Substrate processing apparatus, control method therefor, and computer readable storage medium

A substrate processing device and processing liquid technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve the problems of substrate processing device complexity and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0160]

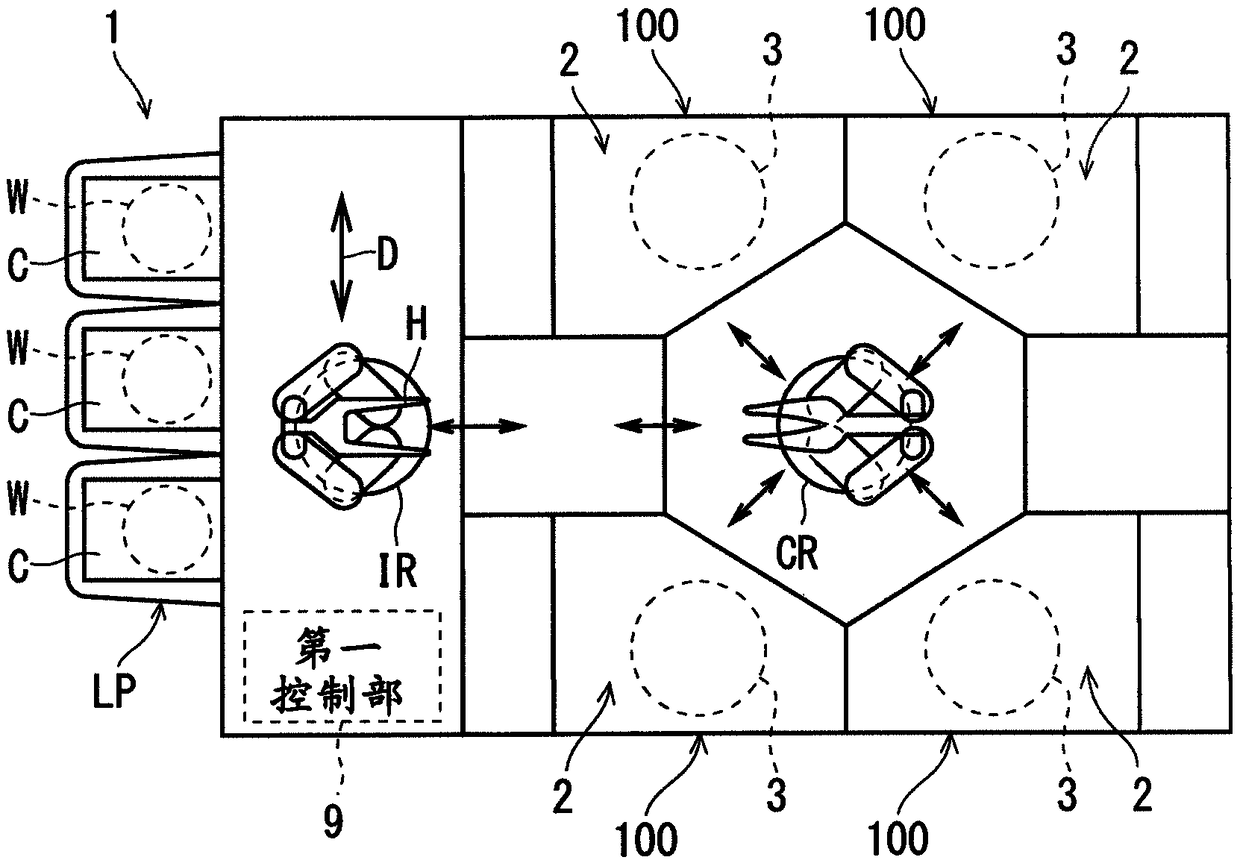

[0161] figure 1 It is a schematic plan view showing an example of a schematic configuration of the substrate processing apparatus 1 of the first embodiment. The substrate processing apparatus 1 is, for example, a single-wafer type apparatus capable of performing various processes by supplying a processing liquid to the surface of a semiconductor substrate (wafer) as an example of a substrate W. Various treatments include, for example, chemical solution treatment for etching with a chemical solution, cleaning treatment for removing contaminants with a liquid, rinsing treatment for rinsing with water, and coating treatment for applying a resist or the like.

