Panel joining structure and panel joining method

A technology for joining structures and panels, applied in the direction of connection between superstructure sub-assemblies, superstructure, superstructure sub-assemblies, etc., can solve another scraping, adhesive dripping in adhesive joints It can prevent dripping or scraping, ensure the bonding quality, and improve the bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0037] First, a first embodiment of the present invention will be described.

[0038] In addition, arrow UP and arrow OUT shown in each figure indicate the upper side in the vehicle vertical direction and the outer side in the vehicle width direction, respectively. The vehicle up-down direction is an example of a vertical direction in the present invention, and the vehicle width direction is an example of a direction intersecting the vertical direction in the present invention.

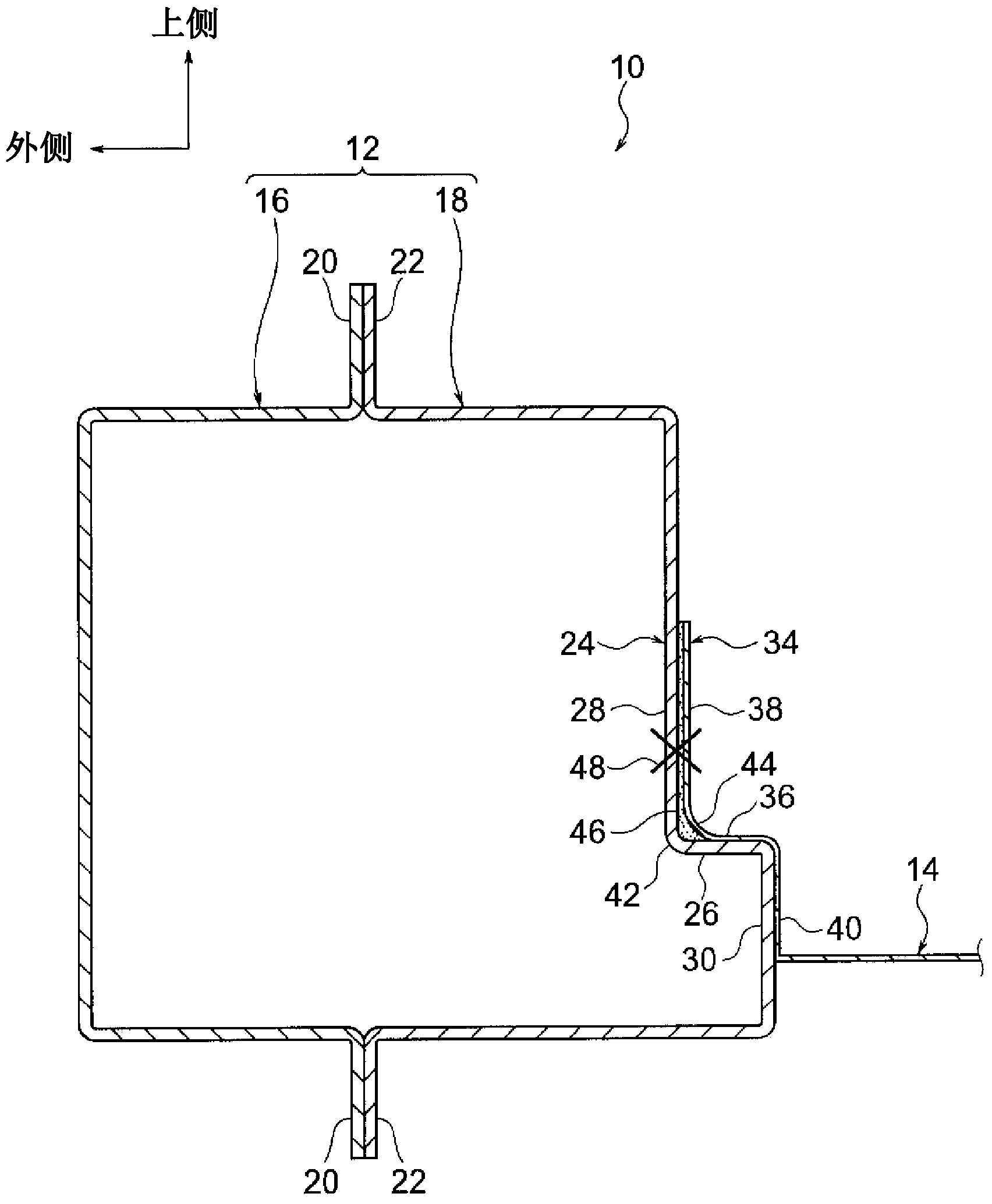

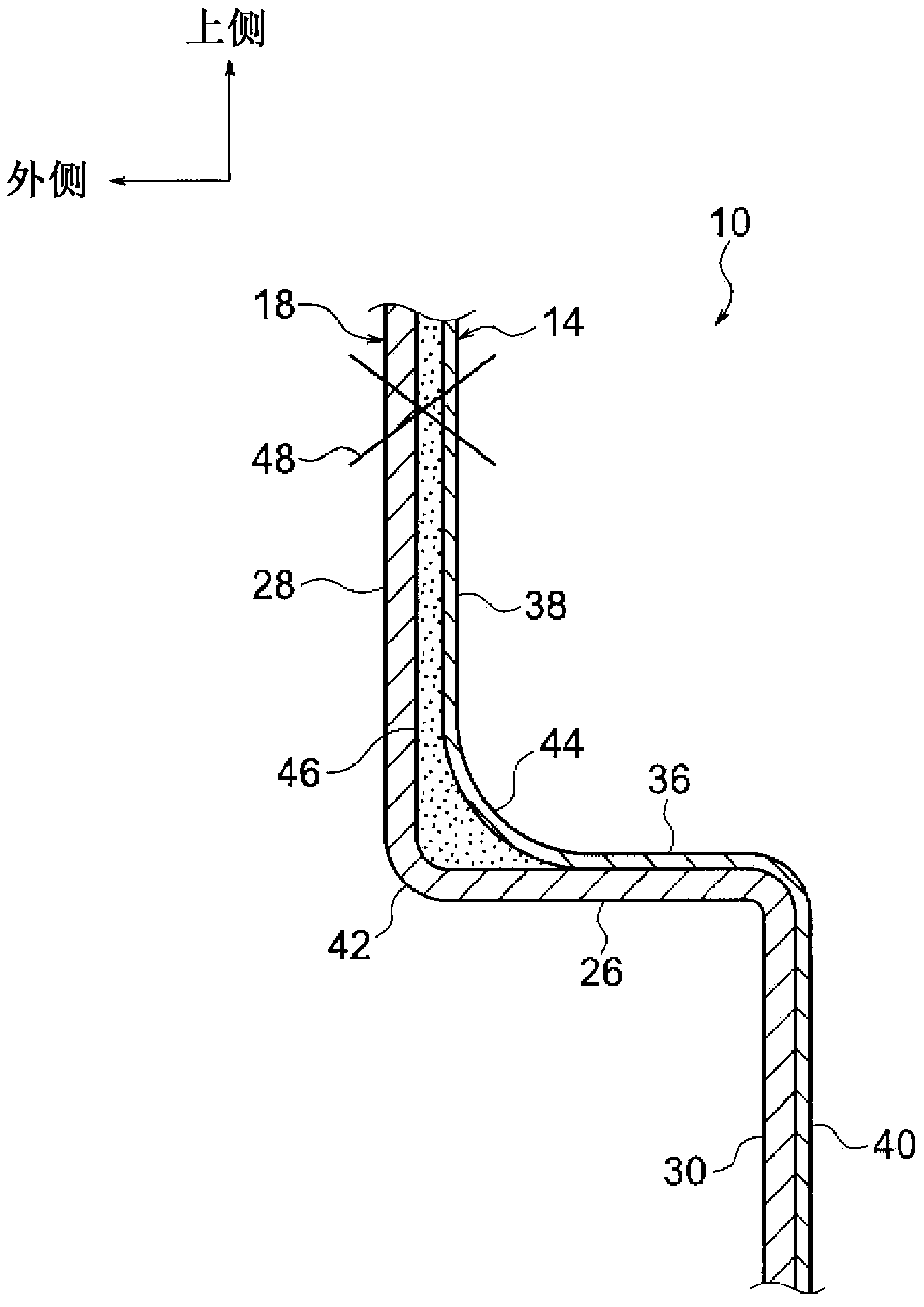

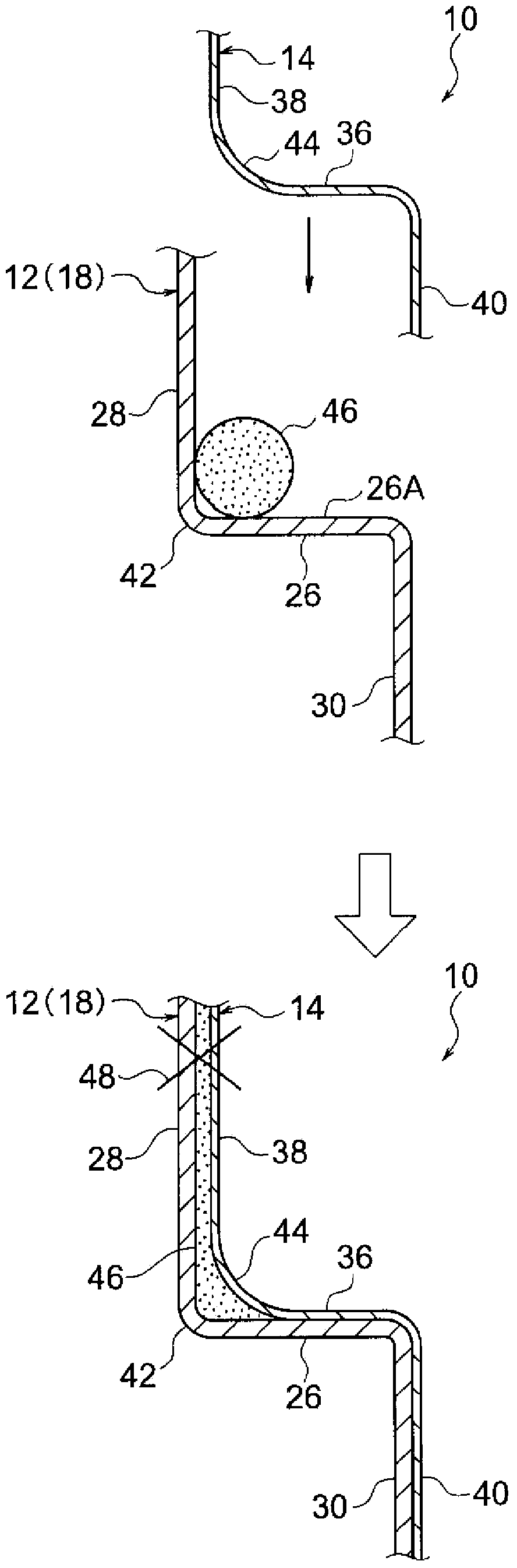

[0039] figure 1 The illustrated panel joint structure 10 according to the first embodiment of the present invention is applied to, for example, a vehicle body of a car or the like, and has a rocker 12 and a floor panel 14 . The rocker 12 is provided on the side of the floor of the vehicle compartment and extends in the front-rear direction of the vehicle. The rocker 12 has a closed cross-sectional shape in a vehicle front view, and has a rocker outer panel 16 and a rocker inner panel 18 which are di...

no. 2 approach

[0064] Hereinafter, a second embodiment of the present invention will be described.

[0065] With respect to the above-mentioned panel joining structure 10 of the first embodiment of the present invention (see figure 2 ), Figure 5 The panel joining structure 60 according to the second embodiment of the present invention shown has a structural change as follows.

[0066] That is, in this panel joint structure 60 , the stepped portion 26 extends in a direction (arrow A direction) inclined with respect to the vehicle width direction as an example of a direction intersecting the vehicle vertical direction. That is, the stepped portion 26 is inclined with respect to the vehicle width direction so as to be directed toward the lower side of the vehicle as it goes inward in the vehicle width direction. In addition, the facing portion 36 also extends in a direction inclined with respect to the vehicle width direction similarly to the above-mentioned step portion 26 .

[0067] In a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com