Patents

Literature

56results about How to "Drip suppression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

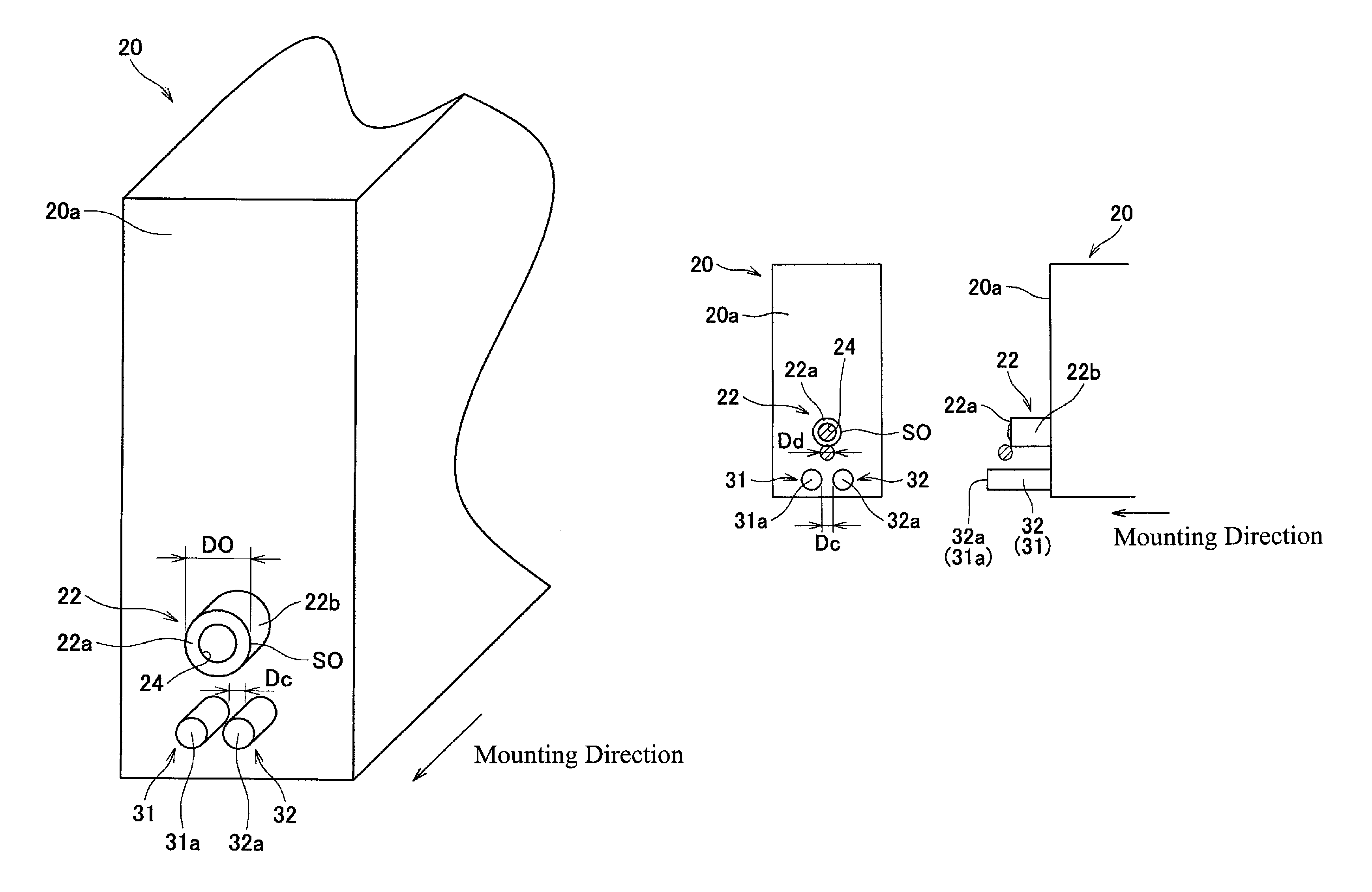

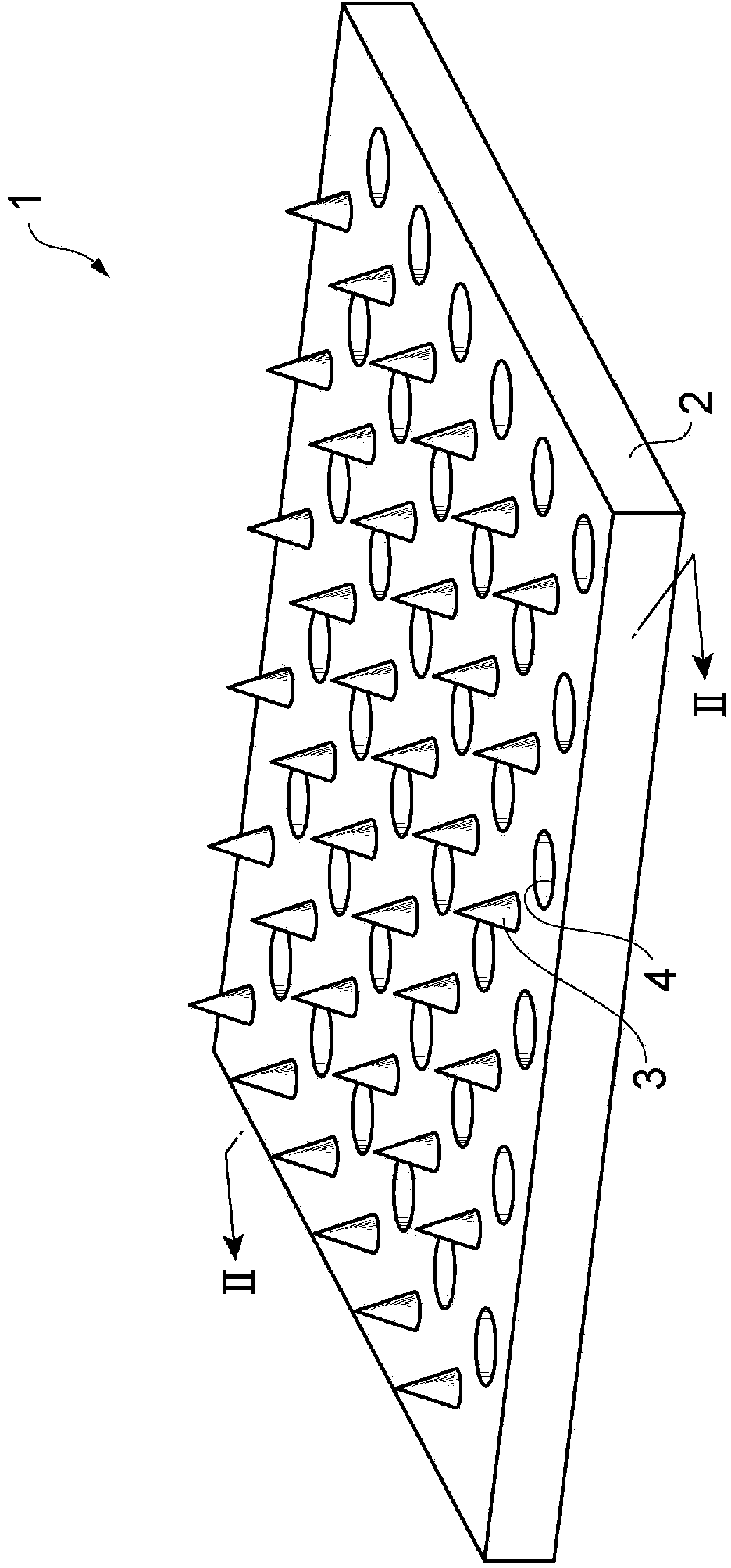

Ink Cartridges And Inkjet Printers

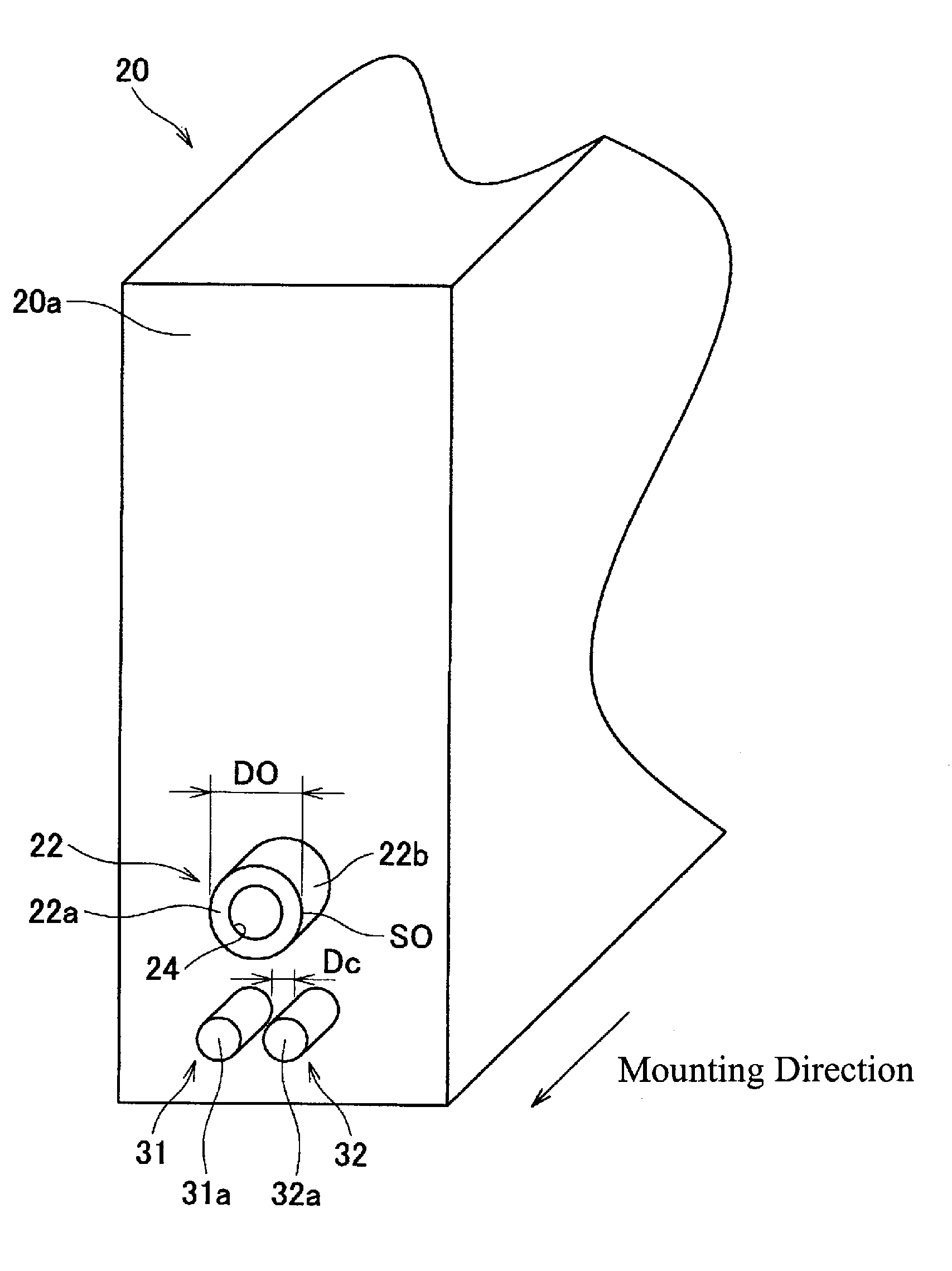

An ink cartridge includes a wall, and an ink supply portion positioned at the wall. The ink supply portion has an ink supply opening formed therein. The ink cartridge also includes a plurality of protrusions which includes a first protrusion and a second protrusion, and each of the first protrusion and the second protrusion extend from the wall. In an embodiment, a distance between the first protrusion and the second protrusion is greater than 0 mm and less than a diameter of the ink supply opening. In another embodiment, the distance between the first protrusion and the second protrusion is greater than 0 mm and less than a diameter of the ink supply opening.

Owner:BROTHER KOGYO KK

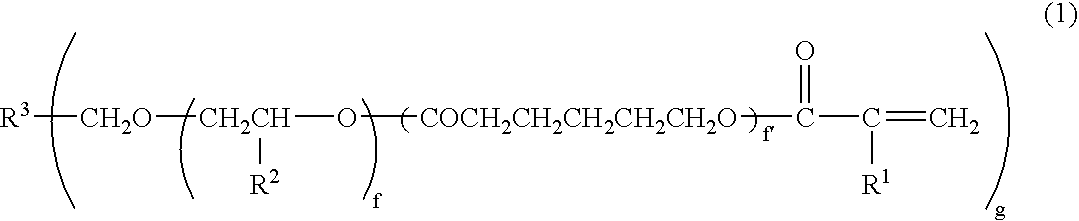

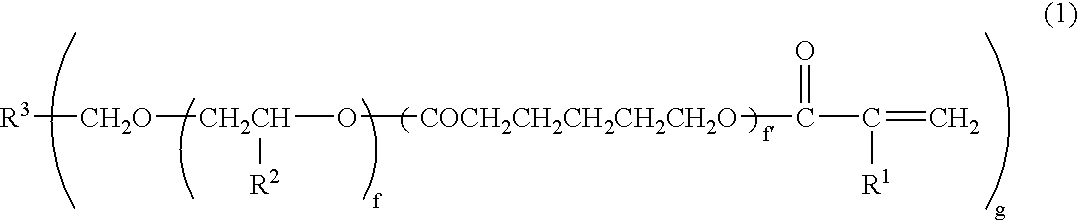

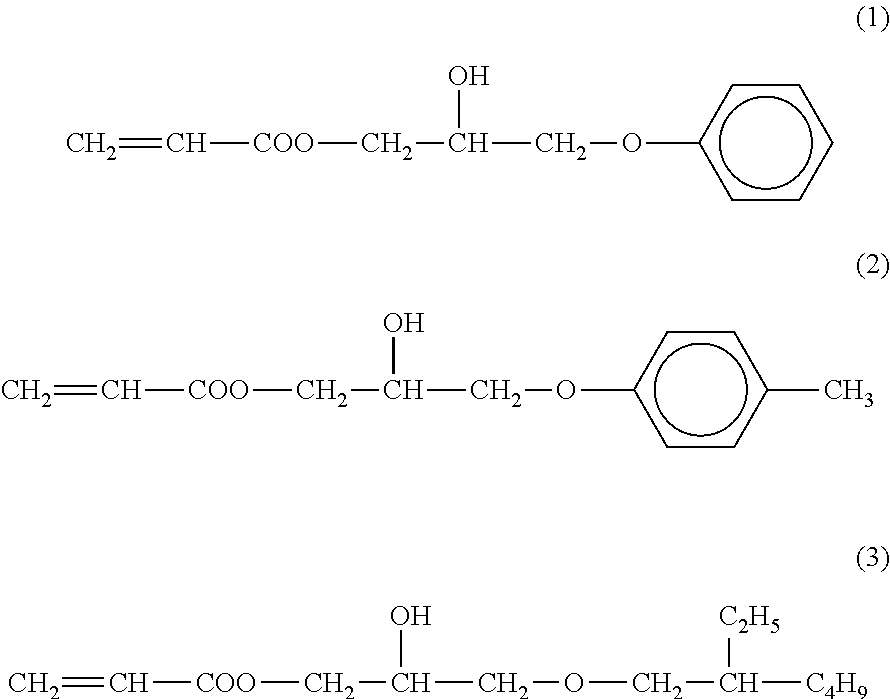

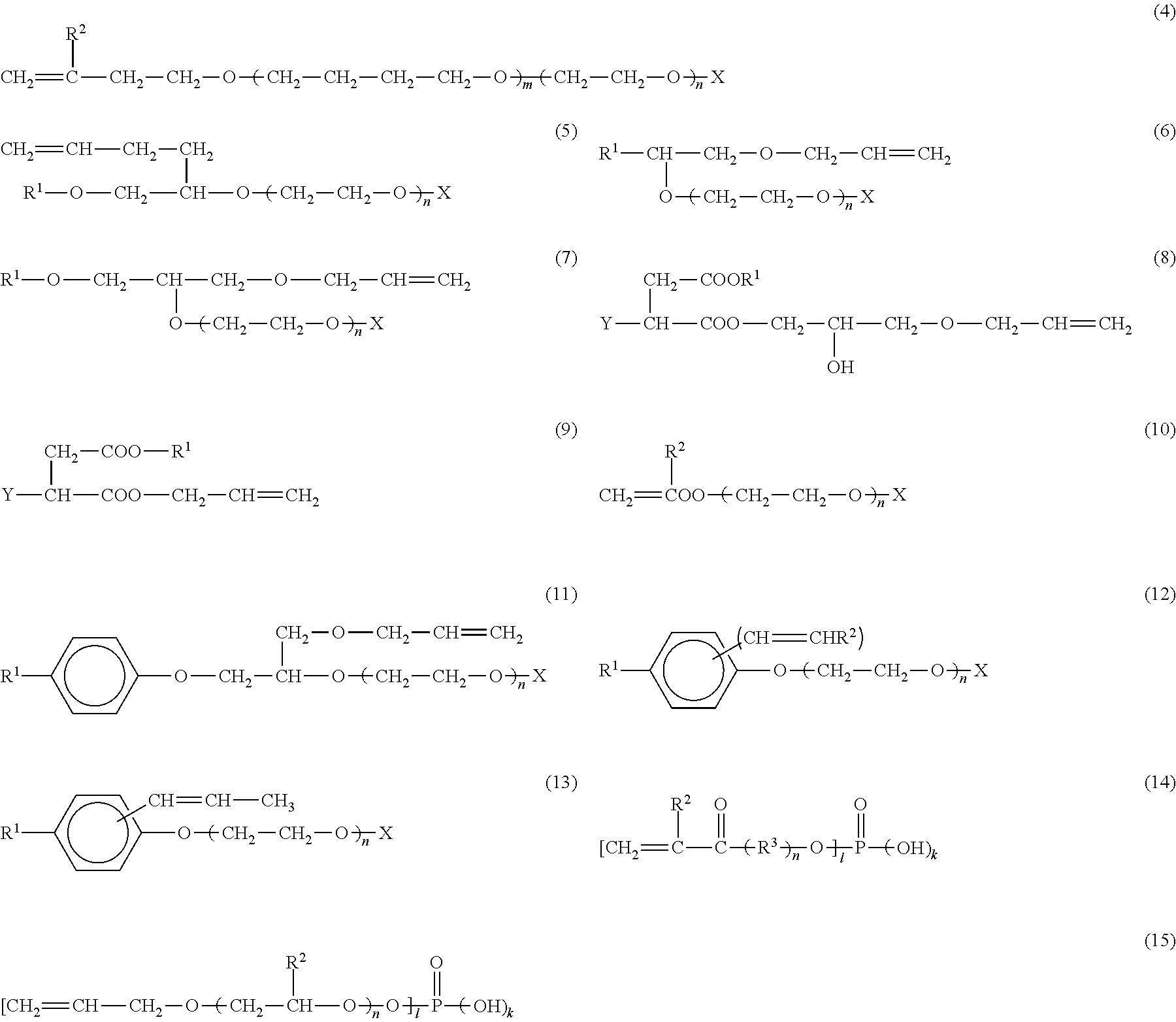

Process for producing photochromic layered product

ActiveUS20070065633A1High surface hardnessExcellent photochromic propertySynthetic resin layered productsCoatingsHigh concentrationPhotochromism

A method of producing a laminate comprising preparing a substrate having curved surfaces; applying a photpolymerizable and curable composition containing a photochromic compound and a phosphorus-containing photopolymerization initiator onto the curved surfaces of the base member; and curing the photopolymerizable and curable composition by the irradiation with an active energy ray having a relative intensity profile of 0 to 5% of wavelength components of not shorter than 200 nm but shorter than 300 nm, 25 to 75% of wavelength components of not shorter than 300 nm but shorter than 400 nm and 25 to 75% of wavelength components of not shorter than 400 nm but not longer than 500 nm while maintaining the substrate at not higher than 100° C. This method makes it possible to form a homogeneous and thin film containing a photochromic compound at a high concentration and having a uniform thickness on the substrate having a curved surface, such as a spectacle lens that is generally available, and to impart photochromic properties while maintaining excellent mechanical and optical properties of the substrate.

