Electronic product shell with carbon fiber and plastic integrated structure and manufacturing method thereof

A technology of electronic products and carbon fiber, which is applied in the field of electronic product casings with integrated carbon fiber and plastic structures and its preparation, which can solve the problems of high glue adhesion, reduced product service life, poor quality stability, etc., to improve production efficiency , prolong the service life, not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0038] Materials and equipment used

[0039] Japan TORAY3K carbon fiber woven prepreg, cutting machine, hot press molding machine, CNC engraving machine, injection molding machine, carbon fiber modified PC black plastic (carbon fiber 30%), OCA optical glue, precision injection mold, coating reaction casting film Machines, PU thermosetting coatings.

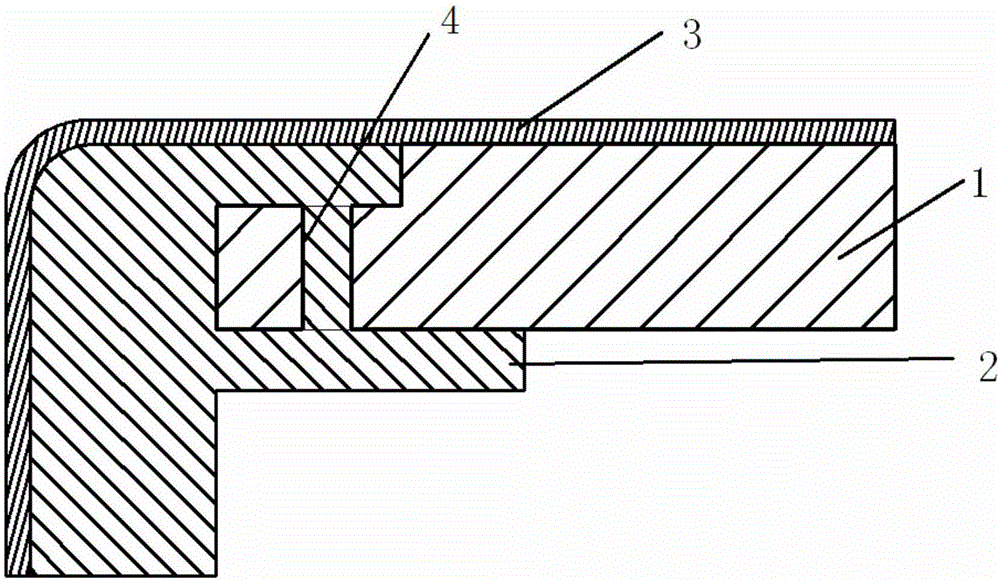

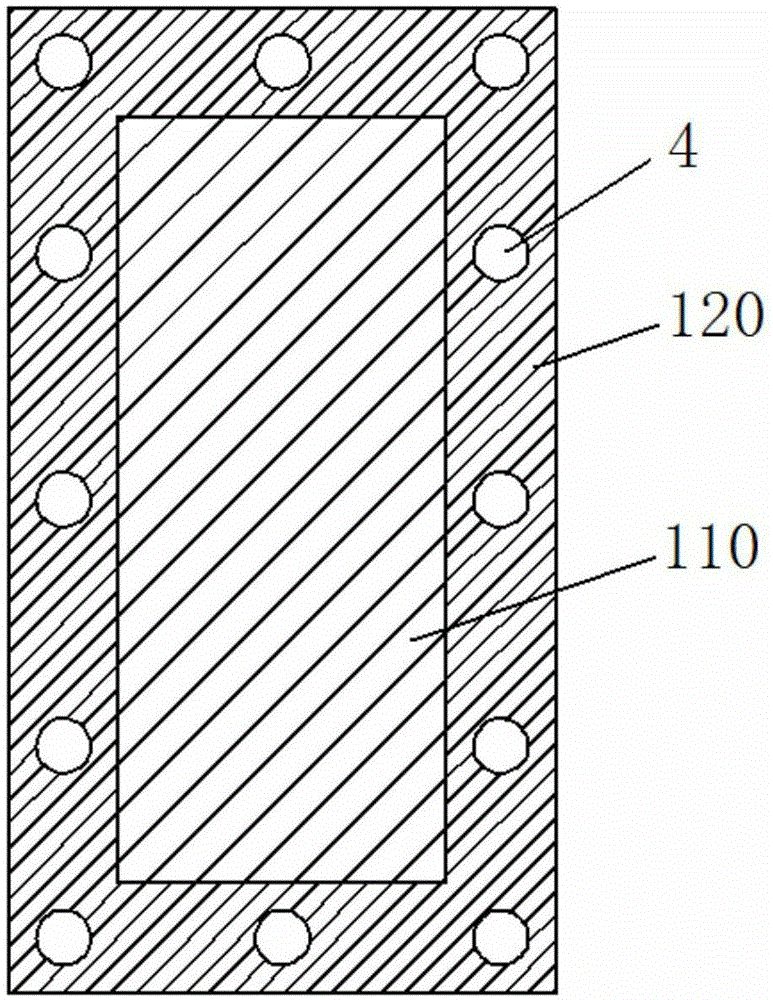

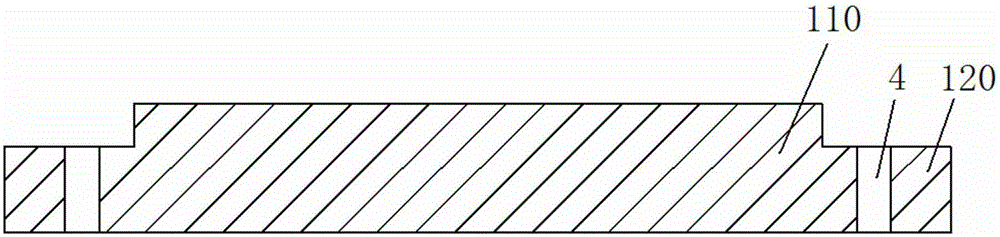

[0040] Preparation of carbon fiber sheets

[0041] Cut the TORAY3K carbon fiber prepreg cloth into 155*120mm, and interleave the carbon fiber cloth according to the requirement. 10~30kg, vacuum -6 MP. Then put the pre-pressed carbon fiber sheet into the forming mold, and then heat and solidify the mold. The curing temperature is 135-150°C, the pressure is 40-60kg, and the curing time is 10-15min. Cool the mold to room temperature, and take out the product in the mold. The carbon fiber sheet rough embryo is obtained; then the carbon fiber sheet rough embryo is placed on the CNC fixture to fix the milling holes. The hole diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com