Amine catalyst composition for production of haloalkene foamed polyurethane

A technology of hydrohalogenated olefins and compositions, which is applied in the field of amine catalyst compositions, can solve problems such as poor catalytic activity of foaming reactions and liquid dripping in spraying methods, and improve storage stability, foaming activity, and foaming. The effect of foaming and resinization on catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~27、 comparative example 1~5

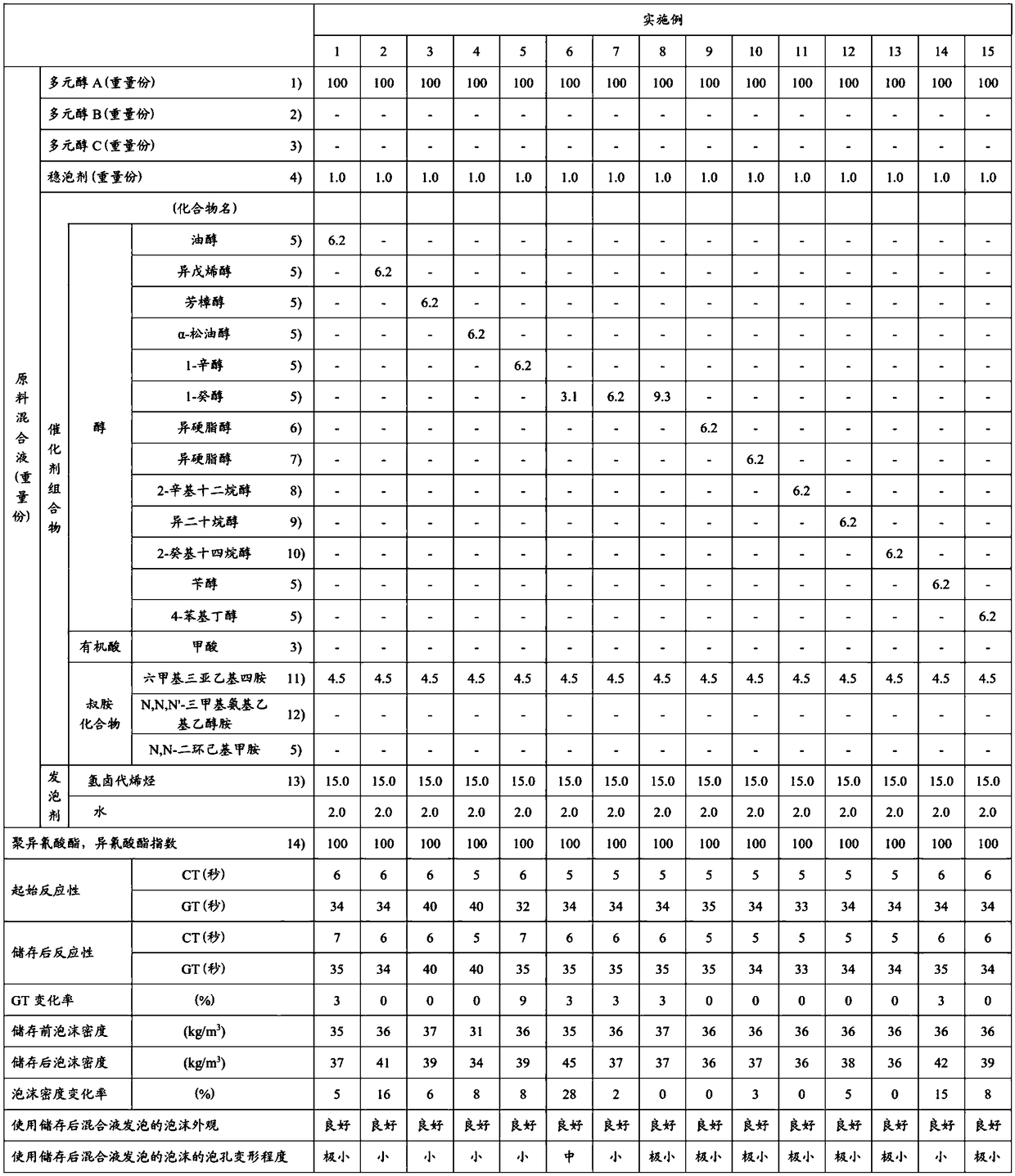

[0100] In the polyol liquid mixture containing the polyol shown in Tables 1 and 2, a foam stabilizer, a catalyst composition, water, and a hydrohalogenated olefin, the weight ratio is determined so that the polyisocyanate becomes a given isocyanate index , after adjusting the liquid temperature of the two components to 20°C, they were stirred and mixed at 7000rpm for 3 seconds using a laboratory mixer to perform a foaming reaction to produce a rigid polyurethane foam. In addition, the addition amount of the amine catalyst composition was adjusted so that the gel time may be 29 to 40 seconds.

[0101] The emulsification time (CT) and gel time (GT) at this time were measured visually, and it was set as initial reactivity. The emulsification time and gel time shown in Tables 1 and 2 are defined as follows.

[0102] Emulsification time: measure the time for the foaming reaction to proceed and foaming to start.

[0103] Gel time: measure the time for the resinification reaction t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com