Solder composition for dispensing coating

A composition and solder technology, applied in welding/cutting media/materials, welding media, welding equipment, etc., can solve the problems of easy dripping and low viscosity of the solder composition, and achieve the effect of suppressing dripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

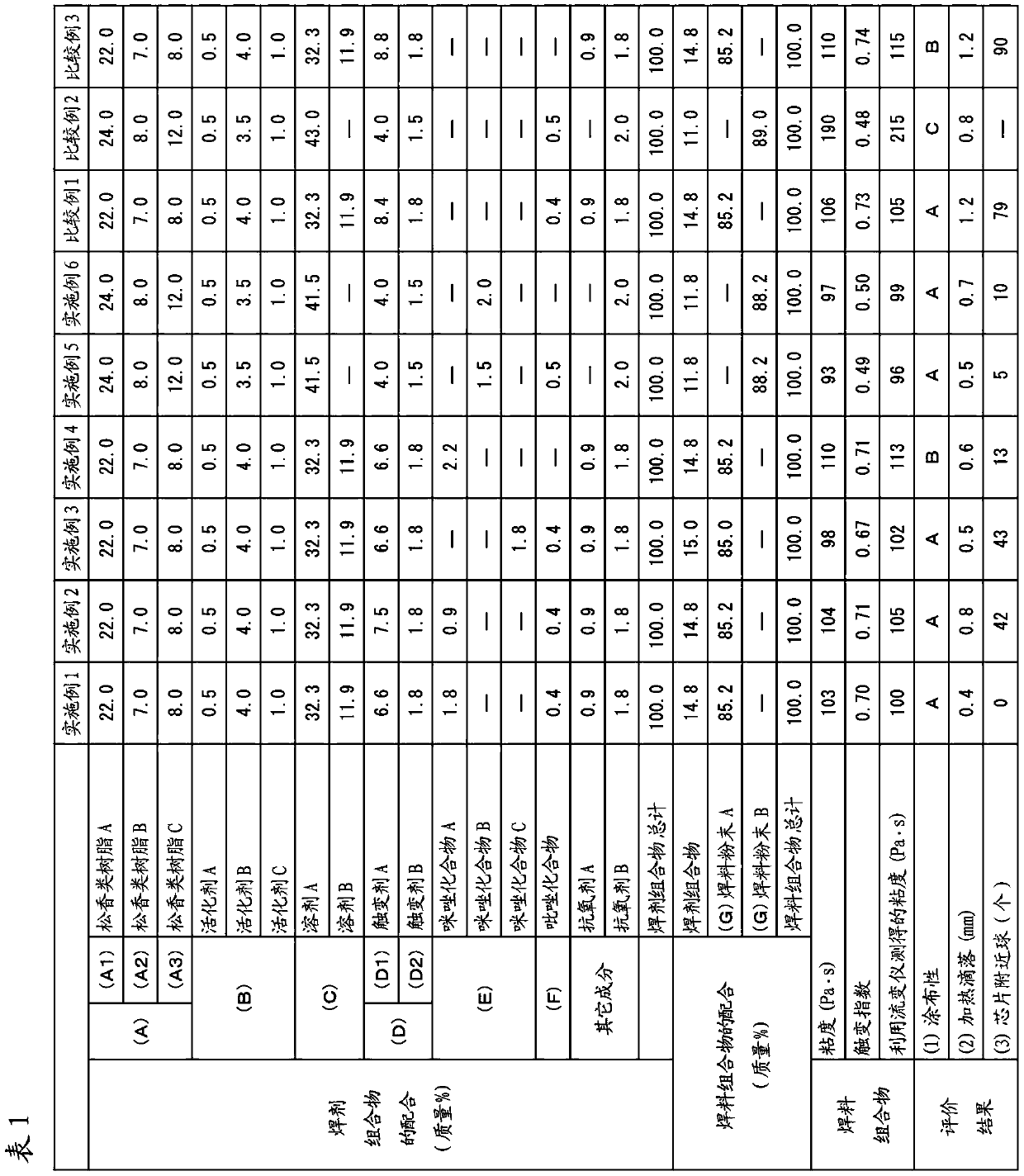

[0113] Rosin-based resin A 22 mass%, rosin-based resin B 7 mass%, rosin-based resin C 8 mass%, thixotropic agent A 6.6 mass%, thixotropic agent B 1.8 mass%, antioxidant A 0.9 mass%, anti-oxidant 1.8% by mass of oxygen agent B, 0.5% by mass of activator A, 4% by mass of activator B, 1% by mass of activator C, 1.8% by mass of imidazole compound A, 0.4% by mass of pyrazole compound, 32.3% by mass of solvent A, and solvent 11.9% by mass of B was put into a container, heated to 160° C. with a mantle heater, and mixed with a kneader (planetary mixer) to obtain a flux composition.