Owner:TOKUYAMA CORP

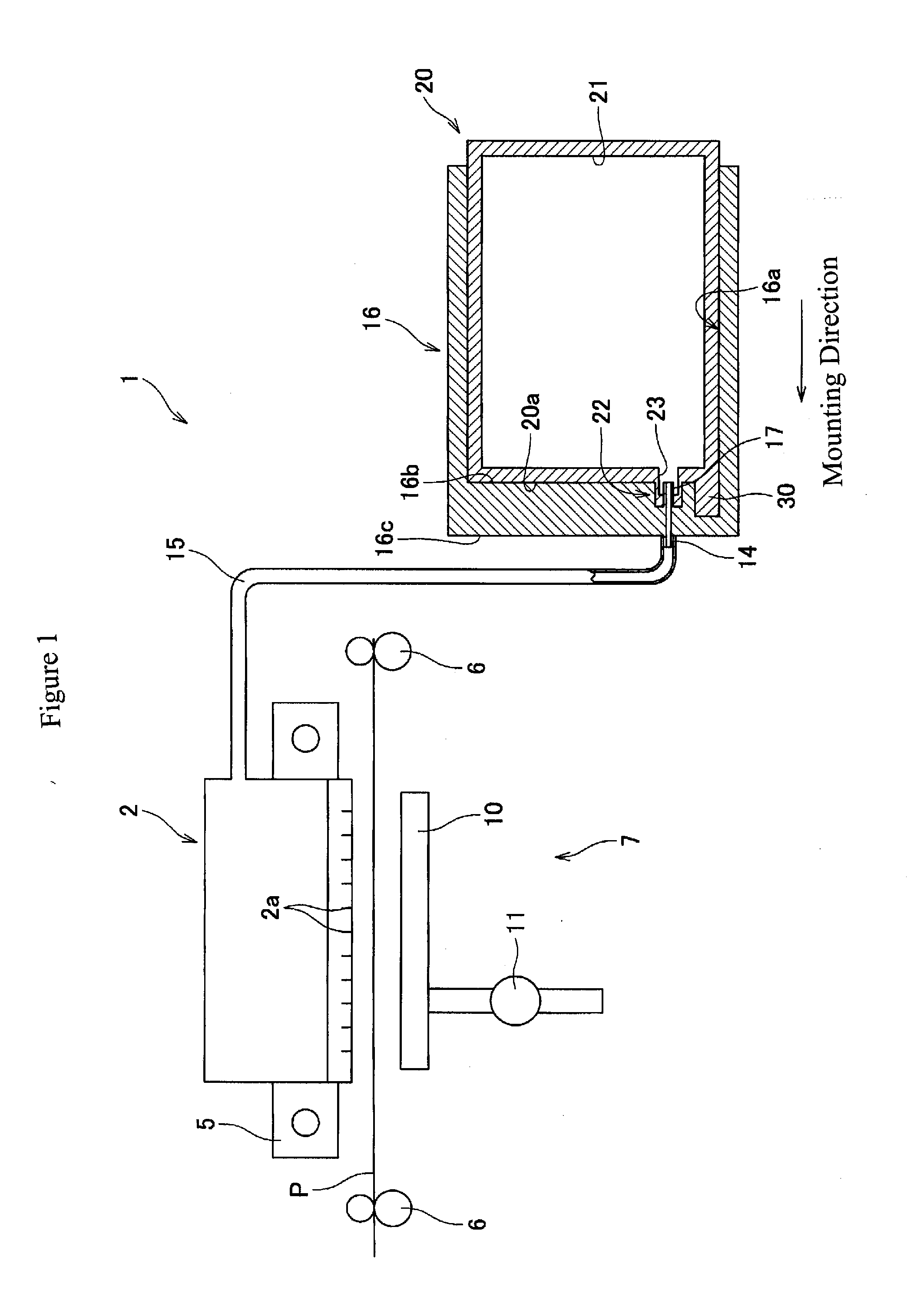

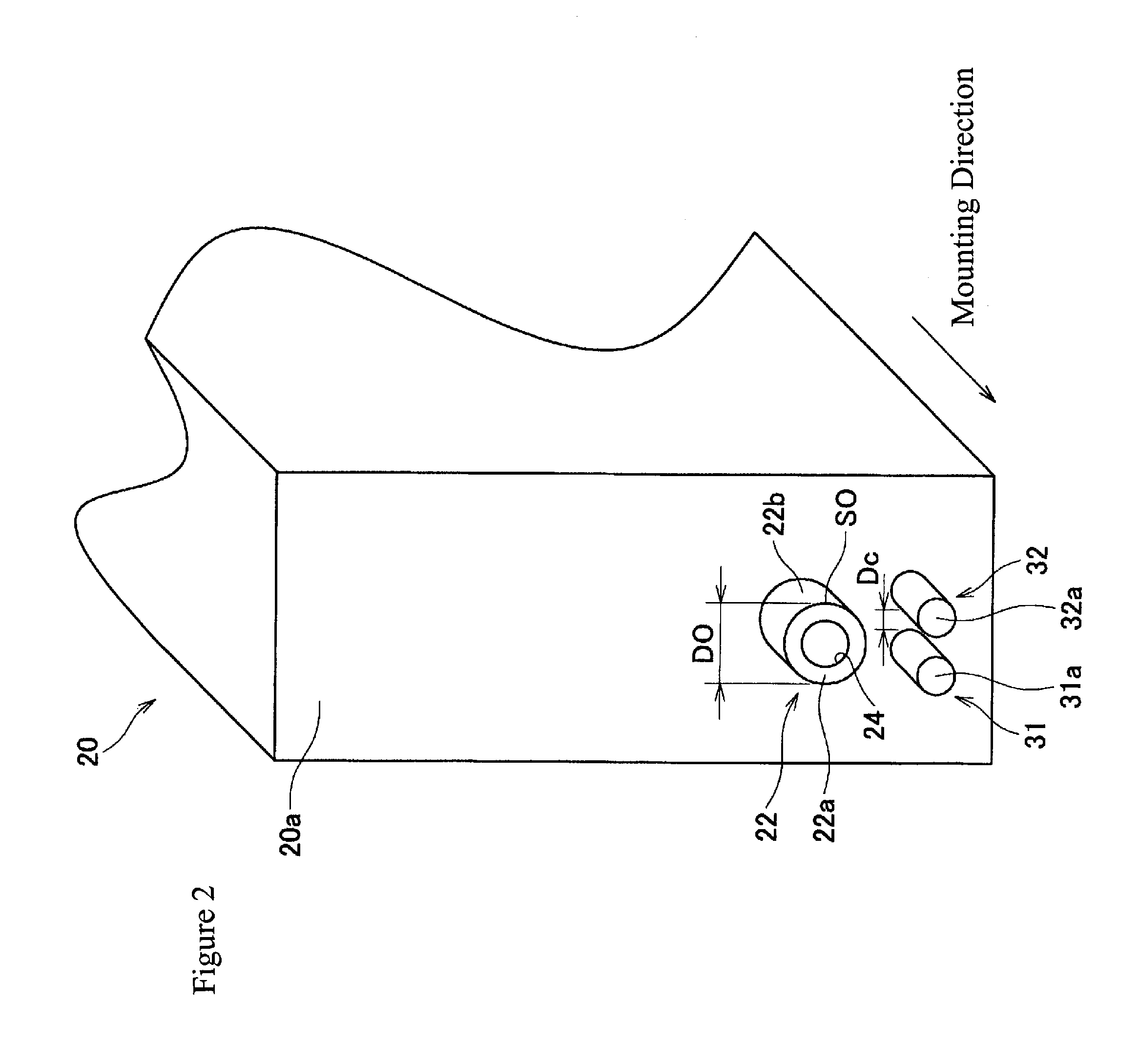

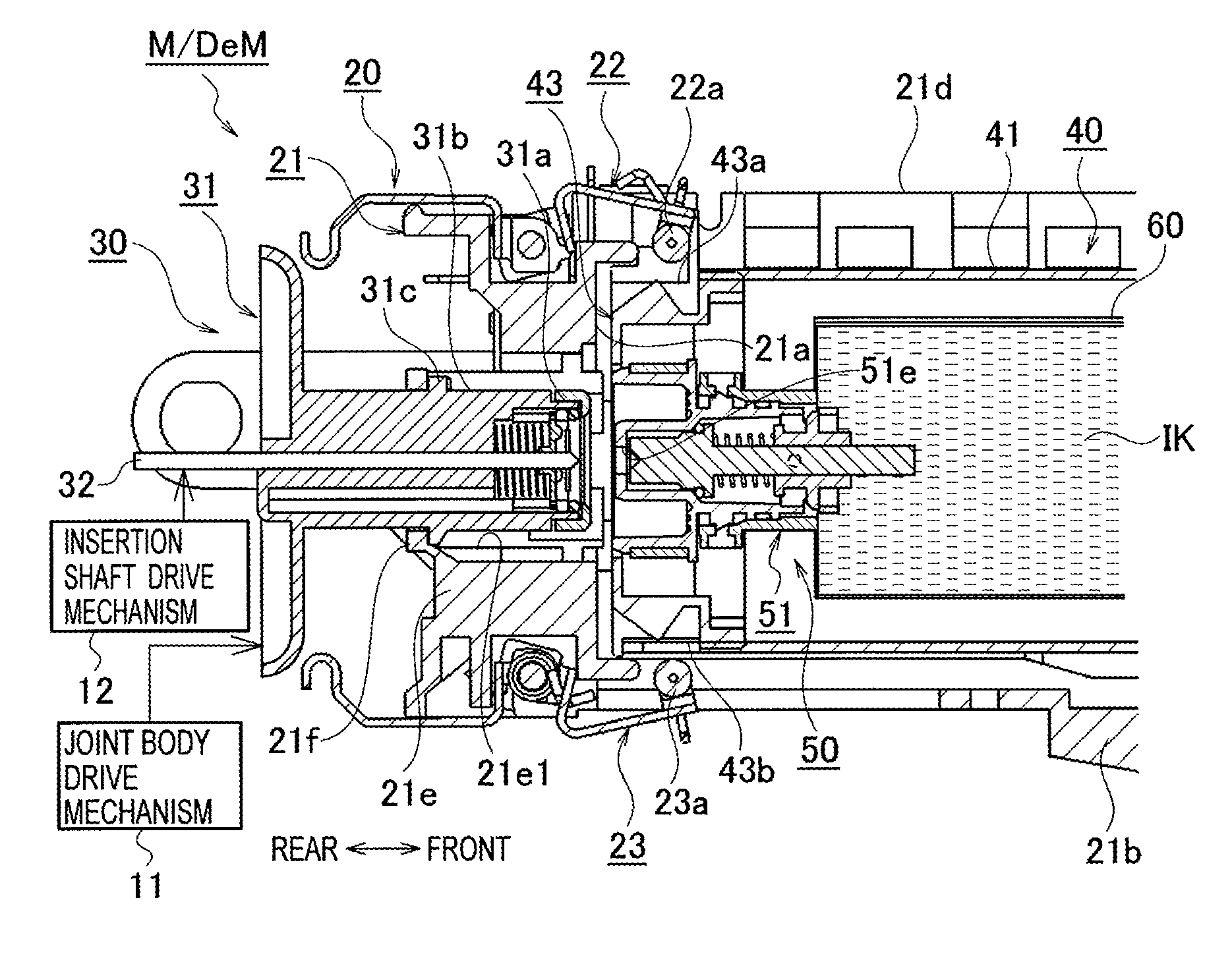

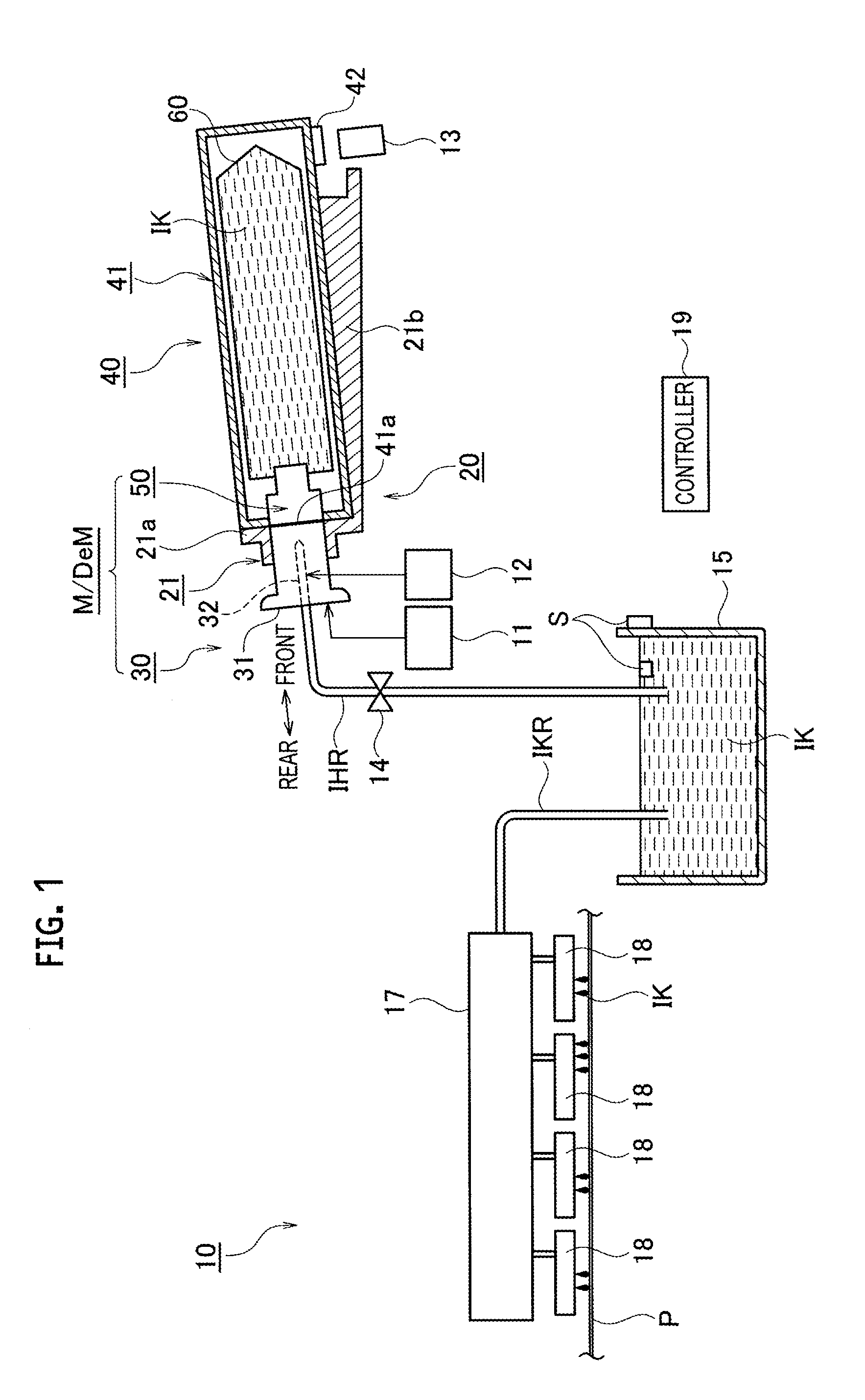

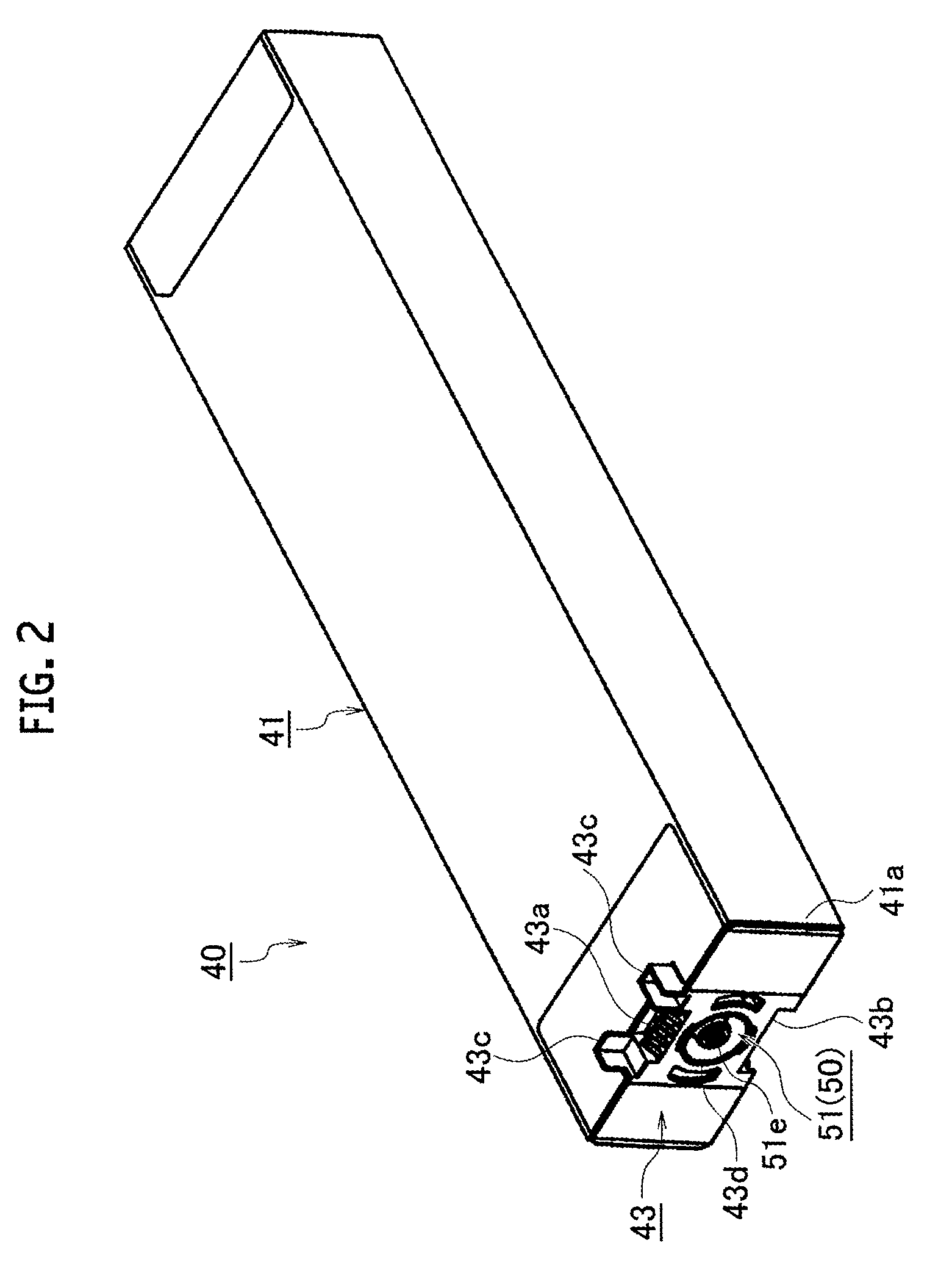

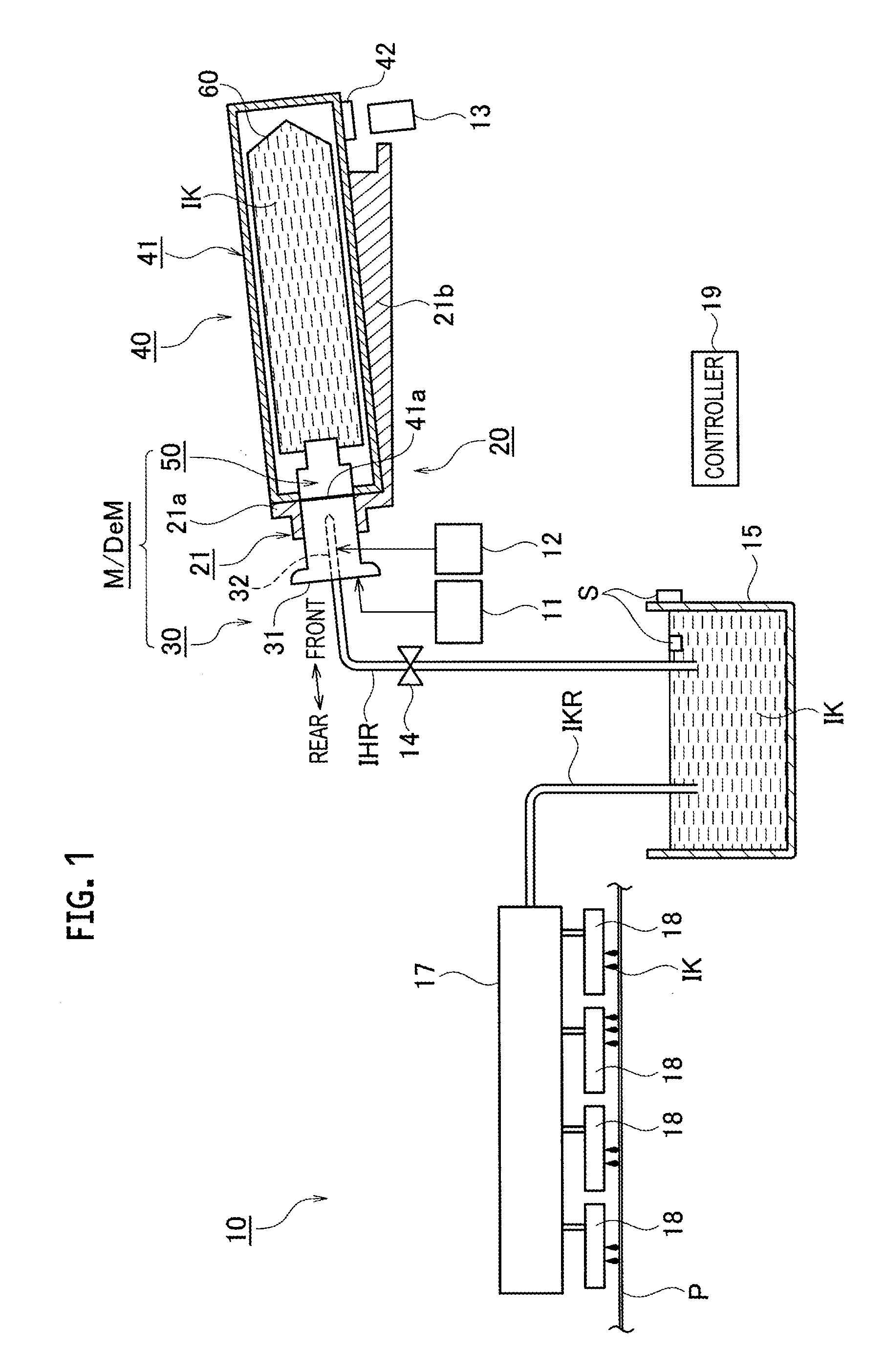

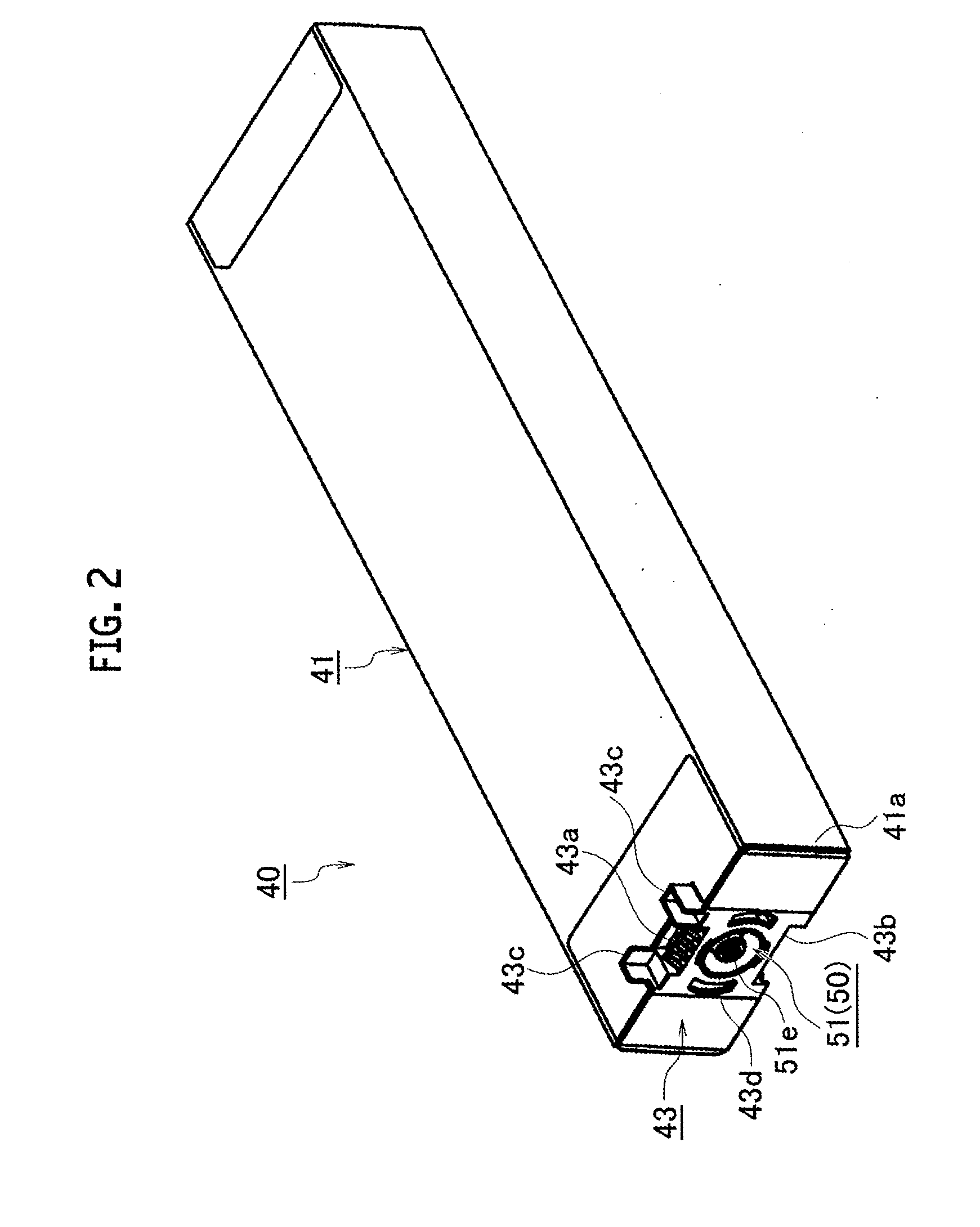

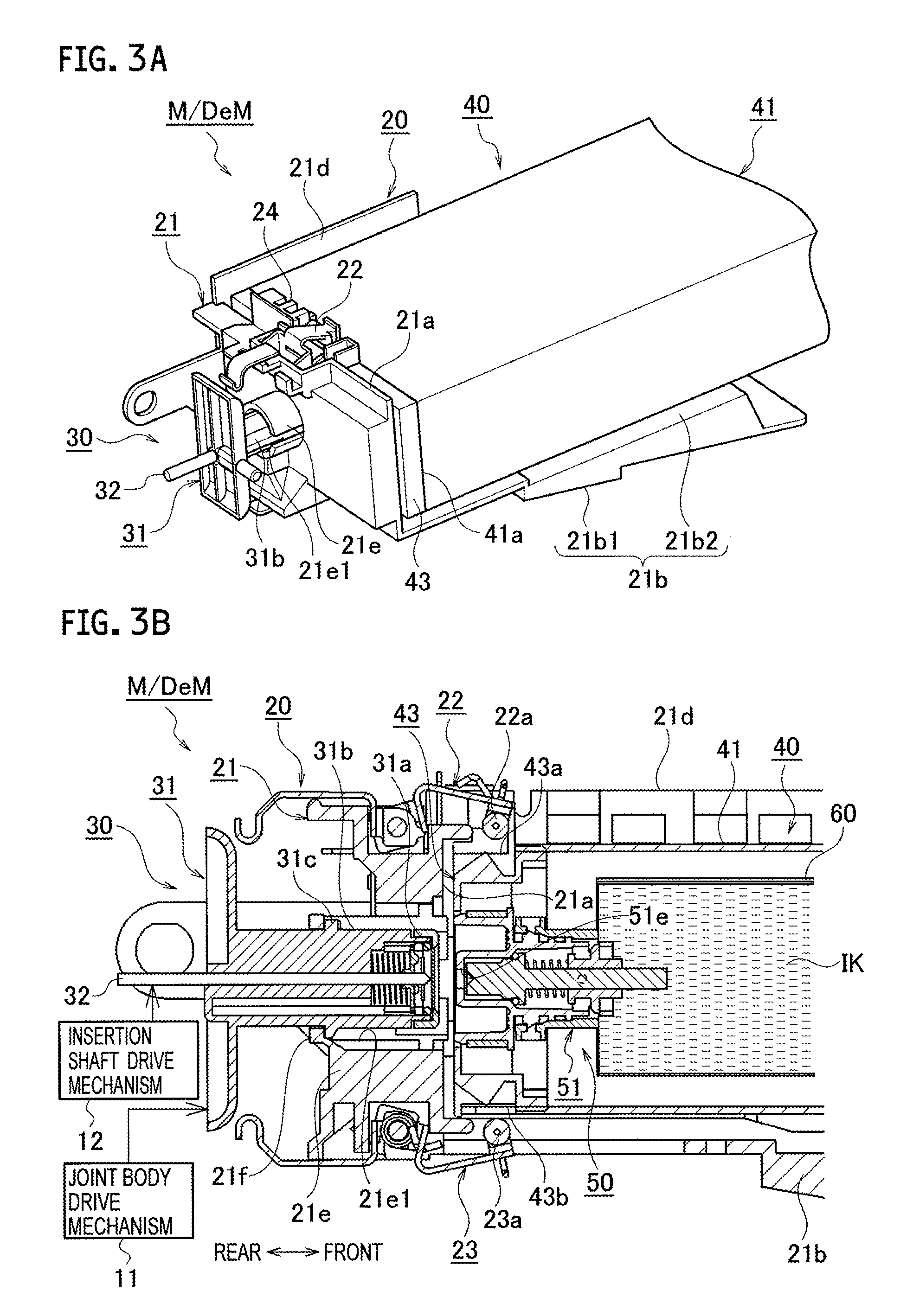

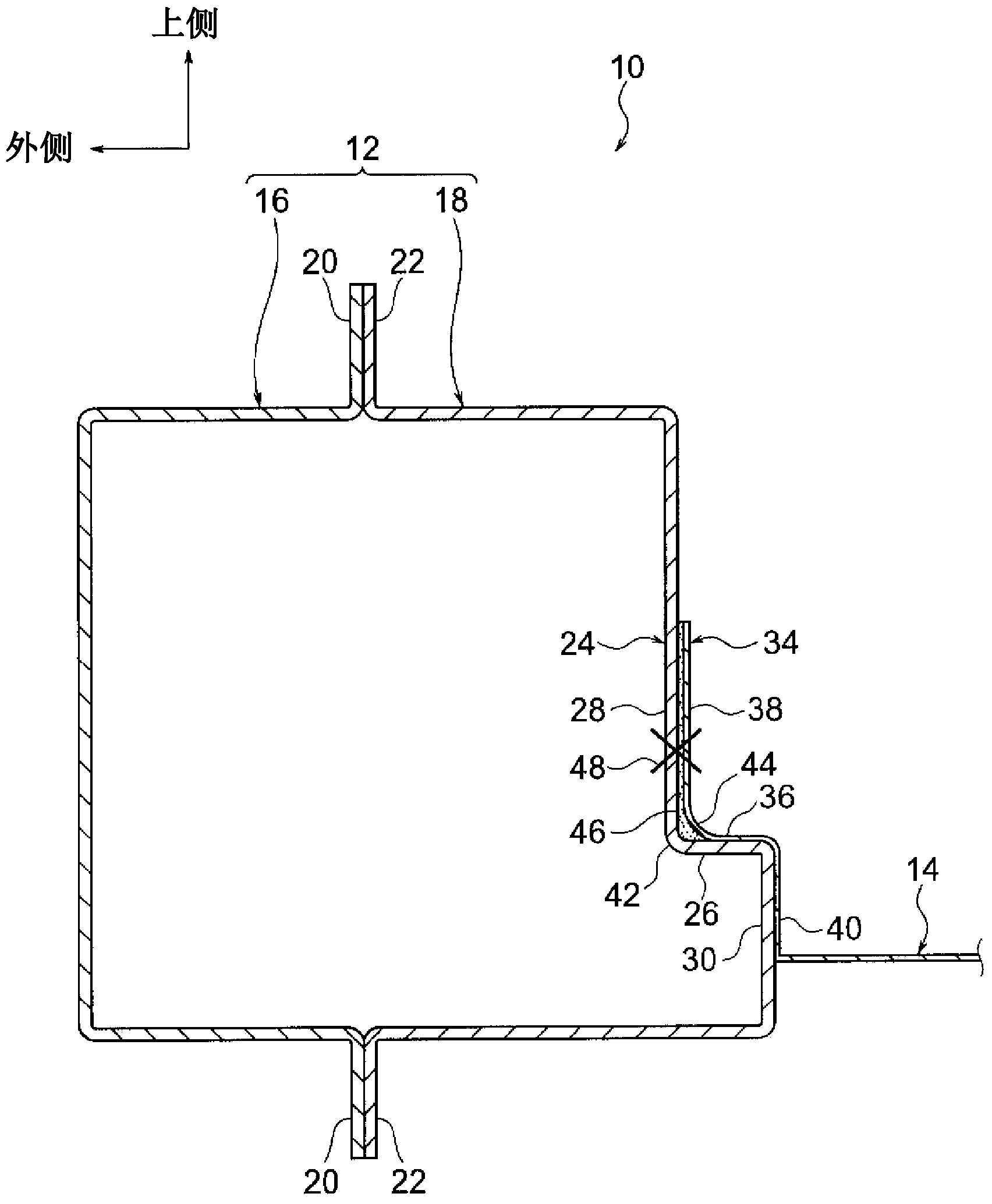

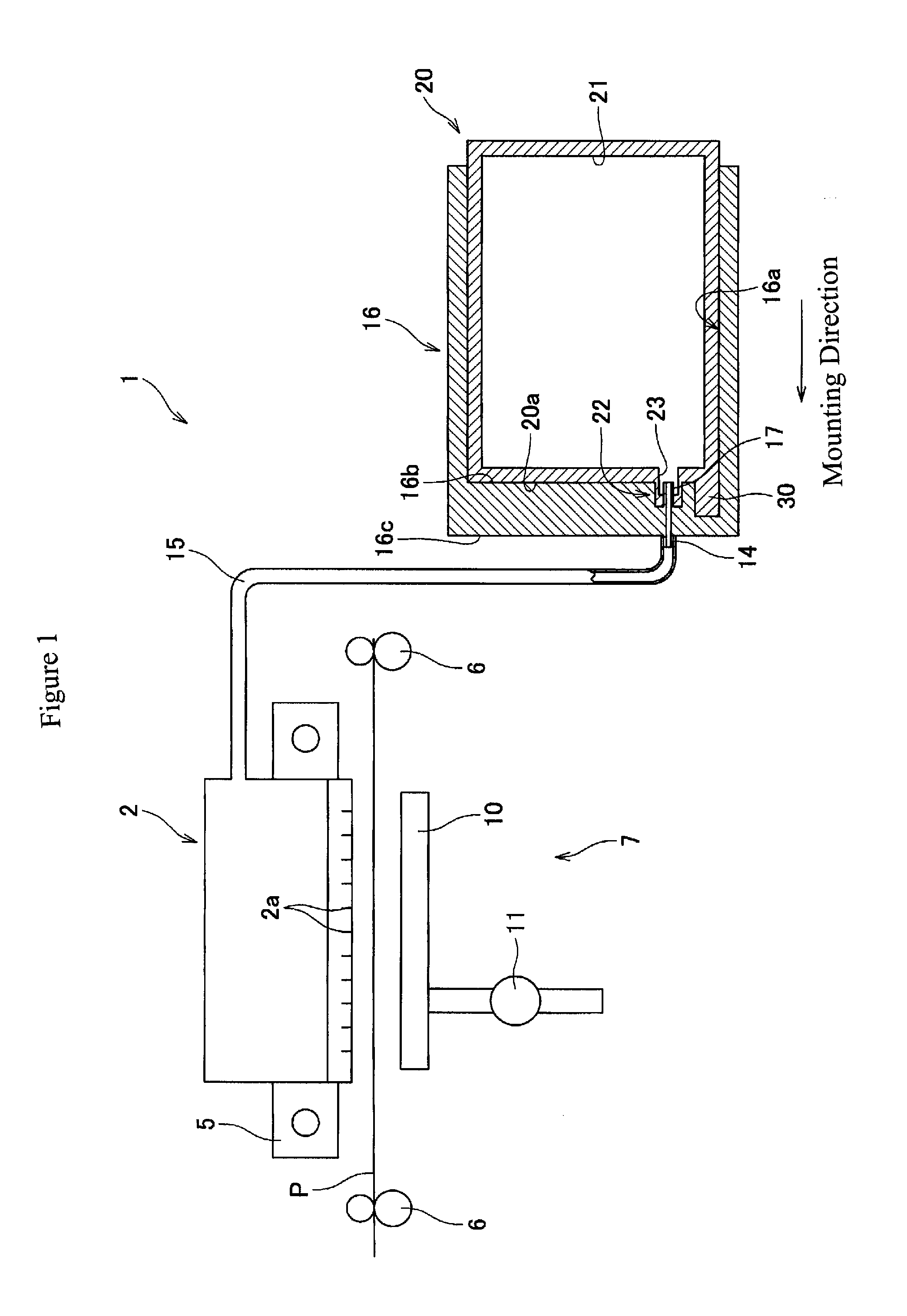

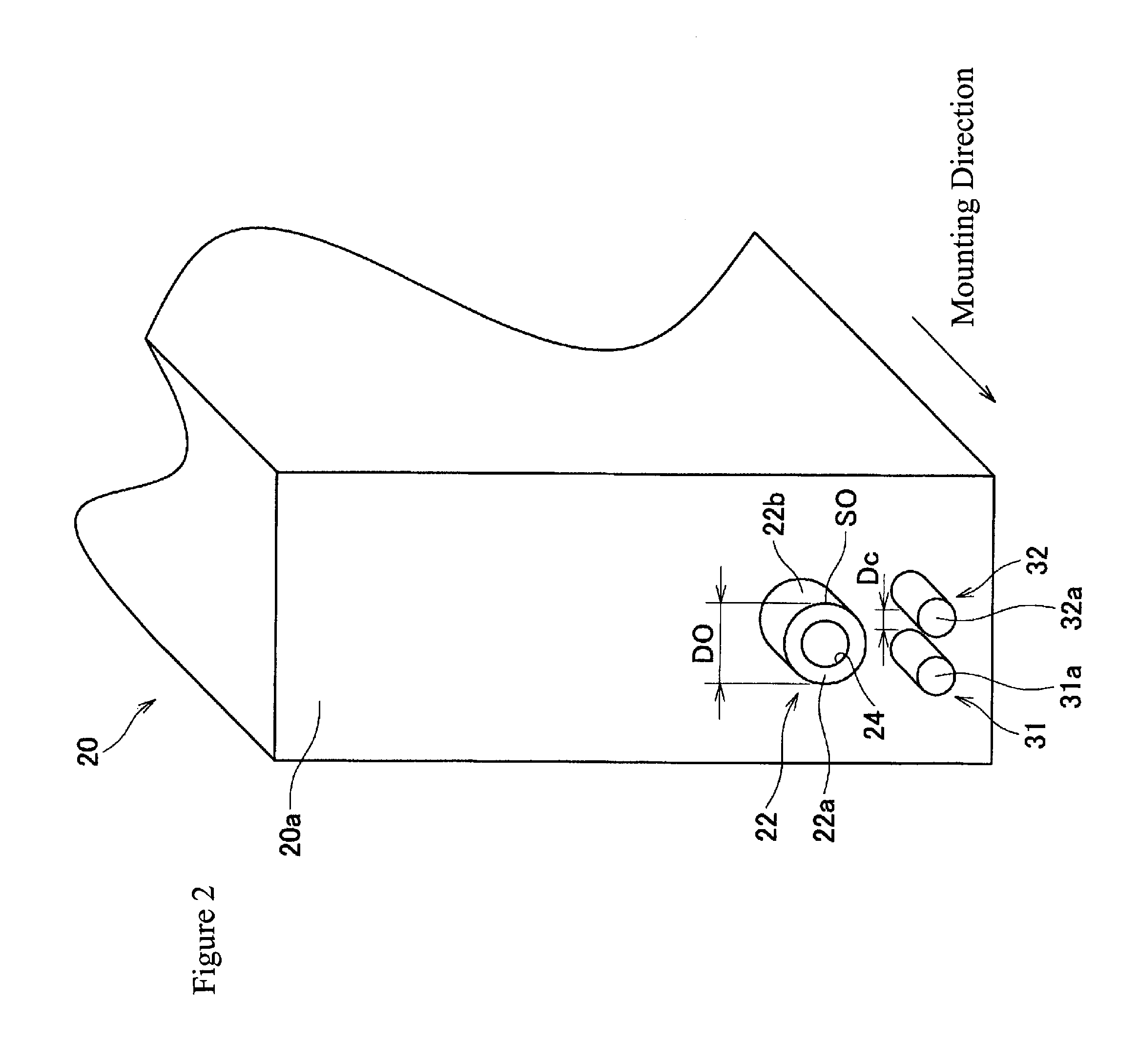

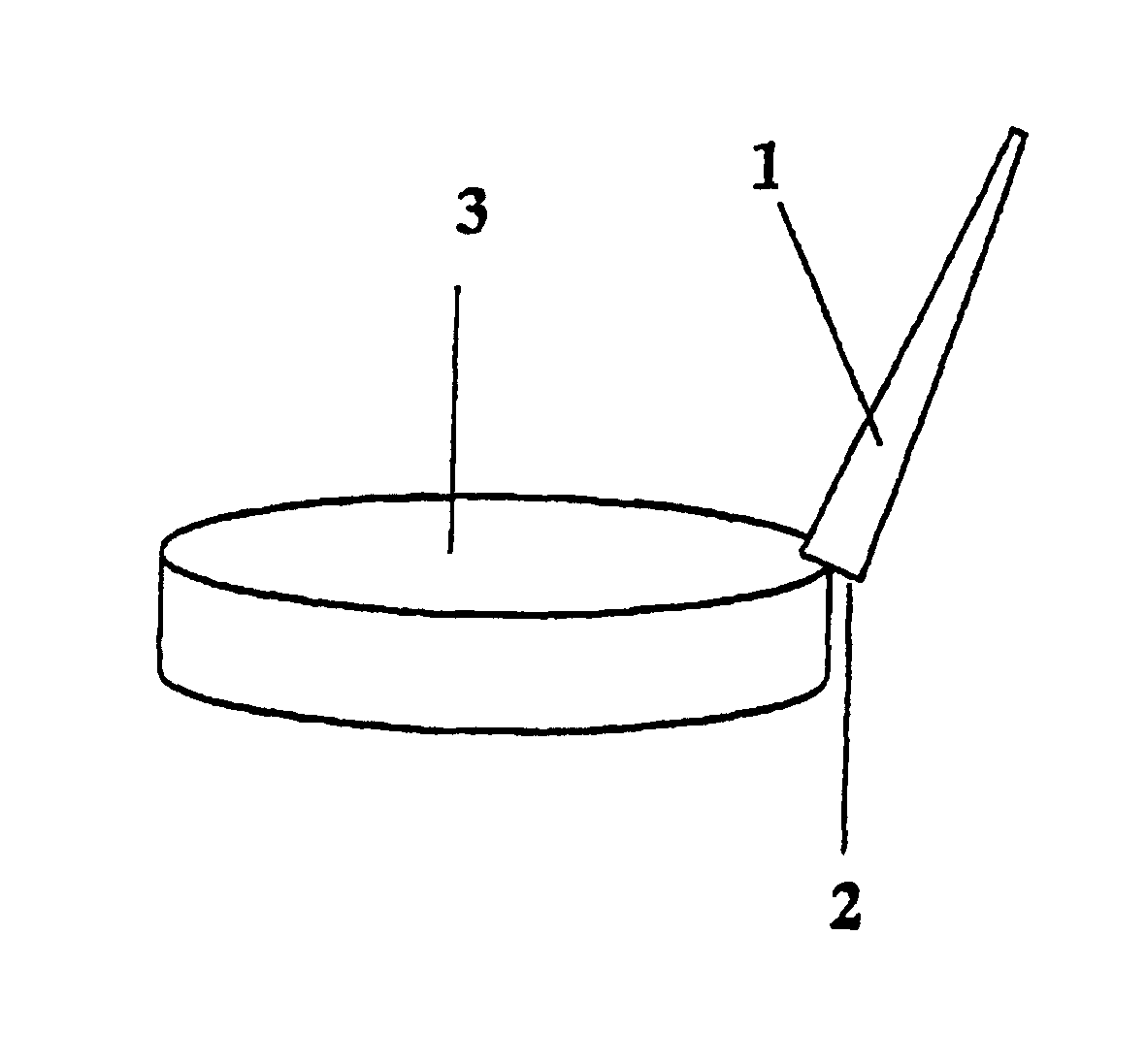

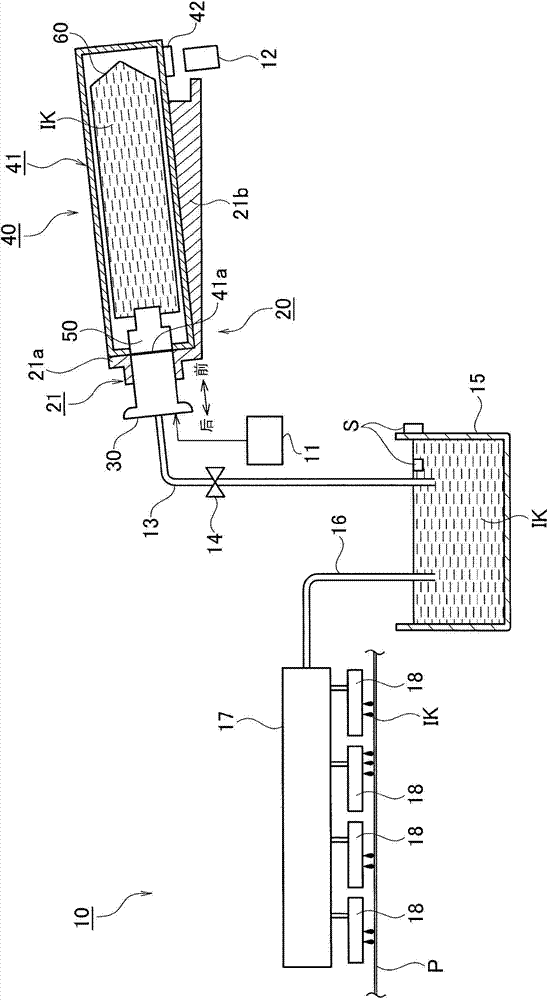

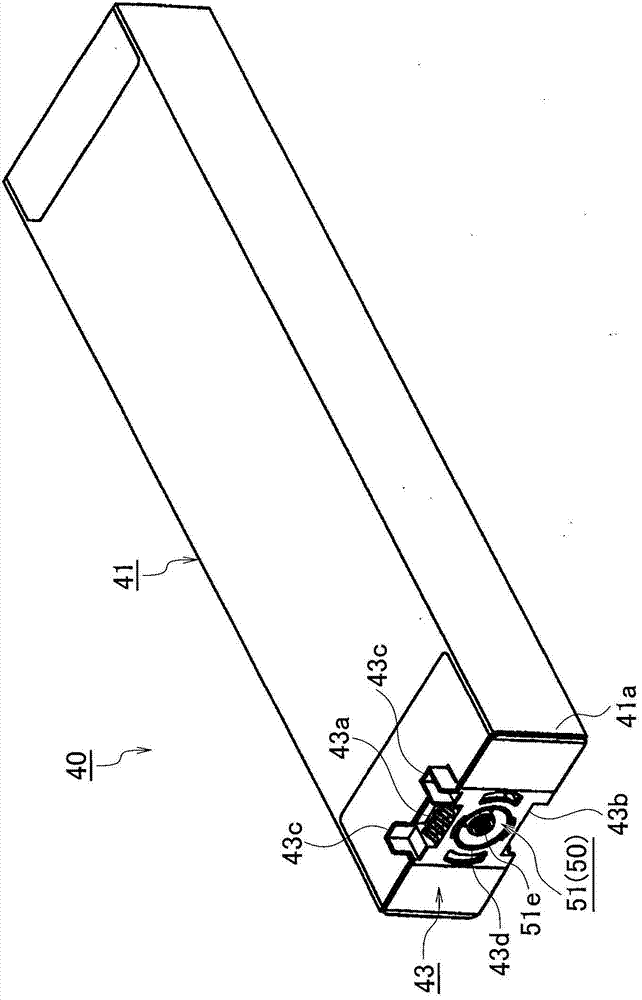

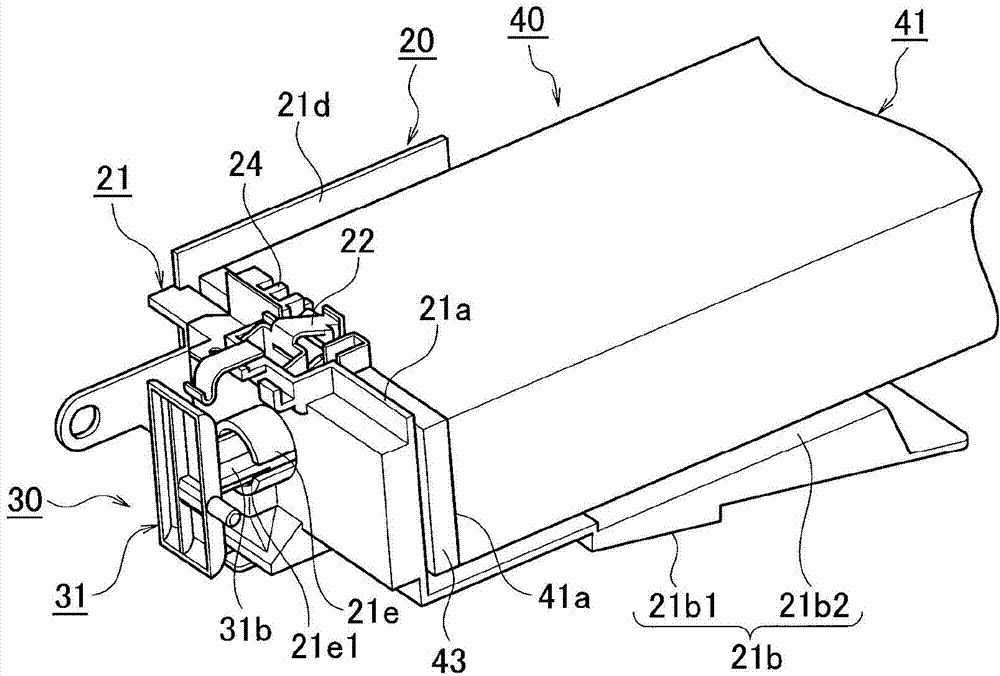

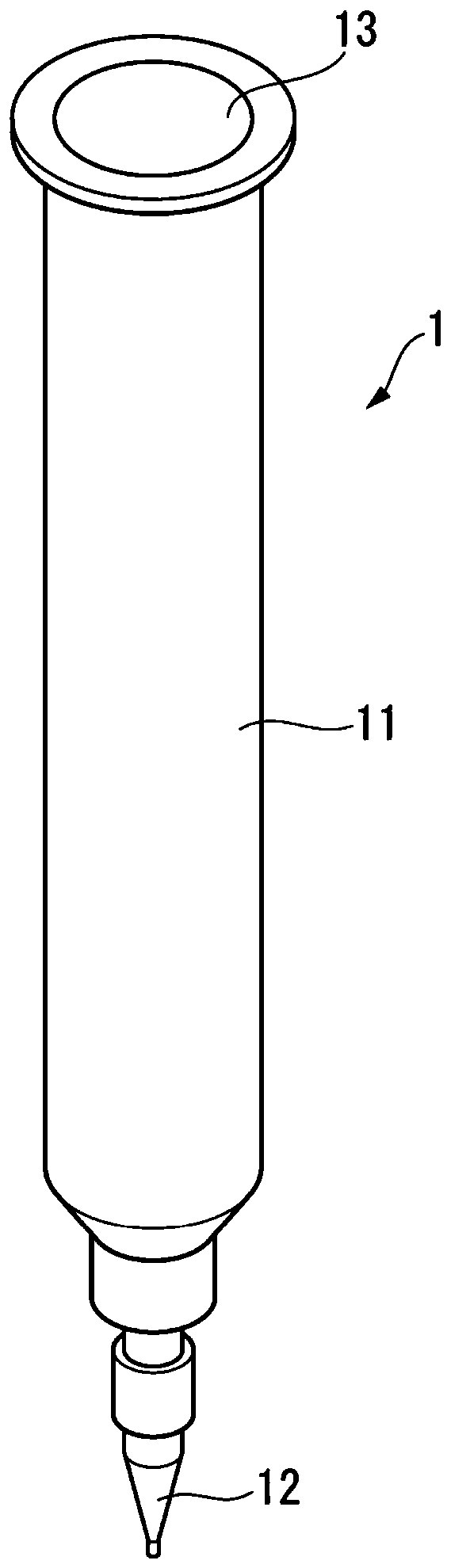

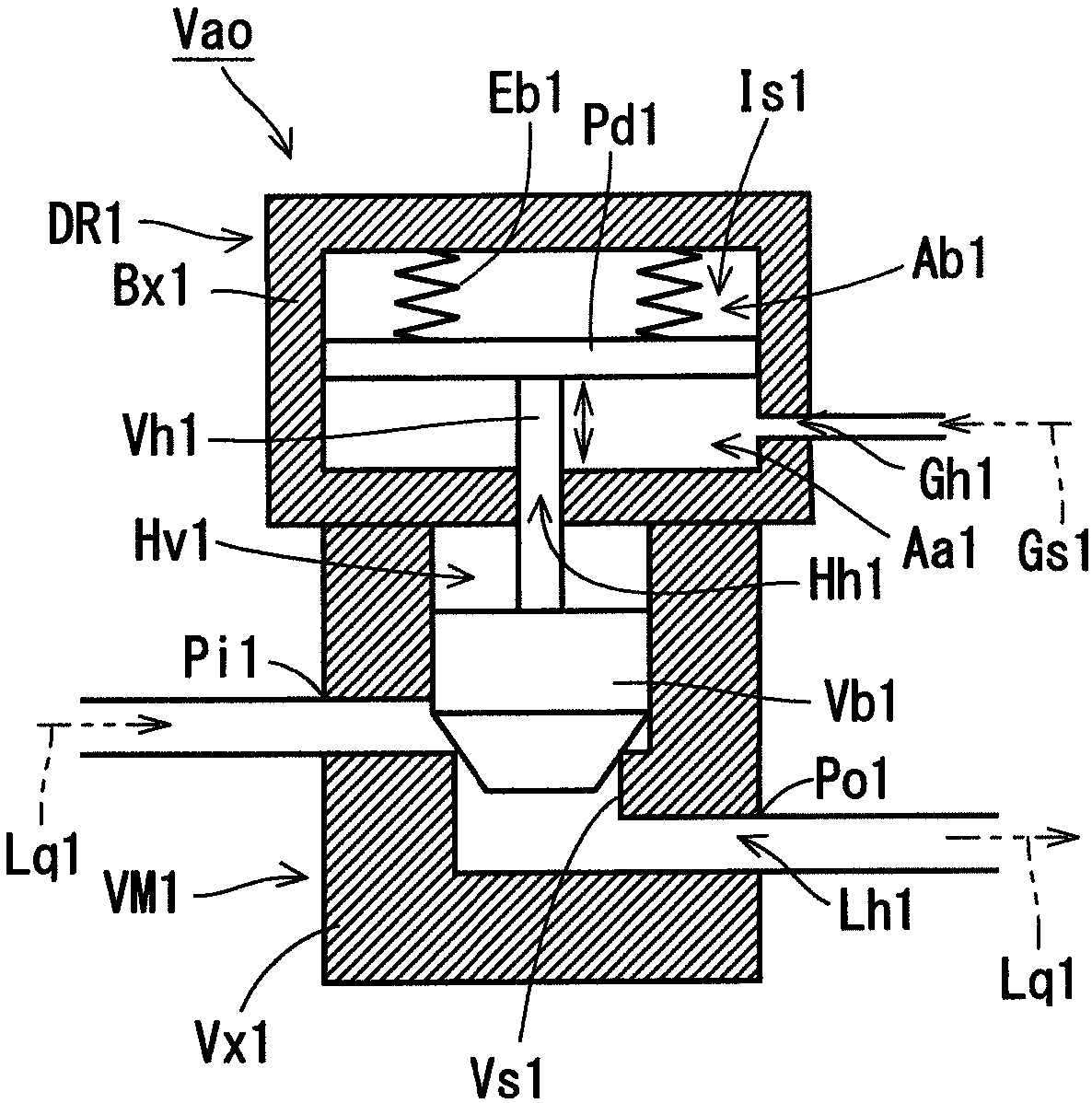

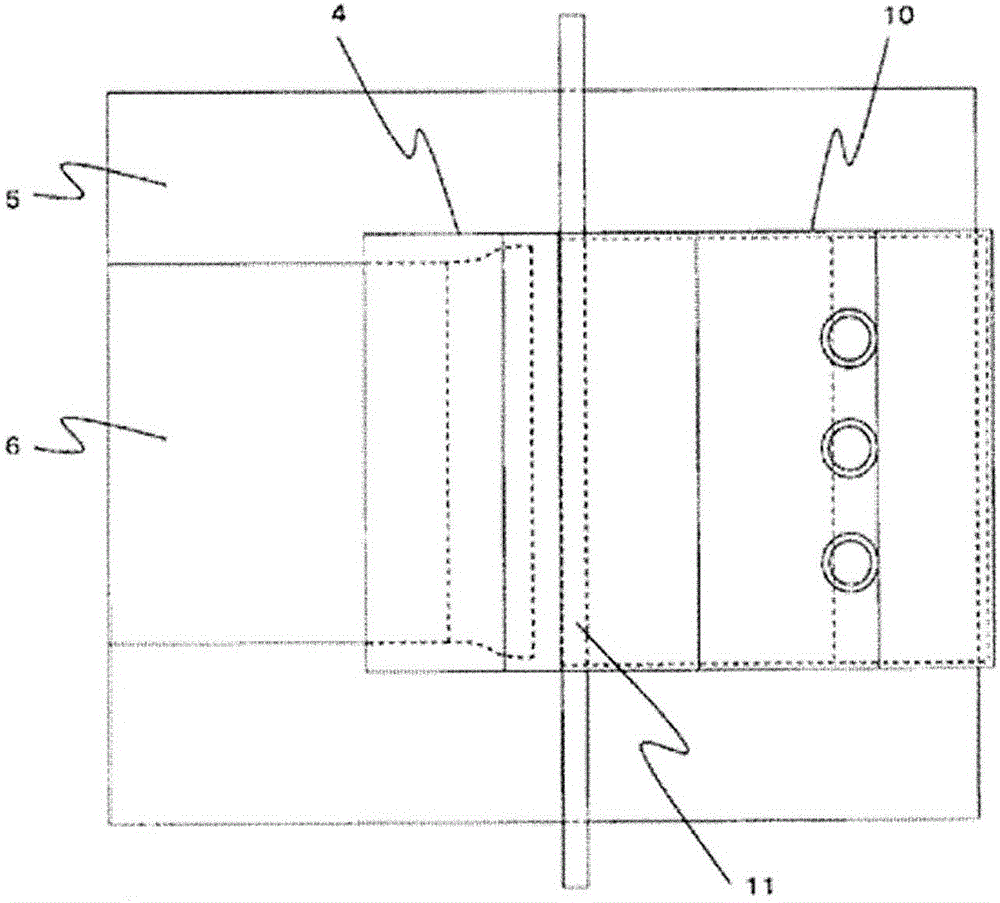

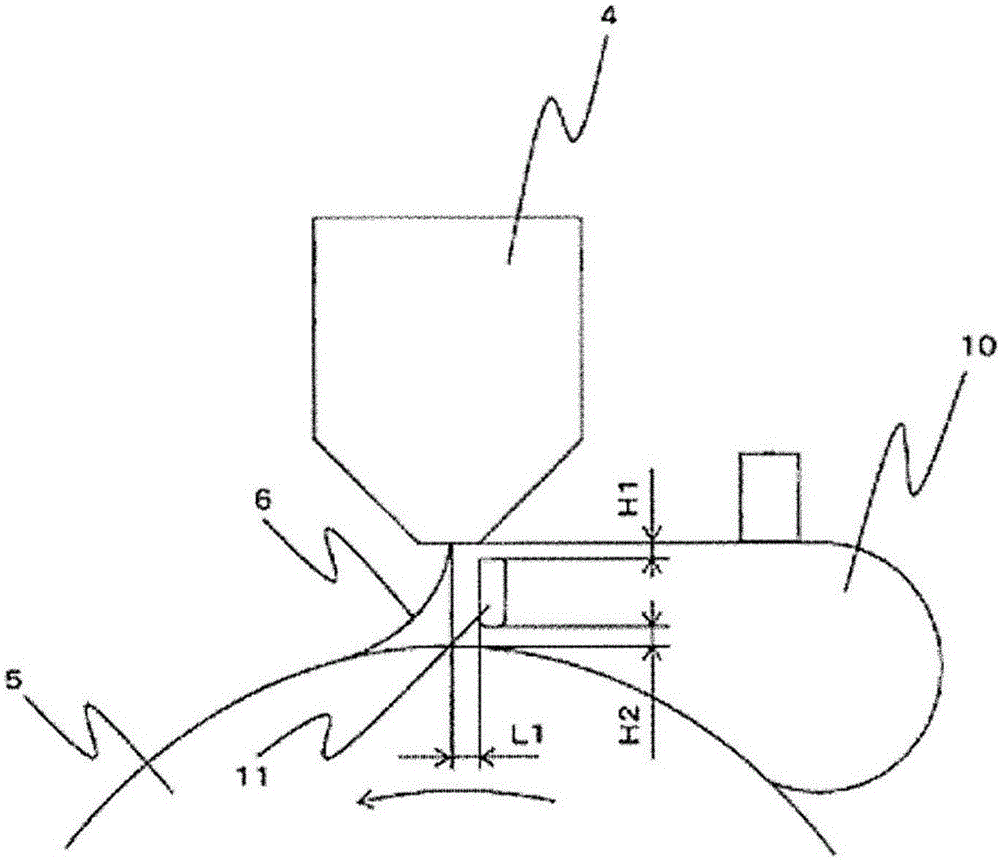

Ink cartridge and mount/demount mechanism for the same

InactiveUS9067424B1Reduce the amount requiredReduce the amount of solutionPrintingPrinting pressMechanical engineering

An ink cartridge includes: an ink storage container configured to store ink; a socket portion provided at one end of the ink storage container and configured to be fitted to and detached from a joint portion of a printing machine; an ink supply port provided in the socket portion; an inside plug configured to seal an ink passage to the ink supply port by using a biasing force coming from a direction of the ink storage container; and an inside plug lock portion configured to lock the inside plug at a position where the inside plug is pressed by an insertion shaft, and maintain a locked state of the inside plug independently of a retreating of the insertion shaft to a retreat position after a locking of the inside plug.

Owner:RISO KAGAKU CORP

Ink cartridge and mount/demount mechanism for the same

InactiveUS20150191020A1Reduce the amount requiredReduce the amount of solutionPrintingEngineeringPrinting press

An ink cartridge includes: an ink storage container configured to store ink; a socket portion provided at one end of the ink storage container and configured to be fitted to and detached from a joint portion of a printing machine; an ink supply port provided in the socket portion; an inside plug configured to seal an ink passage to the ink supply port by using a biasing force coming from a direction of the ink storage container; and an inside plug lock portion configured to lock the inside plug at a position where the inside plug is pressed by an insertion shaft, and maintain a locked state of the inside plug independently of a retreating of the insertion shaft to a retreat position after a locking of the inside plug.