[0162] The substrate processing apparatus 1 includes a load port LP as a container holding mechanism that holds a plurality of carriers C as containers, and a plurality (twelve in this embodiment) of processing units 100 that process a substrate W. Specifically, for example, three sets of processing units 100 e...

no. 3 approach

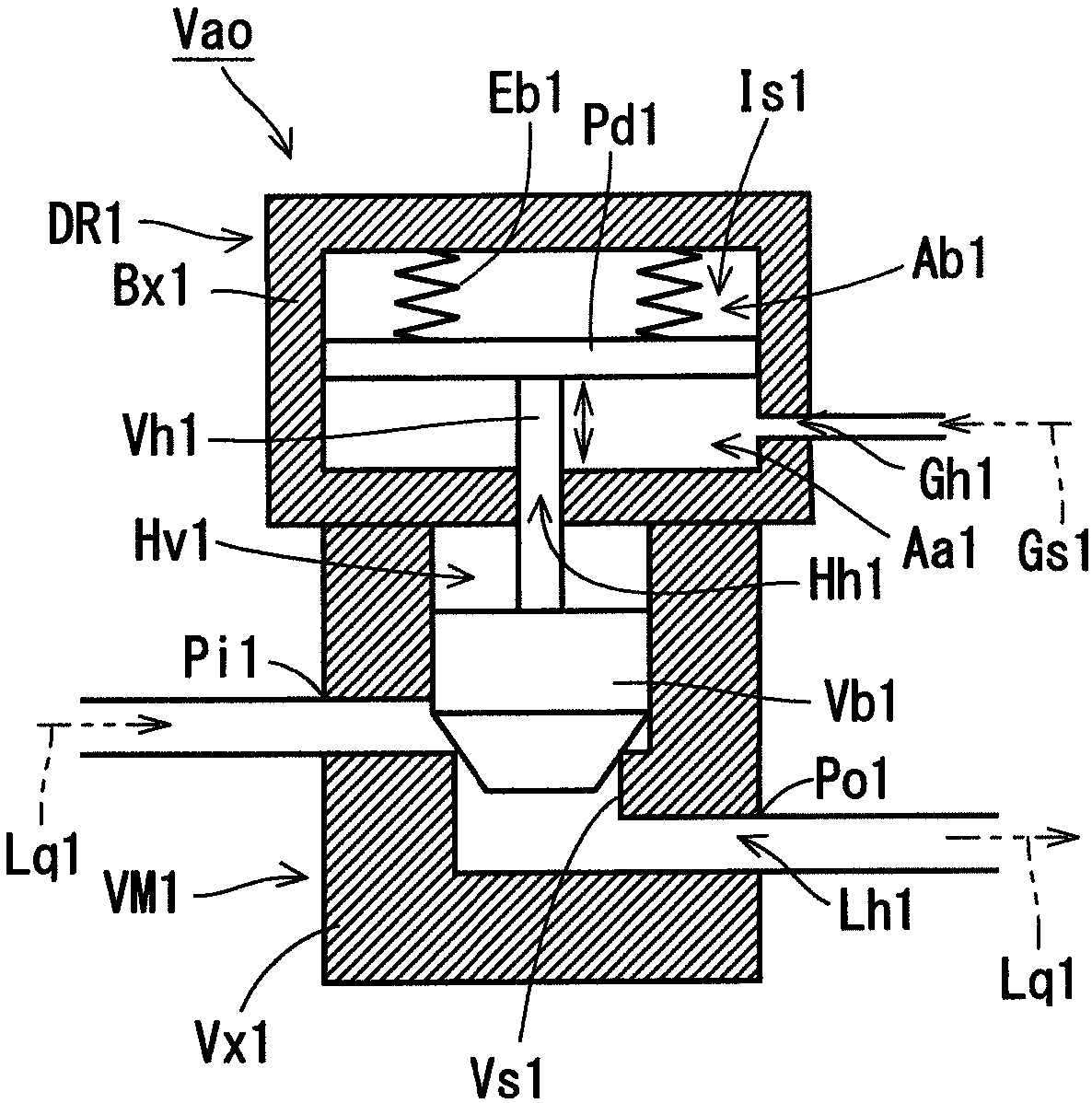

[0281] In each of the above-described embodiments, for example, as the liquid suction operation, suction by a siphon system or suction by a vacuum generator may be used instead of suction by a diaphragm system. The suction of the siphon method and the suction of the vacuum generator method are to suck back and discharge the processing liquid Lq1 present in the part from the discharge valve 51 to the nozzle Nz1 in the piping part P1 when the processing liquid Lq1 discharged from the nozzle Nz1 is replaced. Liquid suction action.

