Microporous polyolefin resin sheet production device and production method

A polyolefin resin, technology for manufacturing equipment, applied in flat products, applications, coatings, etc., can solve problems such as contamination, sheet defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

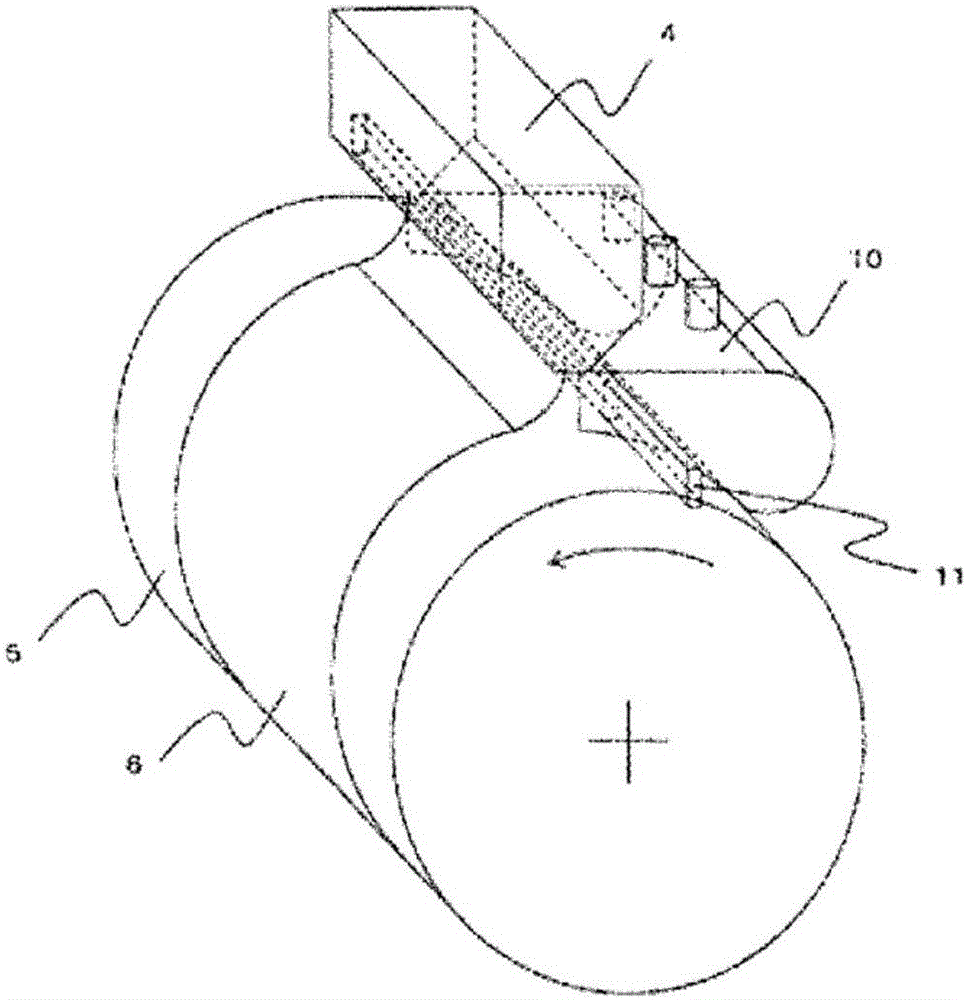

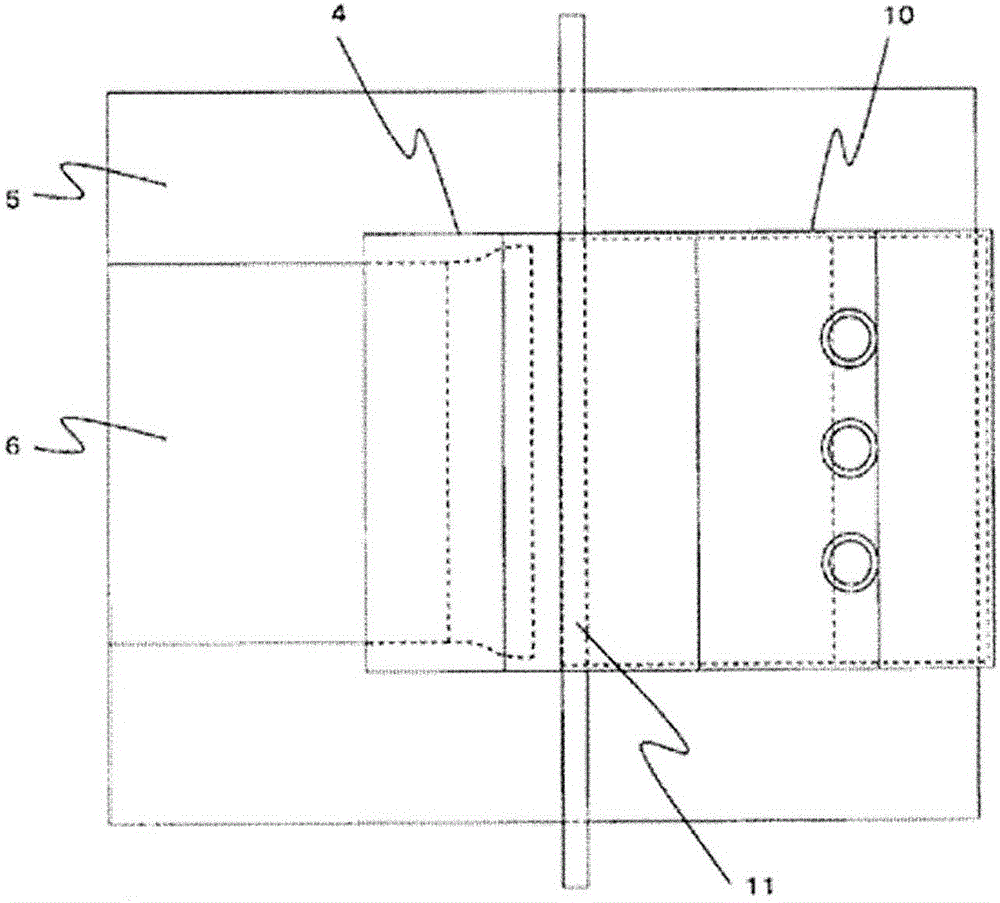

Method used

Image

Examples

Embodiment 1

[0058] A specific sheet manufacturing method in this embodiment is as follows.

[0059] (1) Sheet material

[0060] ·High-density polyethylene (HDPE): viscosity 1000Pa·s. Here, the viscosity is measured by the method of JIS K7117-2 on the condition of a shear rate of 100 / s and a temperature of 200 degreeC.

[0061] ·Liquid paraffin (LP): Dynamic viscosity 50cSt (at 40°C mm2 / s).

[0062] (2) Feeding

[0063] After the sheet material is dried, it is supplied to an extruder, and after passing through a gear pump and a filter, it is supplied to a die. In addition, the temperature of the device before reaching the die was set to 230°C.

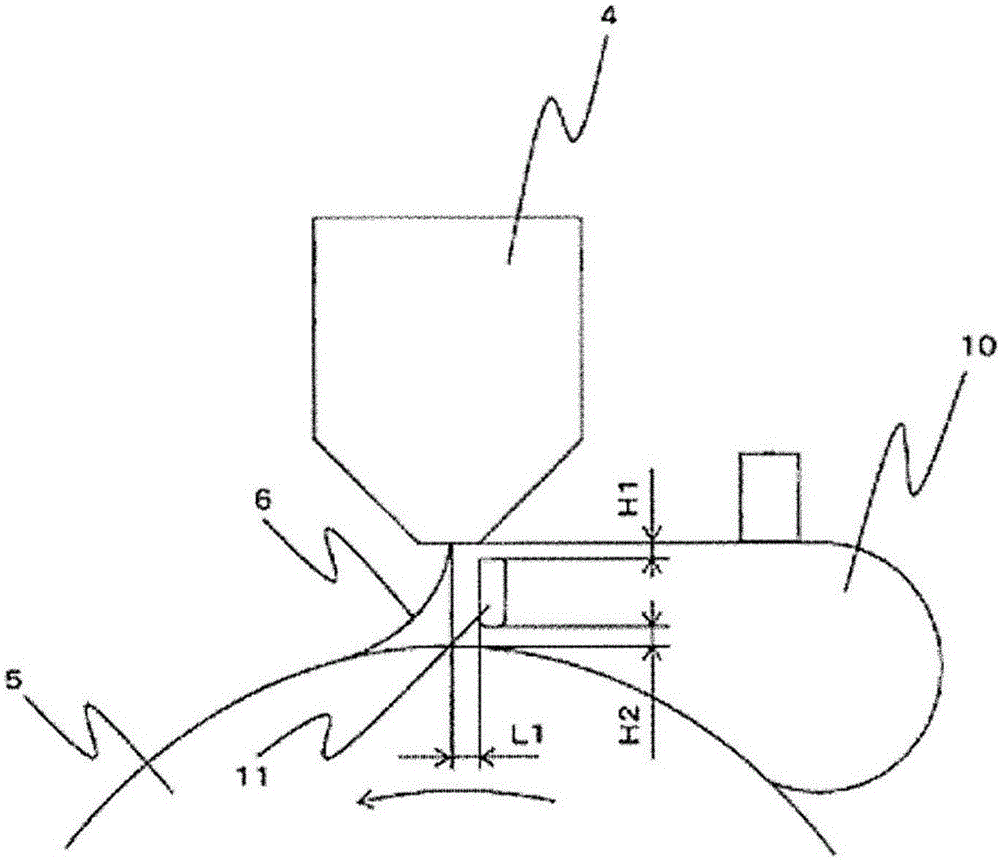

[0064] (3) Die

[0065] The slit width was set to 300 mm, and the above-mentioned sheet material was discharged at a flow rate of 250 kg / hr. It should be noted that the concentration of LP in the polyolefin resin solution is 70% by mass, so 175kg / hr is LP. In addition, depending on the width of the sheet and the degree of decompression, 0.1% o...

Embodiment 2

[0074] Film formation was performed with the same apparatus configuration and film formation conditions as in Example 1 except that the following rectifying plates were used.

[0075] (rectifier plate)

[0076] Make the rectifying plate of square column type without arc at the bottom. The opening of the lower surface of the rectifying plate facing the cooling and solidifying device is defined as the aperture Holes with a pitch of 5 mm are processed along the entire width with the same length as the width and length of the die lip. In addition, the gap between the rectifying plate and the back of the sheet is set to 5 mm, the gap between the lower surface of the die and the upper surface of the rectifying plate facing it is set to 5 mm, and the cooling and solidifying device and the gap below the rectifying plate facing it are set to 5 mm. The surface gap is set to 10 mm, and it is placed in the decompression chamber in this manner. In order to depressurize the inside of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com