Owner:RISO KAGAKU CORP

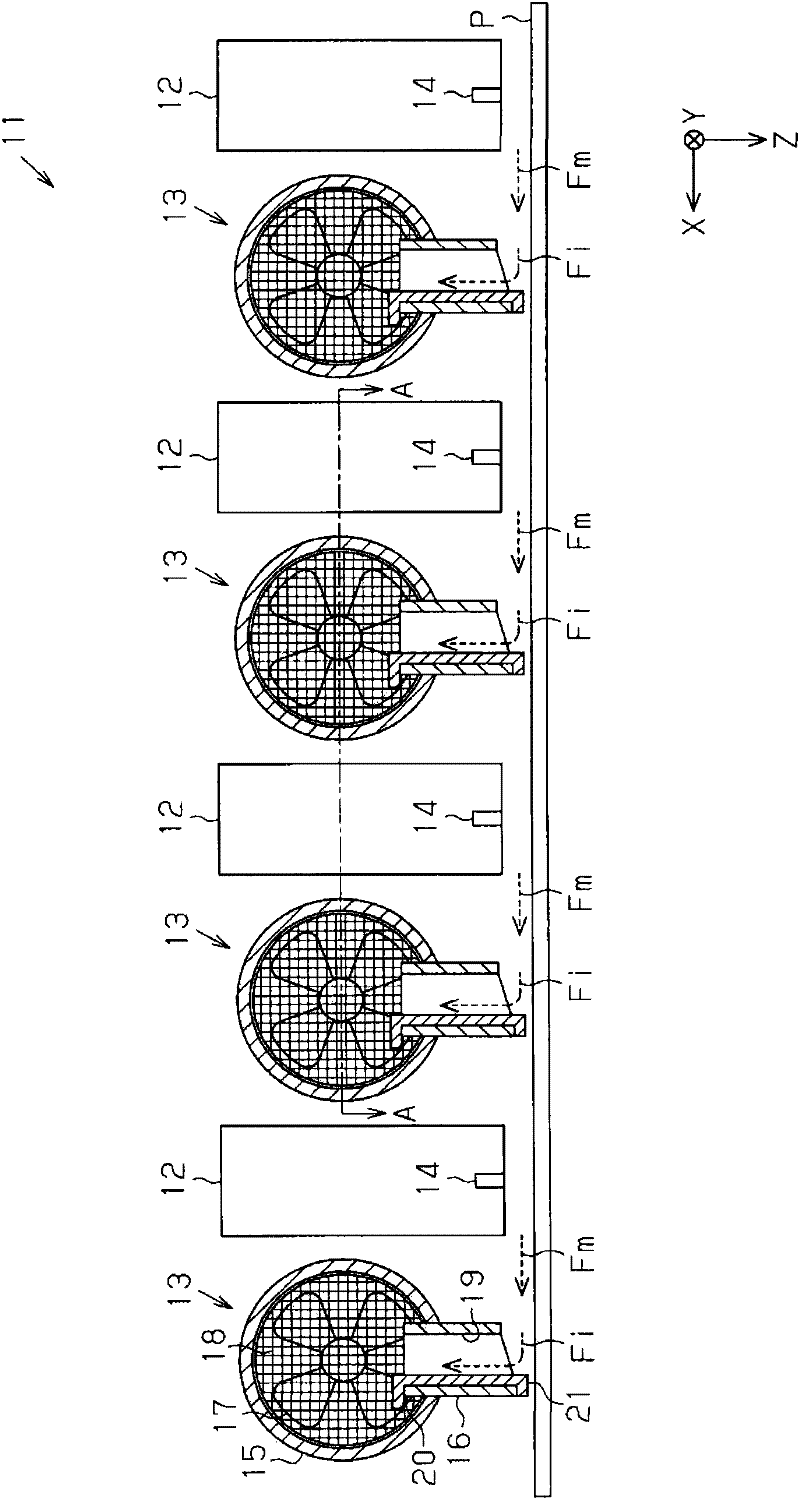

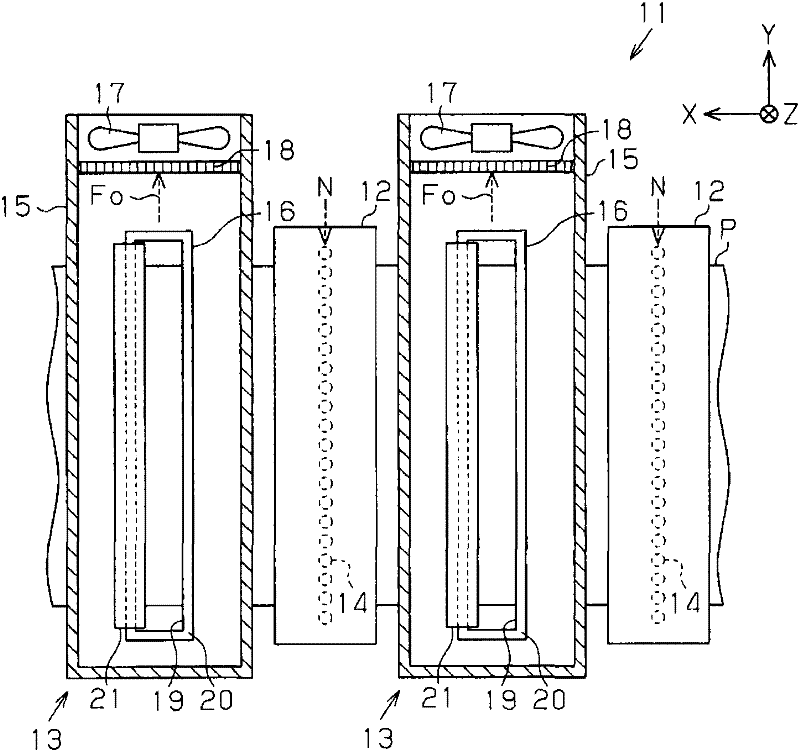

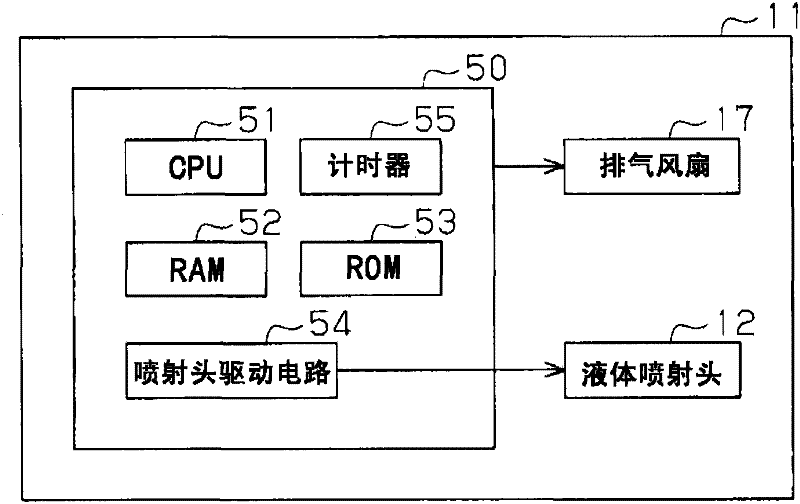

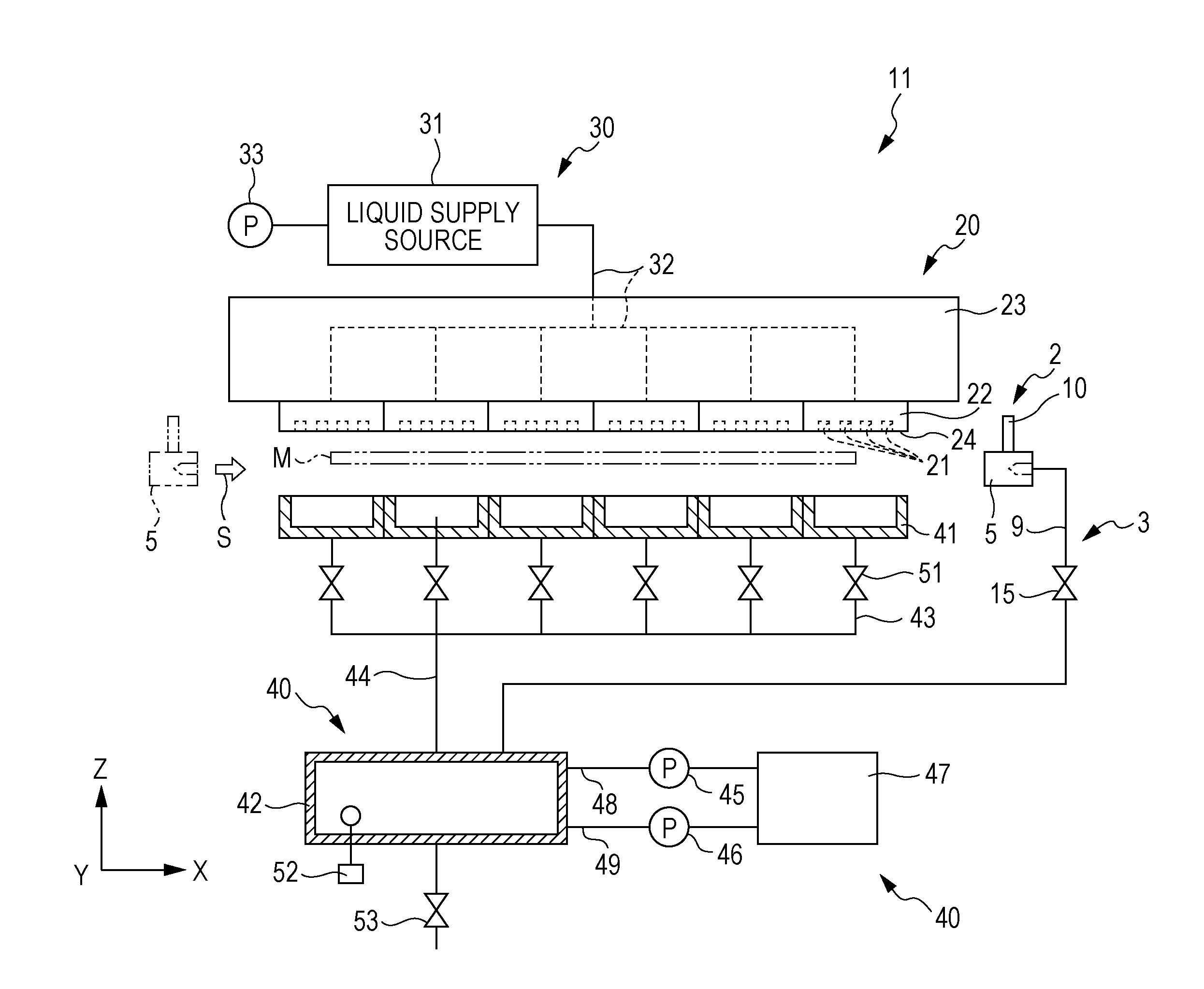

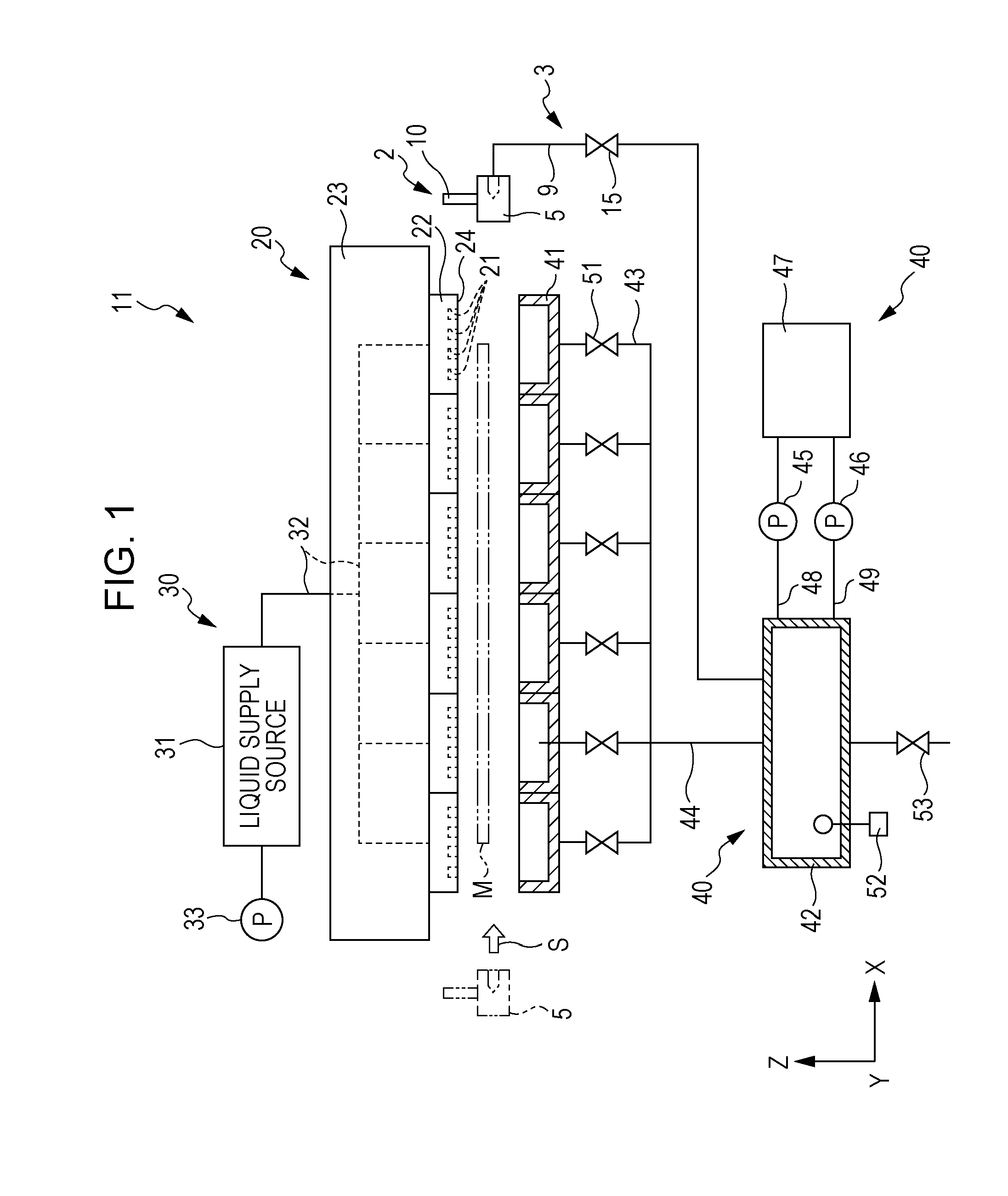

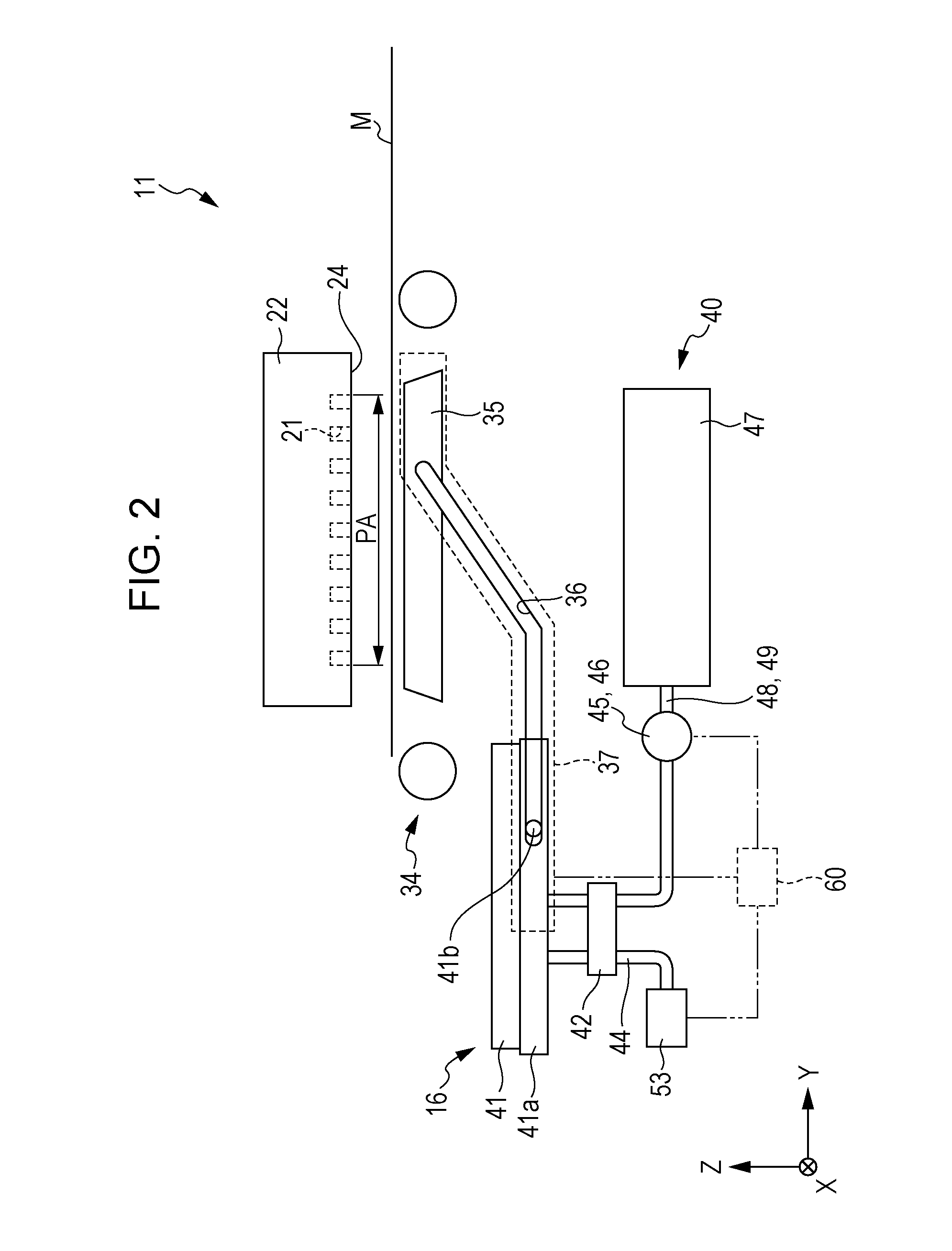

Mist collecting apparatus, liquid ejecting apparatus, and method of controlling mist collecting apparatus

InactiveCN102310636ADrip suppressionDesaturationOther printing apparatusCapillary TubingMechanical engineering

Owner:SEIKO EPSON CORP

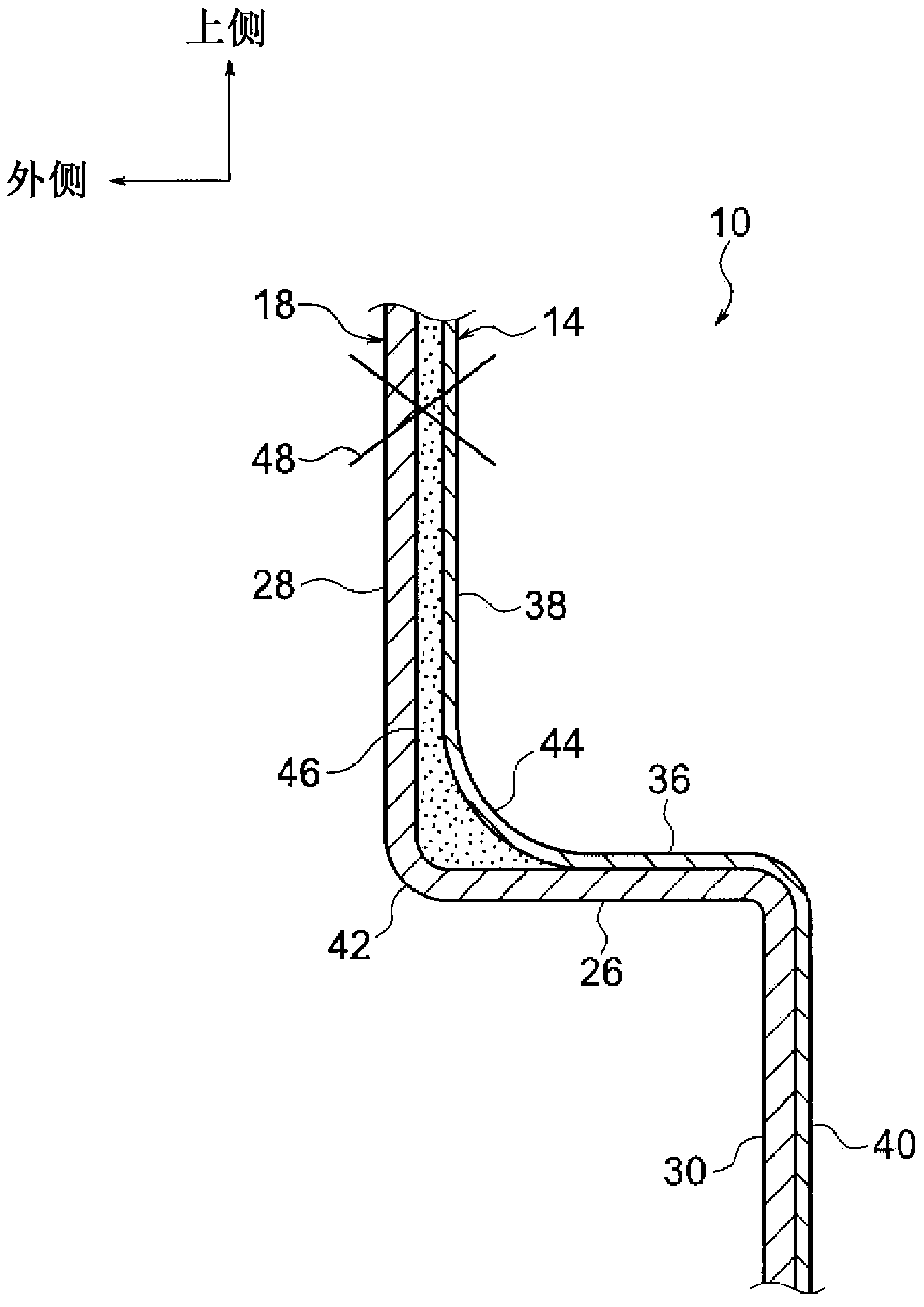

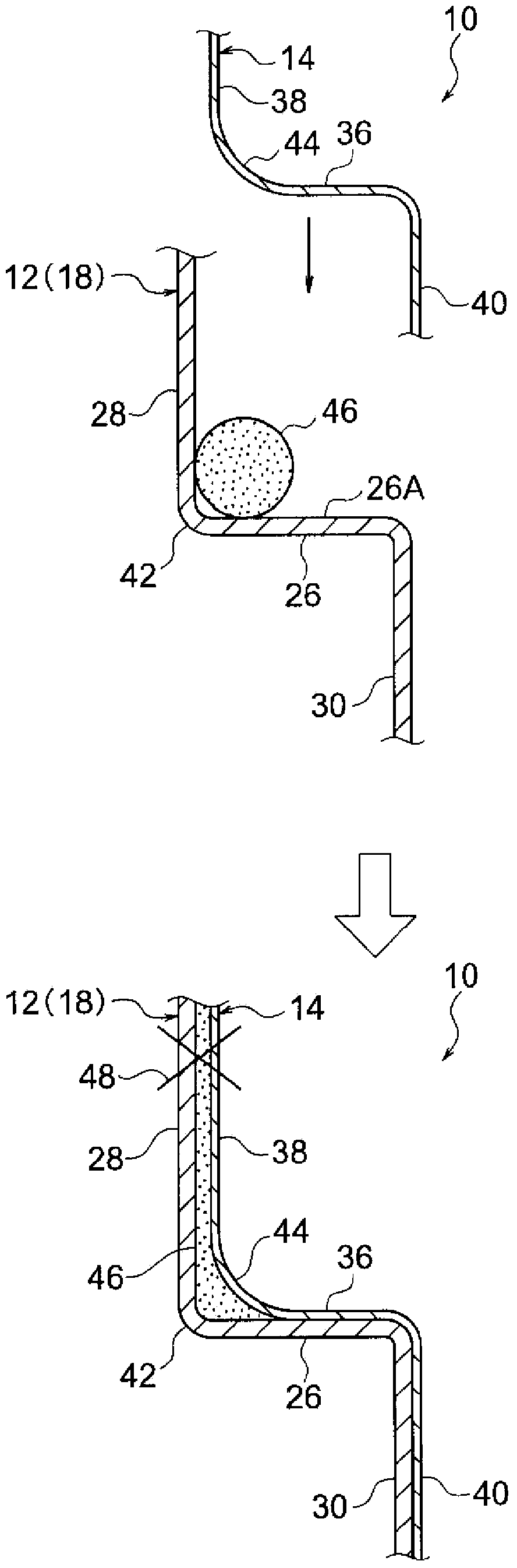

Panel joining structure and panel joining method

ActiveCN104024093ADrip suppressionAnti-scratchMaterial gluingSuperstructure subunitsAdhesiveEngineering

The problem addressed by the present invention is inhibiting the dripping down or scraping off of adhesive when a part to be joined and a part to be joined with are bonded. This panel joining structure (10) is provided with a first panel (18) having a step part (26) extending in a direction that crosses a vertical direction and a joining part (28) extending upward in the vertical direction from one end part of the step part (26) in that crossing direction, and a second panel (14) having a facing part (36) that extends in that crossing direction and also is made to overlap the step part (26) on the upward vertical direction side, a part (38) to be joined that extends in the upward vertical direction from one end part of the facing part (36) in that crossing direction and is joined to the joining part (28) by adhesion and welding, and a downward part (40); that extends downward in the vertical direction from the other end of the facing part (36) in that crossing direction.

Owner:TOYOTA JIDOSHA KK

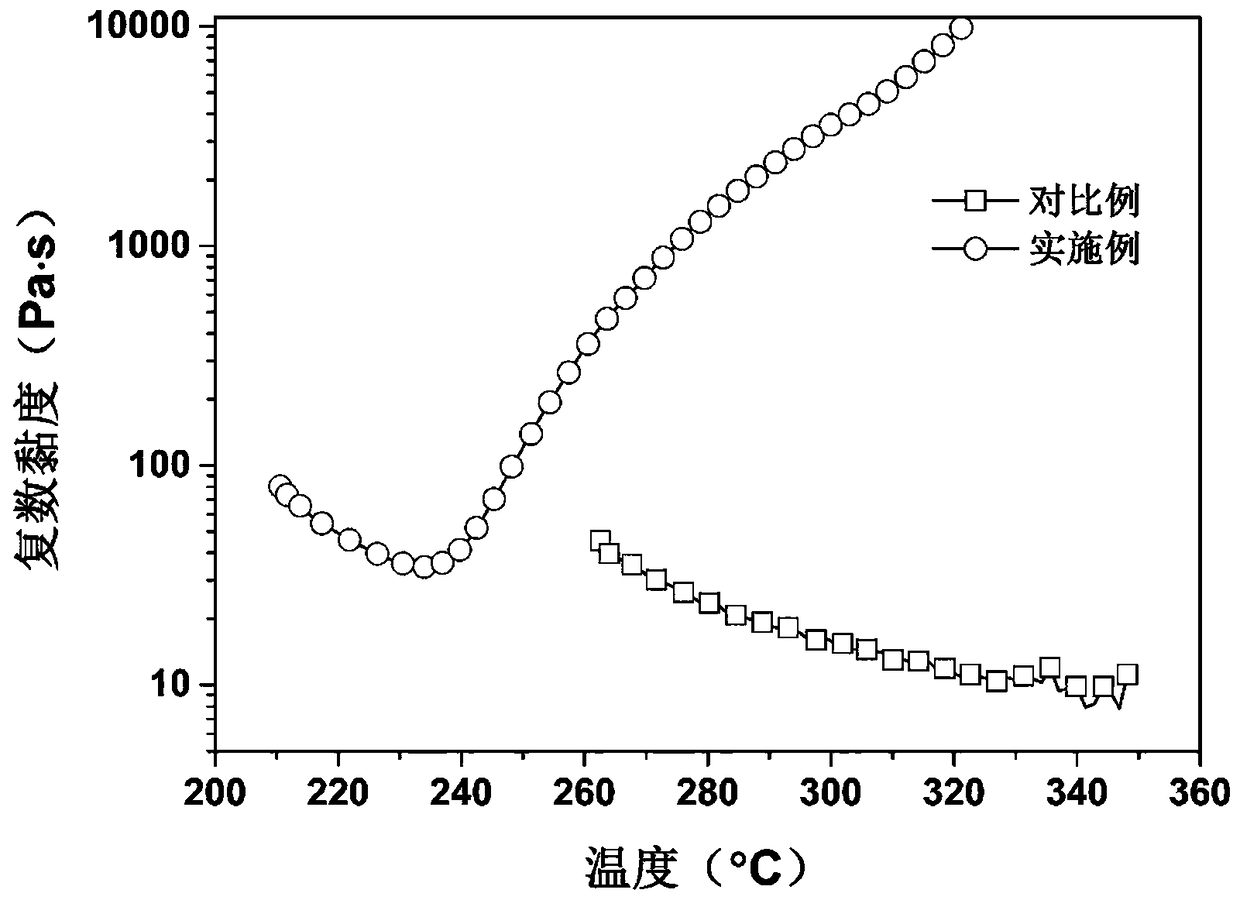

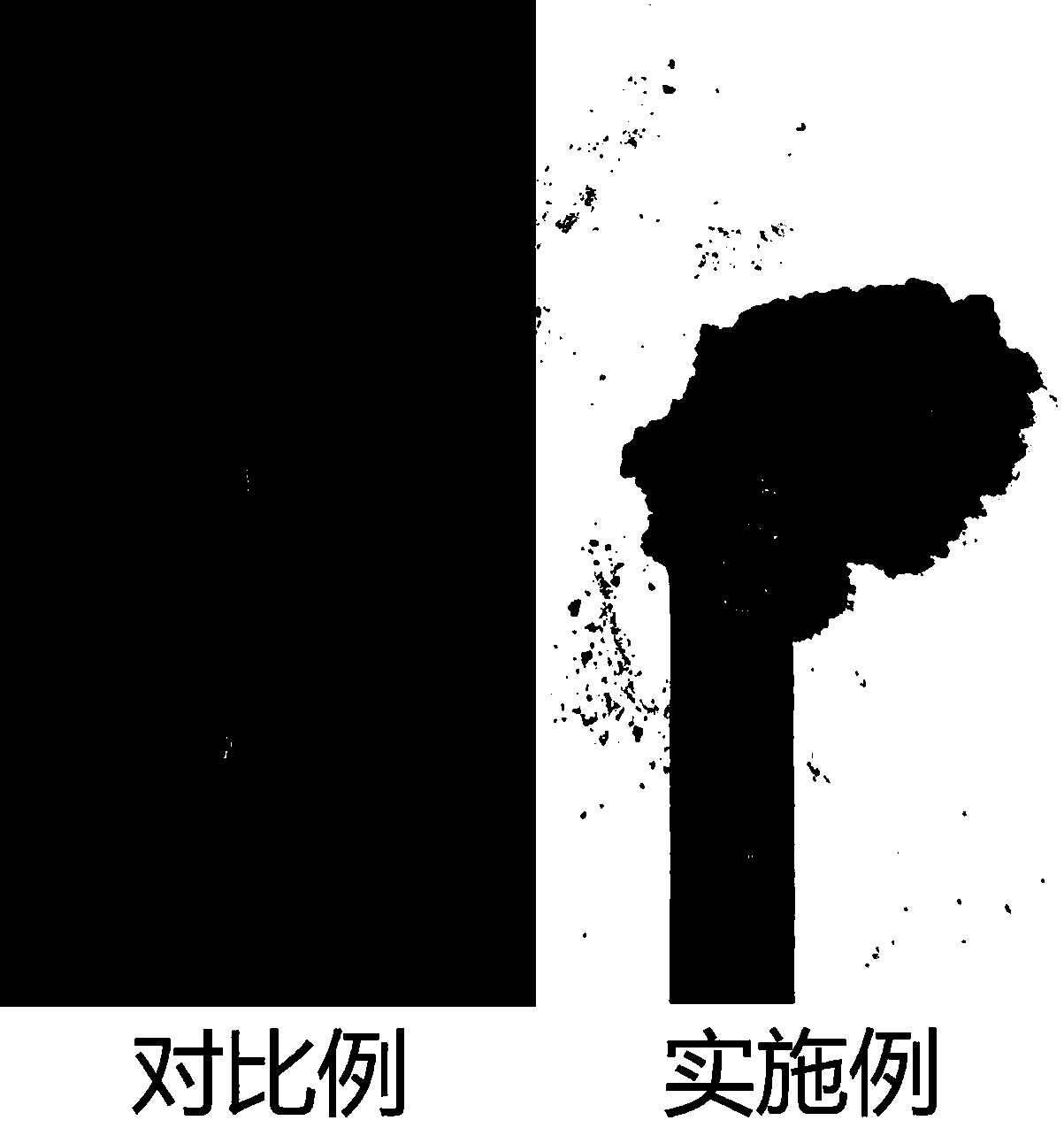

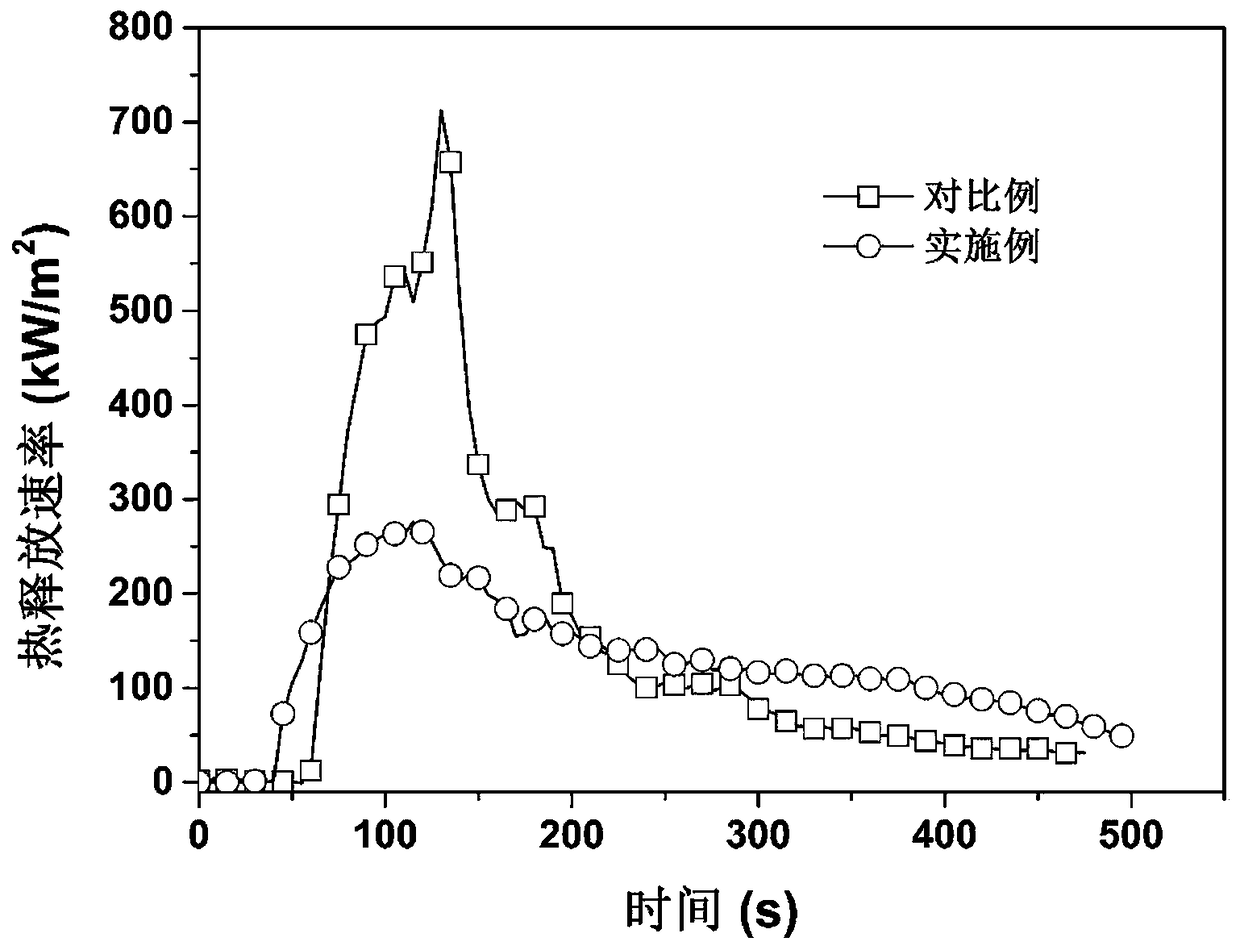

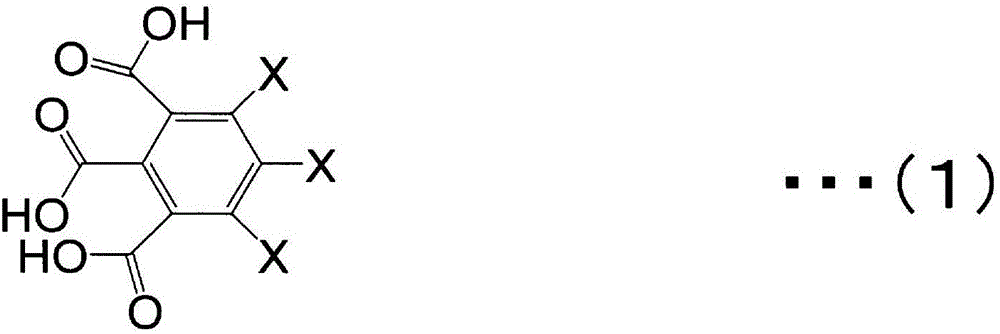

Benzene imide structure based high-temperature self-crosslinking copolyester with effects of flame retardancy, smoke suppression and melt drop resistance and preparation method of copolyester

ActiveCN108359084APreserve thermoplastic processabilityIncrease melt viscosityStructural unitStructure based

The invention discloses a benzene imide structure based high-temperature self-crosslinking copolyester with effects of flame retardancy, smoke suppression and melt drop resistance. Copolyester is prepared from structural units represented by I, II and III or structural units represented by I, II and IV through random copolymerization, wherein the characteristic viscosity [eta] of copolyester is 0.41-1.12 dL / g, and the limit oxygen index is 24.2%-38.7%; the vertical combustion class is in a range from V-2 to V-0; the p-HRR (peak of heat release rate) in a cone calorimetry test is reduced by 7.1%-72.1% as compared with that of pure PET, and total smoke release is decreased by 2.0%-59.2% as compared with that of pure PET. The invention further discloses a preparation method of copolyester. Ahigh-temperature self-crosslinking group introduced in the preparation process is a benzene imide group, and prepared copolyeste cannot be subjected to crosslinking during processing and polymerization, so that thermoplastic processability of polyester is retained; meanwhile, due to the tackifying effect and high charring property brought by the self-crosslinking action at high temperature or during combustion, prepared copolyester has excellent flame retardancy, smoke suppression and melt drop resistance effects.

Owner:SICHUAN UNIV

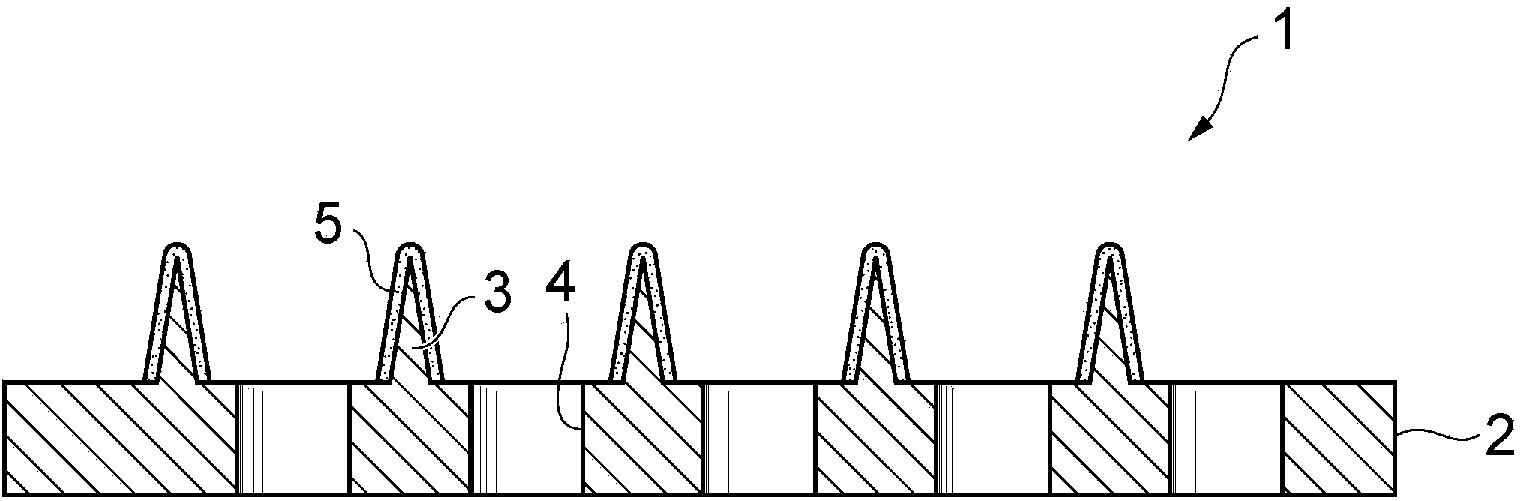

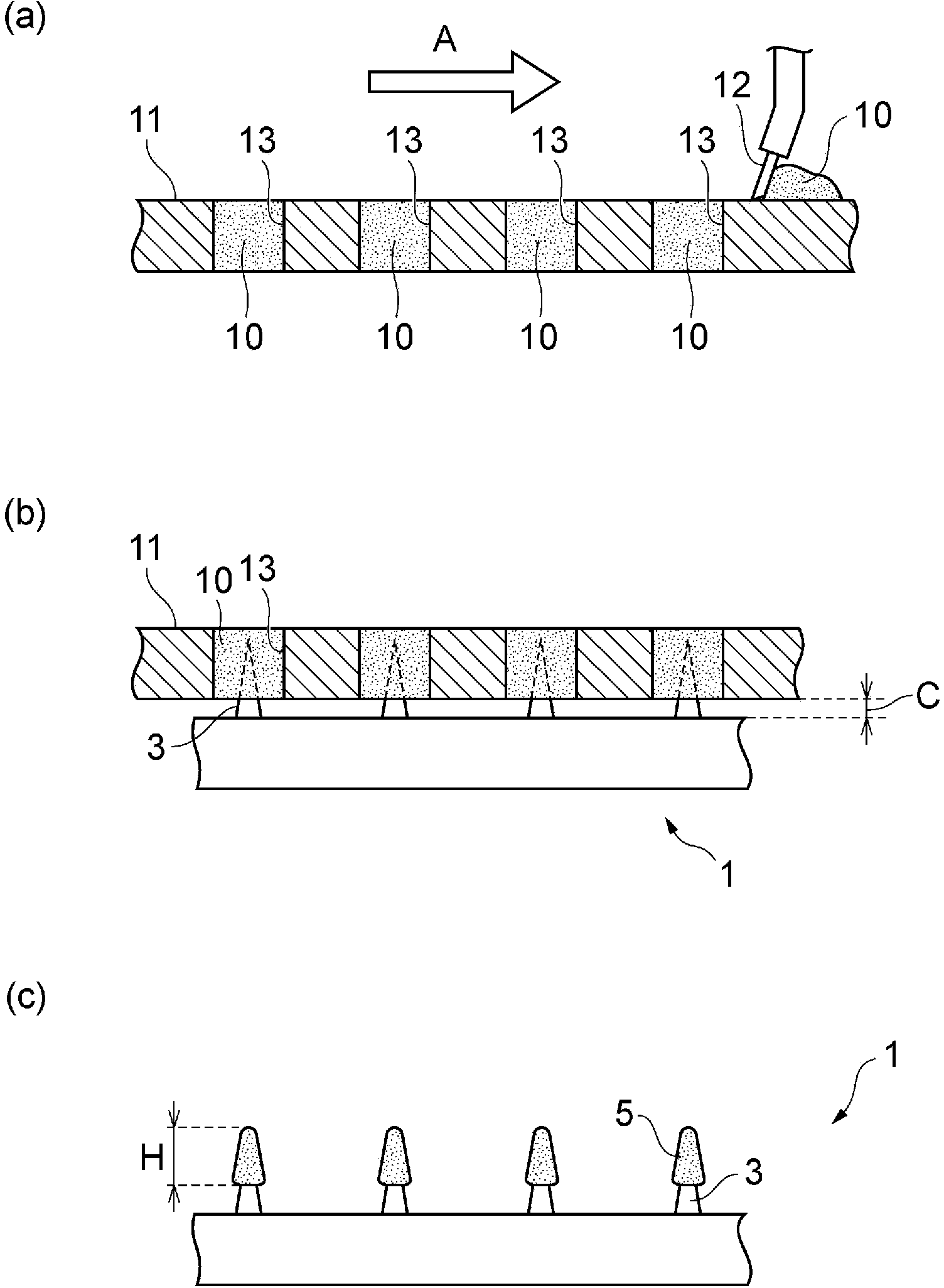

Ink cartridges and inkjet printers

An ink cartridge includes a wall, and an ink supply portion positioned at the wall. The ink supply portion has an ink supply opening formed therein. The ink cartridge also includes a plurality of protrusions which includes a first protrusion and a second protrusion, and each of the first protrusion and the second protrusion extend from the wall. In an embodiment, a distance between the first protrusion and the second protrusion is greater than 0 mm and less than a diameter of the ink supply opening. In another embodiment, the distance between the first protrusion and the second protrusion is greater than 0 mm and less than a diameter of the ink supply opening.