[0114] Then, 14.8% by mass of the obtained flux composition and 85.2% by mass of the solder powder (100% by mass in total) were put into a container and mixed with a kneader (planetary mixer) to prepare a solder composition.

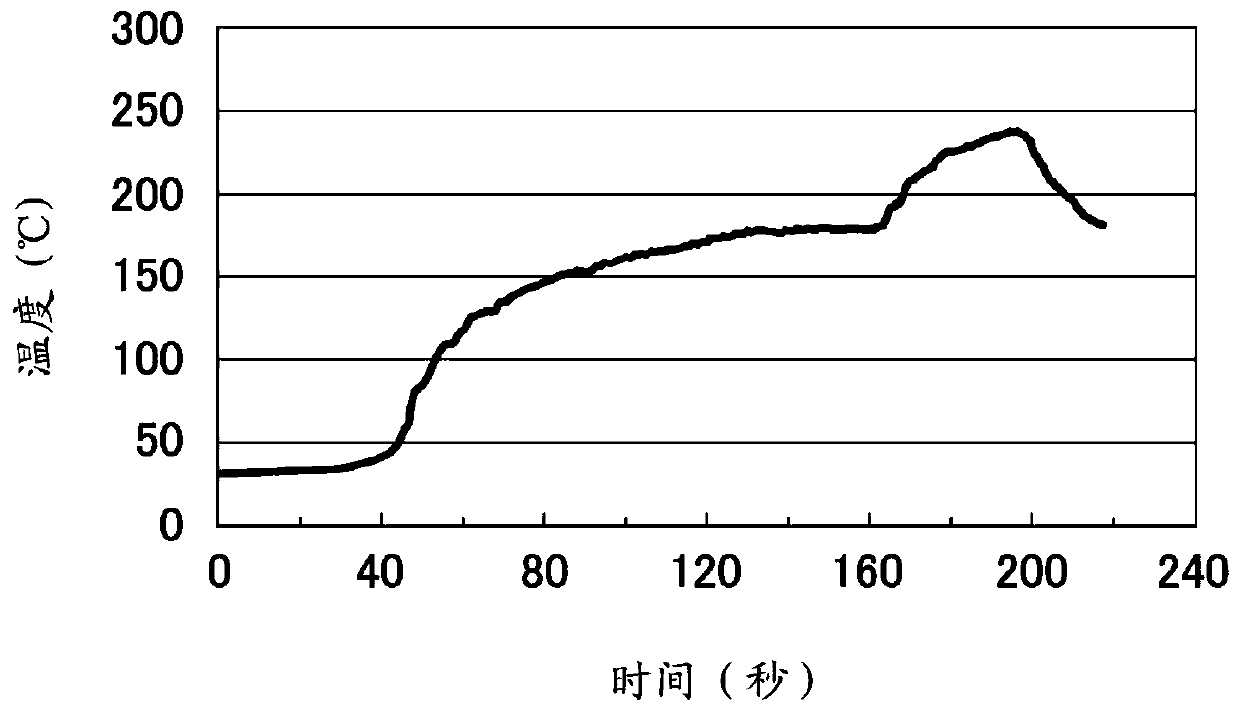

[0115] In addition, the obtained solder composition was measured with an E-type viscometer in accordance with JIS Z3284 Attachment 6. The rotational speed was set at 10 rpm, the te...

Embodiment 2~6 and comparative example 1~3

[0119] A solder composition was obtained in the same manner as in Example 1, except that each material was blended according to the composition shown in Table 1.

[0120] Moreover, about the obtained solder composition, the viscosity and the thixotropic index were measured similarly to Example 1.

[0121]

[0122] The performance of the solder composition (coatability, heating drop, ball near chip) was evaluated or measured by the following methods. Table 1 shows the obtained results.

[0123] (1) Coatability

[0124] Using a dispensing coating device ("SHOT mini" manufactured by Musashi Engineering Co., Ltd.), under the following coating conditions, a 100mm x 100mm coating on a substrate (material: aluminum, size: 150mm x 150mm, thickness: 0.5mm) Discharging of 10,000 points (100 points×100 rows) was performed at equal intervals within the range to obtain a test substrate.

[0125] Nozzle diameter (diameter) of the needle: 0.4mm

[0126] Pressure in extrusion part: 120k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com