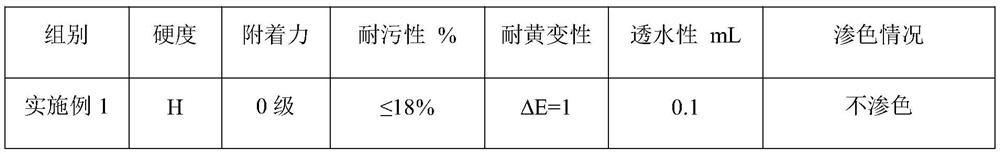

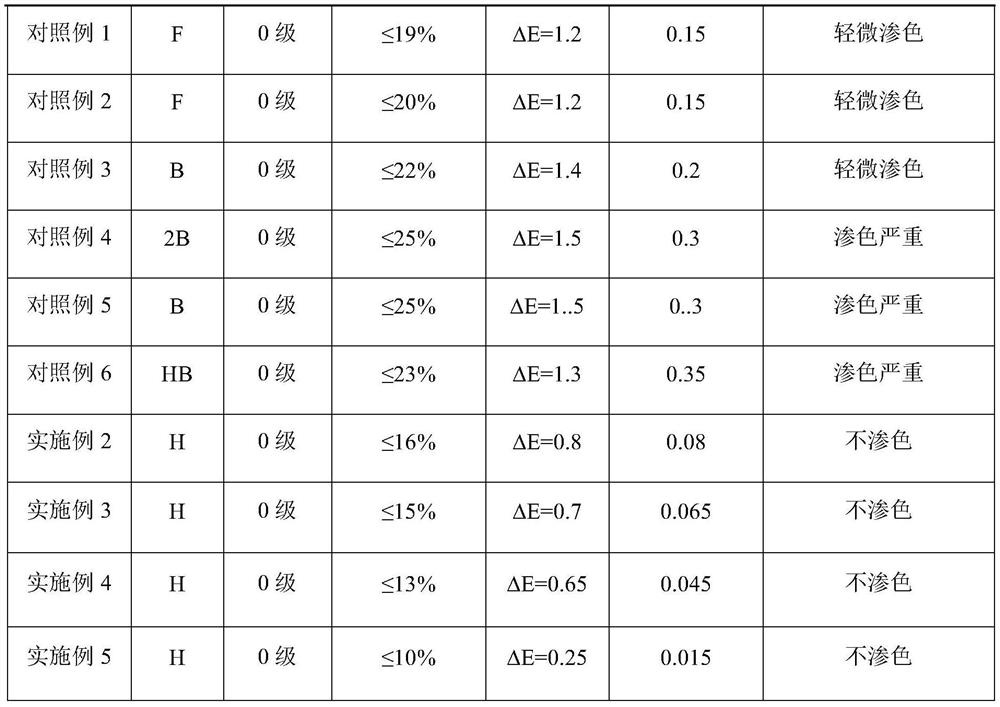

Embodiment 1

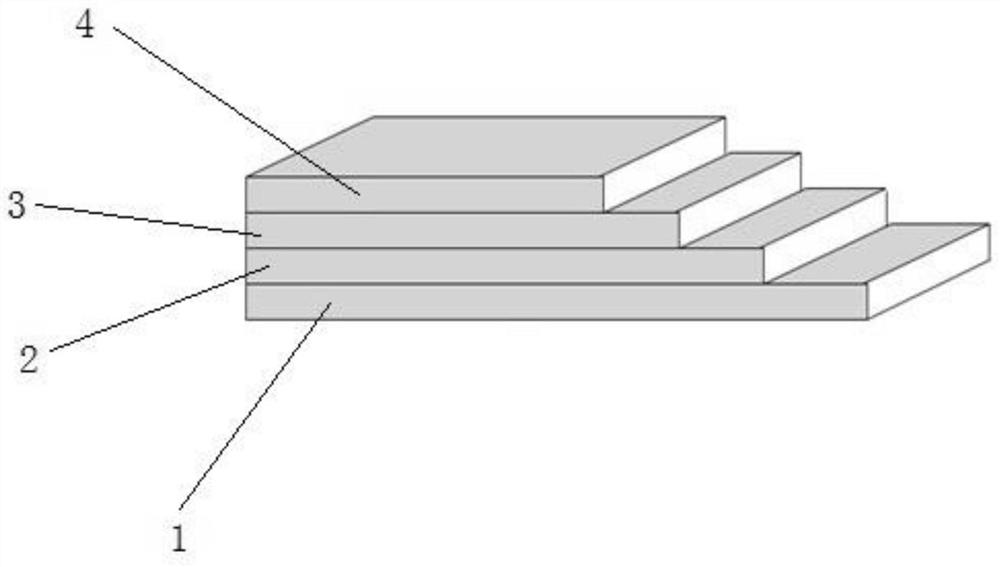

[0032] 1. A water-based wood coating structure for anti-bleeding, comprising a seal coat, a sanding coat and a finish coat;

[0033] The raw materials of the seal coat include the main agent I and the curing agent in a weight ratio of 100:10; by weight, the main agent I includes 65 parts of high-hydroxyl value acrylic dispersion, 4 parts of film-forming aids, and 0.4 parts of wetting agent , 0.2 parts of defoaming agent, 5 parts of thickener and 15 parts of deionized water; in the curing agent, the molar ratio of isocyanate group to hydroxyl group is 1:1;

[0034] The raw materials of the grinding coating include main agent II and curing agent in a weight ratio of 100:10; in parts by weight, main agent II includes 80 parts of water-based acrylic emulsion, 0.3 part of defoamer, 2 parts of film-forming aid, dispersant 0.3 parts, 0.1 parts of leveling agent, 0.1 parts of antifungal agent, 0.8 parts of thickener and 4 parts of deionized water; in the curing agent, the molar ratio ...

Embodiment 2

[0043] 1. A water-based wood coating structure for anti-bleeding, comprising a seal coat, a sanding coat and a finish coat;

[0044] The raw materials of the seal coat include main agent I and curing agent with a weight ratio of 100:15; in parts by weight, main agent I includes 75 parts of high-hydroxyl value acrylic dispersion, 5 parts of film-forming aid, and 0.5 part of wetting agent , 0.3 parts of defoamer, 7 parts of thickener and 30 parts of deionized water; in the curing agent, the molar ratio of isocyanate group to hydroxyl group is 1:1;