Owner:BROTHER KOGYO KK

Halogen-free flame-retarding polyamide composition

The invention relates to a halogen-free flame-retarding polyamide composition, which includes, by weight, 73-93 parts of polyamide, 7-23 parts of melamine or a derivative thereof, 0.1-3 parts of silsesquioxane, and 0.1-1 part of an antioxidant, wherein the melamine or the derivative thereof is subjected to organic treatment. Compared with the prior art, the composition has excellent flame-retarding performance. The composition reaches 0.8 mm UL 94 V-0 in flame-retarding performance and 90 J / m in notch impact strength. The composition has simple process, is convenient to produce and can be applied in the fields of electronic appliances, automobiles and the like.

Owner:上海安凸塑料添加剂有限公司

Liquid ejecting apparatus

A liquid ejecting apparatus includes a liquid ejecting head having a nozzle which ejects a liquid onto a medium, a wiping member that wipes the liquid which has adhered to a nozzle forming surface of the liquid ejecting head, a support member that supports the wiping member, moves the wiping member relative to the liquid ejecting head, and has a receiving portion receiving the liquid wiped by the wiping member, and a connection flow path that is capable of being connected to the support member, wherein the receiving portion and the connection flow path communicate with each other with movement of the support member.

Owner:SEIKO EPSON CORP

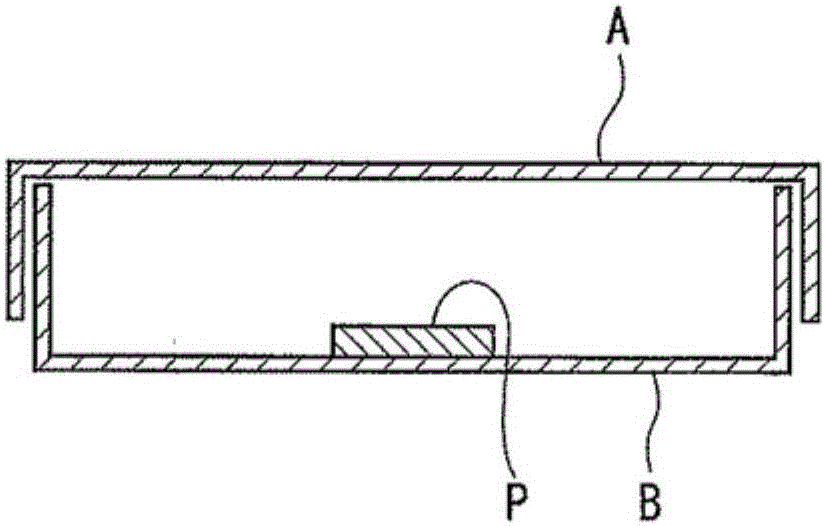

GLP-1 analogue composition for microneedle devices

InactiveCN103391798AIncrease viscosityGood release performancePeptide/protein ingredientsMetabolism disorderPolyethylene glycolGlycerol

A GLP-1 analogue composition for microneedle devices, which contains a GLP-1 analogue and at least one kind of solvent that is selected from the group consisting of water, glycerol, propylene glycol, ethylene glycol, 1,3-butylene glycol and polyethylene glycol.

Owner:HISAMITSU PHARM CO INC

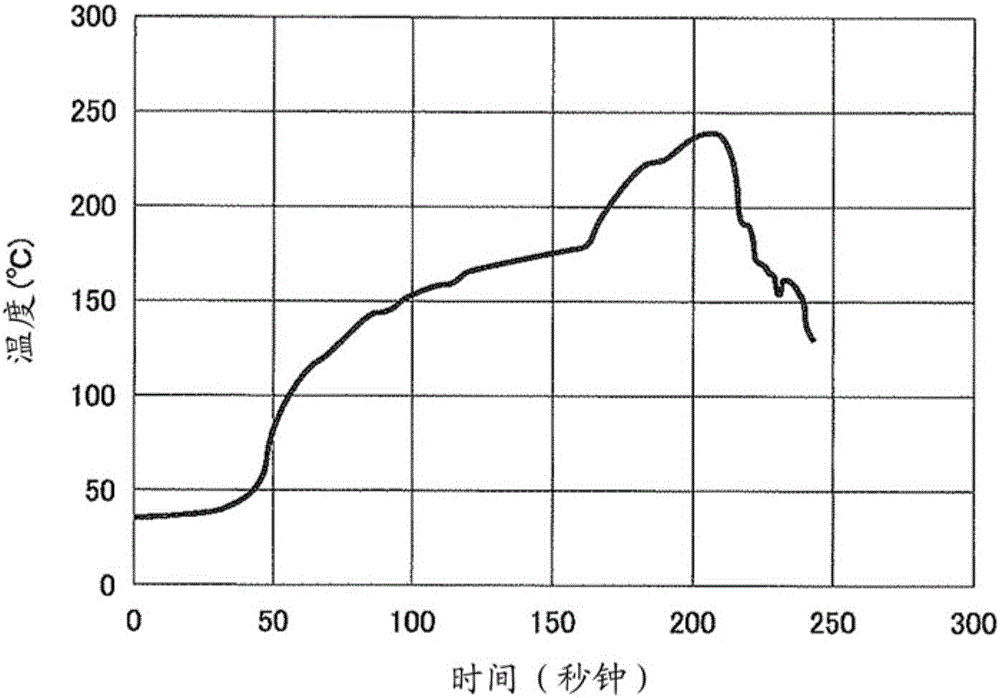

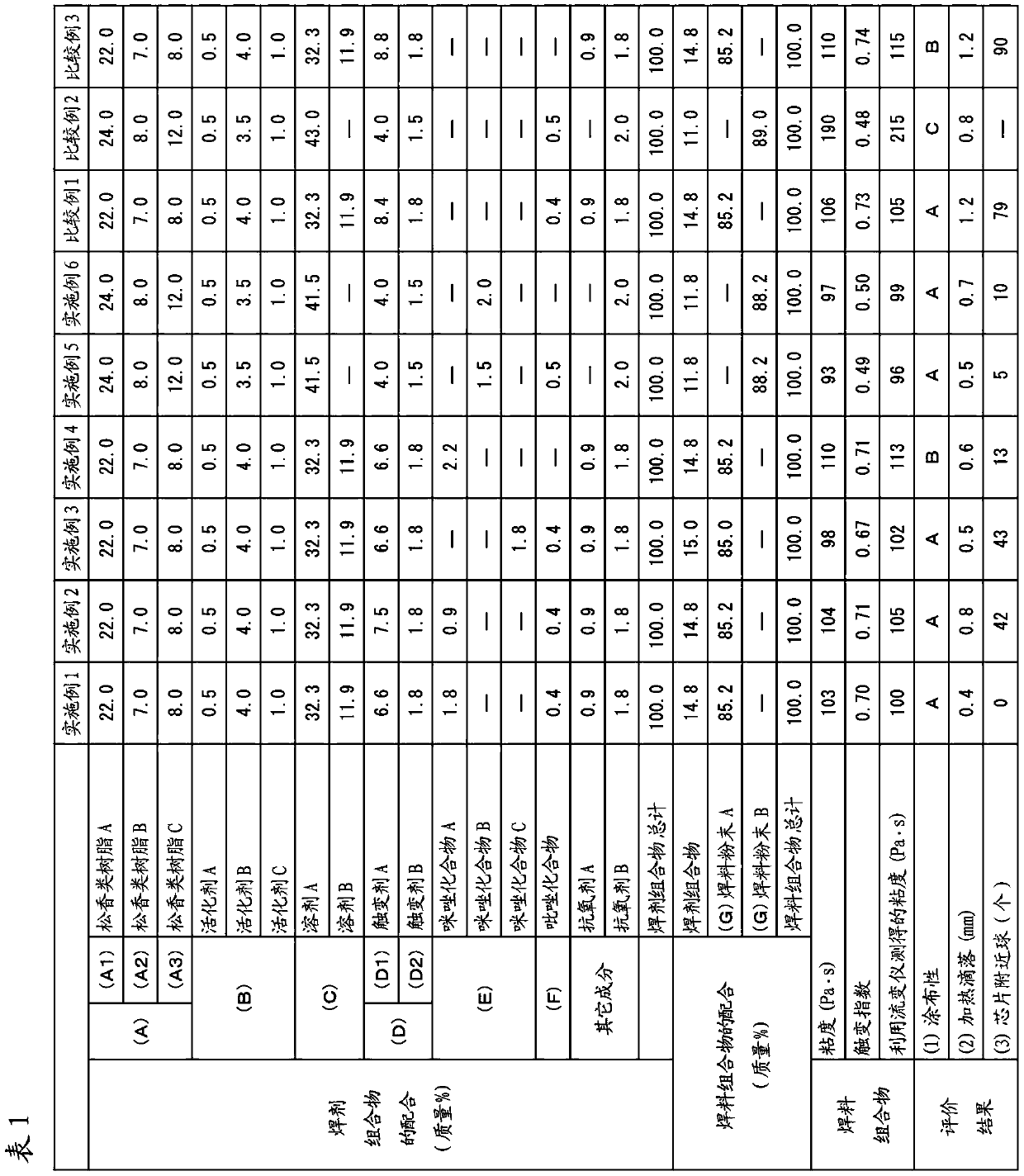

Solder composition and electronic substrate using the same

ActiveCN106001996AImprove wettabilityAvoid corrosionPrinted circuit assemblingWelding/cutting media/materialsMetallurgySolvent

The invention provides a solder composition comprising a solder flux composition and a solder powder (E). The solder flux composition comprises a rosin-based resin (A), an activator (B), a thixotropic agent (C), and a solvent (D), wherein the component (B) contains a polycarboxylic acid (B1) having a melting point between 160 DEG C or higher and 220 DEG C or lower and having three or more carboxyl groups per molecule.

Owner:TAMURA KK

Glp-1 analogue composition for microneedle devices

InactiveUS20130323293A1High viscosityGood release effectPeptide/protein ingredientsMetabolism disorderPolyethylene glycol1,3-Butanediol

A GLP-1 analogue composition for a microneedle device, including a GLP-1 analogue and at least one kind of solvent selected from the group consisting of water, glycerin, propylene glycol, ethylene glycol, 1,3-butylene glycol, and polyethylene glycol.

Owner:HISAMITSU PHARM CO INC

Process for producing photochromic layered product

ActiveUS8409670B2High surface hardnessUniform thicknessSynthetic resin layered productsCoatingsHigh concentrationOptical property

A method of producing a laminate comprising preparing a substrate having curved surfaces; applying a photopolymerizable and curable composition containing a photochromic compound and a phosphorus-containing photopolymerization initiator onto the curved surfaces of the base member; and curing the photopolymerizable and curable composition by the irradiation with an active energy ray having a relative intensity profile of 0 to 5% of wavelength components of not shorter than 200 nm but shorter than 300 nm, 25 to 75% of wavelength components of not shorter than 300 nm but shorter than 400 nm and 25 to 75% of wavelength components of not shorter than 400 nm but not longer than 500 nm while maintaining the substrate at not higher than 100° C. This method makes it possible to form a homogeneous and thin film containing a photochromic compound at a high concentration and having a uniform thickness on the substrate having a curved surface, such as a spectacle lens that is generally available, and to impart photochromic properties while maintaining excellent mechanical and optical properties of the substrate.

Owner:TOKUYAMA CORP

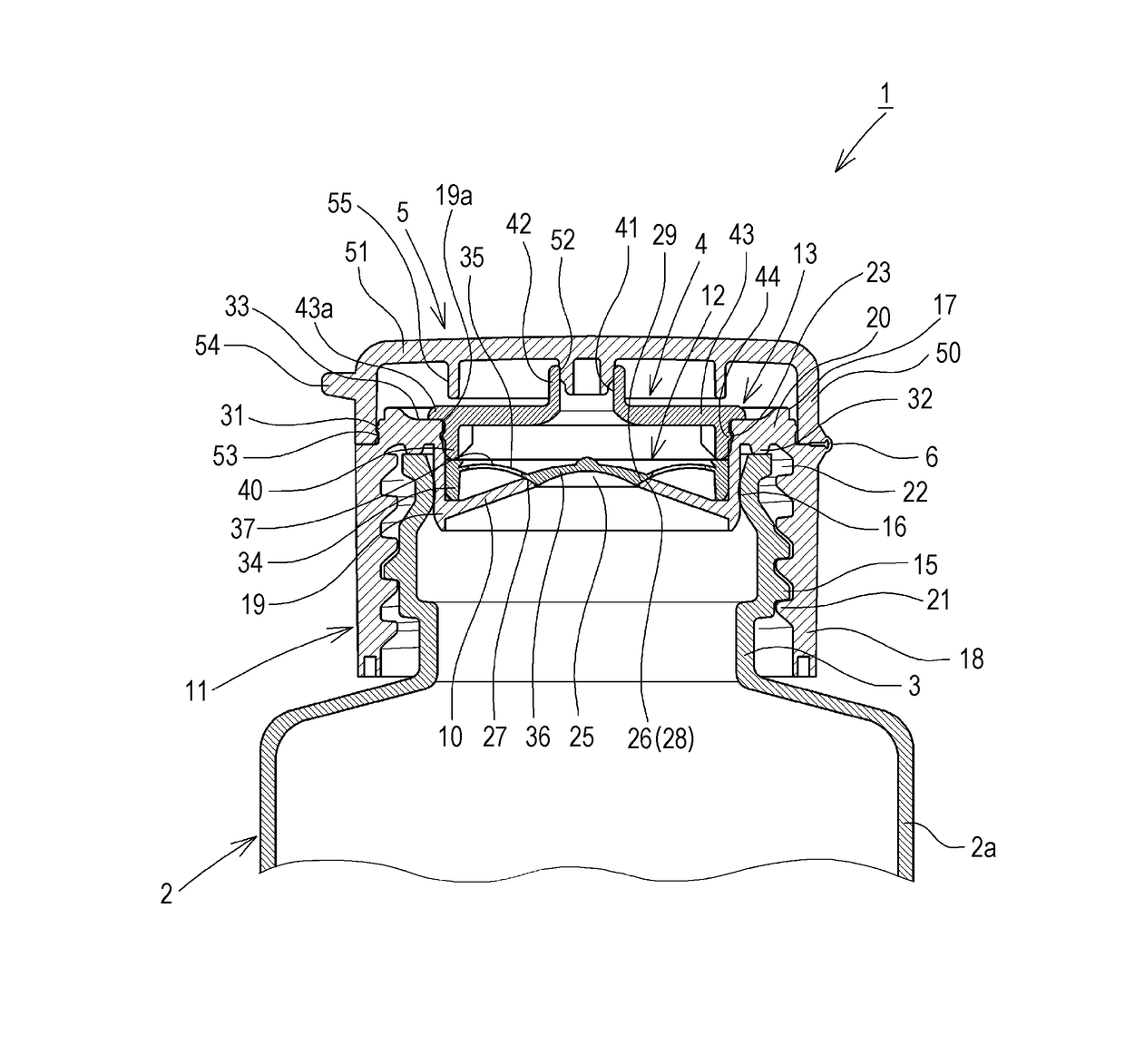

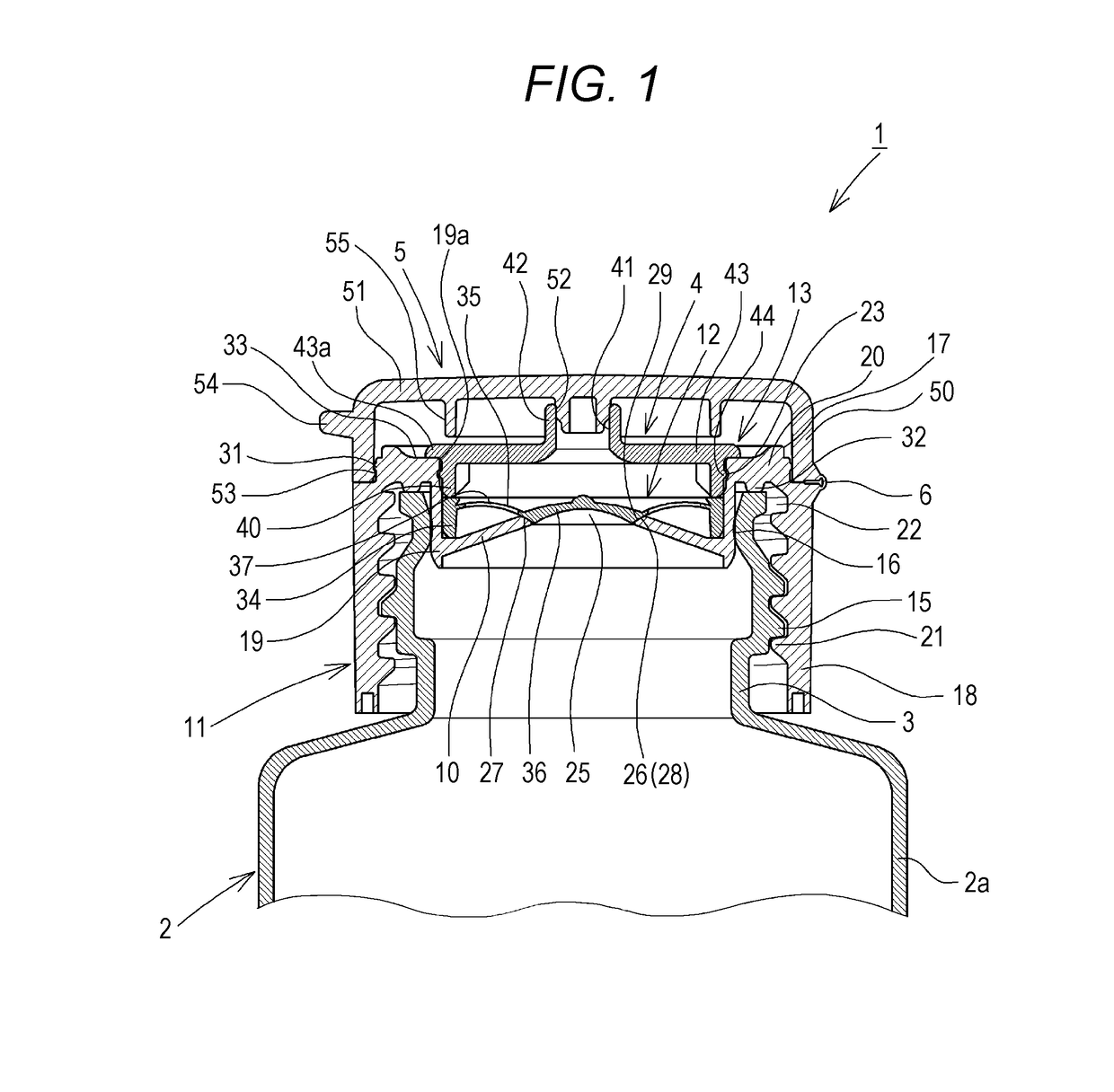

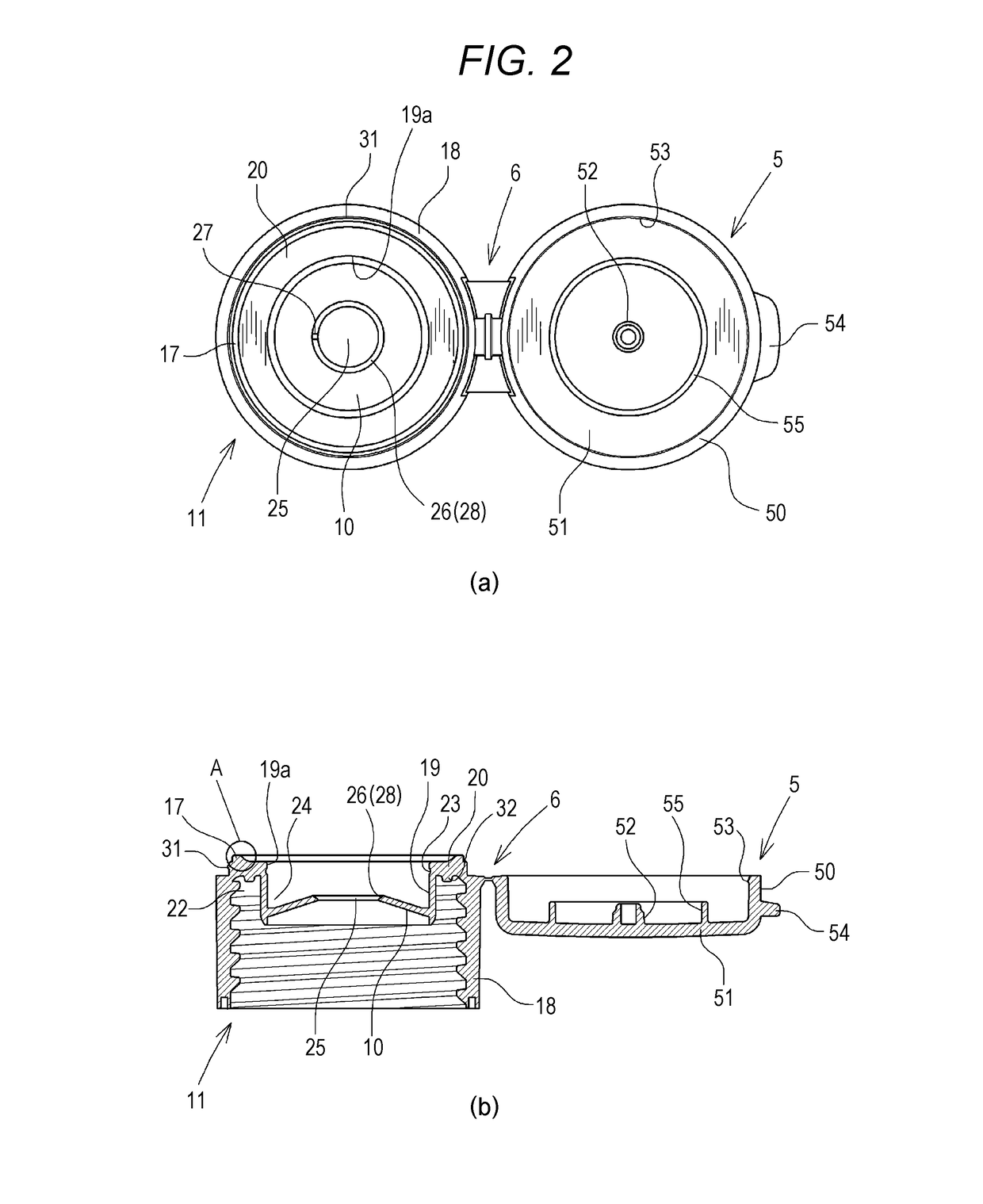

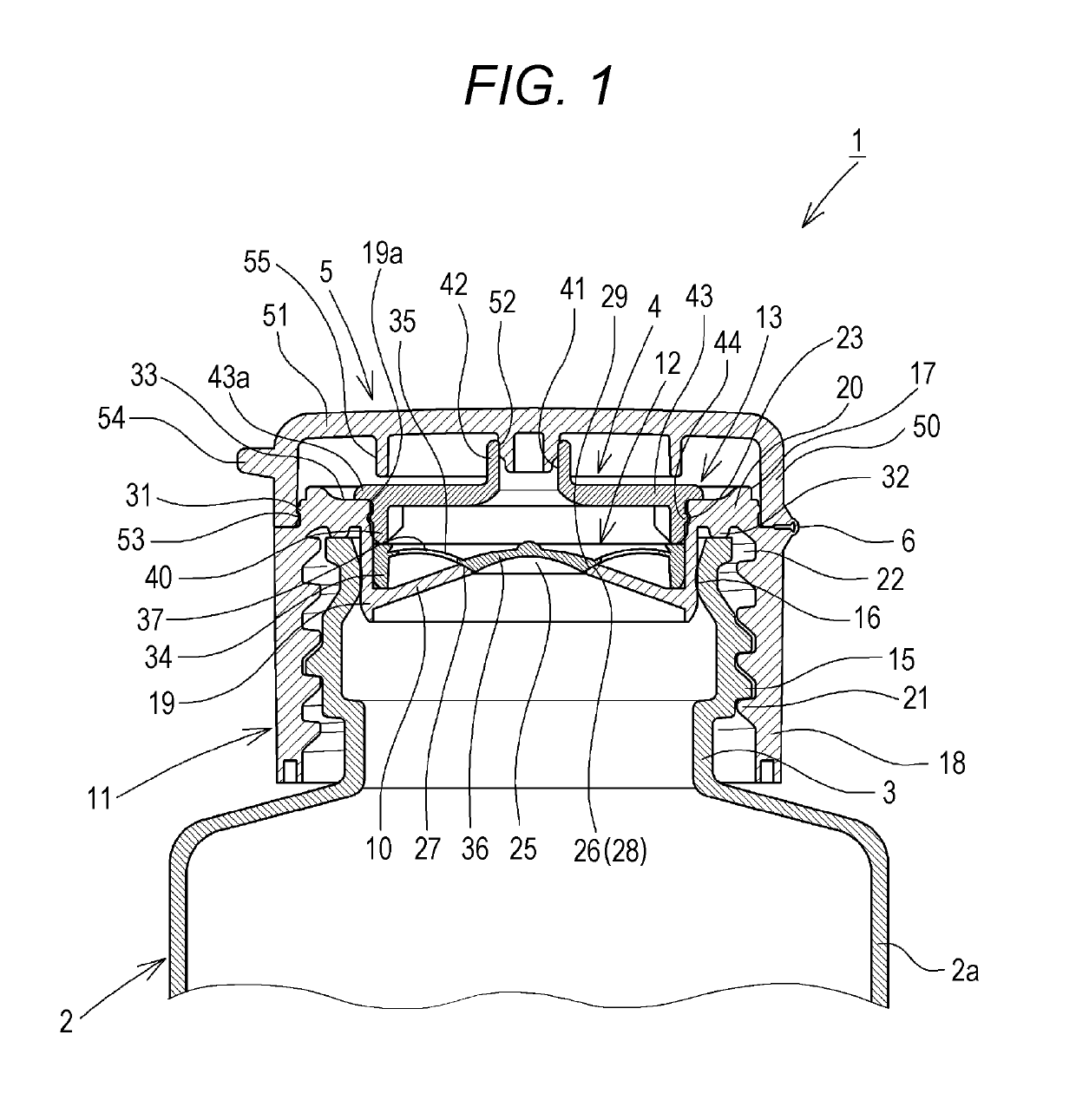

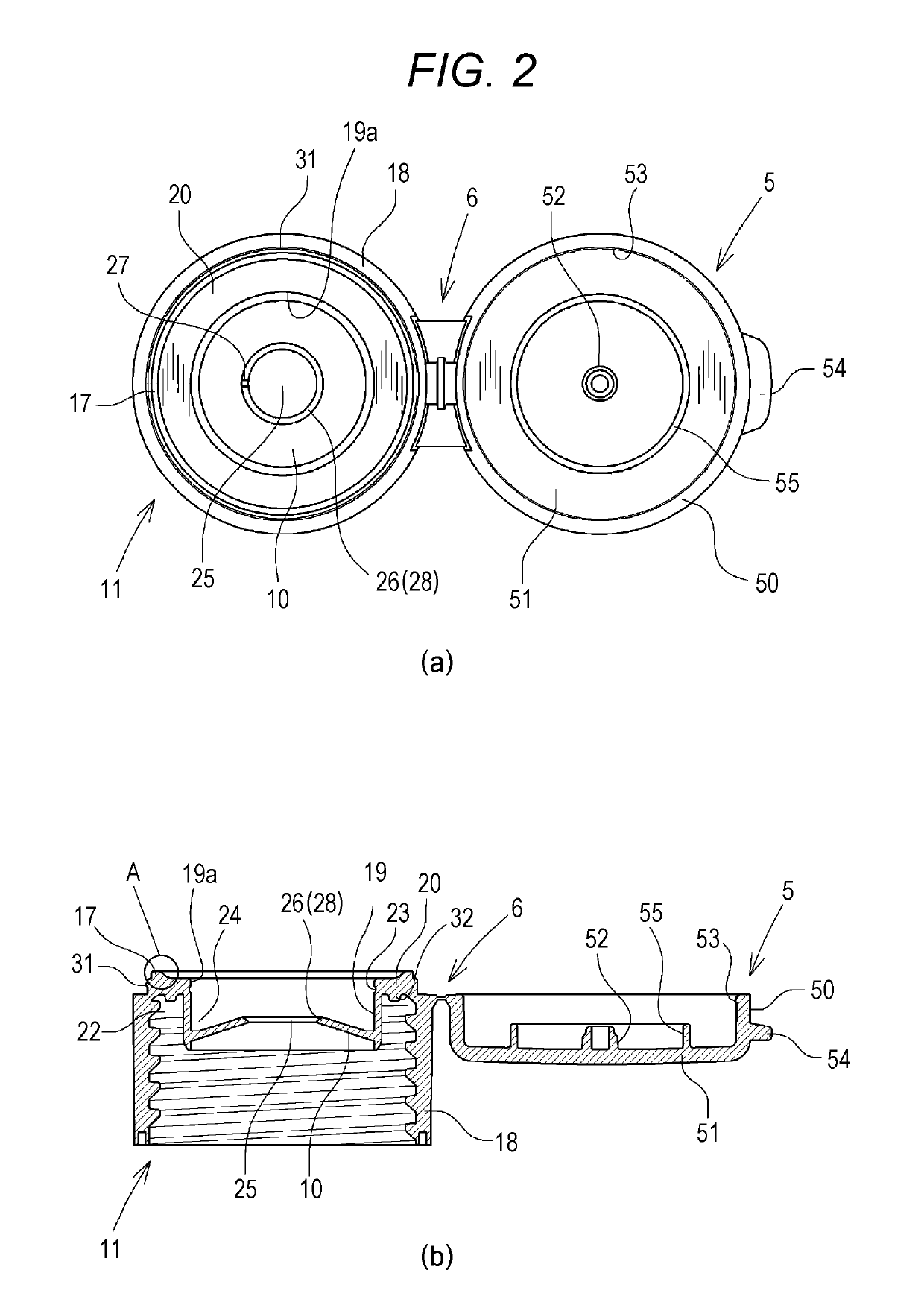

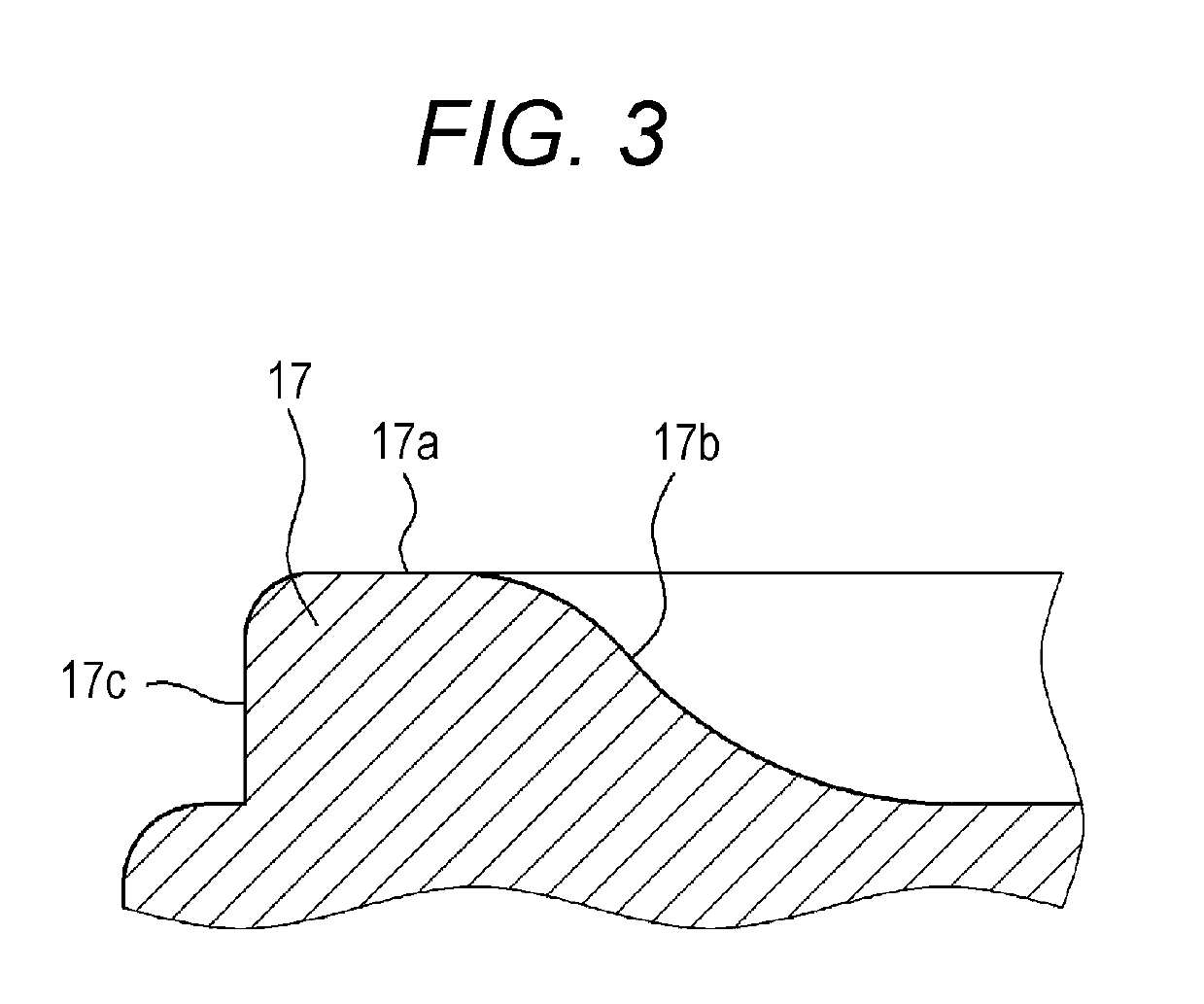

Cap

An annular protruding portion (17) is provided around an inner plug (13) at a radial interval on an annular horizontal wall portion (20) of a cap body 4. Between an annular flange portion (43a) of the inner plug (13) and the annular protruding portion (17), an annular accumulating groove portion (33) is provided. Particularly in the case of a liquid content, the liquid content may be scattered from within a cylindrical guide portion (42) when a lid member (5) is placed after use. The liquid content, however, is blocked by the annular protruding portion (17) and prevented from flowing further outward, while interfering with a top surface portion (51) and a cylindrical scattering suppression portion (55) of the lid member (5). Thus, downward flow of the liquid content along the outer wall surface of the annular horizontal wall portion (20) of a main cap member (11) can be suppressed.