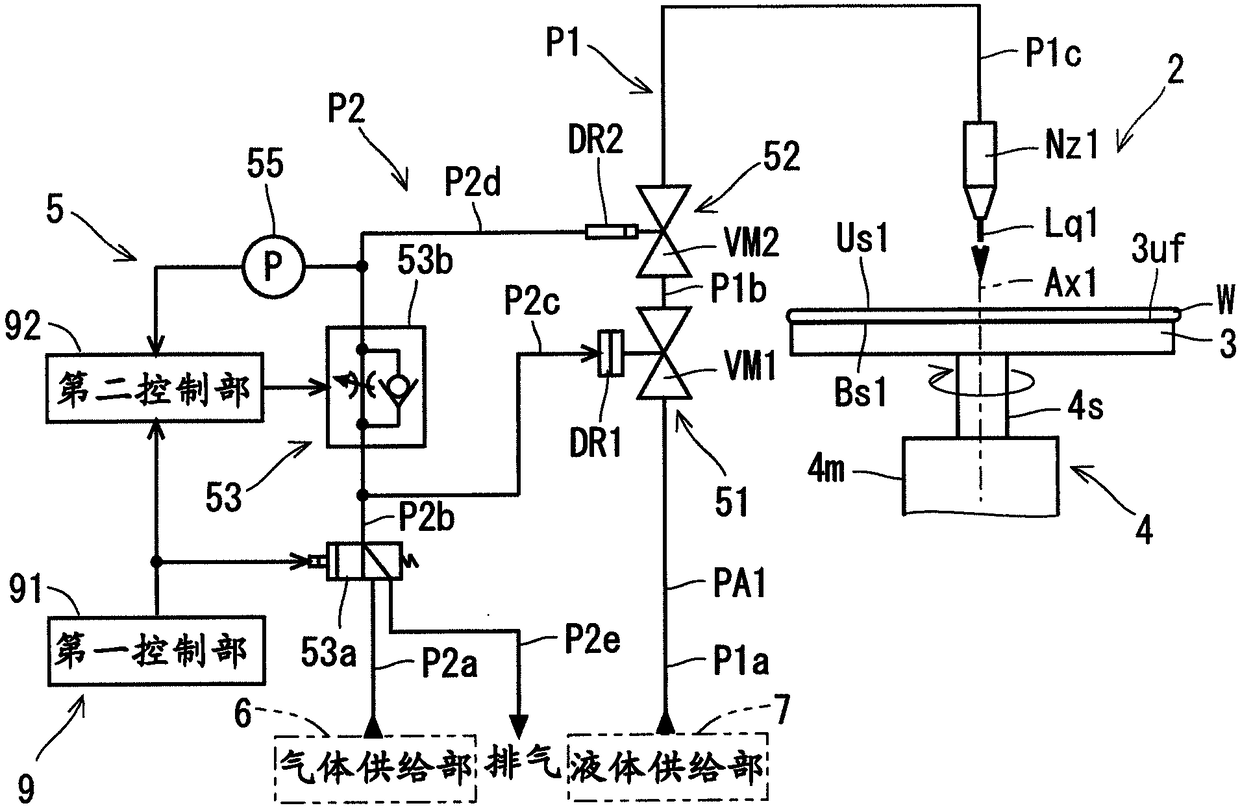

[0282] Figure 12 It is a diagram schematically showing a configuration example of the processing unit 100 of the third embodiment. Such as Figure 12 As shown, as the processing unit 100 of the third embodiment, for example, based on the processing unit 100 of the first embodiment, the processing liquid supply system 5 is replaced with the processing liquid supply system 5B.

[0283] As the processing liquid supply system 5B, for example, based on...

no. 4 approach

[0307] In the third embodiment described above, for example, as Figure 13 As shown, the detection unit 55B may be changed to a detection unit 55C that detects the presence of the processing liquid Lq1 in the piping portion P1B or a specific state related to the flow rate. With this change, the processing liquid supply system 5B is set to the processing liquid supply system 5C. Figure 13 It is a diagram schematically showing a configuration example of the processing unit 100 of the fourth embodiment.

[0308] Here, as the specific state related to the presence of the processing liquid Lq1 in the piping portion P1B, for example, a state in which the liquid level of the processing liquid Lq1 reaches a specific position of the branch pipe portion P1d (also referred to as a specific suck-back state) is used. In this case, for example, if the first branched pipe portion P1d1 is formed of a transparent or semi-transparent pipe, the detecting portion 55C may be arranged to face a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com