[0045] The raw materials of the grinding coating include main agent II and curing agent with a weight ratio of 100:15; in parts by weight, main agent II includes 85 parts of water-based acrylic emulsion, 0.6 part of defoamer, 5 parts of film-forming aid, dispersant 0.6 parts, 0.3 parts of leveling agent, 0.3 parts of fungicide, 1.0 parts of thickener and 6 parts of deionized water; in the curing agent, the molar ratio of isocyanate g...

Embodiment 3

[0054] 1. A water-based wood coating structure for anti-bleeding, comprising a seal coat, a sanding coat and a finish coat;

[0055] The raw materials of the seal coat include the main agent I and the curing agent with a weight ratio of 100:12; by weight, the main agent I includes 70 parts of high-hydroxyl value acrylic dispersion, 4.5 parts of film-forming aids, and 0.4 parts of wetting agent , 0.2 parts of defoamer, 6 parts of thickener and 20 parts of deionized water; in the curing agent, the molar ratio of isocyanate group to hydroxyl group is 1:1;

[0056] The raw materials of the grinding coating include main agent II and curing agent with a weight ratio of 100:12; in parts by weight, main agent II includes 82 parts of water-based acrylic emulsion, 0.5 part of defoamer, 4 parts of film-forming aid, dispersant 0.5 parts, 0.2 parts of leveling agent, 0.2 parts of antifungal agent, 1.0 parts of thickener and 5 parts of deionized water; in the curing agent, the molar ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com