Owner:TOKYO RAITO INDS +1

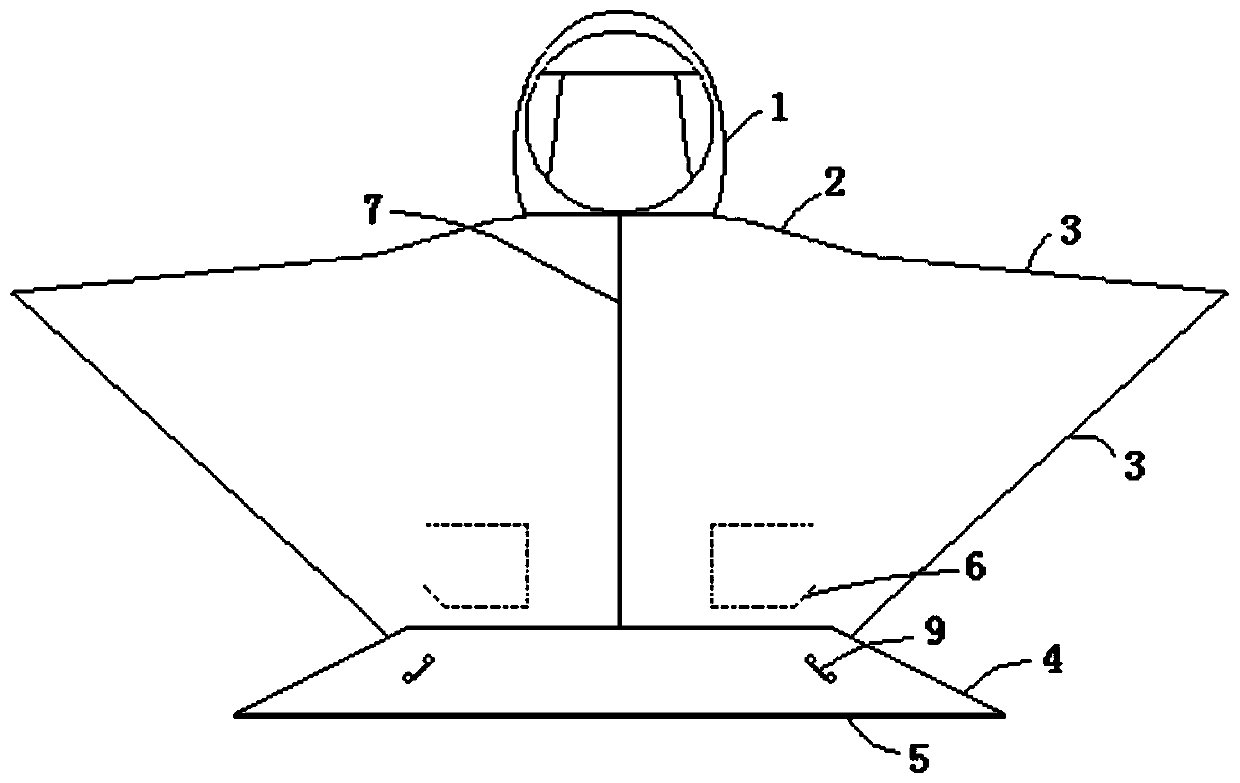

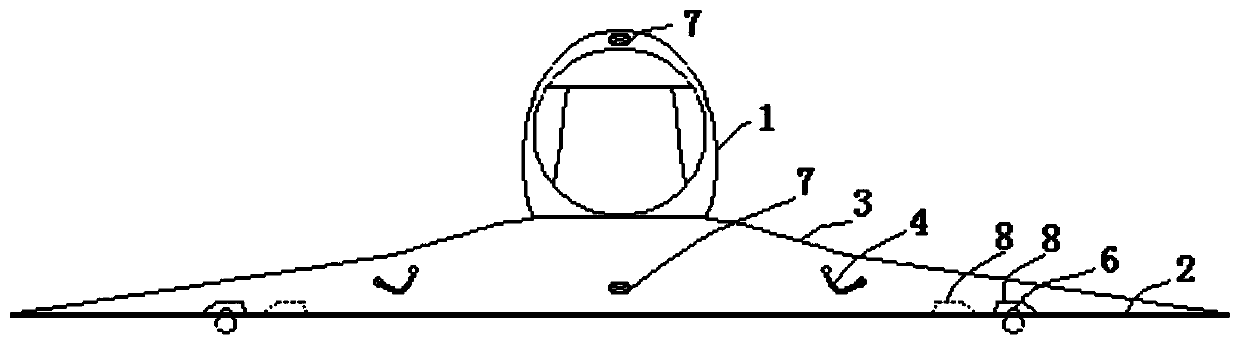

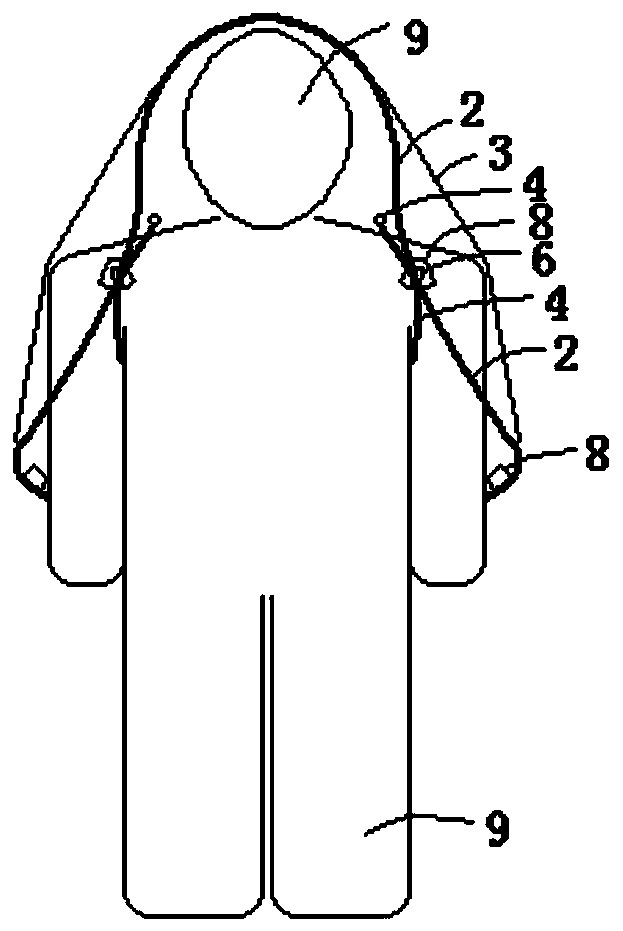

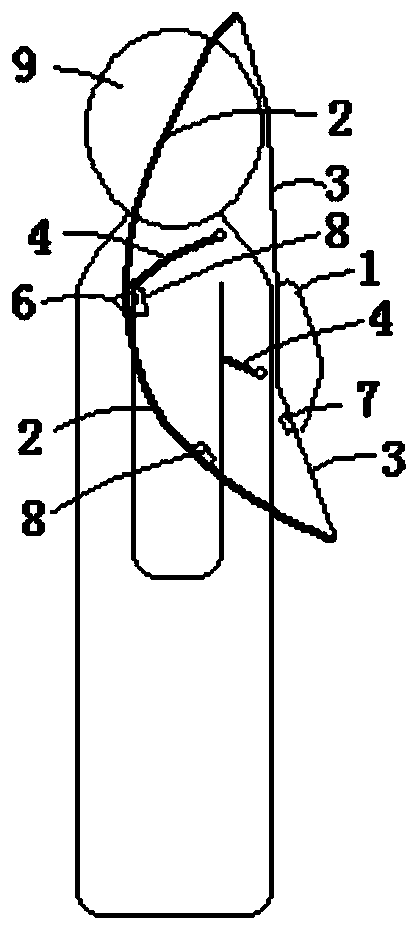

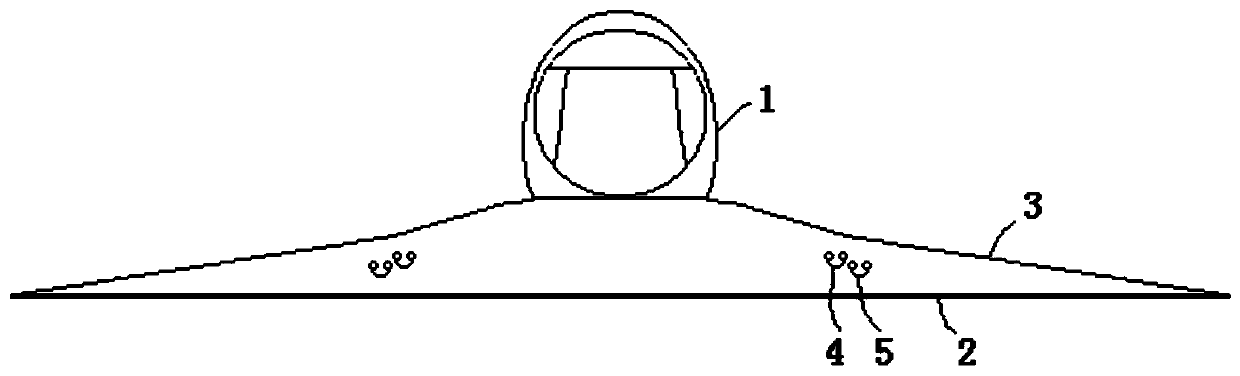

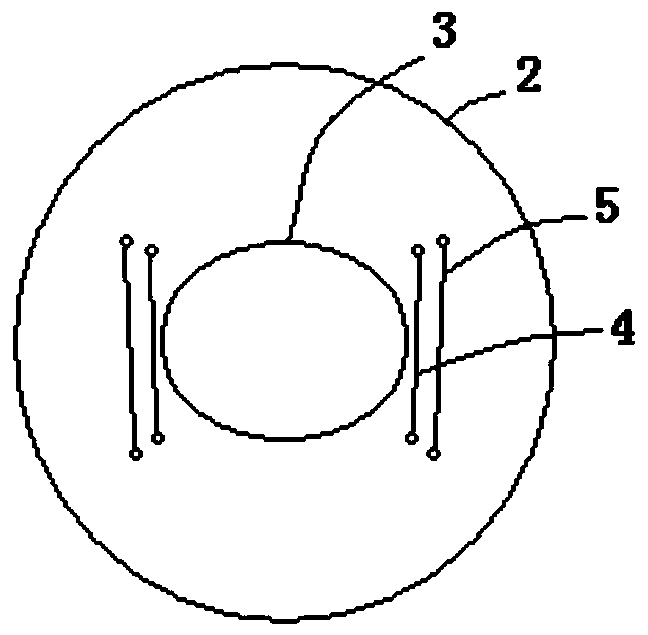

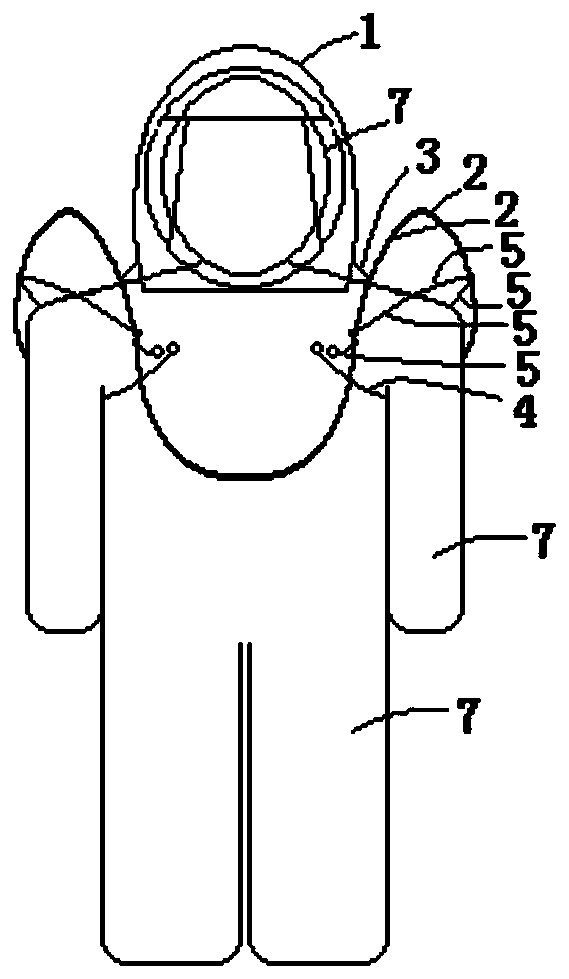

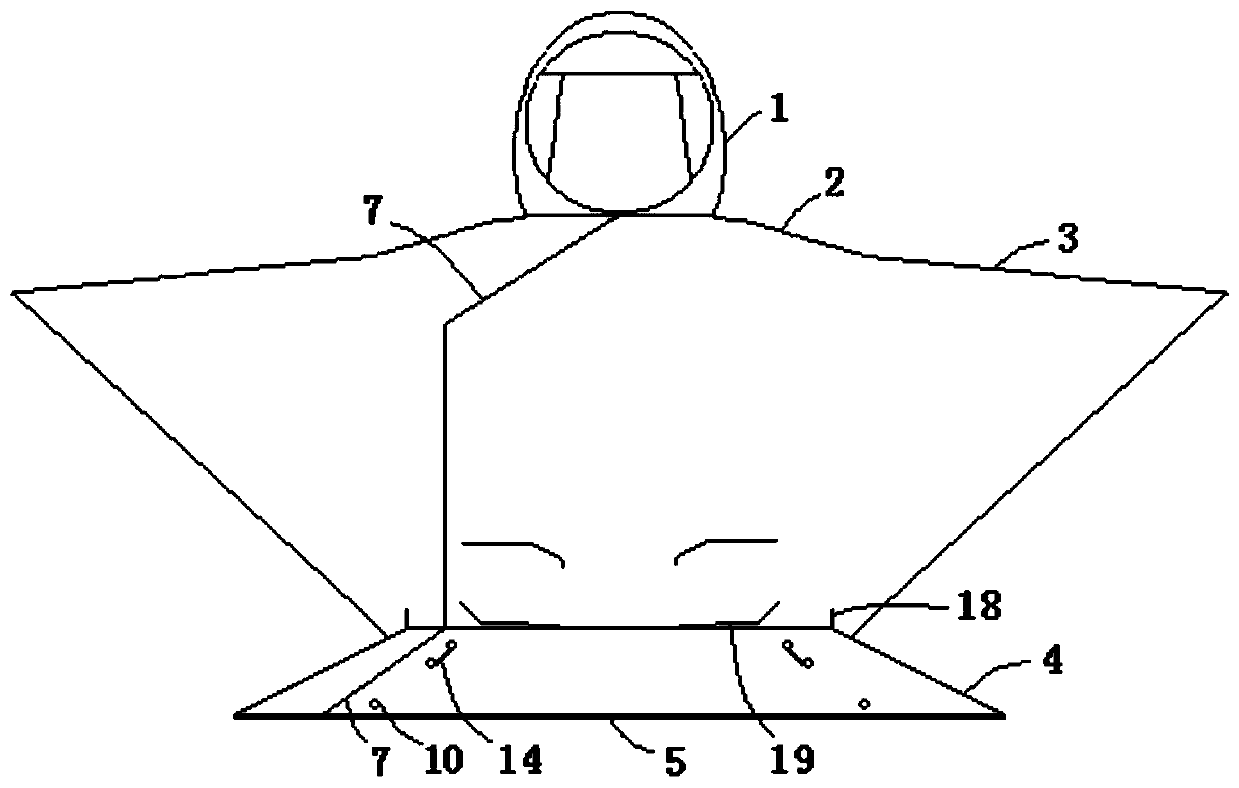

Annular bracket raincoat storable in wearing

InactiveCN110973725AAvoid confictShake suppressionGarment special featuresOvergarmentsStructural engineeringMechanical engineering

According to an annular bracket raincoat storable in wearing, through connected sleeves and a pocket located on the inner surface of the raincoat, the fixing position of the top end of a skirt hem isimproved, the longitudinal height of the whole skirt hem is reduced, and shaking of the support skirt in actual use is restrained and reduced. The annular bracket raincoat storable in wearing is provided with a storage belt, when the raincoat is worn in a non-rainproof state, a wearer turns the storage belt over the reverse side of the support skirt, and the support skirt is automatically bent andstored, so that the support skirt can be attached to a human body to be stored when being worn, the raincoat wearer does not need to hold the support skirt by hand, arm and leg movement of the weareris not affected, and repeated putting-on, taking-off and storage of the raincoat are avoided when repeatedly going in and out of a rainfall area.

Owner:朱江

Cap

Owner:TOKYO RAITO INDS +1

Ink cartridge

An ink cartridge includes a socket portion provided at one end of an ink storage container and configured to be fitted to and detached from a joint portion of a printing machine, an ink supply port provided in the socket portion, and an inner plug configured to seal an ink passage to the ink supply port in response to biasing force applied from a side of the ink storage container. An insertion shaft, provided in the joint portion, pressing the inner plug against the biasing force upon a fitting of the socket portion to the joint portion enables the ink passage to communicate with the ink supply port. An ink holding portion of the inner plug with the insertion shaft pulled out from the ink holding portion after inserted holds the ink near the ink supply port.

Owner:RISO KAGAKU CORP

Coating composition for thick coating

ActiveUS8835553B2Good adhesivenessMaintain good propertiesGroup 4/14 element organic compoundsPigmenting treatmentPolymer scienceMeth-

A coating composition has excellent application workability, facilitates thick coating, rarely causes cracks at an initial drying stage, and provides a dried film having excellent tensile properties and adhesiveness. The composition contains an aggregate and an emulsion with a polymer particle dispersed in an aqueous medium. The polymer particle includes 40% to 98% of a unit formed by polymerizing an alkyl(meth)acrylate monomer, the alkyl group having 4 to 14 carbon atoms, 0.1% to 5% of a unit formed by polymerizing an ethylenically unsaturated carboxylic acid monomer, 1% to 20% of a unit formed by polymerizing a vinyl monomer having a cyano group, 1% to 20% of a unit formed by polymerizing a reaction product of a (meth)acrylic acid and a monofunctional epoxy compound, and 0% to 50% of a unit formed by copolymerizing at least one of the above monomers with another monomer.

Owner:TOAGOSEI CO LTD

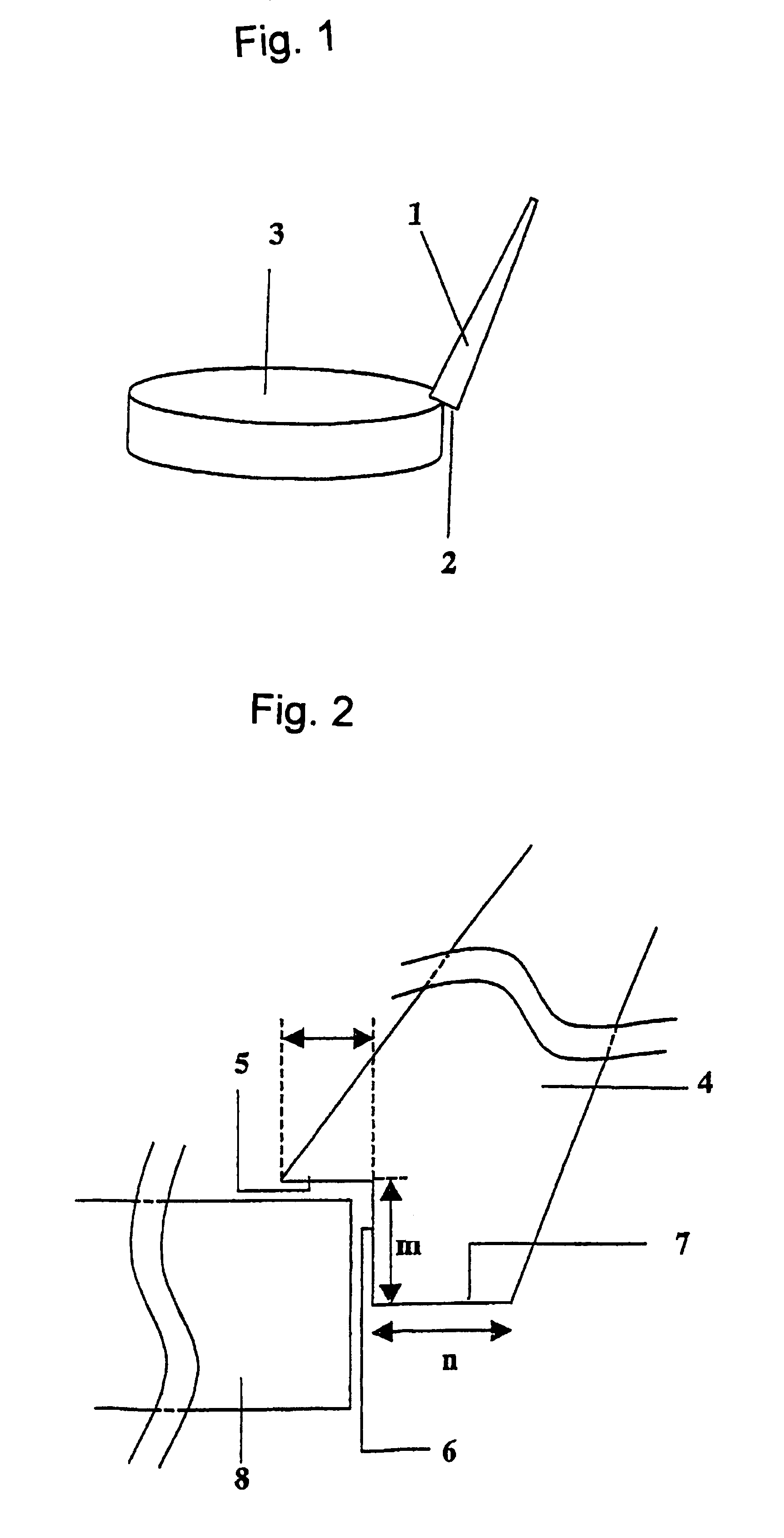

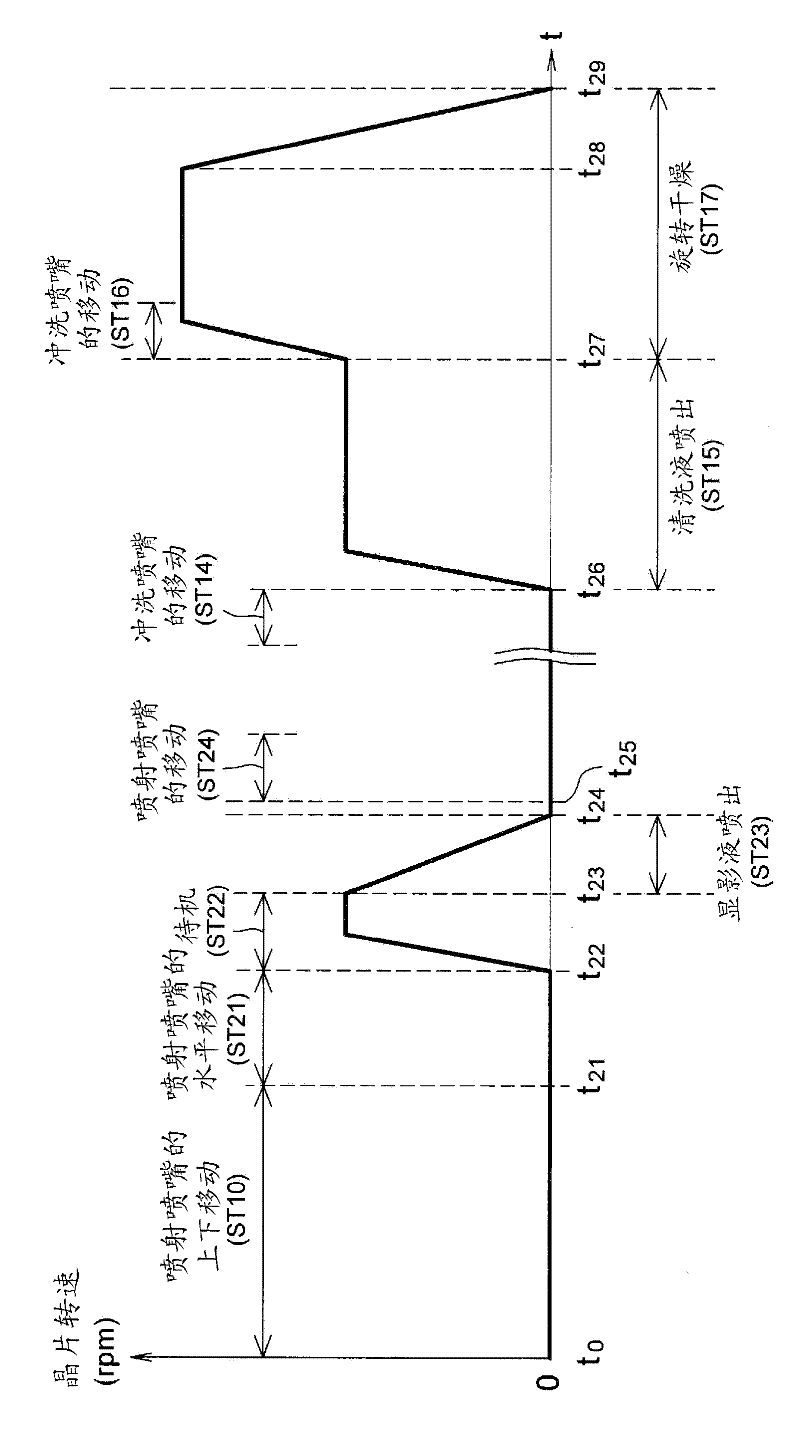

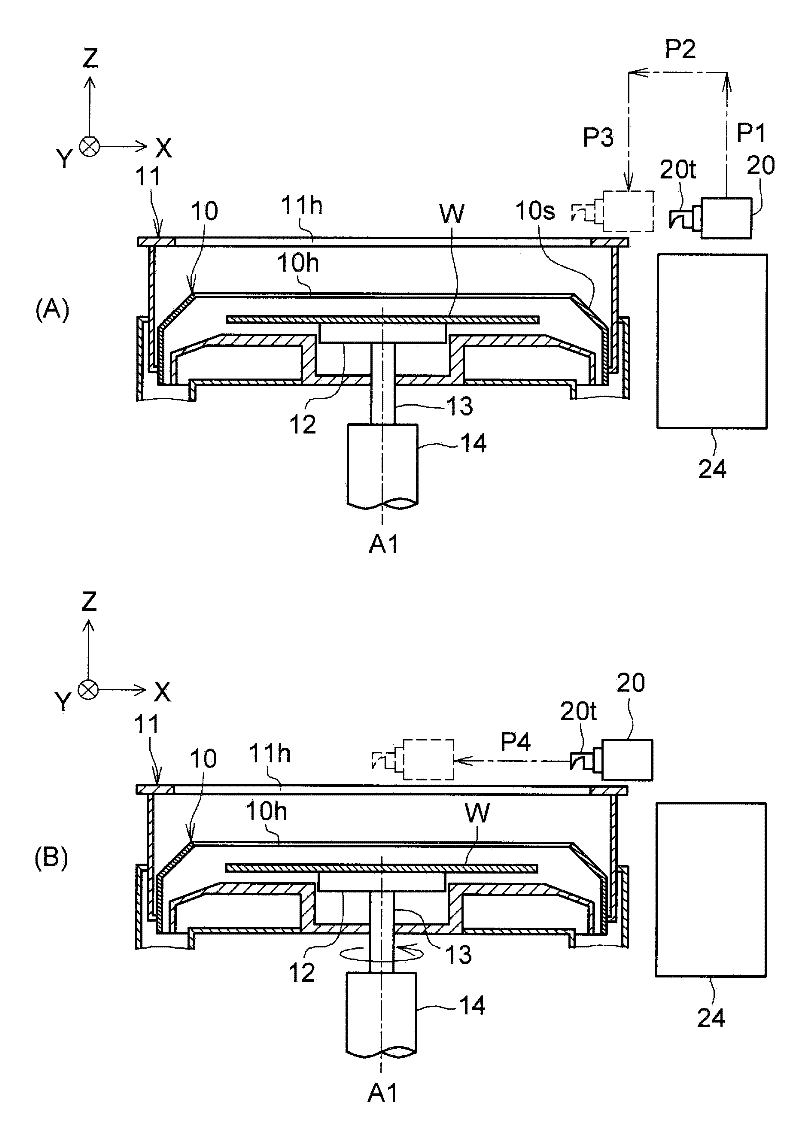

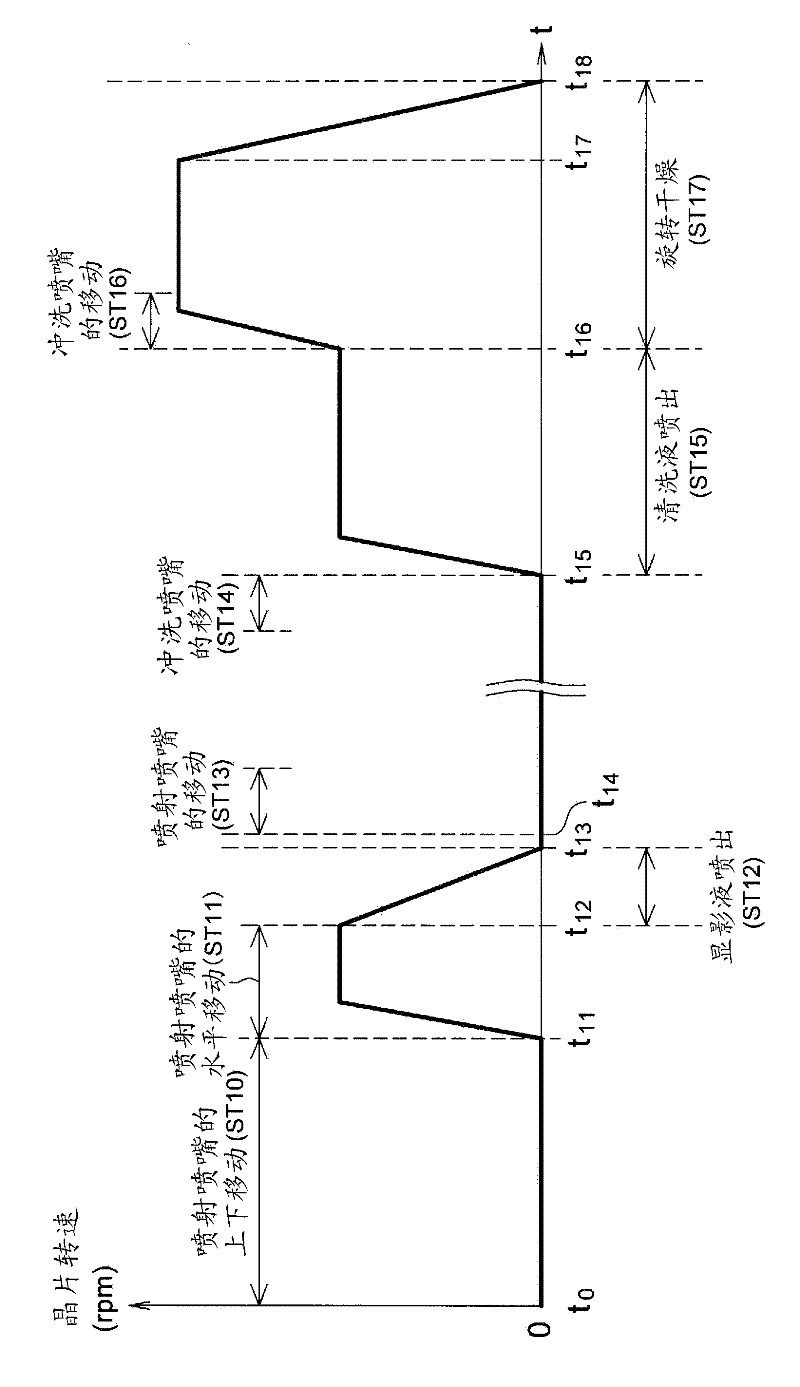

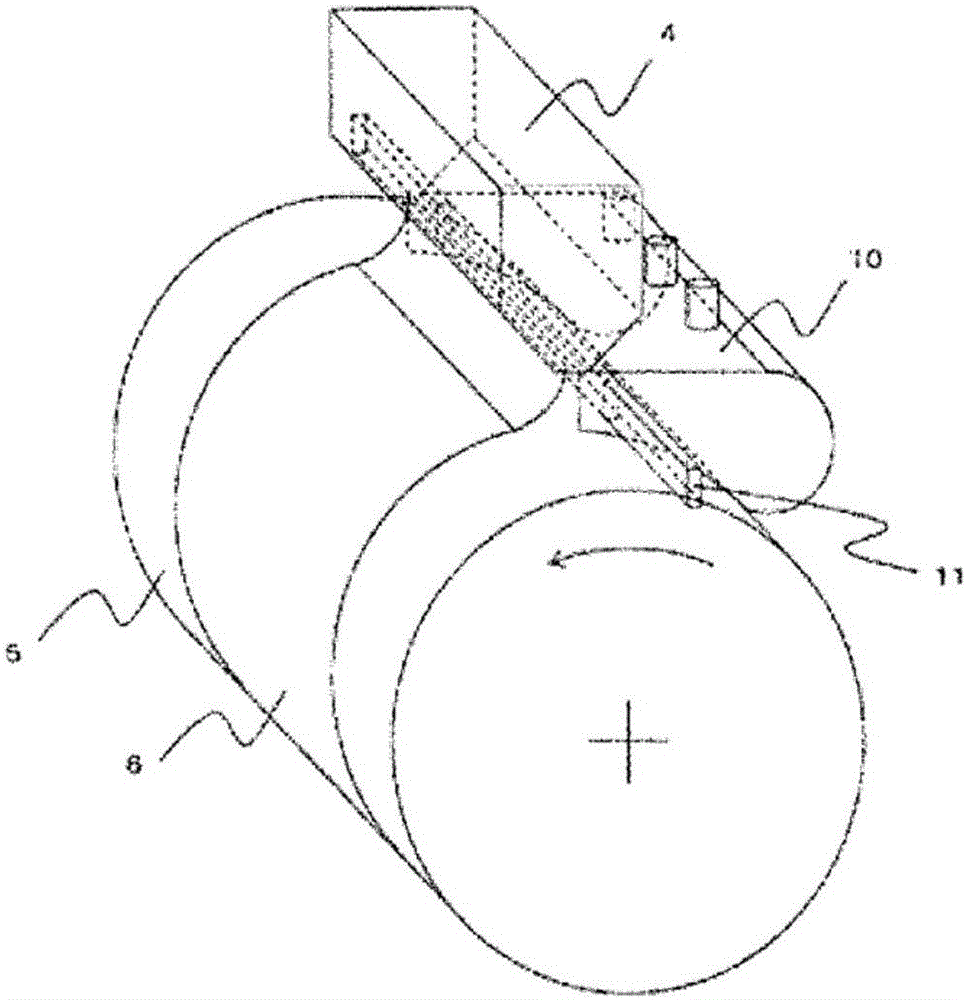

Substrate processing device and method

InactiveCN102543685ADrip suppressionSemiconductor/solid-state device manufacturingPhotosensitive material processingSpray nozzleEngineering

A semiconductor processing device sprays a liquid chemical agent onto a film on a spinning semiconductor substrate. The spray nozzle is moved horizontally from a first upper position comparatively distant from the substrate to a second upper position closer to the substrate, then vertically downward to a lower position. All of these positions are higher than the substrate and none of them overlie the substrate. The spray nozzle is then moved horizontally to a spray position over the substrate and spraying begins. Any residual liquid chemical agent remaining at the outlet of the spray nozzle from the processing of a previous substrate drops off harmlessly at the end of the downward vertical motion instead of dropping onto the film on the substrate.

Owner:LAPIS SEMICON CO LTD

Wearable storage annular support raincoat

InactiveCN110881719AEasy to put on and take offDrip suppressionGarment special featuresOvergarmentsEngineeringPhysical therapy

The invention discloses a wearable storage annular support raincoat. The raincoat is provided with a support rainproof device, a fixing belt and a wearing storage device. When the raincoat is worn ina non-rainproof state, the raincoat is turned over to the back of a wearer when the wearer wears the fixing band, the wearing storage device is fixed on the shoulders, the chest or the waist of the wearer, and the redundant parts, exceeding the width of the wearer, of the left side and the right side of the support rainproof device can be bent to be attached to the shoulders or the waist of the human body. According to the wearable storage annular support raincoat, wearing and taking off of the raincoat can be simplified, wearing storage fitting the human body is achieved, the raincoat does not need to be held by a raincoat wearer, meanwhile, arm and leg movement of the wearer is not affected, and the raincoat is particularly suitable for people who repeatedly get in and out of a rainfallarea, work in rainy days and are in a crowded environment.

Owner:朱江

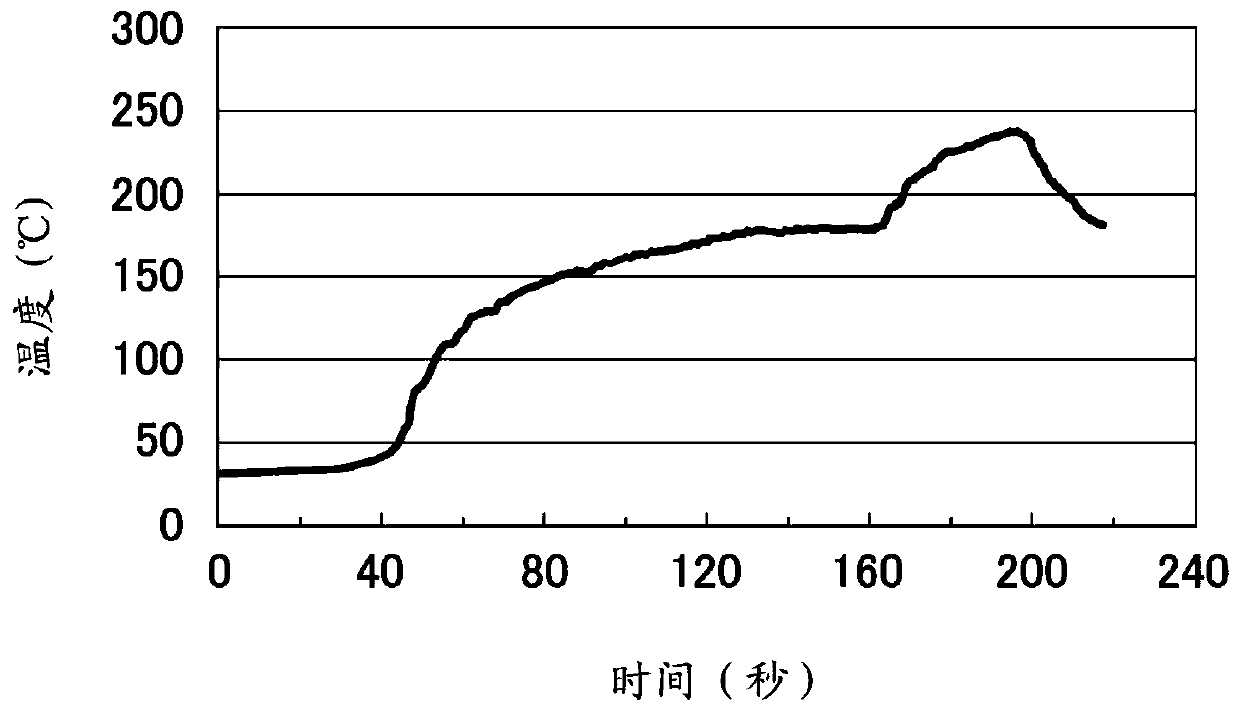

Solder composition for dispensing coating

InactiveCN110315241ADrip suppressionAdequate coatabilityWelding/cutting media/materialsSoldering mediaSolventRosin

This solder composition for dispensing and coating contains a flux composition and (G) a solder powder. The flux composition contains (A) a rosin-based resin, (B) an activator, (C) a solvent, (D) a thixotropic agent, and (E) an imidazole compound, and has a viscosity of 50-120 Pa * s at 25 DEG C as measured by an E-type viscometer.

Owner:TAMURA KK

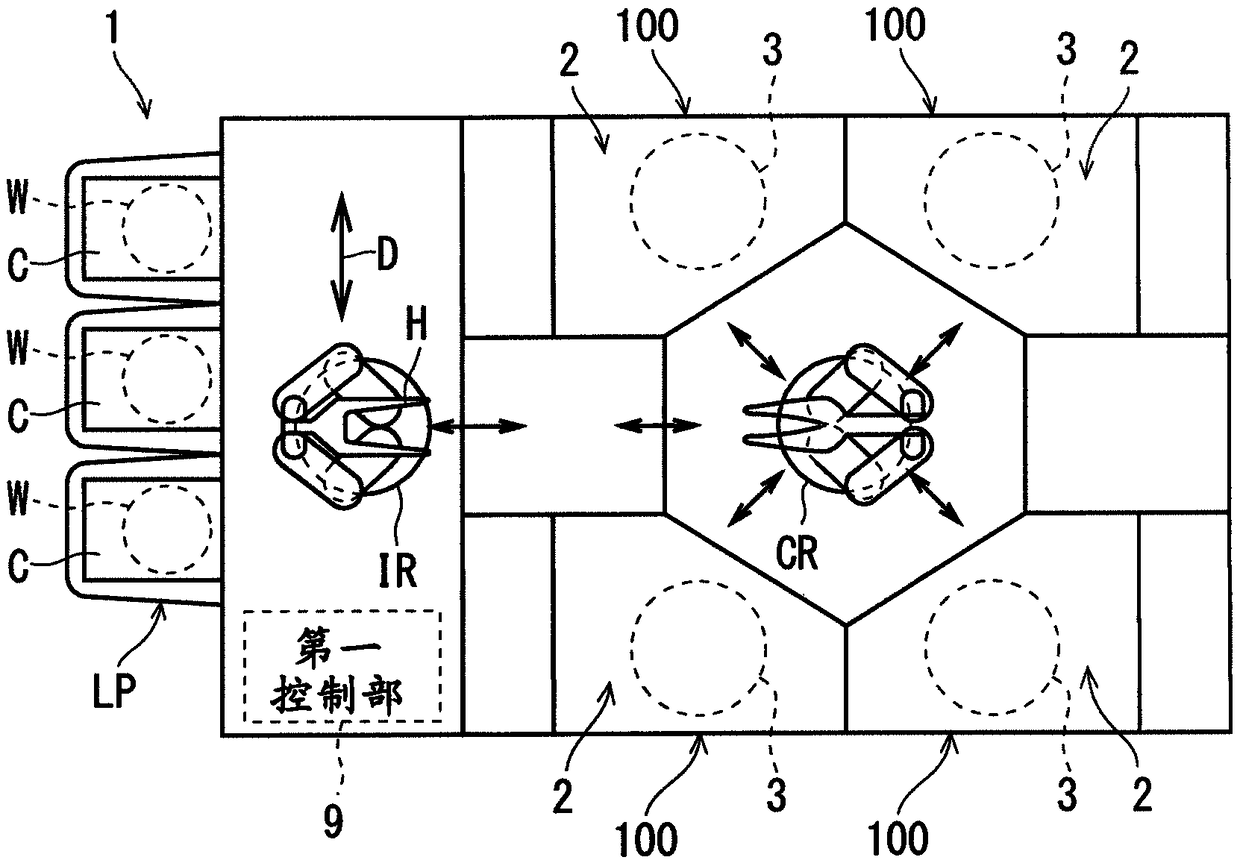

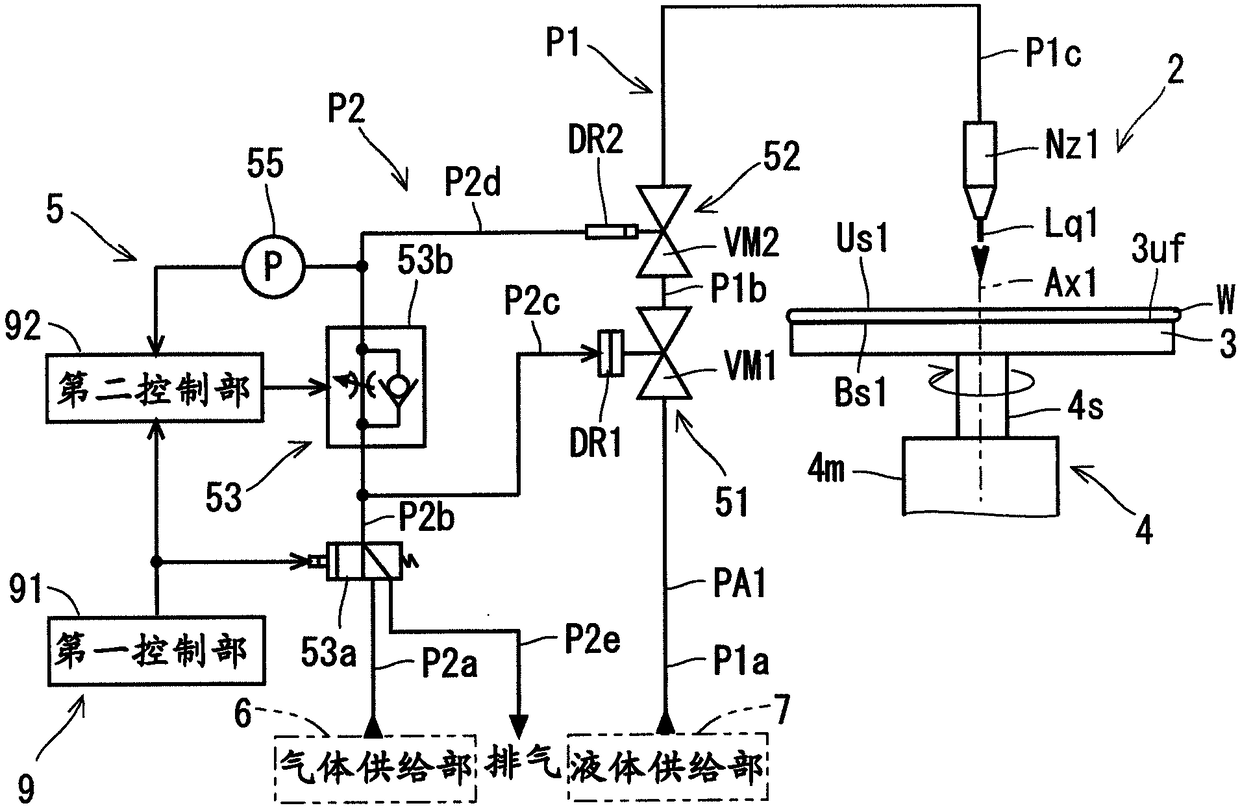

Substrate processing apparatus, control method therefor, and computer readable storage medium

ActiveCN108400103ASuppression of defects in the process of discharging the treatment liquidDrip suppressionSemiconductor/solid-state device manufacturingSpray nozzleEngineering

The invention provides a substrate processing apparatus, a control method therefor, and a computer readable storage medium, which suppress occurrence of defects when discharging a treatment liquid from a nozzle to a substrate via a relatively simple structure. The substrate processing apparatus includes a nozzle, a piping portion, a valve, an activating portion, a control portion, and a detectingportion. The nozzle discharges the treatment liquid to the substrate. The piping portion forms a flow path of the treatment liquid connected to the nozzle. The valve is provided at a midway portion ofthe piping portion, and changes the existence state of the treatment liquid in the piping portion and the nozzle. The activating portion imparts a driving force to the valve to operate the valve. Thecontrol portion operates the valve through the activating portion by outputting a trigger signal. The detecting portion detects a specific state. The control portion calculates the amount of change in the setting relating to the operating speed of the valve operation caused by the activating portion based on the relationship between the actual operating time from the first timing when the triggersignal is output to the second timing when detecting portion detects the specific state and the reference operating time.

Owner:DAINIPPON SCREEN MTG CO LTD

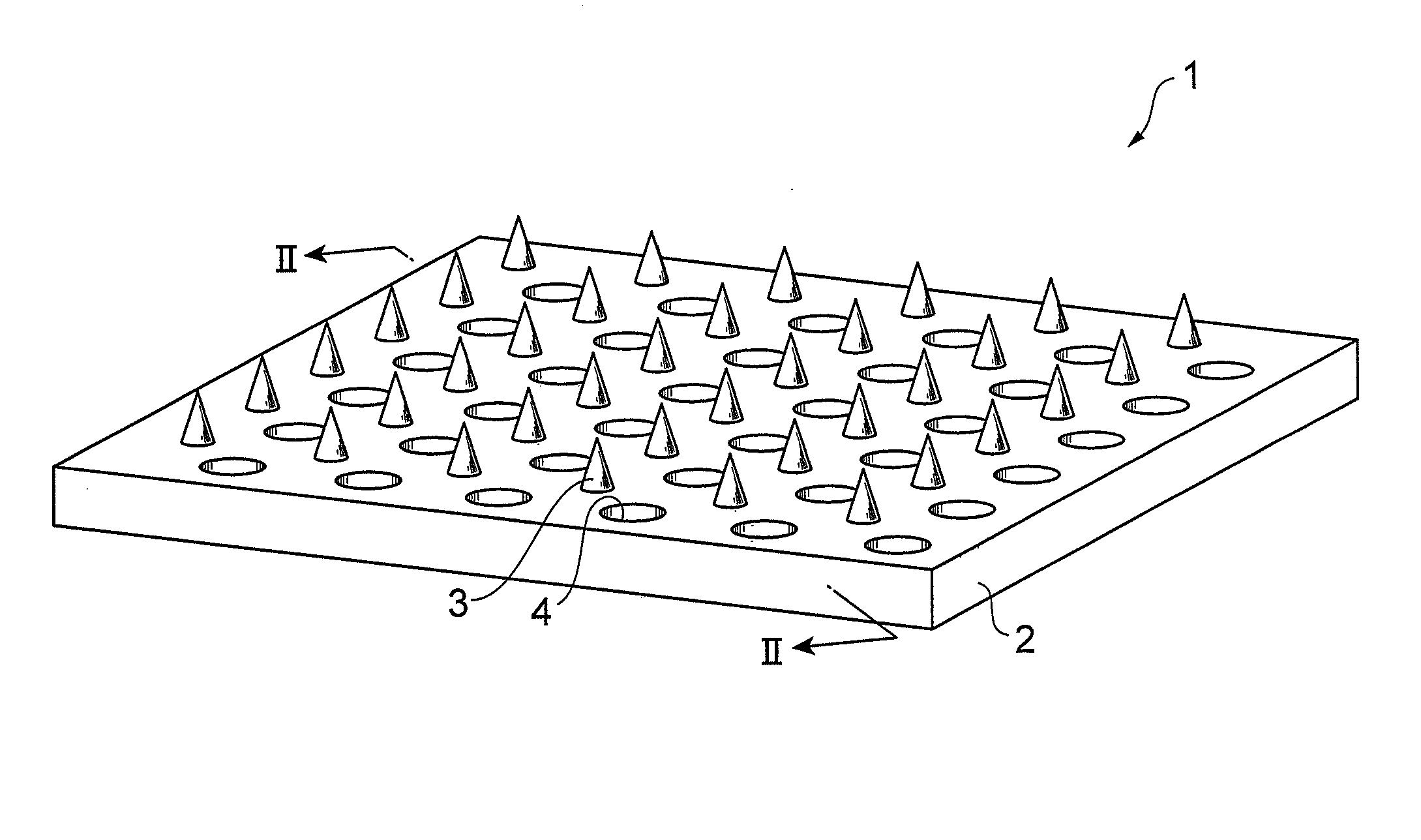

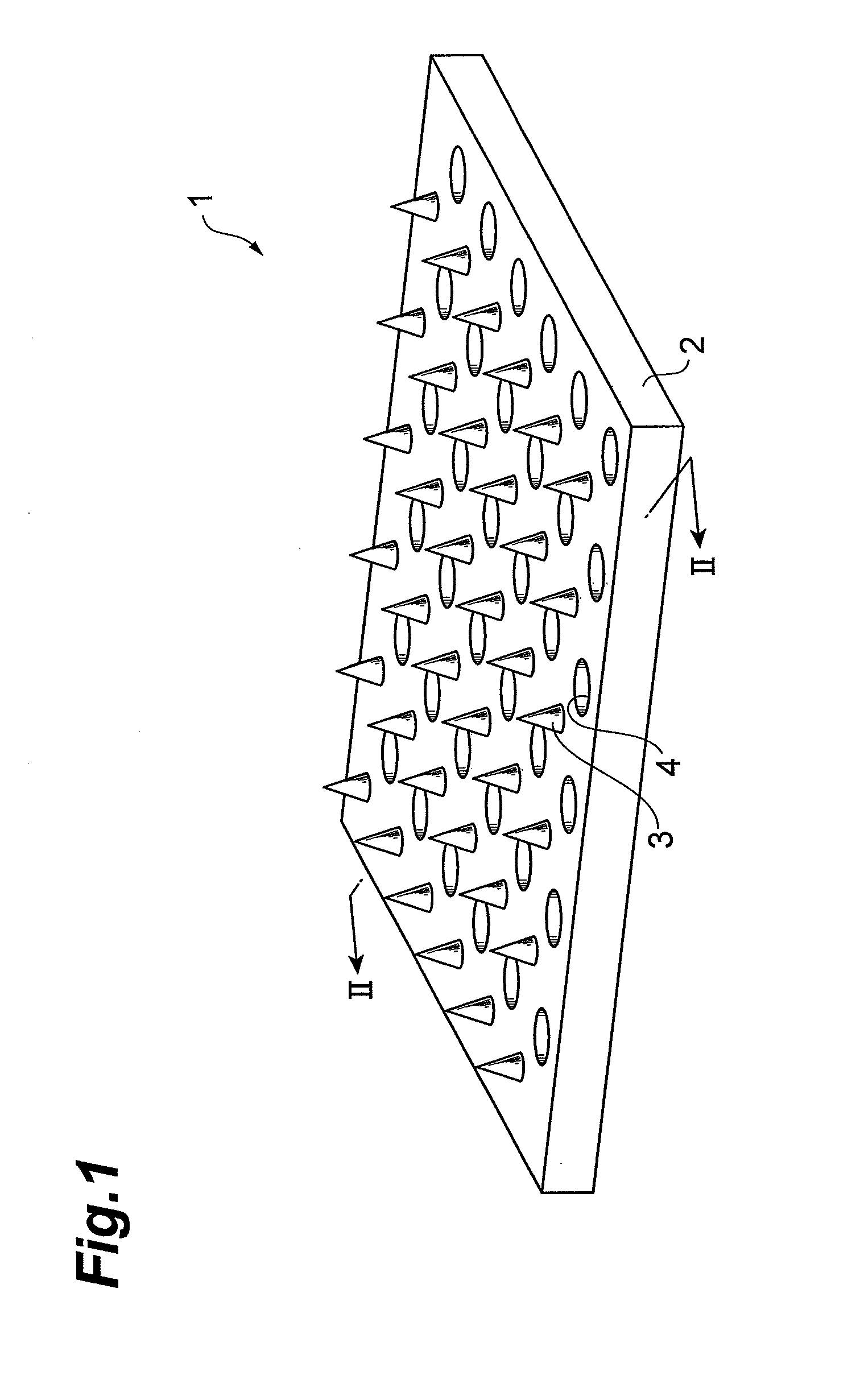

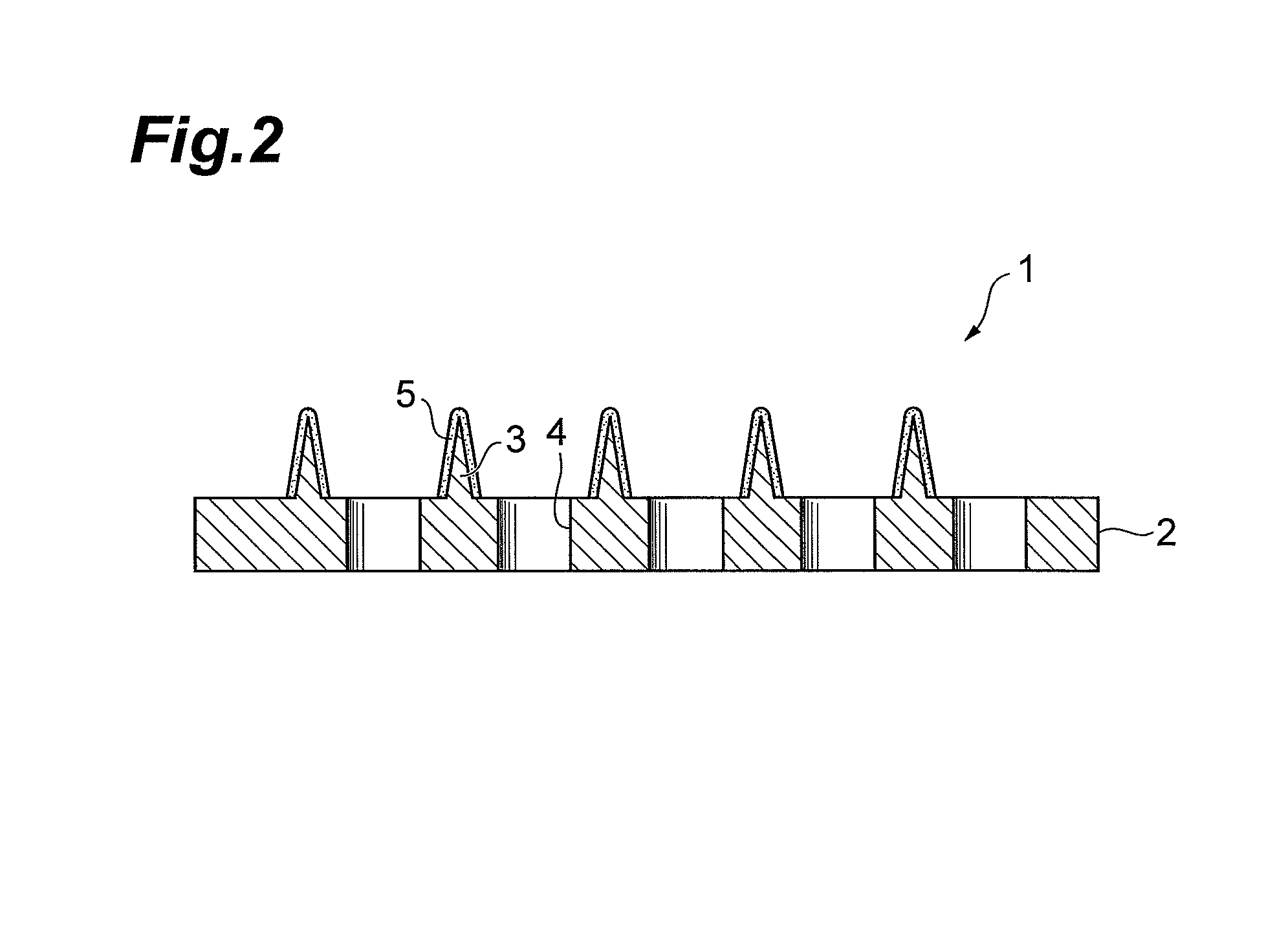

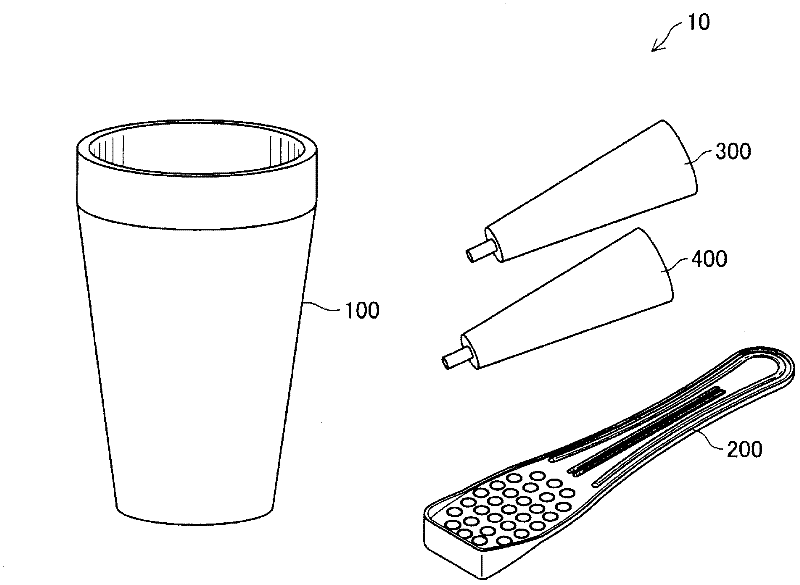

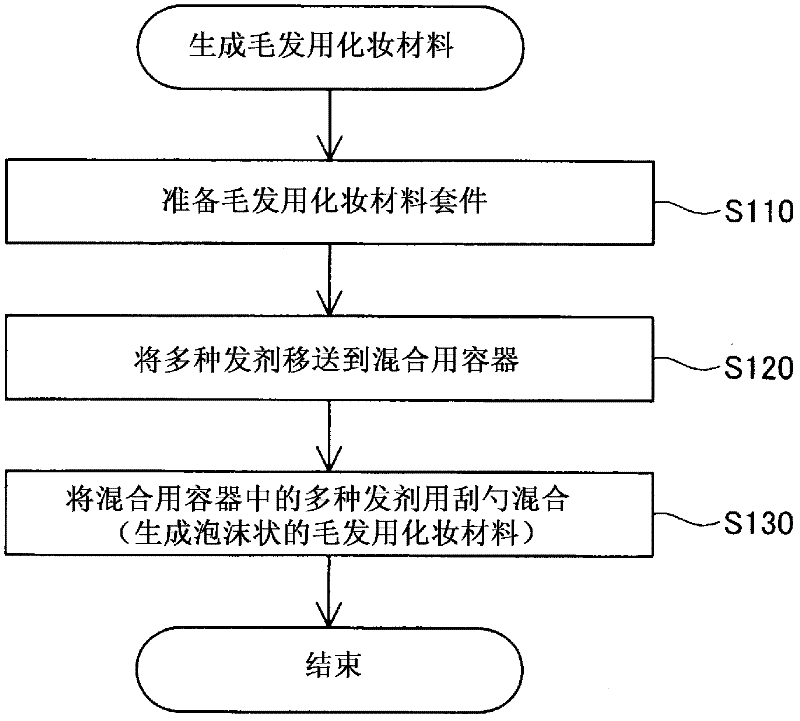

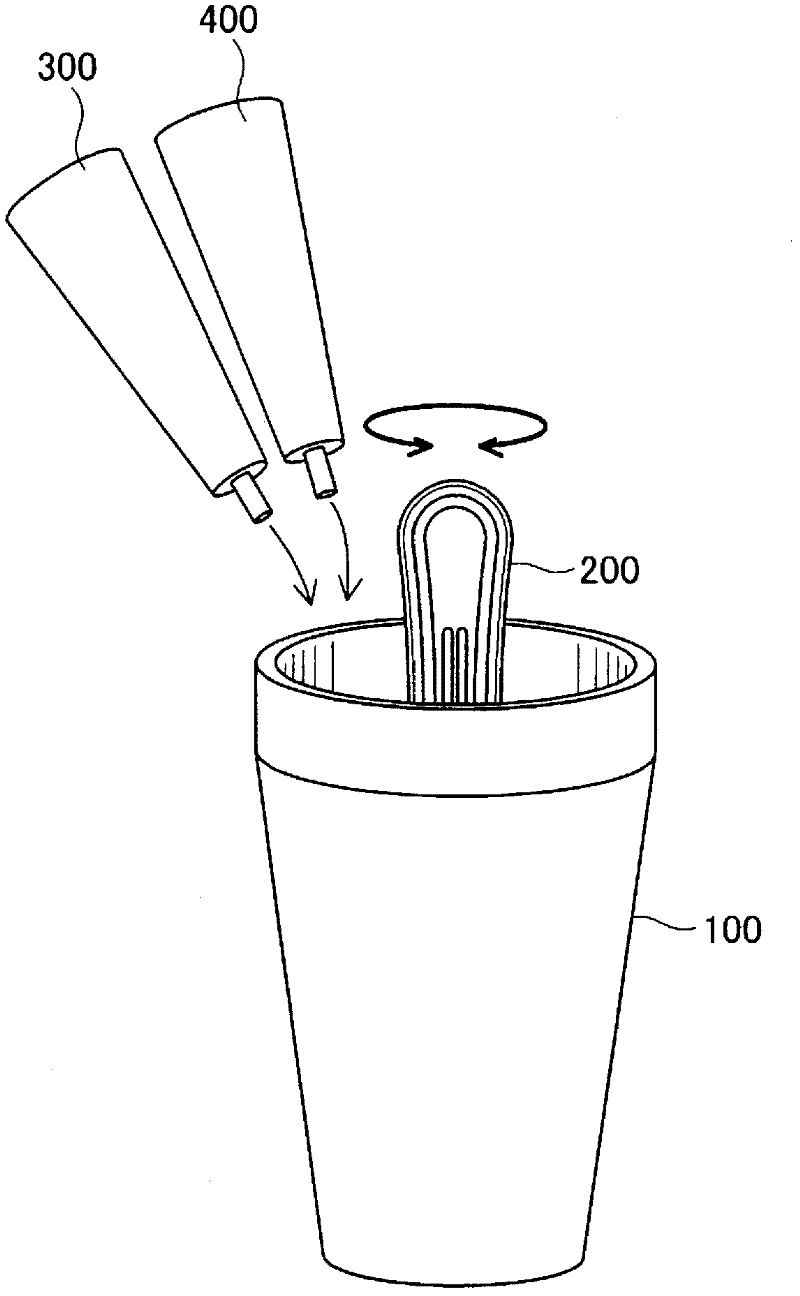

Mixing tool for hair cosmetics, hair cosmetic kit and hair cosmetic preparation method

InactiveCN102525091AInhibition of ruptureUneven suppressionPackaging toiletriesEmulsificationHair streamsHair Cosmetics

The invention provides a mixing tool for hair cosmetics, a hair cosmetic kit and a hair cosmetic preparation method. When different agents are mixed with each other and then automatically foam to change into foamy hair cosmetics, the mixing efficiency is increased and the foaming nonuniform is supressed. A tool for mixing a plurality of different agents with each other, which automatically foam to change into foamy hair cosmetics, includes a flat-plate member. A plurality of apertures are arrangedin vicinity of a front end of the flat-plate member and are formed to pass through the flat-plate member in a thickness direction.

Owner:DARIYA

Support raincoat storable in wearing

InactiveCN110973728ASimplify donning and doffing of raincoatsDrip suppressionOvergarmentsGarment beltsPhysicsEngineering

The invention discloses a support raincoat storable A storage belt is arranged, when the raincoat is worn in a non-rainproof state, a wearer turns over the storage belt to the reverse side of a support rainproof device or shortens the length of the storage belt through a storage belt adjusting device, the redundant parts, exceeding the width of the wearer, of the front, rear, left and right sidesof the support rainproof device can be bent and attached to the human body for storage, and the support raincoat is particularly suitable for people going in and out of a rainfall area repeatedly andlocated in a crowded environment.

Owner:朱江

Microporous polyolefin resin sheet production device and production method

ActiveCN106660253AStable manufacturingDrip suppressionFlat articlesCoatingsPolyolefinDecompression chamber

The invention relates to a microporous polyolefin resin sheet production method. An object is to prevent the occurrence of sheet defects by preventing the dropping of a liquid of low-molecular-weight components in a polymer, diluents, and additives adhering to a rectifier disposed inside a decompression chamber in a production method for a microporous polyolefin resin sheet including discharging a solution including a mixture of a polyolefin resin and a diluent in a sheet shape from a mouthpiece to a cooling / hardening device and cooling the sheet while aspirating the air between the sheet and the cooling / hardening device with an aspiration chamber. Another object is to forcibly aspirate a liquid of low-molecular-weight components in a polymer, diluents, and additives adhering to the rectifier by, while using a production device for a microporous polyolefin resin sheet having a mouthpiece that discharges a liquid including a mixture of a polyolefin resin and a diluent in a sheet shape, a cooling / hardening device that cools the sheet discharged from the mouthpiece, and a decompression chamber that aspirates the air between the sheet and the cooling / hardening device, disposing a rectifier inside the decompression chamber, aspirating each of the inside of the decompression chamber and the inside of the rectifier, and keeping the pressure inside the rectifier lower than the pressure inside the decompression chamber.

Owner:TORAY IND INC

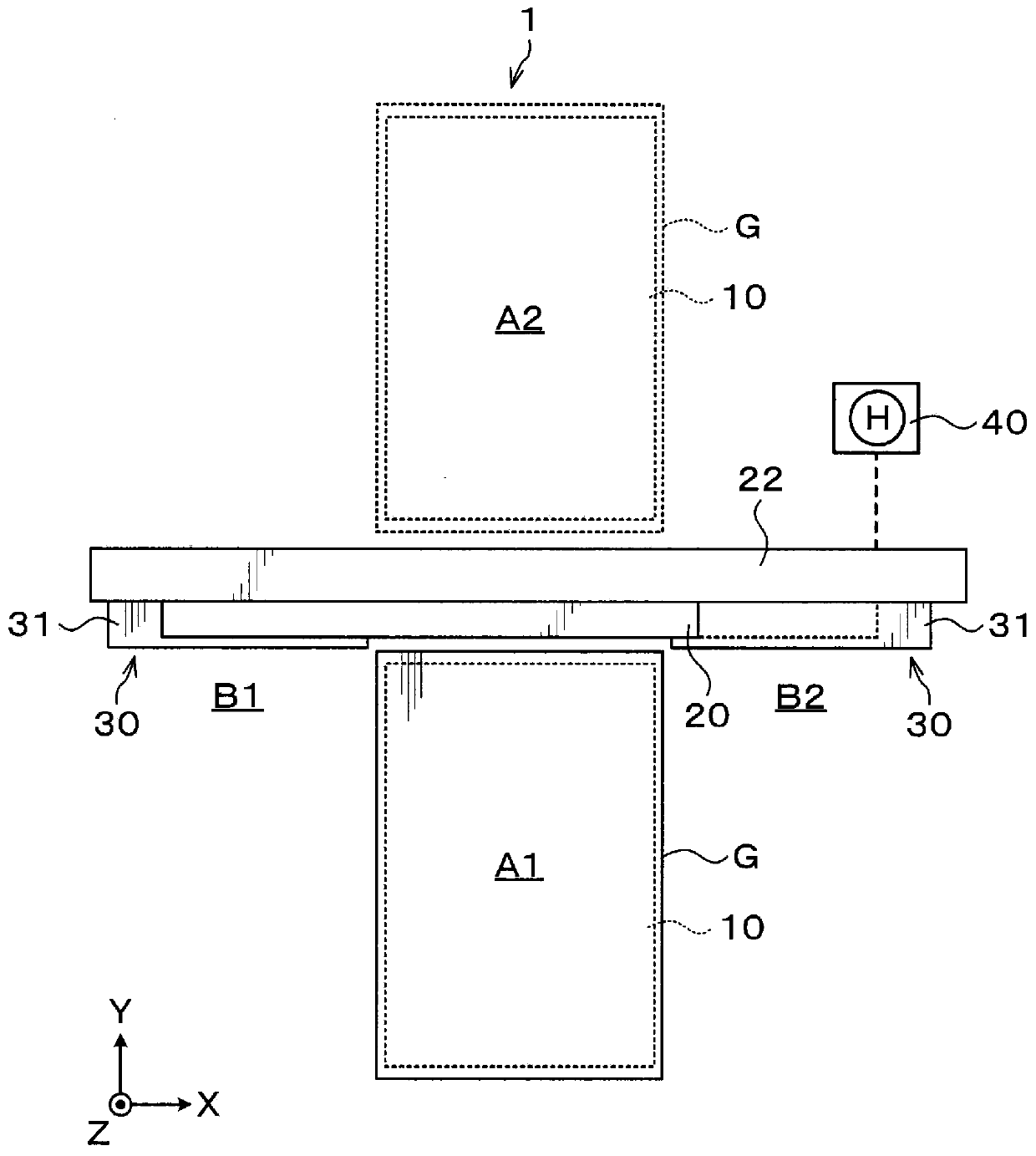

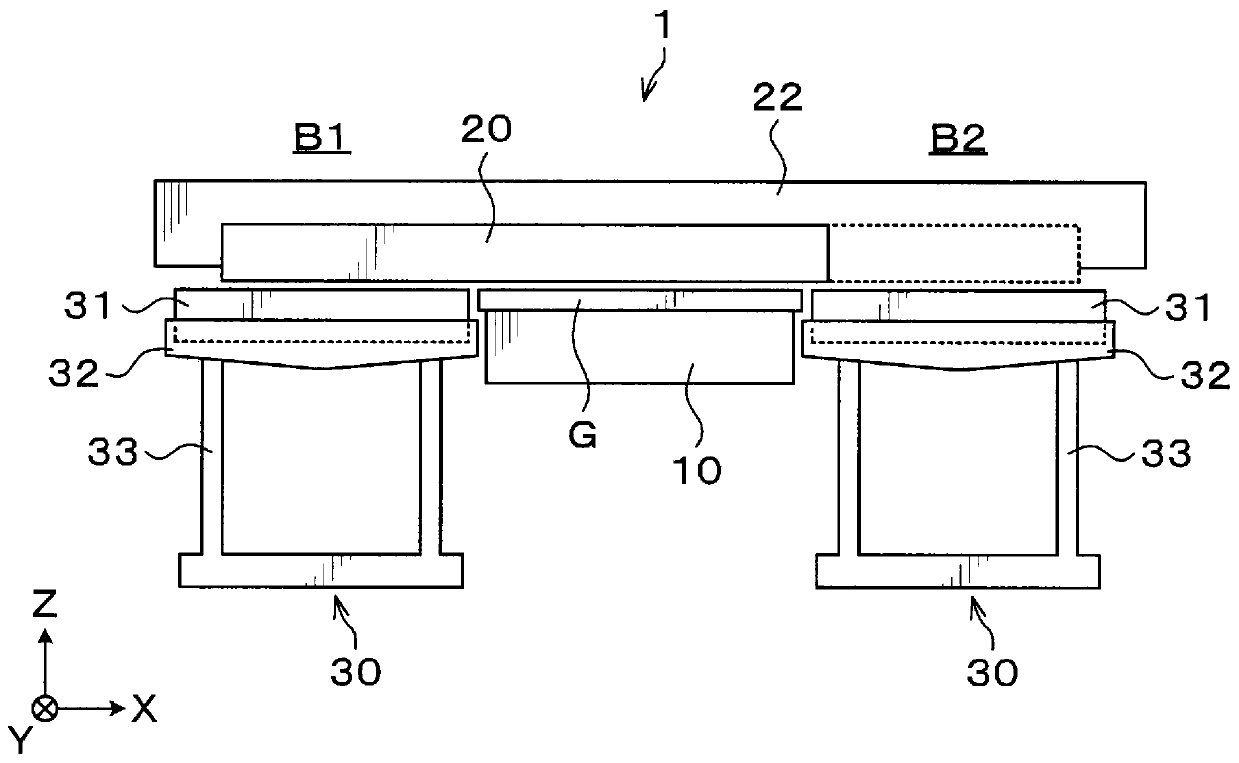

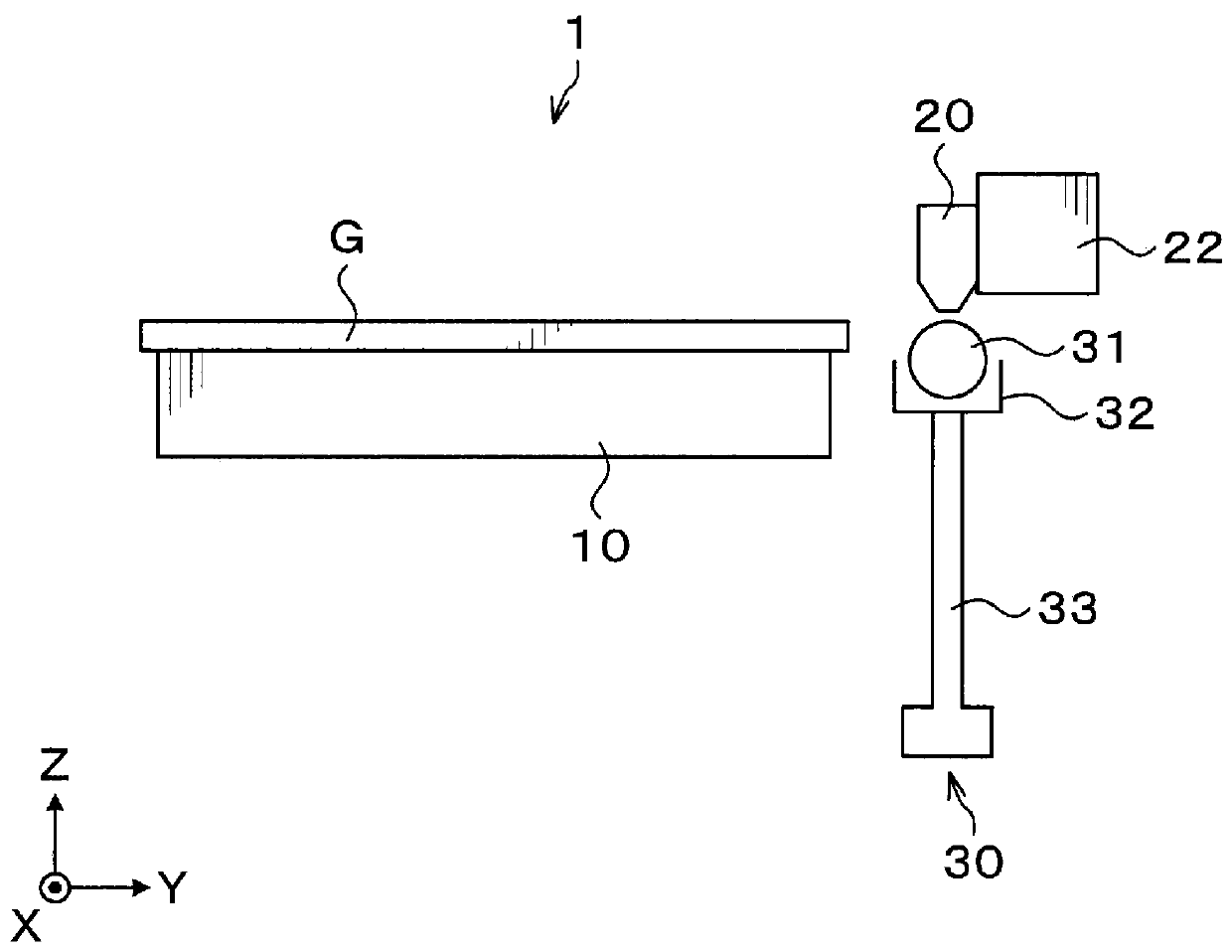

Application device, application method, and computer storage medium

ActiveCN110891697AControl movement speedControl the coating directionPretreated surfacesPolarising elementsEngineeringMechanical engineering

This application device applies an application liquid to a substrate, said application liquid containing an optical material. The application device has: a holding section that holds the substrate; anapplication nozzle for discharging the application liquid to the substrate held by the holding section; a moving mechanism that relatively moves the holding section and the application nozzle in theorthogonal directions; and a liquid receiving section, which is provided, in a plan view, on both outer sides of the substrate held by the holding section, and which receives the application liquid discharged from the application nozzle.

Owner:TOKYO ELECTRON LTD

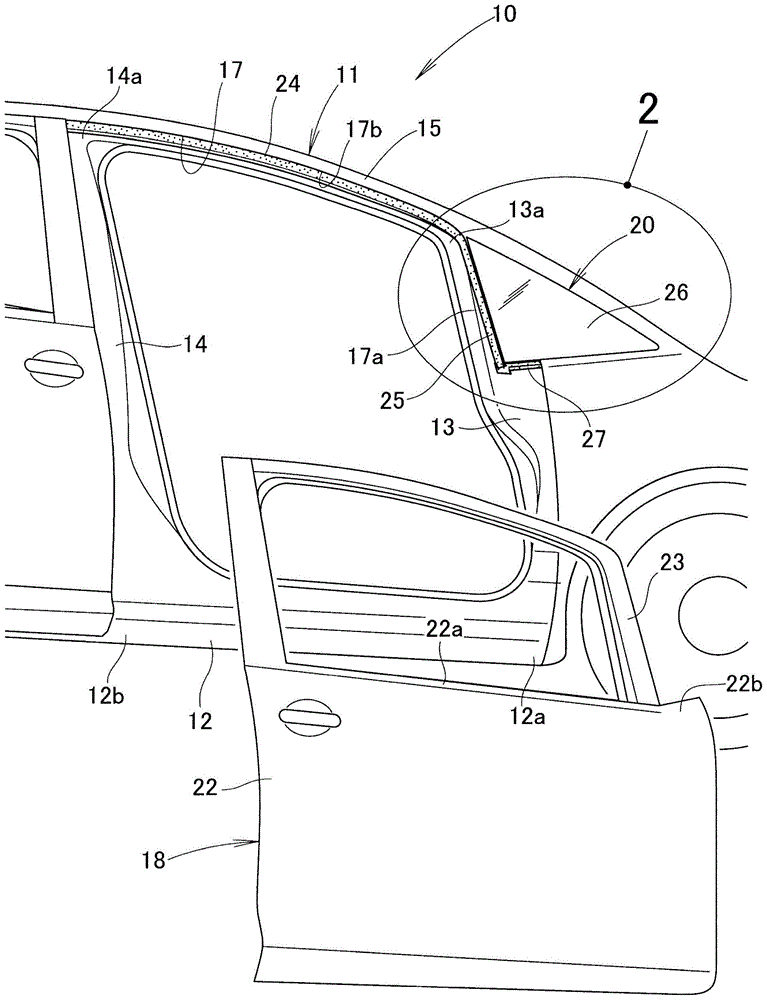

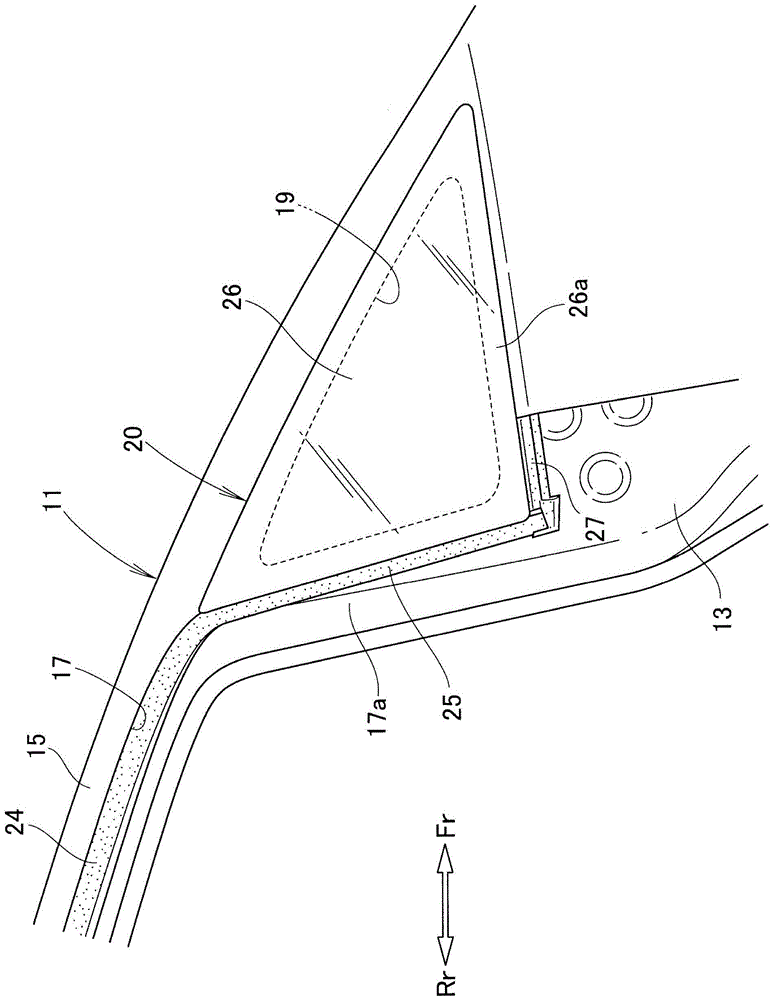

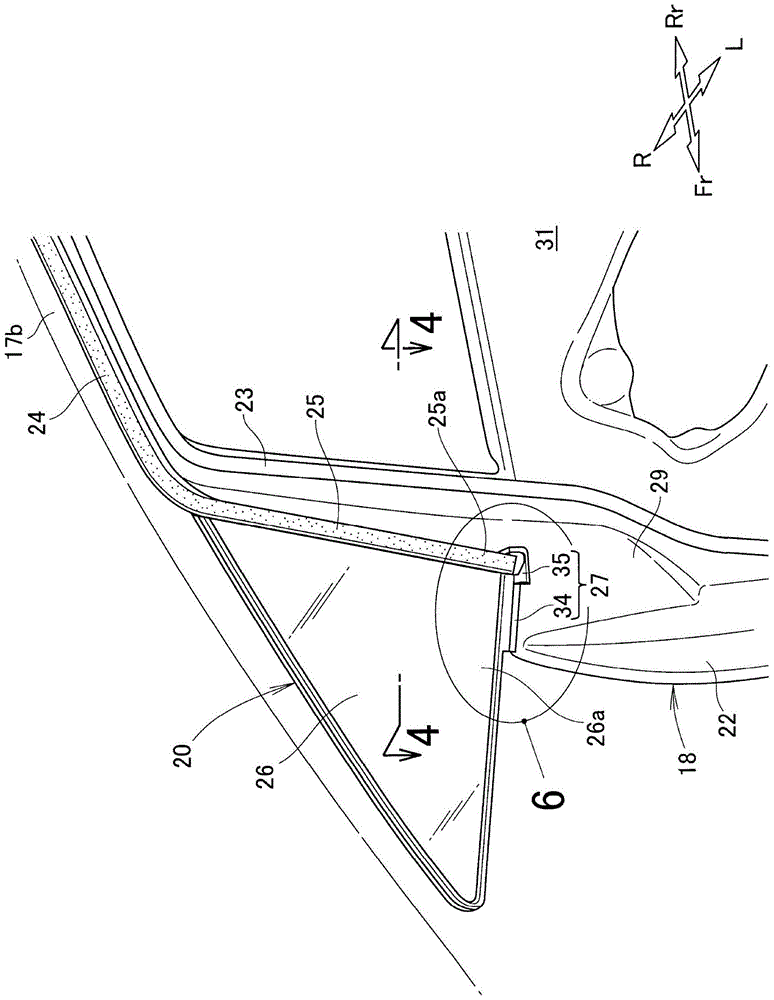

Sealed structure with exterior parts

An exterior member-equipped sealing structure includes: a vertical seal extending downward from a portion above a door opening toward a front of a vehicle body; a front corner pane located forward of the door opening in the vehicle body; and a decorative member for sealing a gap between a lower end of the front corner pane and a front side door. The decorative member includes: a decorative portion for sealing a gap between the lower end of the front corner pane and the front side door; and a receiver extending from the decorative portion to a space under the lower end of the vertical seal.

Owner:HONDA MOTOR CO LTD

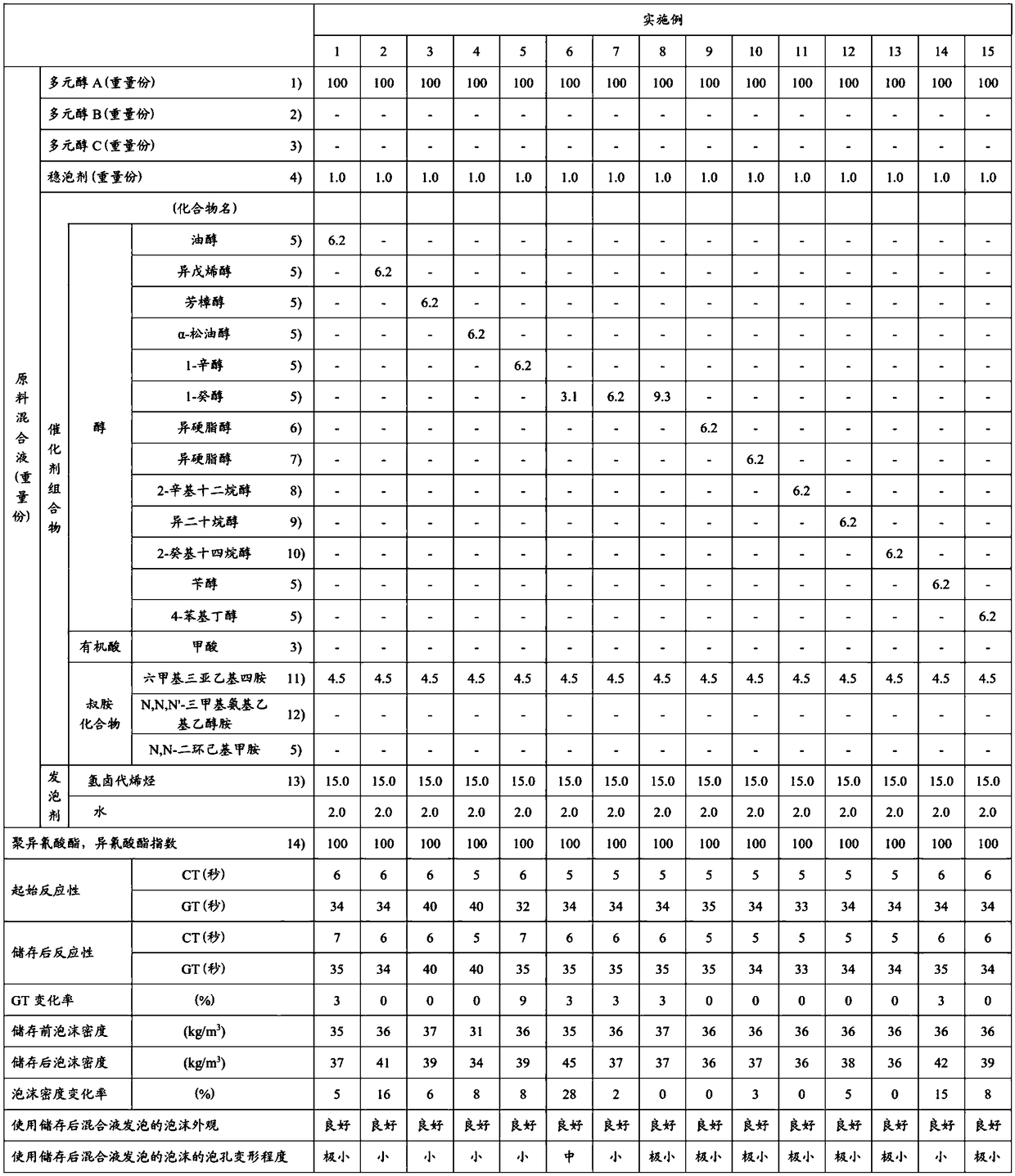

Amine catalyst composition for production of haloalkene foamed polyurethane

Provided is a catalyst composition which improves the storage stability of a liquid polyol blend for the production of a polyurethane foam, said blend containing a hydrohaloolefin as a foaming agent,and which starts a quick foaming reaction with a small addition amount. Also provided is a method for producing a polyurethane foam with use of a liquid polyol blend which contains this catalyst composition. The present invention uses a catalyst composition which contains: one or more alcohols selected from the group consisting of alcohols represented by general formula (1) (hereinafter referred to as the alcohols represented by general formula (1)) and alcohols represented by general formula (2) (hereinafter referred to as the alcohols represented by general formula (2)); and one or more tertiary amine compounds selected from the group consisting of hexamethyl triethylene tetramine, N, N, N'-trimethyl aminoethyl ethanolamine, N, N-dimethylamino ethoxy ethanol, N, N-dimethyl-N', N'-di(2- hydroxypropyl)propylene diamine, N, N, N'-trimethyl-N'-(2- hydroxyethyl)bis(2-aminoethyl) ether and N, N-dimethylamino ethyl-N'-methylamino ethyl-N"-methylamino isopropanol. (In general formula (1), R1represents an unsaturated hydrocarbon group containing at least one double bond and having 5-20 carbon atoms, a linear alkyl group having 6, 8, 10 or 12 carbon atoms or a branched alkyl group having12-24 carbon atoms.) (In general formula (2), m represents a number of 1-4.)

Owner:TOSOH CORP

Wearable and storable annular support raincoat

InactiveCN111387575AAvoid putting on and taking offAchieve expansionConvertible garmentOvergarmentsPhysical therapyMechanical engineering

The invention relates to a support raincoat. A support skirt fixing band and a storable support skirt are arranged; a wearer can control the support skirt fixing band through hands or a body, and thesupport skirt can be prevented from swinging in the rainproof use process. According to the wearable storage support skirt, when the raincoat is worn in a non-rainproof state, a wearer can store the support skirt in a wearing mode, so that the support skirt can be stored in a mode of being attached to the human body when being worn, the raincoat wearer does not need to hold the support skirt by hand, movement of arms and legs of the wearer is not affected, and repeated putting-on, taking-off and storage of the raincoat are avoided when the wearer repeatedly enters and exits a rainfall area.

Owner:朱江

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com